Study on Permeability Enhancement and Heat Transfer of Oil Sands Reservoir Based on Hydrophobic Nanofluids

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Silica Nanoparticles and Nanofluid

2.1.2. Core

2.2. Experimental Method

2.2.1. Preparation of Nanofluids

- (1)

- Prepare or prepare base solution: NaCl solution with 3% mass fraction.

- (2)

- Weighing nanoparticles: Weigh the specified number of grams of nanoparticles and add them to the base solution prepared in advance, and then add a certain quality of cetyltrimethylammonium bromide solid particles.

- (3)

- Stirring: Stir slightly with a clean glass rod for 5 min to help the nanoparticles dissolve in the base solution.

- (4)

- Ultrasonic dispersion (Figure 1): Use an ultrasonic homogenizer (Figure 1b) to disperse for 2 h, the ultrasonic power is 240 W. The ultrasonic dispersion instrument model is SCIENTZ-1500F, manufactured by Ningbo Xinzhi Biotechnology Co., Ltd. (Ningbo, China) and the equipment is located at Northwest University, Xi’an City, Shaanxi Province, China. In order to avoid the overheating of ultrasonic, stop for 10 min after 15 min of ultrasonic each time to cool down the nanofluid naturally, complete the configuration after 8 times of ultrasonic, and then measure the PH value of the nanofluid with a PH meter. By interfering with the agglomeration and sedimentation of nanoparticles by ultrasound, dispersed and stable nanofluids can be obtained.

