Long-Term Reliability of Semi-Transparent Photovoltaic Panels Based on Luminescent Solar Concentrators †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Prototype Assembly

2.2. Optical Characterization

2.3. Photodegradation Analysis

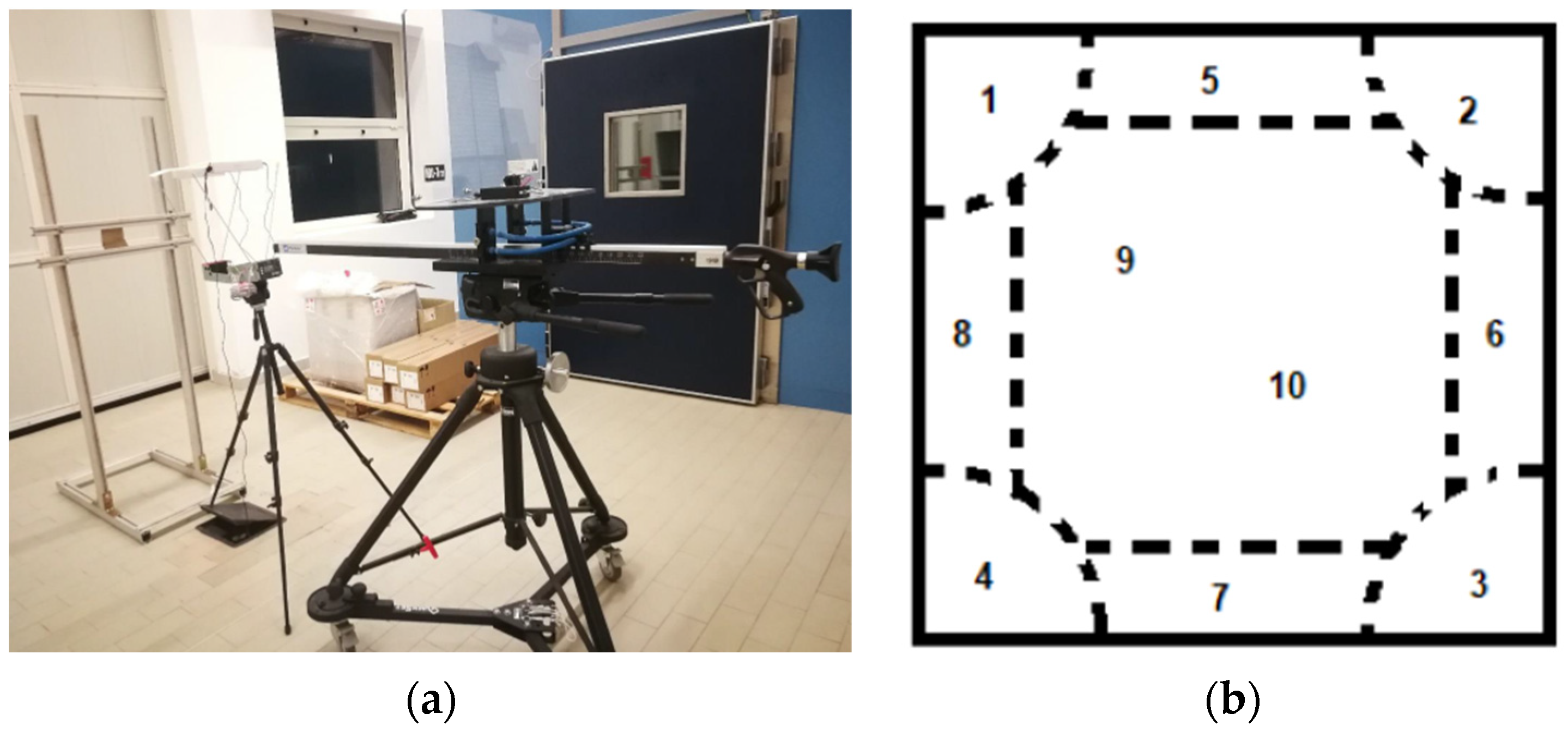

2.4. Hail Impacts Analysis

3. Results and Discussion

3.1. Optical Characterization—Results

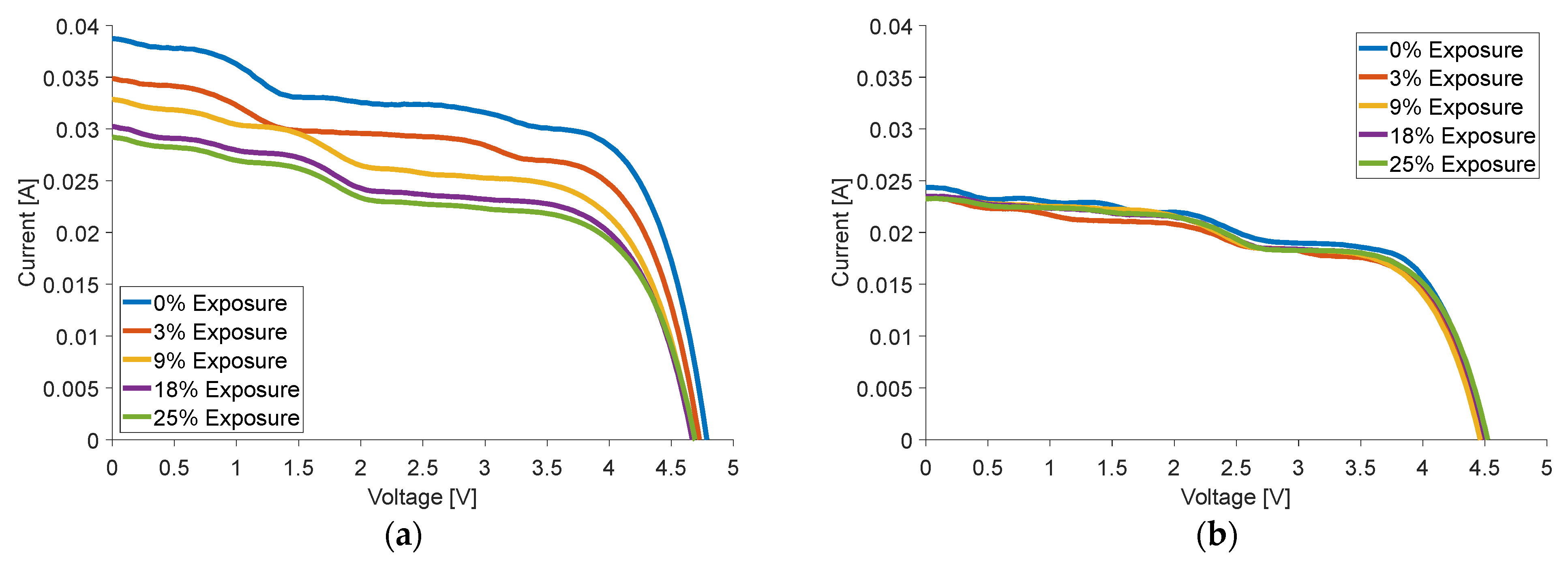

3.2. Photodegradation Analysis—Results

3.3. Hail Impact Analysis—Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AVT | Average Visible Transimttance |

| BIPV | Building Integrated Photovoltaic |

| CIE | International Commission on Illumination |

| CMF | Color Matching Function |

| CPV | Concentrated Photovoltaic |

| CRI | Color Rendering Index |

| EVA | Ethyl Vinyl Acetate |

| LG | Laminated Glass |

| LSC | Luminescent Solar Concentrators |

| MPP | Maximum Power Point |

| MPPT | Maximum Power Point Tracker |

| OCV | Open-Circuit Voltage |

| PCB | Printed Circuit Board |

| PCE | Power Conversion Efficiency |

| POAI | Plane of Array Irradiance |

| PV | Photovoltaic |

| PVB | Polyvinyl Butyral |

References

- Masson, G.; Bosch, E.; Van Rechem, A.; de l’Epine, M. Snapshot of Global PV Markets 2023 Task 1 Strategic PV Analysis and Outreach PVPS; IEA PVPS: Paris, France, 2023; Volume I. [Google Scholar]

