Review on Lithium-Ion Battery Heat Dissipation Based on Microchannel–PCM Coupling Technology

Abstract

1. Introduction

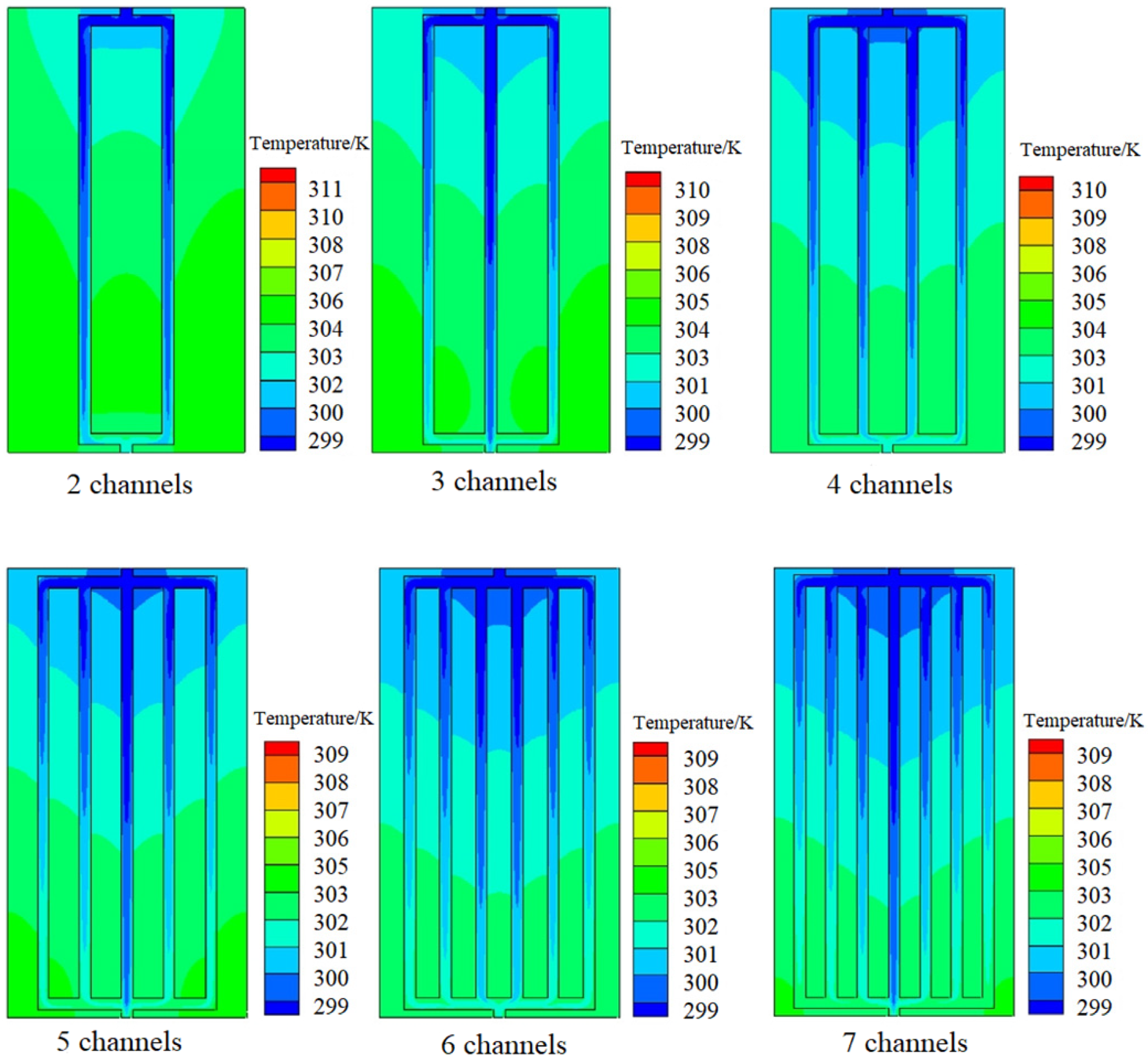

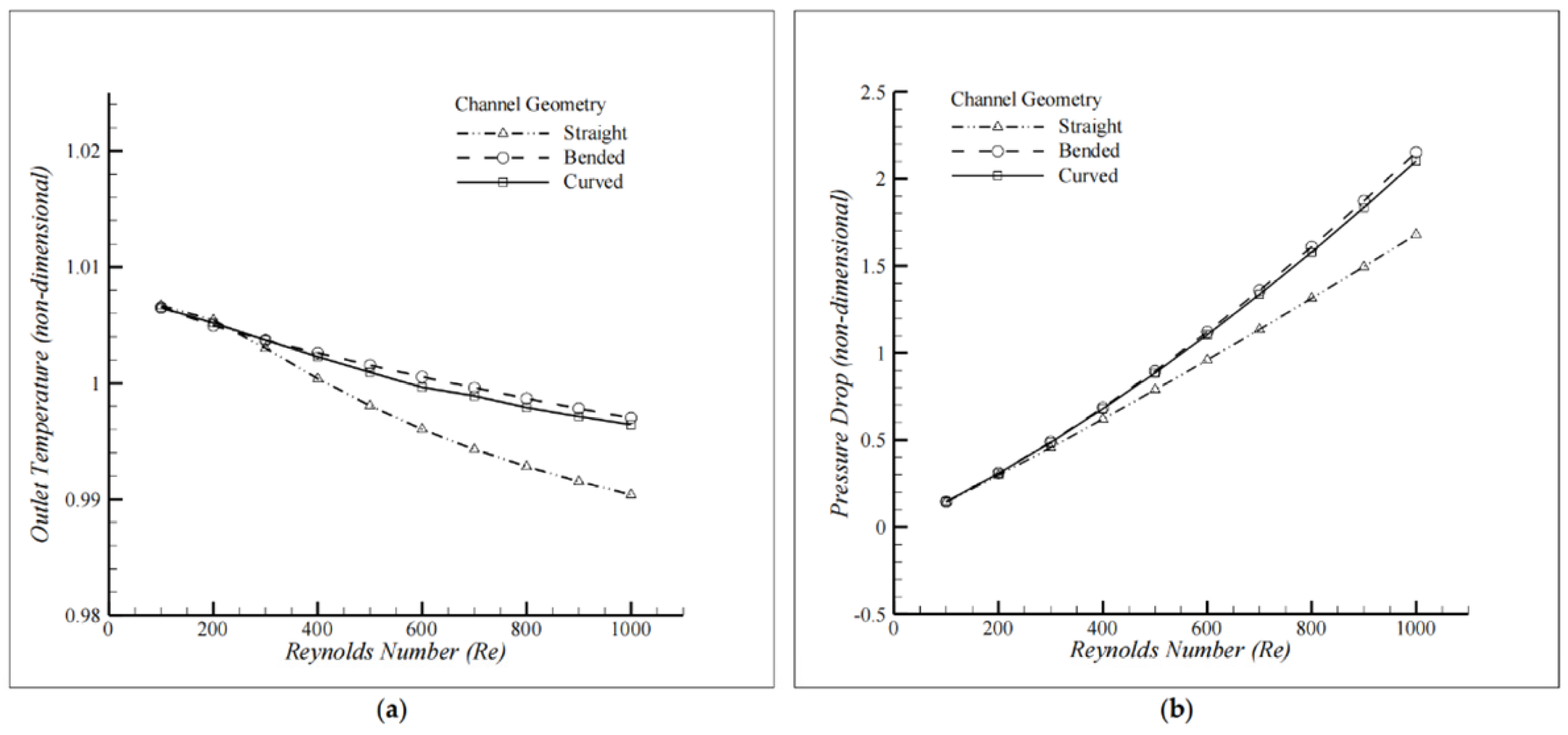

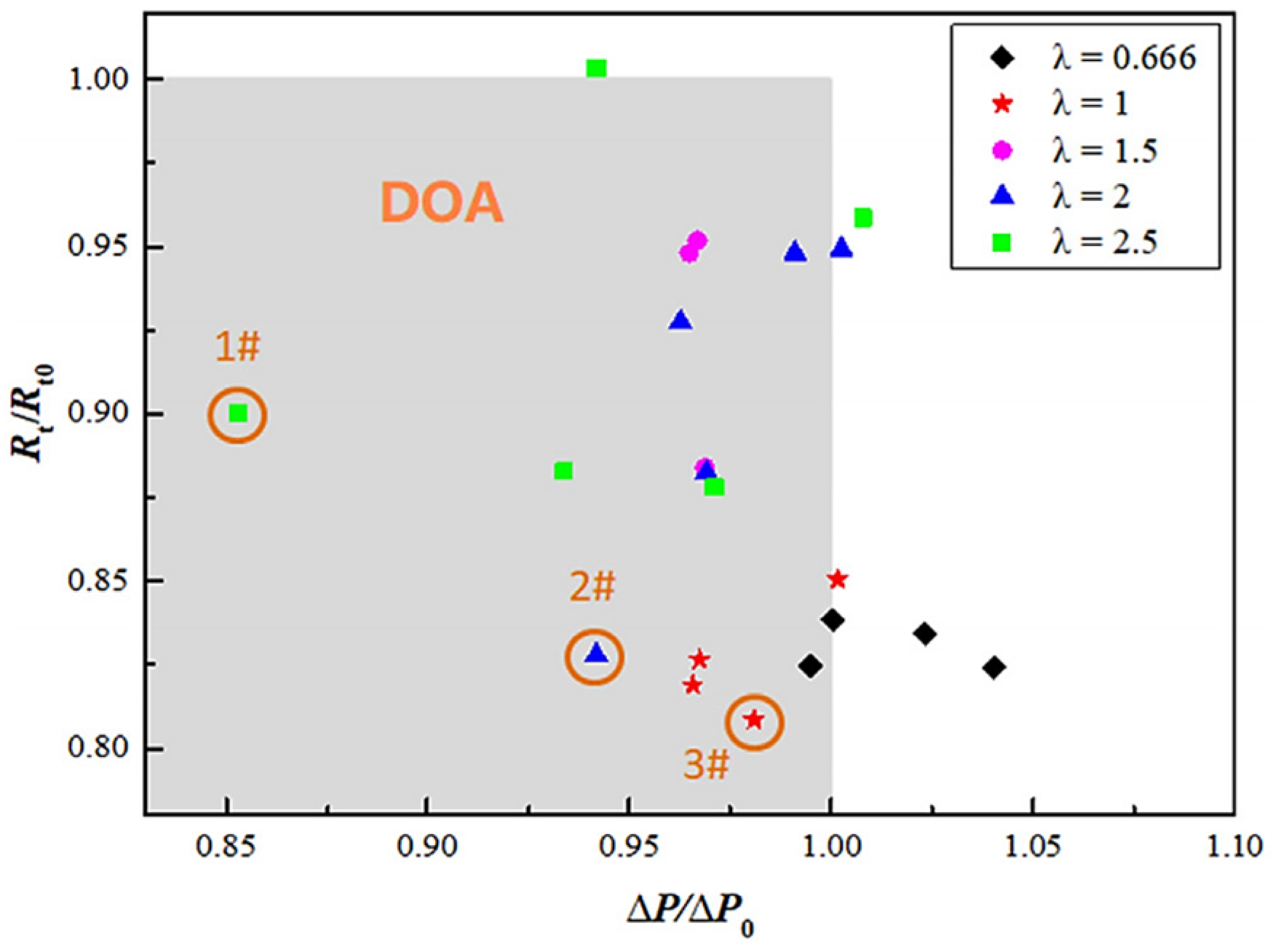

2. Pure Microchannel Technology

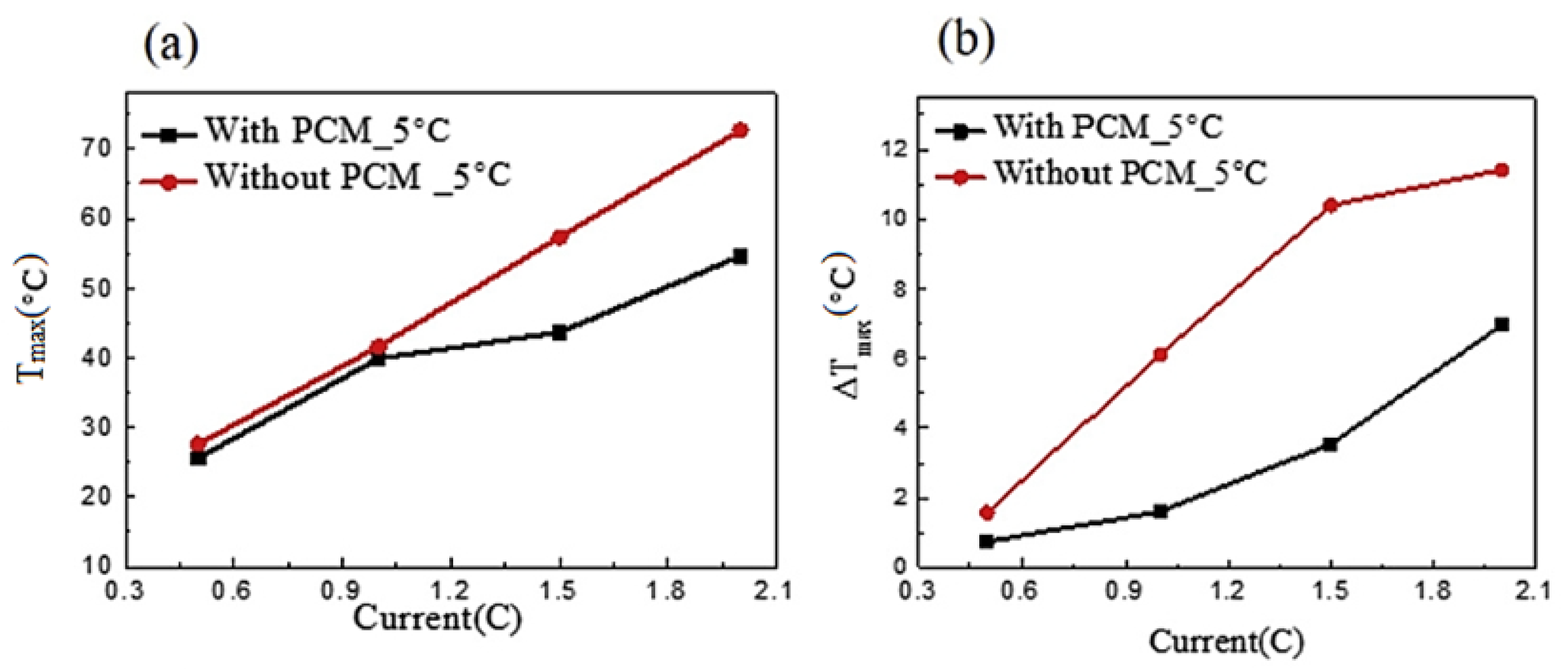

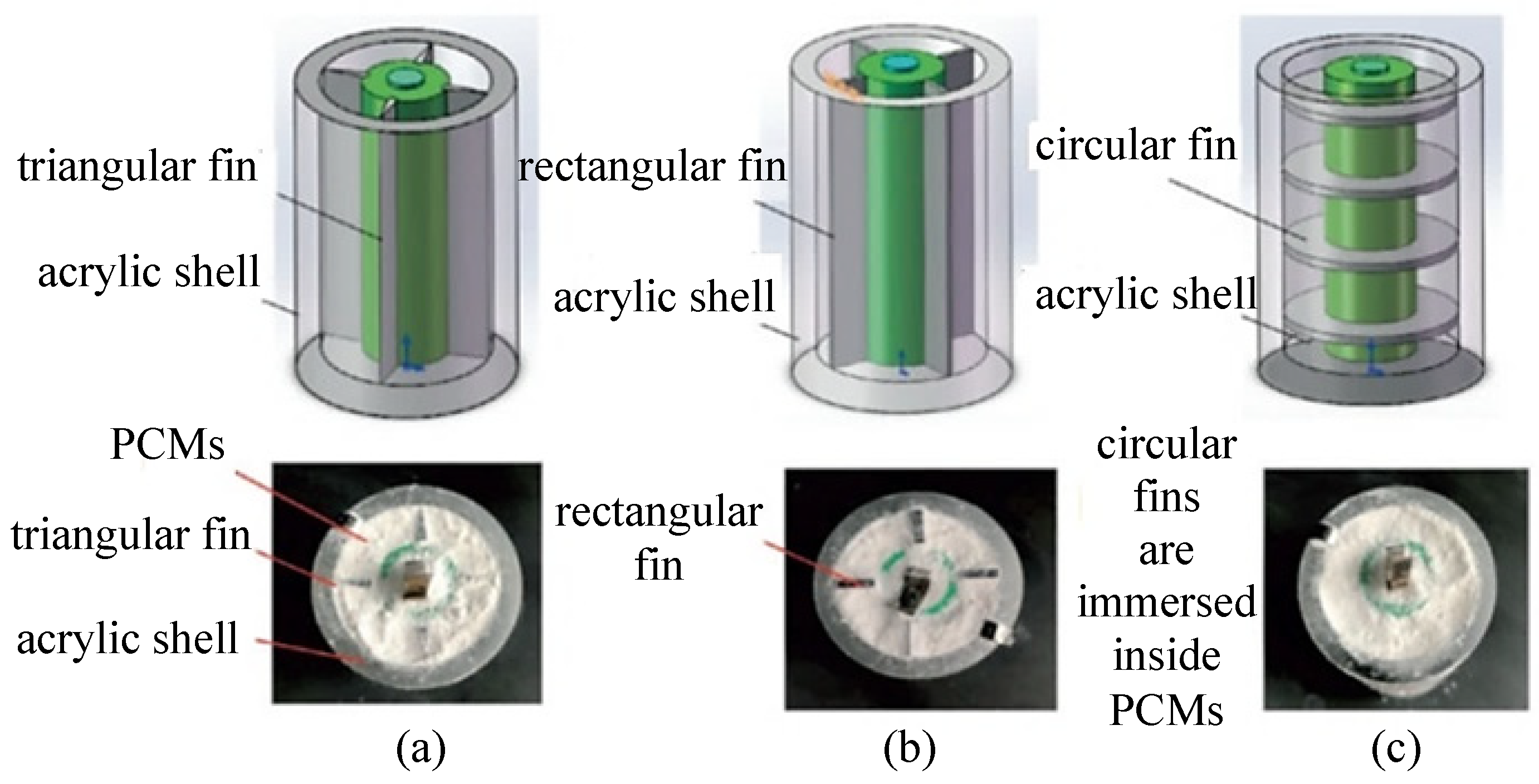

3. Pure Phase-Change Materials

4. Microchannel–PCM Coupling Technology

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| BTMSs | Battery thermal management systems |