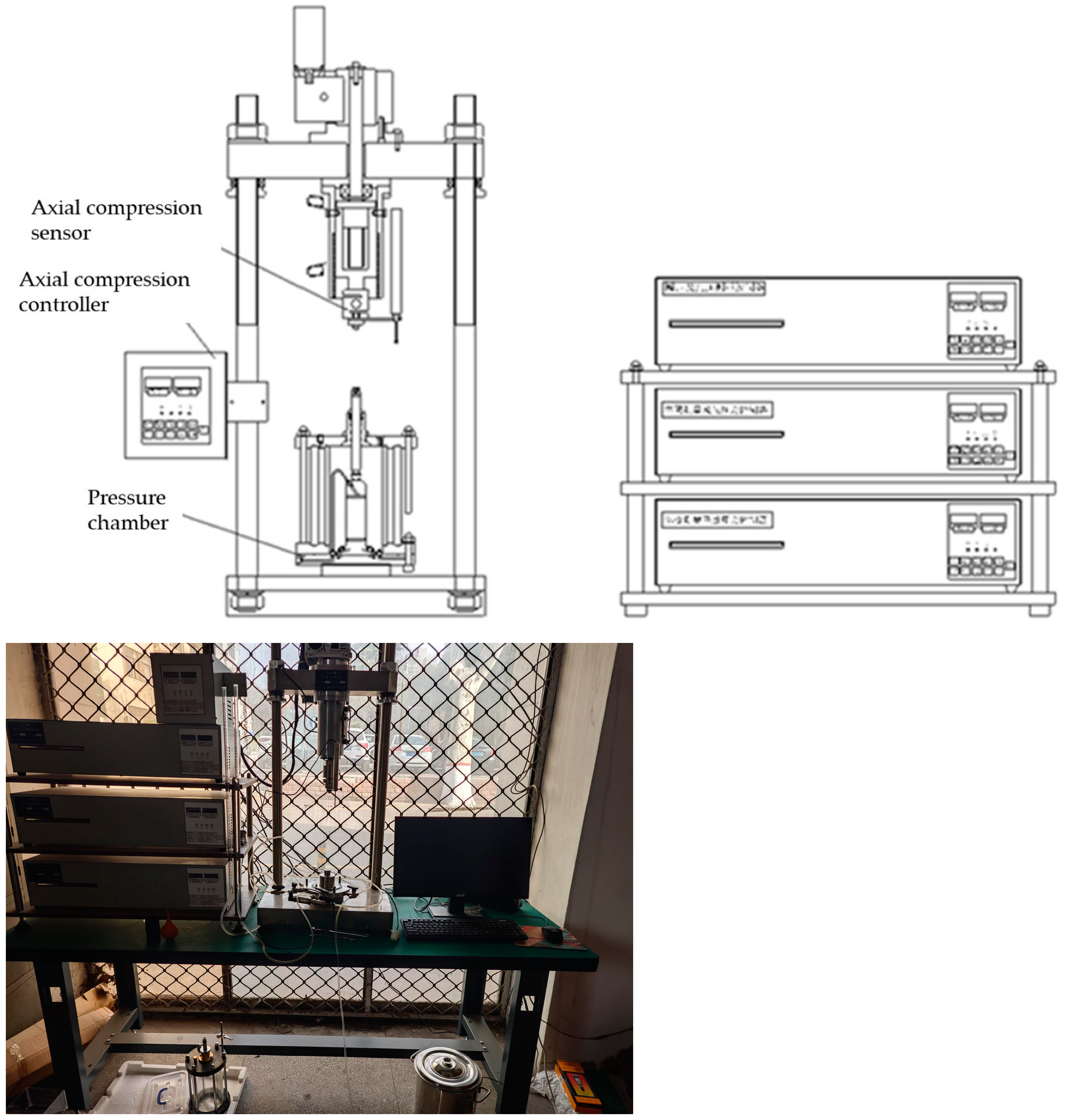

2.2.2. Triaxial Shear Seepage Experiment

- Axial force: 0–60 kN, measurement accuracy: ±1% (10–95% FS);

- Control mode:

- Equal strain control: 0.002–4 mm/min ± 10%;

- Equal stress control: 0 kN~60 kN, control accuracy ± 1%;

- Soil sample specifications: Φ101 × 200, Φ61.8 × 125, Φ39.1 × 80, Φ25 × 50 mm;

- Surrounding pressure: 0–1.99 MPa, control accuracy: ±0.5%FS, set value (0.01~1.95 MPa);

- Counter pressure: 0–0.99 MPa, control accuracy: ±0.5%FS, set value (0.01~0.99 MPa);

- Constant pressure difference control permeability;

- Constant flow permeation (0.02~30 mL/min);

- Volume change: 0–480 mL, digital display.

- (1)

- The oil sands cores were soaked in 3% NaCl solution and 0.05, 0.1, and 0.15 wt% nanofluids, respectively (Table 4).

- (2)

- According to the test requirements, be familiar with the functions of each valve of the instrument and the flow direction of the inlet and outlet liquid of the pipeline.

- (3)

- Determine the predetermined confining pressure value and pore pressure value of this test (Table 4).

- (4)

- Install the cores and energize each controller, and preheat for 10–20 min.

- (5)

- After the core is put into the pressure chamber (Figure 3), the confining pressure is raised to the specified value, the pore pressure is loaded to the specified value. After a period of consolidation, the permeability of the rock sample is tested, the permeability was tested by the steady-state method, and the differential pressure was 0.5 MPa following Darcy’s law. Then, the strain loading mode (loading rate of 0.1 mm/min) is used for triaxial compression after the permeability test is completed, and the loading is stopped when the axial strain is 3%, 6%, 9%, and 12%. The permeability of the rock sample is tested until the axial strain is 12%, the permeability test is completed, and the experiment is over. A total of five permeability tests are required.