- Gürtürk, M. Economic Feasibility of Solar Power Plants Based on PV Module with Levelized Cost Analysis. Energy 2019, 171, 866–878. [Google Scholar] [CrossRef]

- Mangherini, G.; Diolaiti, V.; Bernardoni, P.; Andreoli, A.; Vincenzi, D. Review of Façade Photovoltaic Solutions for Less Energy-Hungry Buildings. Energies 2023, 16, 6901. [Google Scholar] [CrossRef]

- Fugattini, S.; Gulzar, U.; Andreoli, A.; Carbone, L.; Boschetti, M.; Bernardoni, P.; Gjestila, M.; Mangherini, G.; Camattari, R.; Li, T.; et al. Binder-Free Nanostructured Germanium Anode for High Resilience Lithium-Ion Battery. Electrochim. Acta 2022, 411, 139832. [Google Scholar] [CrossRef]

- Mukhopadhyay, B.; Das, D. Multi-Objective Dynamic and Static Reconfiguration with Optimized Allocation of PV-DG and Battery Energy Storage System. Renew. Sustain. Energy Rev. 2020, 124, 109777. [Google Scholar] [CrossRef]

- Diolaiti, V.; Andreoli, A.; Bernardoni, P.; Mangherini, G.; Ouelhazi, M.A.; Venczia, E.; Ricci, M.; Proietti, R.Z.; Vincenzi, D. Nanostructured Germanium Anode for Lithium-Ion Batteries for Aerospace Technologies. In Proceedings of the 2022 IEEE 22nd International Conference on Nanotechnology (NANO), Palma de Mallorca, Spain, 4–8 July 2022; pp. 56–59. [Google Scholar]

- Diolaiti, V.; Andreoli, A.; Chauque, S.; Bernardoni, P.; Mangherini, G.; Ricci, M.; Zaccaria, R.P.; Ferroni, M.; Vincenzi, D. Comparison of Porous Germanium Thin Films on SS and Mo as Anode for High-Performance LIBs. IEEE Trans. Nanotechnol. 2023, 22, 552–557. [Google Scholar] [CrossRef]

- Boschetti, M.; Vincenzi, D.; Mangherini, G.; Bernardoni, P.; Andreoli, A.; Gjestila, M.; Camattari, R.; Fugattini, S.; Caramori, S.; Cristino, V.; et al. Modular Stand-Alone Photoelectrocatalytic Reactor for Emergent Contaminant Degradation via Solar Radiation. Sol. Energy 2021, 228, 120–127. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Şirin, C. Experimental Investigation of a Parabolic Greenhouse Dryer Improved with Copper Oxide Nano-Enhanced Latent Heat Thermal Energy Storage Unit. Int. J. Energy Res. 2021, 46, 3647–3662. [Google Scholar] [CrossRef]

- Smith, D.E.; Hughes, M.D.; Patel, B.; Borca-Tasciuc, D.A. An Open-Source Monte Carlo Ray-Tracing Simulation Tool for Luminescent Solar Concentrators with Validation Studies Employing Scattering Phosphor Films. Energies 2021, 14, 455. [Google Scholar] [CrossRef]

- Van Sark, W.G.J.H.M.; Barnham, K.W.J.; Slooff, L.H.; Chatten, A.J.; Büchtemann, A.; Meyer, A.; Mccormack, S.J.; Koole, R.; Farrell, D.J.; Bose, R.; et al. Luminescent Solar Concentrators-A Review of Recent Results. Opt. Express 2008, 16, 21773–21792. [Google Scholar] [CrossRef] [PubMed]