| PCMs | Phase-change materials |

| SSPCMs | Solid–solid phase-change materials |

| SGPCMs | Solid–gas phase-change materials |

| SLPCMs | Solid–liquid phase-change materials |

| LGPCMs | Liquid–gas phase-change materials |

| PW | Phase transition wax |

| DOA | Design optimization area |

References

- Akbarzadeh, M.; Kalogiannis, T.; Jaguemont, J.; Jin, L.; Behi, H.; Karimi, D.; Beheshti, H.; Van Mierlo, J.; Berecibar, M. A comparative study between air cooling and liquid cooling thermal management systems for a high-energy lithium-ion battery module. Appl. Therm. Eng. 2021, 198, 117503. [Google Scholar] [CrossRef]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Rahmani, A.; Dibaj, M.; Akrami, M. Recent advancements in battery thermal management systems for enhanced performance of Li-Ion batteries: A comprehensive review. Batteries 2024, 10, 265. [Google Scholar] [CrossRef]

- Hwang, F.S.; Confrey, T.; Reidy, C.; Picovici, D.; Callaghan, D.; Culliton, D.; Nolan, C. Review of battery thermal management systems in electric vehicles. Renew. Sust. Energ. Rev. 2024, 192, 114171. [Google Scholar] [CrossRef]

- Sturm, P.; Foessleitner, P.; Fruhwirt, D.; Galler, R.; Wenighofer, R.; Heindl, S.F.; Krausbar, S.; Heger, O. Fire tests with lithium-ion battery electric vehicles in road tunnels. Fire Saf. J. 2022, 134, 103695. [Google Scholar] [CrossRef]

- Shi, C.; Zhu, D.; Zhang, L.; Song, S.; Sheldon, B.W. Transfer learning prediction on lithium-ion battery heat release under thermal runaway condition. Nano Res. Energy 2024, 3, e9120147. [Google Scholar] [CrossRef]