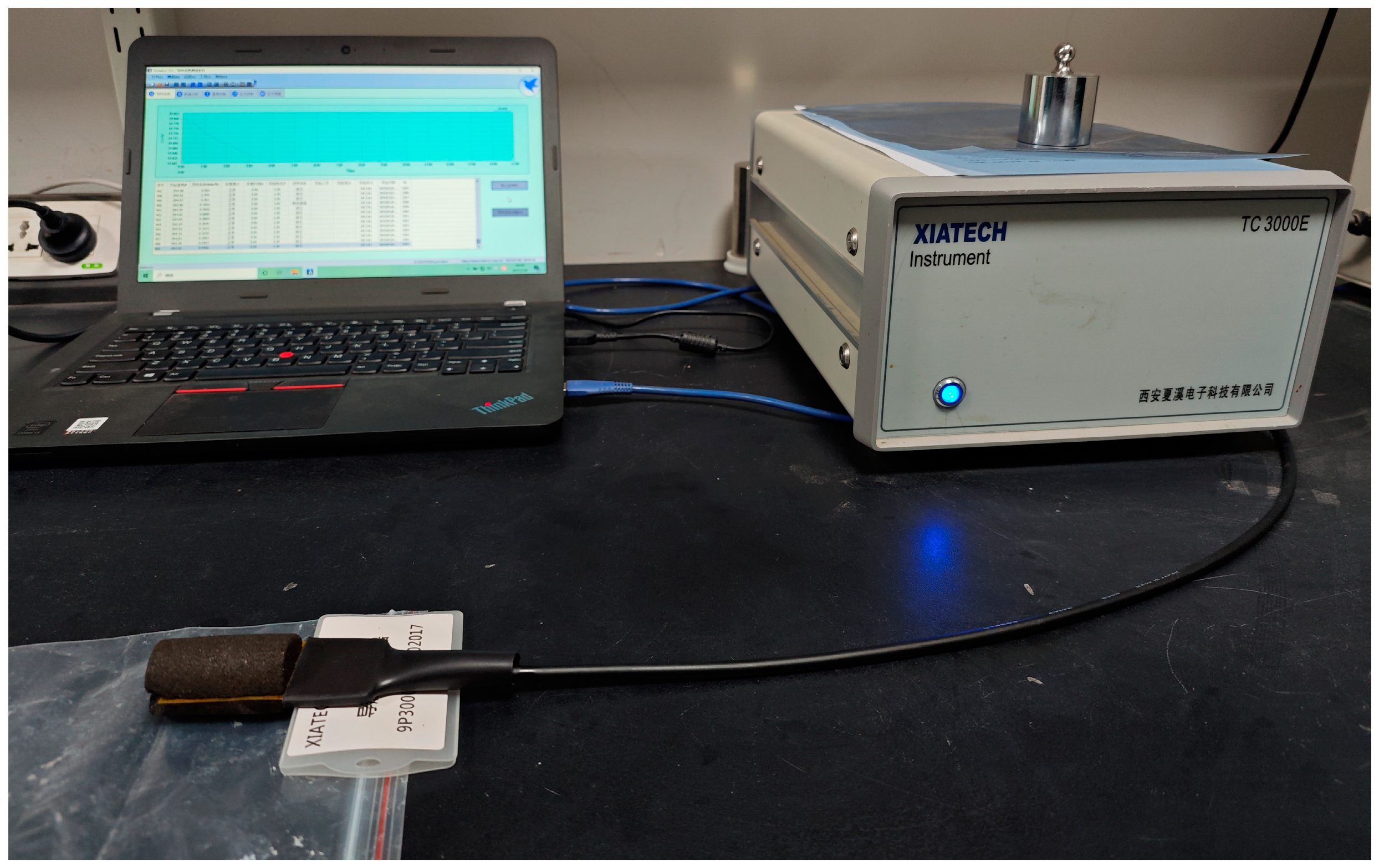

2.2.3. Thermal Conductivity Experiment

3. Results and Discussion

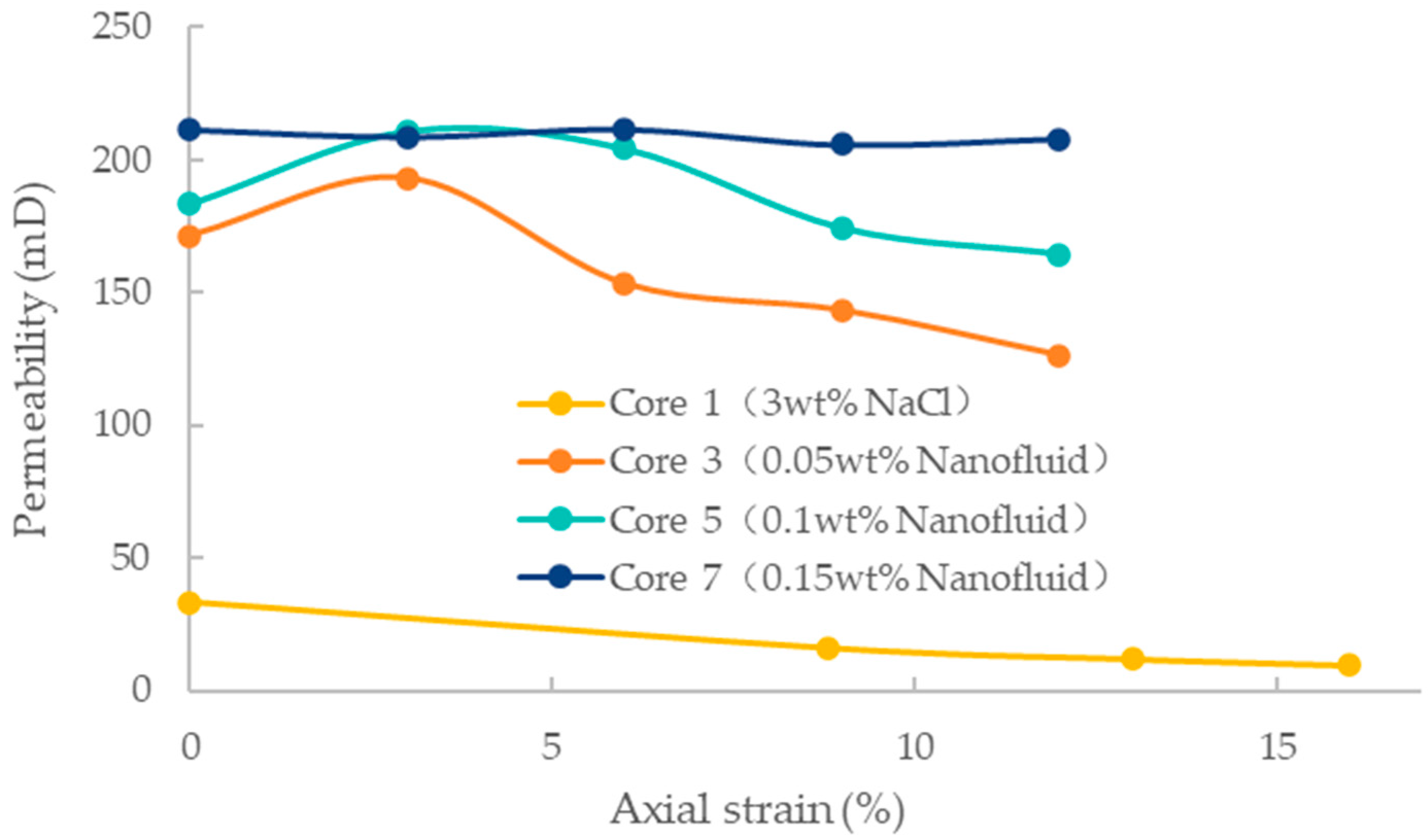

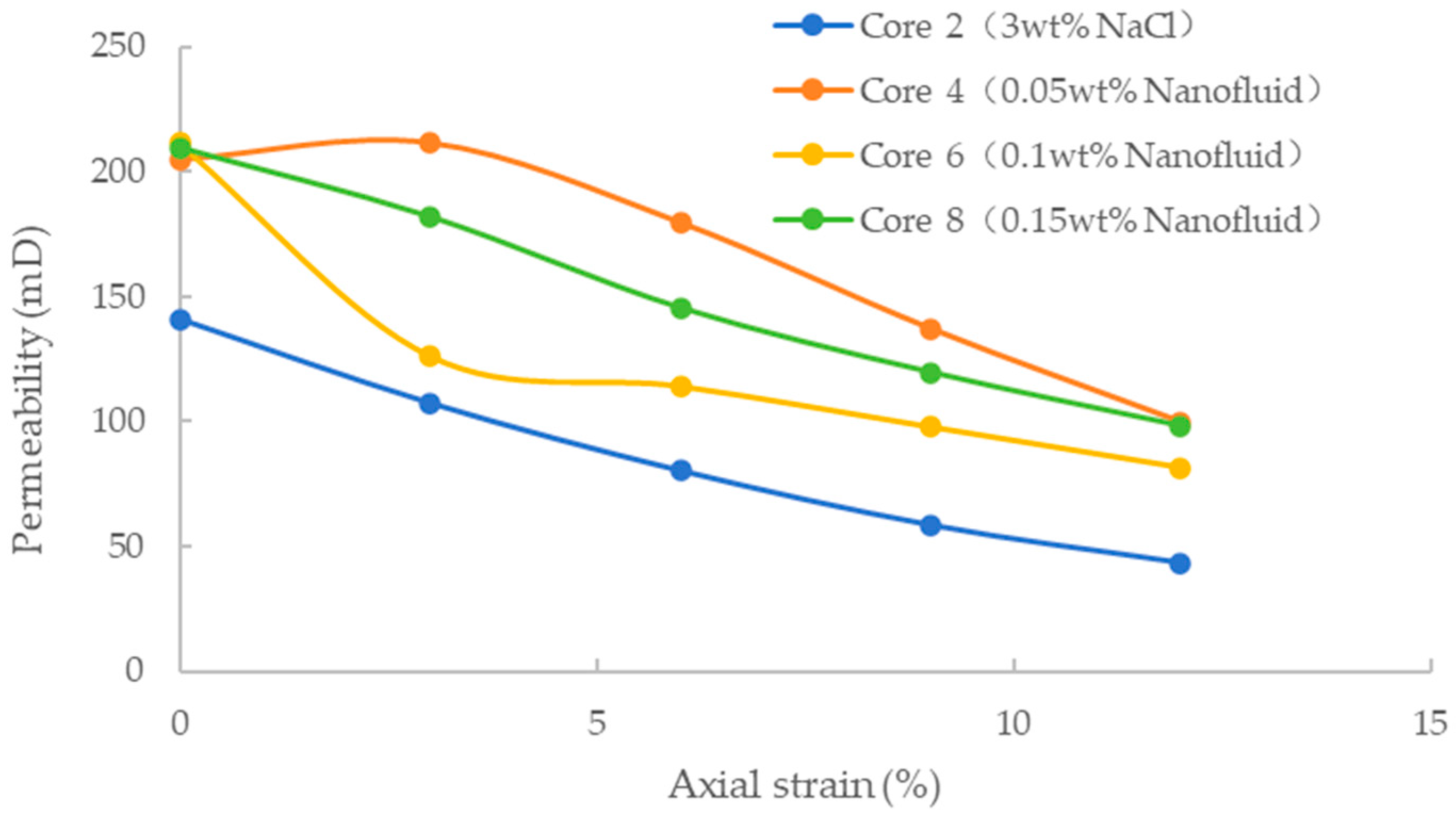

3.1. Increased Permeability of Nanofluids

3.2. Increased Thermal Conductivity of Nanofluids

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, H.; Nikolov, A.; Wasan, D. Enhanced oil recovery (EOR) using nanoparticle dispersions: Underlying mechanism and imbibition experiments. Energy Fuels 2014, 28, 3002–3009. [Google Scholar] [CrossRef]

- Pouyan, A.; Hamidreza, A.; Shahin, K.; Armin, K. Investigation of the simultaneous chemicals influences to promote oil-in-water emulsions stability during enhanced oil recovery applications. J. Mol. Liq. 2019, 275, 57–70. [Google Scholar] [CrossRef]

- Ma, W.Y.; Tian, Q.; Cao, M.S.; Gao, Z.J.; Chen, Y.J.; Zhu, J. Research Progress on Nanoparticle Dispersion Technology: Dispersion Methods and Mechanisms (1). China Powder Technol. 2002, 3, 28–31. [Google Scholar] [CrossRef]

- Gao, R.M. Research on Oilfield Water Injection Technology Improvement by Active SiO2 Nanopowders. Oilfield Chem. 2004, 3, 248–250+267. [Google Scholar] [CrossRef]

- Xiong, J.H.; Li, Q.T.; Tao, J.Q.; He, Y.J.; Zhang, J.; Liu, J.G. Application and understanding of nano-depressurization and injection process in water injection wells. Oil Drill. Prod. Technol. 2010, 32, 78–80. [Google Scholar] [CrossRef]

