Energy-Saving Design Strategies for Industrial Heritage in Northeast China Under the Concept of Ultra-Low Energy Consumption

Abstract

:1. Introduction

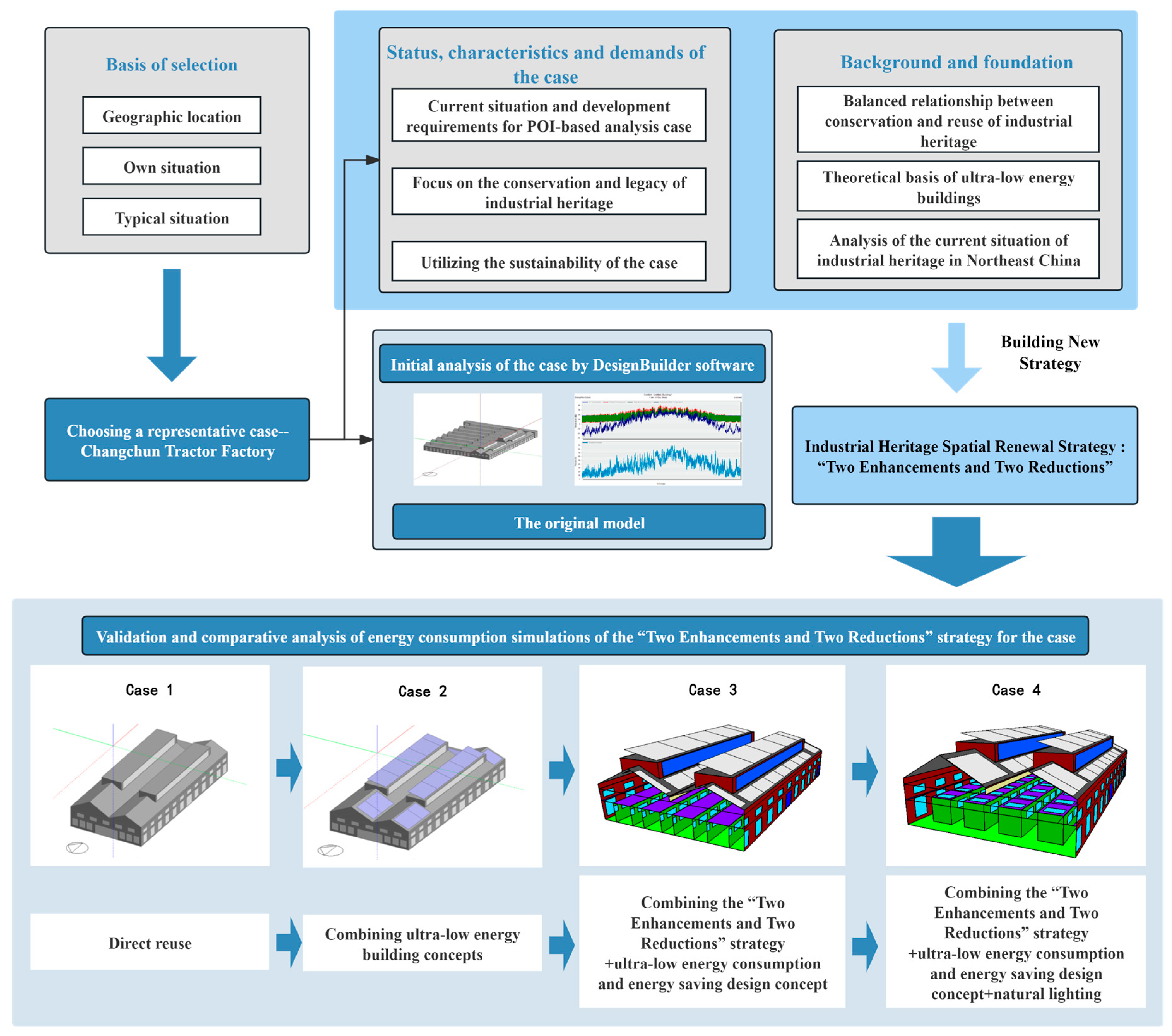

- To investigate the current energy consumption status and energy-saving potential of industrial heritage buildings in Northeast China using DesignBuilder energy simulation software.