- Akinlabi, A.H.; Solyali, D. Configuration, design, and optimization of air-cooled battery thermal management system for electric vehicles: A review. Renew. Sust. Energ. Rev. 2020, 125, 109815. [Google Scholar] [CrossRef]

- Mali, V.; Saxena, R.; Kumar, K.; Kalam, A.; Tripathi, B. Review on battery thermal management systems for energy-efficient electric vehicles. Renew. Sust. Energ. Rev. 2021, 151, 111611. [Google Scholar] [CrossRef]

- Chen, D.; Jiang, J.; Kim, G.-H.; Yang, C.; Pesaran, A. Comparison of different cooling methods for lithium ion battery cells. Appl. Therm. Eng. 2016, 94, 846–854. [Google Scholar] [CrossRef]

- Sharma, D.K.; Prabhakar, A. A review on air cooled and air centric hybrid thermal management techniques for Li-ion battery packs in electric vehicles. J. Energy Storage 2021, 41, 102885. [Google Scholar] [CrossRef]

- Thakur, A.K.; Prabakaran, R.; Elkadeem, M.R.; Sharshir, S.W.; Arici, M.; Wang, C.; Zhao, W.; Hwang, J.-Y.; Saidur, R. A state of art review and future viewpoint on advance cooling techniques for Lithium-ion battery system of electric vehicles. J. Energy Storage 2020, 32, 101771. [Google Scholar] [CrossRef]

- Xu, H.; Huang, J.; Tian, W.; Li, Z. Thermal performance optimization of integrated microchannel cooling plate for IGBT power module. Micromachines 2023, 14, 1498. [Google Scholar] [CrossRef] [PubMed]

- Imran, A.A.; Mahmoud, N.S.; Jaffal, H.M. Numerical and experimental investigation of heat transfer in liquid cooling serpentine mini-channel heat sink with different new configuration models. Therm. Sci. Eng. Prog. 2018, 6, 128–139. [Google Scholar] [CrossRef]

- Qian, Z.; Li, Y.; Rao, Z. Thermal performance of lithium-ion battery thermal management system by using mini-channel cooling. Energy Convers. Manag. 2016, 126, 622–631. [Google Scholar] [CrossRef]

- Deng, T.; Zhang, G.; Ran, Y. Study on thermal management of rectangular Li-ion battery with serpentine-channel cold plate. Int. J. Heat Mass Transfer 2018, 125, 143–152. [Google Scholar] [CrossRef]

- Zhang, F.; Li, X.; Zhao, H.; Huang, Z.; Lu, X.; Shi, Y. Symmetrical complex serpentine channel introduction of secondary openings with open Y fins integrated optimization design. Int. J. Therm. Sci. 2024, 195, 108620. [Google Scholar] [CrossRef]

- Fan, L.; Li, J.; Chen, Y.; Zhou, D.; Jiang, Z.; Sun, J. Study on the cooling performance of a new secondary flow serpentine liquid cooling plate used for lithium battery thermal management. Int. J. Heat Mass Transfer 2024, 218, 124711. [Google Scholar] [CrossRef]

- Sheng, L.; Su, L.; Zhang, H.; Li, K.; Fang, Y.; Ye, W.; Fang, Y. Numerical investigation on a lithium ion battery thermal management utilizing a serpentine-channel liquid cooling plate exchanger. Int. J. Heat Mass Transfer 2019, 141, 658–668. [Google Scholar] [CrossRef]

- Patil, M.S.; Seo, J.-H.; Panchal, S.; Jee, S.-W.; Lee, M.-Y. Investigation on thermal performance of water-cooled Li-ion pouch cell and pack at high discharge rate with U-turn type microchannel cold plate. Int. J. Heat Mass Transfer 2020, 155, 119728. [Google Scholar] [CrossRef]

- Monika, K.; Datta, S.P. Comparative assessment among several channel designs with constant volume for cooling of pouch-type battery module. Energy Convers. Manag. 2022, 251, 114936. [Google Scholar] [CrossRef]

- Amalesh, T.; Narasimhan, N.L. Introducing new designs of minichannel cold plates for the cooling of Lithium-ion batteries. J. Power Sources 2020, 479, 228775. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, Z.; Fu, T.; Wu, H. Numerical investigation on lithium-ion battery thermal management utilizing a novel tree-like channel liquid cooling plate exchanger. Int. J. Heat Mass Transfer 2022, 183, 122143. [Google Scholar] [CrossRef]

- He, P.; Lu, H.; Fan, Y.; Ruan, H.; Wang, C.; Zhu, Y. Numerical investigation on a lithium-ion battery thermal management system utilizing a double-layered I-shaped channel liquid cooling plate exchanger. Int. J. Therm. Sci. 2023, 187, 108200. [Google Scholar] [CrossRef]

- Liu, F.; Chen, Y.; Qin, W.; Li, J. Optimal design of liquid cooling structure with bionic leaf vein branch channel for power battery. Appl. Therm. Eng. 2023, 218, 119283. [Google Scholar] [CrossRef]

- Naqvi, A.A.; Uddin, E.; Khan, M.Z.U. Passive mixing and convective heat transfer enhancement for nanofluid flow across corrugated base microchannels. Energies 2023, 16, 7893. [Google Scholar] [CrossRef]

- Yang, M.; Cao, B.-Y. Numerical study on flow and heat transfer of a hybrid microchannel cooling scheme using manifold arrangement and secondary channels. Appl. Therm. Eng. 2019, 159, 113896. [Google Scholar] [CrossRef]