- Liu, P.S.; Tao, X.H.; Li, X.H.; Zhao, M.Y.; Zhang, Z.J. Study on depressurization and injection enhancement of water-based nano-polysilicon in low-permeability reservoirs. Oilfield Chem. 2017, 34, 604–609. [Google Scholar] [CrossRef]

- Suleimanov, B.A.; Ismailov, F.S.; Veliyev, E.F. Nanofluid for enhanced oil recovery. J. Pet. Sci. Eng. 2011, 78, 431–437. [Google Scholar] [CrossRef]

- Gao, P.; Feng, Q.; Chen, X.; Li, S.; Sun, Y.; Li, J.; Zhou, J.; Qian, F. Numerical simulation and field application of biological nano-technology in the low- and medium-permeability reservoirs of an offshore oilfield. J. Pet. Explor. Prod. Technol. 2022, 12, 3275–3288. [Google Scholar] [CrossRef]

- Wang, T.R.; Zhang, Y.; Li, L.; Yang, Z.; Liu, Y.F.; Fang, J.C.; Dai, C.L.; You, Q. Experimental study on pressure-decreasing performance and mechanism of nanoparticles in low permeability reservoir. J. Pet. Sci. Eng. 2018, 166, 693–703. [Google Scholar] [CrossRef]

- Mohammad, R.A.; Pouyan, A.; Mohammad, S.; Masoud, R. Wettability modification of oil-wet carbonate reservoirs using silica-based nanofluid: An experimental approach. J. Pet. Sci. Eng. 2019, 178, 700–710. [Google Scholar] [CrossRef]

- Cervenan, M.R.; Vermeulen, F.E.; Chute, F.S. Thermal conductivity and specific heat of oil sand samples. Can. J. Earth Sci. 1981, 18, 926–931. [Google Scholar] [CrossRef]

- Agar, J.G.; Morgenstern, N.R.; Scott, J.D. Thermal expansion and pore pressure generation in oil sands. Can. Geotech. J. 1986, 23, 327–333. [Google Scholar] [CrossRef]

- Hepler, L.G.; His, C. AOSTRA Technical Handbook on Oil Sands, Bitumens and Heavy Oils; Alberta Oil Sands Technology and Research Authority: Edmonton, AB, Canada, 1989. [Google Scholar]

- Heris, S.Z.; Esfahany, M.N.; Etemad, S.G. Experimental investigation of convective heat transfer of Al2O3/water nanofluid in circular tube. Int. J. Heat Fluid Flow 2007, 28, 203–210. [Google Scholar] [CrossRef]

- Saeedinia, M.; Akhavan-Behabadi, M.A.; Razi, P. Thermal and rheological characteristics of CuO–Base oil nanofluid flow inside a circular tube. Int. Commun. Heat Mass Transf. 2012, 39, 152–159. [Google Scholar] [CrossRef]

- Ganvir, R.B.; Walke, P.V.; Kriplani, V.M. Heat transfer characteristics in nanofluid—A review. Renew. Sustain. Energy Rev. 2017, 75, 451–460. [Google Scholar] [CrossRef]

- Xuan, Y.M.; Li, Q. Heat transfer enhancement of nanofluids. Int. J. Heat Fluid Flow 2000, 21, 58–64. [Google Scholar] [CrossRef]

- Zhu, D.S.; Li, X.F.; Wang, N.; Wang, X.J.; Gao, J.W.; Li, H. Dispersion behavior and thermal conductivity characteristics of Al2O3–H2O nanofluids. Curr. Appl. Phys. 2009, 9, 131–139. [Google Scholar] [CrossRef]

- Xie, H.Q.; Wang, J.C.; Cheng, S.X.; Liu, Y. Study on the thermal conductivity of materials measured by hot needle method. J. Appl. Sci. 2002, 1, 6–9. [Google Scholar]