- Debije, M.G.; Rajkumar, V.A. Direct versus Indirect Illumination of a Prototype Luminescent Solar Concentrator. Sol. Energy 2015, 122, 334–340. [Google Scholar] [CrossRef]

- De Bruin, T.A.; Van Sark, W.G.J.H.M. Investigation of Quantum Dot Luminescent Solar Concentrator Single, Double and Triple Structures: A Ray Tracing Simulation Study. Ceram. Int. 2023, 49, 24454–24468. [Google Scholar] [CrossRef]

- Corrado, C.; Leow, S.W.; Osborn, M.; Carbone, I.; Hellier, K.; Short, M.; Alers, G.; Carter, S.A. Power Generation Study of Luminescent Solar Concentrator Greenhouse. J. Renew. Sustain. Energy 2016, 8, 043502. [Google Scholar] [CrossRef]

- Mangherini, G.; Bernardoni, P.; Baccega, E.; Andreoli, A.; Diolaiti, V.; Vincenzi, D. Design of a Ventilated Façade Integrating a Luminescent Solar Concentrator Photovoltaic Panel. Sustainability 2023, 15, 9146. [Google Scholar] [CrossRef]

- Bernardoni, P.; Mangherini, G.; Gjestila, M.; Andreoli, A.; Vincenzi, D. Performance Optimization of Luminescent Solar Concentrators under Several Shading Conditions. Energies 2021, 14, 816. [Google Scholar] [CrossRef]

- Bergren, M.R.; Makarov, N.S.; Ramasamy, K.; Jackson, A.; Guglielmetti, R.; McDaniel, H. High-Performance CuInS2 Quantum Dot Laminated Glass Luminescent Solar Concentrators for Windows. ACS Energy Lett. 2018, 3, 520–525. [Google Scholar] [CrossRef]

- Li, W.; Wang, X.; Lin, J.; Meng, X.; Wang, L.; Wang, M.; Jing, Q.; Song, Y.; Vomiero, A.; Zhao, H. Controllable and Large-Scale Synthesis of Carbon Quantum Dots for Efficient Solid-State Optical Devices. Nano Energy 2024, 122, 109289. [Google Scholar] [CrossRef]

- Lin, J.; Wang, L.; Jing, Q.; Zhao, H. Highly Efficient and High Color Rendering Index Multilayer Luminescent Solar Concentrators Based on Colloidal Carbon Quantum Dots. Chem. Eng. J. 2024, 481, 148441. [Google Scholar] [CrossRef]

- Slooff, L.H.; Bende, E.E.; Burgers, A.R.; Budel, T.; Pravettoni, M.; Kenny, R.P.; Dunlop, E.D.; Büchtemann, A. A Luminescent Solar Concentrator with 7.1% Power Conversion Efficiency. Phys. Status Solidi—Rapid Res. Lett. 2008, 2, 257–259. [Google Scholar] [CrossRef]

- Goldschmidt, J.C.; Peters, M.; Bösch, A.; Helmers, H.; Dimroth, F.; Glunz, S.W.; Willeke, G. Increasing the Efficiency of Fluorescent Concentrator Systems. Sol. Energy Mater. Sol. Cells 2009, 93, 176–182. [Google Scholar] [CrossRef]

- Bomm, J.; Büchtemann, A.; Chatten, A.J.; Bose, R.; Farrell, D.J.; Chan, N.L.A.; Xiao, Y.; Slooff, L.H.; Meyer, T.; Meyer, A.; et al. Fabrication and Full Characterization of State-of-the-Art Quantum Dot Luminescent Solar Concentrators. Sol. Energy Mater. Sol. Cells 2011, 95, 2087–2094. [Google Scholar] [CrossRef]

- Inman, R.H.; Shcherbatyuk, G.V.; Medvedko, D.; Gopinathan, A.; Ghosh, S. Cylindrical Luminescent Solar Concentrators with Near-Infrared Quantum Dots. Opt. Express 2011, 19, 24308. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, M.; Zhang, Y.; He, H.; Xie, W.; Yang, M.; Ding, J.; Bao, J.; Sun, S.; Gao, C. Optimization of Large-Size Glass Laminated Luminescent Solar Concentrators. Sol. Energy 2015, 117, 260–267. [Google Scholar] [CrossRef]