- Al Hallaj, S.; Selman, J.R. A novel thermal management system for electric vehicle batteries using phase-change material. J. Electrochem. Soc. 2000, 147, 3231–3236. [Google Scholar] [CrossRef]

- Ling, Z.; Wen, X.; Zhang, Z.; Fang, X.; Gao, X. Thermal management performance of phase change materials with different thermal conductivities for Li-ion battery packs operated at low temperatures. Energy 2018, 144, 977–983. [Google Scholar] [CrossRef]

- Shen, Z.-G.; Chen, S.; Liu, X.; Chen, B. A review on thermal management performance enhancement of phase change materials for vehicle lithium-ion batteries. Renew. Sust. Energ. Rev. 2021, 148, 111301. [Google Scholar] [CrossRef]

- Khan, Z.; Khan, Z.; Ghafoor, A. A review of performance enhancement of PCM based latent heat storage system within the context of materials, thermal stability and compatibility. Energy Convers. Manag. 2016, 115, 132–158. [Google Scholar] [CrossRef]

- Huang, X.; Alva, G.; Jia, Y.; Fang, G. Morphological characterization and applications of phase change materials in thermal energy storage: A review. Renew. Sust. Energ. Rev. 2017, 72, 128–145. [Google Scholar] [CrossRef]

- Mohamed, S.A.; Al-Sulaiman, F.A.; Ibrahim, N.I.; Zahir, M.H.; Al-Ahmed, A.; Saidur, R.; Yilbas, B.S.; Sahin, A.Z. A review on current status and challenges of inorganic phase change materials for thermal energy storage systems. Renew. Sust. Energ. Rev. 2017, 70, 1072–1089. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sust. Energ. Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Zeynali Famileh, I.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew. Sust. Energ. Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- Oró, E.; de Gracia, A.; Castell, A.; Farid, M.M.; Cabeza, L.F. Review on phase change materials (PCMs) for cold thermal energy storage applications. Appl. Energy 2012, 99, 513–533. [Google Scholar] [CrossRef]

- Cunha, S.; Leite, P.; Aguiar, J. Characterization of innovative mortars with direct incorporation of phase change materials. J. Energy Storage 2020, 30, 101439. [Google Scholar] [CrossRef]

- Wong-Pinto, L.-S.; Milian, Y.; Ushak, S. Progress on use of nanoparticles in salt hydrates as phase change materials. Renew. Sust. Energ. Rev. 2020, 122, 109727. [Google Scholar] [CrossRef]

- Ibrahim, N.I.; Al-Sulaiman, F.A.; Rahman, S.; Yilbas, B.S.; Sahin, A.Z. Heat transfer enhancement of phase change materials for thermal energy storage applications: A critical review. Renew. Sust. Energ. Rev. 2017, 74, 26–50. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, X.; Yang, B.; Cai, S. A review of battery thermal management systems using liquid cooling and PCM. J. Energy Storage 2024, 76, 109836. [Google Scholar] [CrossRef]

- Weng, J.; Ouyang, D.; Yang, X.; Chen, M.; Zhang, G.; Wang, J. Optimization of the internal fin in a phase-change-material module for battery thermal management. Appl. Therm. Eng. 2020, 167, 114698. [Google Scholar] [CrossRef]

- Guo, X.; Goumba, A.P. Process intensification principles applied to thermal energy storage systems-a brief review. Front. Energy Res. 2018, 6, 17. [Google Scholar] [CrossRef]

- Reyez-Araiza, J.L.; Pineda-Piñón, J.; López-Romero, J.M.; Gasca-Tirado, J.R.; Arroyo Contreras, M.; Jáuregui Correa, J.C.; Apátiga-Castro, L.M.; Rivera-Muñoz, E.M.; Velazquez-Castillo, R.R.; Pérez Bueno, J.d.J.; et al. Thermal energy storage by the encapsulation of phase change materials in building elements—A review. Materials 2021, 14, 1420. [Google Scholar] [CrossRef] [PubMed]

- Hassan, A.; Shakeel Laghari, M.; Rashid, Y. Micro-encapsulated phase change materials: A review of encapsulation, safety and thermal characteristics. Sustainability 2016, 8, 1046. [Google Scholar] [CrossRef]

- Yuan, H.; Liu, S.; Li, T.; Yang, L.; Li, D.; Bai, H.; Wang, X. Review on thermal properties with influence factors of solid–liquid organic phase-change micro/nanocapsules. Energies 2024, 17, 604. [Google Scholar] [CrossRef]

- Al-Shannaq, R.; Farid, M.M.; Ikutegbe, C.A. Methods for the synthesis of phase change material microcapsules with enhanced thermophysical properties—A state-of-the-art review. Micro 2022, 2, 426–474. [Google Scholar] [CrossRef]

- Ahmed, W.; Hussain, A.; Shahid, H.; Ali, I.; Ali, H.M. Experimental study on heat storage properties comparison of paraffin/metal foams phase change material composites. J. Therm. Sci. 2024, 33, 469–478. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, X.L.; Venkataraman, M.; Wiener, J.; Palanisamy, S.; Sozcu, S.; Tan, X.D.; Kremenakova, D.; Zhu, G.C.; Yao, J.M.; et al. Structural analysis of phase change materials (PCMs)/expanded graphite (EG) composites and their thermal behavior under hot and humid conditions. ChemPlusChem 2023, 88, e202300081. [Google Scholar] [CrossRef] [PubMed]