- Gao, Y.F.; Wang, X.Y.; Ren, Z.L.; Chen, M.; Jiang, H.L. Dilatancy-induced permeability model during water injection in Karamay continental oil sands. Oil Drill. Prod. Technol. 2021, 43, 244–249. [Google Scholar] [CrossRef]

| Items | Metric Values |

|---|---|

| Appearance | White powder |

| Silicon oxide content (%) | 98 |

| Average particle size (nm) | 20 |

| Specific surface area (m2/g) | ≥600 |

| Core Number | Diameter (mm) | Length (mm) | Weight (g) | Density (g/cm3) | Volume (cm3) |

|---|---|---|---|---|---|

| 1-1 | 25.18 | 52.3 | 47.04 | 1.81 | 26.03 |

| 1-2 | 25.1 | 52.4 | 47.04 | 1.82 | 25.91 |

| 1-3 | 25.02 | 52.36 | 47 | 1.83 | 25.73 |

| 1-4 | 25.04 | 51.8 | 44.03 | 1.73 | 25.50 |

| 1-5 | 25.06 | 52.8 | 47.03 | 1.81 | 26.03 |

| 1-6 | 25.1 | 53.2 | 46.71 | 1.78 | 26.31 |

| 1-7 | 25.02 | 52.5 | 46.47 | 1.80 | 25.80 |

| 1-8 | 25.16 | 53.02 | 46.96 | 1.78 | 26.35 |

| Mineral Type | Non-Clay Minerals | |||||||

|---|---|---|---|---|---|---|---|---|

| Quartz | Feldspar | Dolomite | Calcite | Anhydrite | Plaster | Pyrite | Siderite | |

| Mass Percentage (%) | 34.9 | 20.3 | 6.3 | 1.6 | 1.3 | 0.3 | 1.4 | 3.2 |

| Mineral type | Clay minerals | |||||||

| Aemon mixed layer | Illite | Kaolinite | Chlorite | |||||

| Mass Percentage (%) | 1.5 | 9.8 | 8.3 | 11.1 | ||||

| Core Number | Nanofluid Concentration/wt% | Confining Pressure/MPa | Pore Pressure/MPa | Effective Confining/MPa |

|---|---|---|---|---|

| 1 | 0 (3%NaCl) | 1 | 0.5 | 0.5 |

| 2 | 0 (3%NaCl) | 2 | 1 | 1 |

| 3 | 0.05 | 1 | 0.5 | 0.5 |

| 4 | 0.05 | 2 | 1 | 1 |

| 5 | 0.1 | 1 | 0.5 | 0.5 |

| 6 | 0.1 | 2 | 1 | 1 |

| 7 | 0.15 | 1 | 0.5 | 0.5 |

| 8 | 0.15 | 2 | 1 | 1 |

| Technical Indicators | Parameters |

|---|---|

| Resolution | 0.005 W/(m·K) |

| Measuring range | 0.001~10 W/(m·K) |

| Repeatability | ±3% |

| Accuracy | ±3% |

| Temperature range | −160~150 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Chen, Z.; Liang, X.; Li, Y.; Shen, S.; Li, D.; Huang, Z. Study on Permeability Enhancement and Heat Transfer of Oil Sands Reservoir Based on Hydrophobic Nanofluids. Energies 2025, 18, 927. https://doi.org/10.3390/en18040927

Gao Y, Chen Z, Liang X, Li Y, Shen S, Li D, Huang Z. Study on Permeability Enhancement and Heat Transfer of Oil Sands Reservoir Based on Hydrophobic Nanofluids. Energies. 2025; 18(4):927. https://doi.org/10.3390/en18040927

Chicago/Turabian StyleGao, Yanfang, Zupeng Chen, Xuelin Liang, Yanchao Li, Shijie Shen, Dengke Li, and Zhi Huang. 2025. "Study on Permeability Enhancement and Heat Transfer of Oil Sands Reservoir Based on Hydrophobic Nanofluids" Energies 18, no. 4: 927. https://doi.org/10.3390/en18040927

APA StyleGao, Y., Chen, Z., Liang, X., Li, Y., Shen, S., Li, D., & Huang, Z. (2025). Study on Permeability Enhancement and Heat Transfer of Oil Sands Reservoir Based on Hydrophobic Nanofluids. Energies, 18(4), 927. https://doi.org/10.3390/en18040927