- Bronstein, N.D.; Yao, Y.; Xu, L.; O’Brien, E.; Powers, A.S.; Ferry, V.E.; Alivisatos, A.P.; Nuzzo, R.G. Quantum Dot Luminescent Concentrator Cavity Exhibiting 30-Fold Concentration. ACS Photonics 2015, 2, 1576–1583. [Google Scholar] [CrossRef]

- Currie, M.J.; Mapel, J.K.; Heidel, T.D.; Goffri, S.; Baldo, M.A. High-Efficiency Organic Solar Concentrators for Photovoltaics. Science 2008, 321, 226–228. [Google Scholar] [CrossRef]

- Wilson, L.R.; Klampaftis, E.; Richards, B.S. Enhancement of Power Output from a Large-Area Luminescent Solar Concentrator with 4.8× Concentration via Solar Cell Current Matching. IEEE J. Photovolt. 2017, 7, 802–809. [Google Scholar] [CrossRef]

- Ha, S.J.; Kang, J.H.; Choi, D.H.; Nam, S.K.; Reichmanis, E.; Moon, J.H. Upconversion-Assisted Dual-Band Luminescent Solar Concentrator Coupled for High Power Conversion Efficiency Photovoltaic Systems. ACS Photonics 2018, 5, 3621–3627. [Google Scholar] [CrossRef]

- Castelletto, S.; Boretti, A. Luminescence Solar Concentrators: A Technology Update. Nano Energy 2023, 109, 108269. [Google Scholar] [CrossRef]

- Li, S.; Haussener, S. Radiative Transfer in Luminescent Solar Concentrators. J. Quant. Spectrosc. Radiat. Transf. 2024, 319, 108957. [Google Scholar] [CrossRef]

- Liu, H.; He, W.; Liu, X.; Zhu, J.; Yu, H.; Hu, Z. Building Integrated Concentrating Photovoltaic Window Coupling Luminescent Solar Concentrator and Thermotropic Material. Energy 2023, 284, 129237. [Google Scholar] [CrossRef]

- Mangherini, G.; Baccega, E.; Diolaiti, V. Integration of Phase Change Material into PV Windows to Improve the Efficiency of Semi-Transparent Panels Based on Luminescent Solar Concentrator Technology. Sustainability 2024, 16, 11148. [Google Scholar] [CrossRef]

- Rafiee, M.; Chandra, S.; Ahmed, H.; McCormack, S.J. An Overview of Various Configurations of Luminescent Solar Concentrators for Photovoltaic Applications. Opt. Mater. 2019, 91, 212–227. [Google Scholar] [CrossRef]

- Delgado-Sanchez, J.M. Luminescent Solar Concentrators: Photo-Stability Analysis and Long-Term Perspectives. Sol. Energy Mater. Sol. Cells 2019, 202, 110134. [Google Scholar] [CrossRef]

- De Bruin, T.A.; Terricabres-Polo, R.; Kaul, A.; Zawacka, N.K.; Prins, P.T.; Gietema, T.F.J.; de Waal, A.C.; de Boer, D.K.G.; Vanmaekelbergh, D.A.M.; Leblans, P.; et al. Analysis of the 1 Year Outdoor Performance of Quantum Dot Luminescent Solar Concentrators. Solar RRL 2023, 7, 2201121. [Google Scholar] [CrossRef]

- IEC 62108:2016; Concentrator Photovoltaic (CPV) Modules and Assemblies—Design Qualification and Type Approval. IEC: Geneva, Switzerland, 2016.