- Zuo, H.M.; Wang, R.; Yu, G.J.; Wang, H.J.; Wang, H.; Ruan, F.T.; Xu, Z.Z.; Zou, L.H.; Li, D.S. Construction of MXene, carbon nanotubes and PDMS on cotton fabrics for electromagnetic interference shielding and hydrophobic performances. Mater. Lett. 2025, 382, 137914. [Google Scholar] [CrossRef]

- Lv, S.; Feng, M.Q.; Qian, Z.Q.; Lv, W.H.; Ma, X.S.; Jiang, C.J.; Zhang, B.L. The passive cooling and thermal properties of the dual functional film composed of Graphene and PDMS-TiO2: Application in the passive heat sink. Sol. Energy Mater. Sol. Cells 2024, 276, 113077. [Google Scholar] [CrossRef]

- Wu, N.; Che, S.; Sun, L.; Liu, H.C.; Li, Z.X.; Sun, Y.K.; Qian, J.X.; Yang, W.; Li, Y.F. Dual network structures of polyurethane/boron nitride nanosheets/alumina for improved thermal management of polymers. ACS Appl. Nano Mater. 2023, 6, 17196–17205. [Google Scholar] [CrossRef]

- Lafdi, K.; Mesalhy, O.; Shaikh, S. Experimental study on the influence of foam porosity and pore size on the melting of phase change materials. J. Appl. Phys. 2007, 102, 083549. [Google Scholar] [CrossRef]

- Hussain, A.; Tso, C.Y.; Chao, C.Y.H. Experimental investigation of a passive thermal management system for high-powered lithium ion batteries using nickel foam-paraffin composite. Energy 2016, 115, 209–218. [Google Scholar] [CrossRef]

- Chan, K.C.; Tso, C.Y.; Hussain, A.; Chao, C.Y.H. A theoretical model for the effective thermal conductivity of graphene coated metal foams. Appl. Therm. Eng. 2019, 161, 114112. [Google Scholar] [CrossRef]

- Shahid, S.; Agelin-Chaab, M. Investigation of heat transfer enhancement techniques on a scalable novel hybrid thermal management strategy for lithium-Ion battery packs. Batteries 2024, 10, 32. [Google Scholar] [CrossRef]

- Manoj Kumar, P.; Anandkumar, R.; Mylsamy, K.; Prakash, K.B. Experimental investigation on thermal conductivity of nanoparticle dispersed paraffin (NDP). Mater. Today Proc. 2021, 45, 735–739. [Google Scholar] [CrossRef]

- Hamza, F.; Mustapha, F.; Mustapha, E.A.; Yassine, H.; Adeel, A.; Ahmed, H.; Ayman, B. Cooling of recent microprocessors by the fusion of nano-enhanced phase change materials. Mater. Today Proc. 2020, 30, 865–869. [Google Scholar]

- Pereira, J.; Moita, A.; Moreira, A. An overview of the nano-enhanced phase change materials for energy harvesting and conversion. Molecules 2023, 28, 5763. [Google Scholar] [CrossRef]

- Wang, C.L.; Leong, J.C. Analysis of thermal management strategies for 21700 lithium-ion batteries incorporating phase change materials and porous copper foam with different battery orientations. Energies 2024, 17, 1553. [Google Scholar] [CrossRef]

- Ren, H.; Dang, C.; Yin, L.; Chen, Z. Optimization research on battery thermal management system based on PCM and mini-channel cooling plates. Case Stud. Therm. Eng. 2024, 53, 103880. [Google Scholar] [CrossRef]

- Liu, Z.; Xiong, C.; Du, X. Research on the optimization control strategy of a battery thermal management system based on serpentine liquid cooling combined with phase change material. J. Power Sources 2025, 630, 236127. [Google Scholar] [CrossRef]

- Rabiei, M.; Gharehghani, A.; Saeedipour, S.; Andwari, A.M.; Konno, J. Proposing a hybrid BTMS using a novel structure of a microchannel cold plate and PCM. Energies 2023, 16, 6238. [Google Scholar] [CrossRef]

- Huang, Q.; Li, X.; Zhang, G.; Deng, J.; Wang, C. Thermal management of Lithium-ion battery pack through the application of flexible form-stable composite phase change materials. Appl. Therm. Eng. 2021, 183, 116151. [Google Scholar] [CrossRef]

- Agyenim, F.; Hewitt, N.; Eames, P.; Smyth, M. A review of materials, heat transfer and phase change problem formulation for latent heat thermal energy storage systems (LHTESS). Renew. Sust. Energ. Rev. 2010, 14, 615–628. [Google Scholar] [CrossRef]

- Sun, Z.; Fan, R.; Zheng, N. Thermal management of a simulated battery with the compound use of phase change material and fins: Experimental and numerical investigations. Int. J. Therm. Sci. 2021, 165, 106945. [Google Scholar] [CrossRef]