- To propose the “Two Enhancements and Two Reductions” design strategy, which balances ultra-low energy consumption design principles with the imperative to conserve and adaptively reuse industrial heritage structures.

- To verify the effectiveness of the “Two Enhancements and Two Reductions” strategy and demonstrate its potential for achieving ultra-low energy consumption in practice.

2. State of the Art

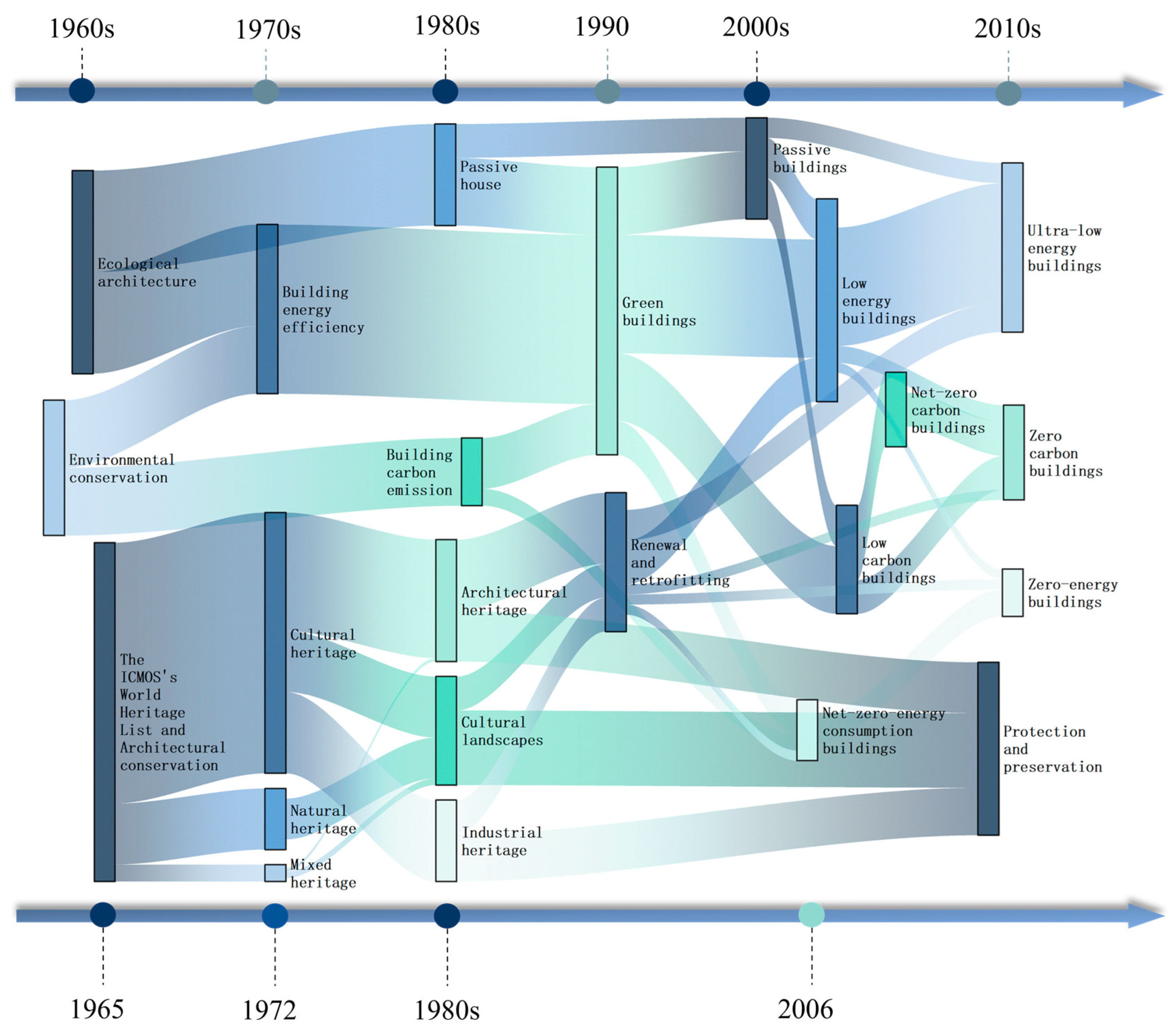

2.1. Ultra-Low-Energy Buildings

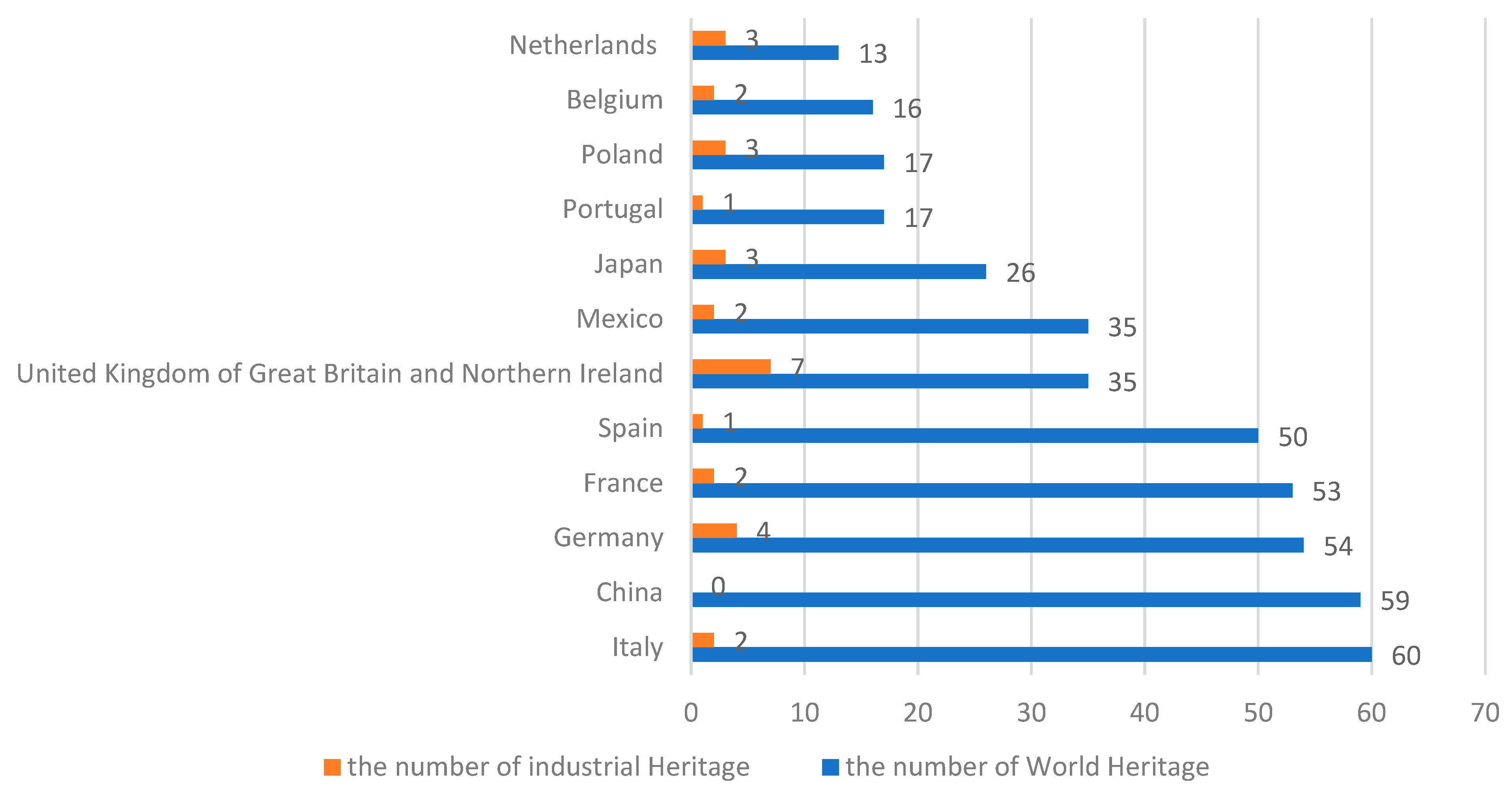

2.2. Reuse of Industrial Heritage

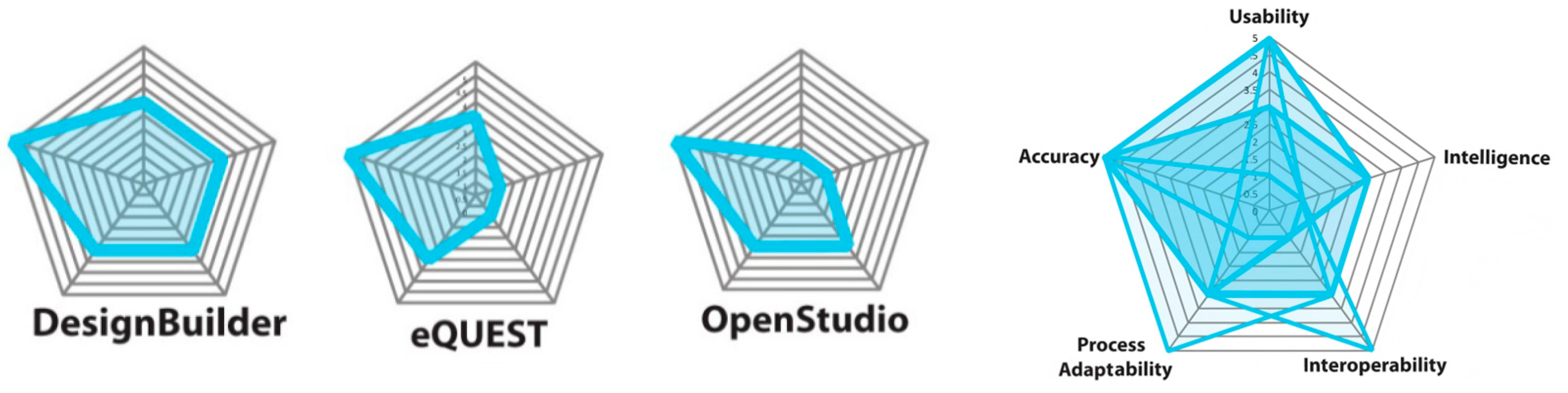

2.3. Selection of Energy Simulation Software