- Naim, W.; Novelli, V.; Nikolinakos, I.; Barbero, N.; Dzeba, I.; Grifoni, F.; Ren, Y.; Alnasser, T.; Velardo, A.; Borrelli, R.; et al. Transparent and Colorless Dye-Sensitized Solar Cells Exceeding 75% Average Visible Transmittance. JACS Au 2021, 1, 409–426. [Google Scholar] [CrossRef] [PubMed]

- Lunt, R.R. Theoretical Limits for Visibly Transparent Photovoltaics. Appl. Phys. Lett. 2012, 101, 043902. [Google Scholar] [CrossRef]

- De Bruin, T.A.; Van Sark, W.G.J.H.M. Shining Lights on Limits: Optimizing Luminescent Solar Concentrators for Solar Windows. Adv. Photon-Res. 2024, 6, 2400068. [Google Scholar] [CrossRef]

- Ohno, Y. CIE Fundamentals for Color Measurements. In Proceedings of the IS&Ts NIP16: 2000 International Conference on Digital Printing Technologies, Vancouver, BC, Canada, 15–20 October 2000; Volume 16, pp. 540–545. [Google Scholar]

- Eder, G.; Peharz, G.; Trattnig, R.; Bonomo, P.; Saretta, E.; Frontini, F.; Polo Lopez, C.S.; Rose Wilson, H.; Eisenlohr, J.; Martín Chivelet, N.; et al. COLOURED BIPV Market, Research and Development IEA PVPS Task 15, Report IEA-PVPS T15-07: 2019; IEA PVPS: Paris, France, 2019. [Google Scholar]

- Dai, P.P.; Li, C.; Zhang, X.T.; Xu, J.; Chen, X.; Wang, X.L.; Jia, Y.; Wang, X.; Liu, Y.C. A Single Eu2+-Activated High-Color-Rendering Oxychloride White-Light Phosphor for White-Light-Emitting Diodes. Light: Sci. Appl. 2016, 5, e16024. [Google Scholar] [CrossRef]

- Ohno, Y. Color Rendering and Luminous Efficacy of White LED Spectra. In Proceedings of the Fourth International Conference on Solid State Lighting, Denver, CO, USA, 3–6 August 2004; Volume 5530, p. 88. [Google Scholar] [CrossRef]

- Chakraborty, S.; Haldkar, A.K.; Manoj Kumar, N. Analysis of the Hail Impacts on the Performance of Commercially Available Photovoltaic Modules of Varying Front Glass Thickness. Renew. Energy 2023, 203, 345–356. [Google Scholar] [CrossRef]

- Gupta, V.; Sharma, M.; Pachauri, R.; Babu, K.N.D. Impact of Hailstorm on the Performance of PV Module: A Review. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 1923–1944. [Google Scholar] [CrossRef]

- Bernardoni, P.; Mangherini, G.; Andreoli, A.; Diolaiti, V.; Marrazzo, R.; Melchiorre, F.; Zanardi, S.; Vincenzi, D. Design of a Color Neutral Nonpatterned Photovoltaic Window Based on Luminescent Solar Concentrator. Solar RRL 2024, 8, 2400195. [Google Scholar] [CrossRef]

- Roche, D.; Outhred, H.; Kaye, J.R. Analysis and Control of Mismatch Power Loss in Photovoltaic Arrays. Prog. Photovolt. Res. Appl. 1995, 3, 115–127. [Google Scholar] [CrossRef]

- Matvienko, O.O.; Savin, Y.N.; Kryzhanovska, A.S.; Vovk, O.M.; Dobrotvorska, M.V.; Pogorelova, N.V.; Vashchenko, V.V. Dispersion and Aggregation of Quantum Dots in Polymer-Inorganic Hybrid Films. Thin Solid Film. 2013, 537, 226–230. [Google Scholar] [CrossRef]