- Tian, B.; Yang, W.; Luo, L.; Wang, J.; Zhang, K.; Fan, J.; Wu, J.; Xing, T. Synergistic enhancement of thermal conductivity for expanded graphite and carbon fiber in paraffin/EVA form-stable phase change materials. Sol. Energy 2016, 127, 48–55. [Google Scholar] [CrossRef]

- Li, X.; Li, L.; Hang, W.; Wang, W.; Yin, M.; Wang, X.; Bei, S.; Xu, Q.; Liu, J.; Zheng, K. Systematic investigation of hybrid cold plate combining embedded phase change material with liquid cooling minichannels under different ambient temperatures for battery thermal management. J. Energy Storage 2025, 108, 115125. [Google Scholar] [CrossRef]

- Liu, Z.W.; Huadan, C.; Wang, B.Y.; Li, P. Coupling optimization of protruding fin and PCM in hybrid cooling system and cycle strategy matching for lithium-ion battery thermal management. Int. J. Therm. Sci. 2025, 207, 109372. [Google Scholar] [CrossRef]

- Mousavi, S.; Siavashi, M.; Zadehkabir, A. A new design for hybrid cooling of Li-ion battery pack utilizing PCM and mini channel cold plates. Appl. Therm. Eng. 2021, 197, 117398. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, J.; Zhang, G.; Hu, Y.; Shao, D.; Jiang, L.; Wen, Y. A novel leak-proof thermal conduction slot battery thermal management system coupled with phase change materials and liquid-cooling strategies. Energies 2024, 17, 939. [Google Scholar] [CrossRef]

- Kshetrimayum, K.S.; Yoon, Y.-G.; Gye, H.-R.; Lee, C.-J. Preventing heat propagation and thermal runaway in electric vehicle battery modules using integrated PCM and micro-channel plate cooling system. Appl. Therm. Eng. 2019, 159, 113797. [Google Scholar] [CrossRef]

- Mousavi, S.; Zadehkabir, A.; Siavashi, M.; Yang, X. An improved hybrid thermal management system for prismatic Li-ion batteries integrated with mini-channel and phase change materials. Appl. Energy 2023, 334, 120643. [Google Scholar] [CrossRef]

- Yang, H.; Li, M.; Wang, Z.; Ma, B. A compact and lightweight hybrid liquid cooling system coupling with Z-type cold plates and PCM composite for battery thermal management. Energy 2023, 263, 126026. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, T.; Zhou, L.; Gong, J.; Li, J. A parametric study of a hybrid battery thermal management system that couples PCM with wavy microchannel cold plate. Appl. Therm. Eng. 2023, 219, 119625. [Google Scholar] [CrossRef]

- Yao, F.; Guan, X.; Chen, Q.; Lin, L. Research on thermal management system of lithium-ion battery with a new type of spider web liquid cooling channel and phase change materials. J. Energy Storage 2024, 81, 110447. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; Wu, Z.; Cao, W.; Zhang, X. An energy saving strategy on the composite phase change material and spiral liquid cooling channel for battery thermal management. Renew. Energy 2024, 227, 120529. [Google Scholar] [CrossRef]

- Debbarma, A. Study of thermal management of Li-Ion batteries with an encapsulated phase-change material and Iinternal liquid channels. Energy Technol. 2024, 12, p1. [Google Scholar] [CrossRef]

- Chen, Y.N.; Zhuang, Y.J.; Feng, J.C.; Huang, S.M. Numerical investigation on flow and heat transfer characteristics in honeycomb-like microchannel heat sink encapsulated with phase change material. Appl. Therm. Eng. 2023, 232, 121060. [Google Scholar] [CrossRef]

| Types | Advantages | Disadvantages |

|---|---|---|

| Organic | High melting enthalpy Long-term thermal and chemical stability Compatibility with most building materials | Incompatibility with some container materials, e.g., plastic Flammability Low thermal conductivity (about 0.2 W/(m⋅K)) |

| Inorganic | High storage density High thermal conductivity Low cost Compatibility with plastic containers Non-flammability | Corrosion Significant volume expansion Phase segregation |

| Eutectic | Appropriate and adjustable transition temperature High enthalpy of fusion Congruence of phase change | High cost Limited thermo-physical properties |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Xu, W.; Tian, H.; Cao, Y.; Gu, J.; Zhou, H.; Jin, Y. Review on Lithium-Ion Battery Heat Dissipation Based on Microchannel–PCM Coupling Technology. Energies 2025, 18, 631. https://doi.org/10.3390/en18030631

Chen J, Xu W, Tian H, Cao Y, Gu J, Zhou H, Jin Y. Review on Lithium-Ion Battery Heat Dissipation Based on Microchannel–PCM Coupling Technology. Energies. 2025; 18(3):631. https://doi.org/10.3390/en18030631

Chicago/Turabian StyleChen, Jun, Wanli Xu, Hao Tian, Yichao Cao, Jincheng Gu, Haijun Zhou, and Yong Jin. 2025. "Review on Lithium-Ion Battery Heat Dissipation Based on Microchannel–PCM Coupling Technology" Energies 18, no. 3: 631. https://doi.org/10.3390/en18030631

APA StyleChen, J., Xu, W., Tian, H., Cao, Y., Gu, J., Zhou, H., & Jin, Y. (2025). Review on Lithium-Ion Battery Heat Dissipation Based on Microchannel–PCM Coupling Technology. Energies, 18(3), 631. https://doi.org/10.3390/en18030631