- Makarskas, V.; Jurevičius, M.; Zakis, J.; Kilikevičius, A.; Borodinas, S.; Matijošius, J.; Kilikevičienė, K. Investigation of the Influence of Hail Mechanical Impact Parameters on Photovoltaic Modules. Eng. Fail. Anal. 2021, 124, 105309. [Google Scholar] [CrossRef]

| Specimen | Surface Area | Glass Thickness | Glass Typology |

|---|---|---|---|

| Sample 1 | 10 × 10 cm2 | 3 mm | Non-tempered |

| Sample 2 | 10 × 10 cm2 | 4 mm | Non-tempered |

| Sample 3 | 10 × 10 cm2 | 4 mm | Chemically tempered |

| Sample 4 | 30 × 30 cm2 | 4 mm | Chemically tempered |

| Sample 5 | 30 × 30 cm2 | 4 mm | Chemically tempered |

| Specimen | AVT [%] | CRI |

|---|---|---|

| RED | 20.5 | 39 |

| VIO | 79.6 | 98 |

| Condition | Target Exposure [kWh/m2] >600 W/m2 | Total Exposure [kWh/m2] >600 W/m2 | Total Exposure [kWh/m2] <600 W/m2 |

|---|---|---|---|

| MPP | 450 | 450.7 | 272.2 |

| OCV | 50 | 51.3 | 24.8 |

| Target POAI Exposure [kWh/m2] >600 W/m2 | Total POAI Exposure [kWh/m2] <600 W/m2 | Exposure Level [%] |

|---|---|---|

| 0 | 0 | 0% |

| 13.4 | 9.0 | 3% |

| 40.8 | 20.8 | 9% |

| 81.0 | 47.5 | 18% |

| 111.8 | 53.4 | 25% |

| 158.4 | 75.9 | 35% |

| 236.5 | 189.4 | 53% |

| 273.9 | 213.6 | 61% |

| 323.0 | 229.9 | 72% |

| 450.7 | 272.2 | 100% |

| Exposure [%] | VOC [V] | ISC [mA] | PMAX [mW] | VMAX [V] | IMAX [mA] | FF | POAI [W/m2] | PCE [%] |

|---|---|---|---|---|---|---|---|---|

| 0 | 4.80 | 38.83 | 114.87 | 3.95 | 29.08 | 0.62 | 997 | 1.15 |

| 3 | 4.73 | 35.11 | 100.59 | 3.91 | 25.73 | 0.61 | 997 | 1.01 |

| 9 | 4.68 | 33.44 | 90.22 | 3.73 | 24.19 | 0.58 | 997 | 0.91 |

| 18 | 4.68 | 30.18 | 83.05 | 3.89 | 21.35 | 0.59 | 997 | 0.83 |

| 25 | 4.68 | 29.46 | 83.01 | 3.89 | 21.34 | 0.60 | 997 | 0.83 |

| Exposure [%] | VOC [V] | ISC [mA] | PMAX [mW] | VMAX [V] | IMAX [mA] | FF | POAI [W/m2] | PCE [%] |

|---|---|---|---|---|---|---|---|---|

| 0 | 4.50 | 24.28 | 67.99 | 3.85 | 17.66 | 0.62 | 997 | 0.68 |

| 3 | 4.48 | 23.34 | 63.86 | 3.70 | 17.26 | 0.61 | 997 | 0.64 |

| 9 | 4.46 | 23.26 | 63.96 | 3.63 | 17.62 | 0.62 | 997 | 0.64 |

| 18 | 4.50 | 23.49 | 65.68 | 3.70 | 17.75 | 0.62 | 997 | 0.66 |

| 25 | 4.52 | 23.27 | 65.06 | 3.80 | 17.12 | 0.62 | 997 | 0.65 |

| 35 | 4.52 | 23.47 | 65.11 | 3.67 | 17.74 | 0.61 | 995 | 0.65 |

| 53 | 4.57 | 22.60 | 59.97 | 3.67 | 16.34 | 0.58 | 1004 | 0.60 |

| 61 | 4.08 | 22.90 | 59.83 | 3.60 | 16.62 | 0.58 | 995 | 0.60 |

| 71 | 4.44 | 23.96 | 63.16 | 3.63 | 17.40 | 0.59 | 1008 | 0.63 |

| 100 | 4.51 | 23.02 | 62.21 | 3.77 | 16.50 | 0.61 | 1000 | 0.62 |

| Test Parameters | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample 1 | m [g] | 8.09 | 7.99 | 8.10 | 8.00 | 8.19 | 8.13 | 7.77 | 8.01 | 7.74 | 7.80 |

| v [m/s] | 22.89 | 22.59 | 23.02 | 23.02 | 22.79 | 22.89 | 22.69 | 23.02 | 22.46 | 22.70 | |

| IZ | 1 | 4 | 2 | 5 | 9 | 10 | 6 | 8 | 7 | 3 | |

| Sample 2 | m [g] | 8.04 | 8.03 | 7.79 | 8.06 | 7.98 | 7.97 | 7.88 | 7.96 | 8.06 | 7.81 |

| v [m/s] | 22.87 | 22.49 | 22.68 | 22.64 | 22.54 | 21.79 | 22.31 | 22.41 | 22.27 | 22.27 | |

| IZ | 1 | 2 | 6 | 10 | 9 | 8 | 4 | 7 | 3 | 5 | |

| Sample 3 | m [g] | 7.80 | 7.99 | 8.04 | 7.79 | 7.91 | 8.04 | 8.02 | 7.92 | 8.04 | 8.13 |

| v [m/s] | 22.46 | 22.41 | 23.05 | 22.46 | 22.28 | 22.25 | 22.16 | 22.23 | 22.15 | 22.44 | |

| IZ | 8 | 9 | 5 | 4 | 7 | 10 | 6 | 3 | 2 | 1 | |

| Sample 4 | m [g] | 7.94 | 7.87 | 7.92 | 8.01 | 8.03 | 8.02 | 8.09 | 7.87 | 8.05 | 8.14 |

| v [m/s] | 22.15 | 22.19 | 22.21 | 22.95 | 22.73 | 22.39 | 22.84 | 22.94 | 22.55 | 22.94 | |

| IZ | 4 | 7 | 3 | 2 | 6 | 9 | 10 | 5 | 8 | 1 | |

| Sample 5 | m [g] | 8.05 | 7.90 | 8.10 | 7.97 | 7.97 | 8.03 | 7.94 | 8.02 | 7.93 | 7.91 |

| v [m/s] | 22.71 | 22.84 | 22.25 | 22.98 | 22.63 | 22.57 | 21.79 | 23.01 | 22.97 | 22.22 | |

| IZ | 1 | 10 | 5 | 9 | 6 | 6 | 3 | 2 | 9 | 7 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mangherini, G.; Sollazzo, L.; Diolaiti, V.; Gawronska, M.; Sanna, C.; Damiano, A.; Vincenzi, D. Long-Term Reliability of Semi-Transparent Photovoltaic Panels Based on Luminescent Solar Concentrators. Energies 2025, 18, 674. https://doi.org/10.3390/en18030674

Mangherini G, Sollazzo L, Diolaiti V, Gawronska M, Sanna C, Damiano A, Vincenzi D. Long-Term Reliability of Semi-Transparent Photovoltaic Panels Based on Luminescent Solar Concentrators. Energies. 2025; 18(3):674. https://doi.org/10.3390/en18030674

Chicago/Turabian StyleMangherini, Giulio, Leonardo Sollazzo, Valentina Diolaiti, Malgorzata Gawronska, Carla Sanna, Alfonso Damiano, and Donato Vincenzi. 2025. "Long-Term Reliability of Semi-Transparent Photovoltaic Panels Based on Luminescent Solar Concentrators" Energies 18, no. 3: 674. https://doi.org/10.3390/en18030674

APA StyleMangherini, G., Sollazzo, L., Diolaiti, V., Gawronska, M., Sanna, C., Damiano, A., & Vincenzi, D. (2025). Long-Term Reliability of Semi-Transparent Photovoltaic Panels Based on Luminescent Solar Concentrators. Energies, 18(3), 674. https://doi.org/10.3390/en18030674