3. Methods and Strategies

3.1. Experiment Overview

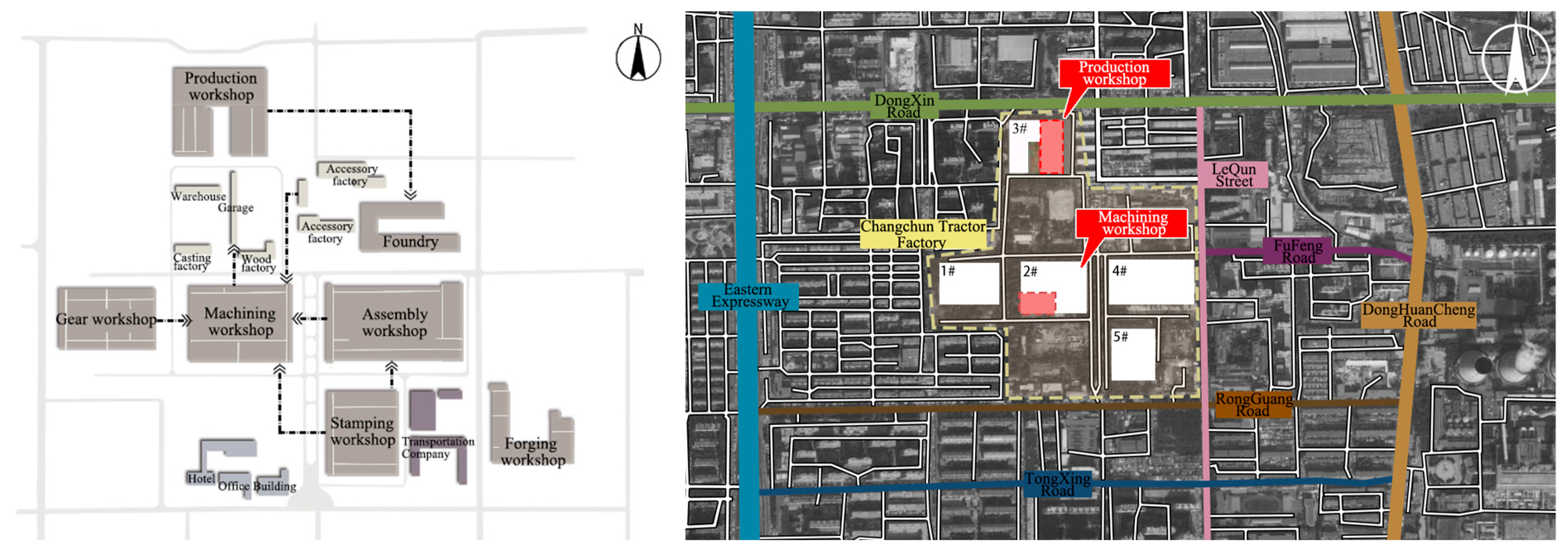

3.2. The Case Study

3.3. Model Construction and Simulation Settings

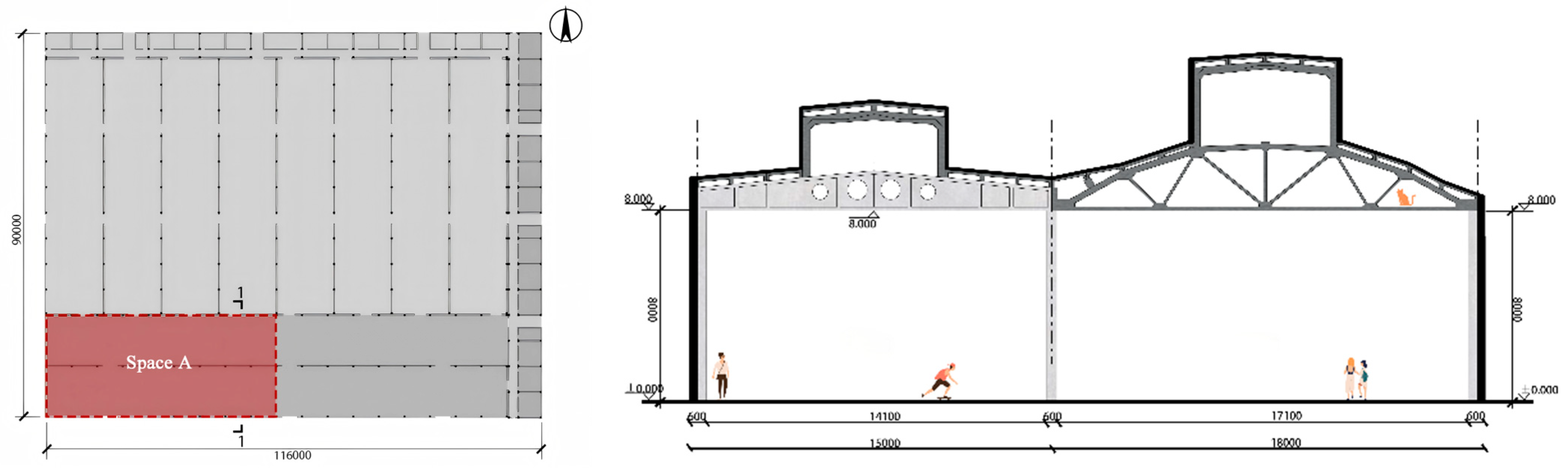

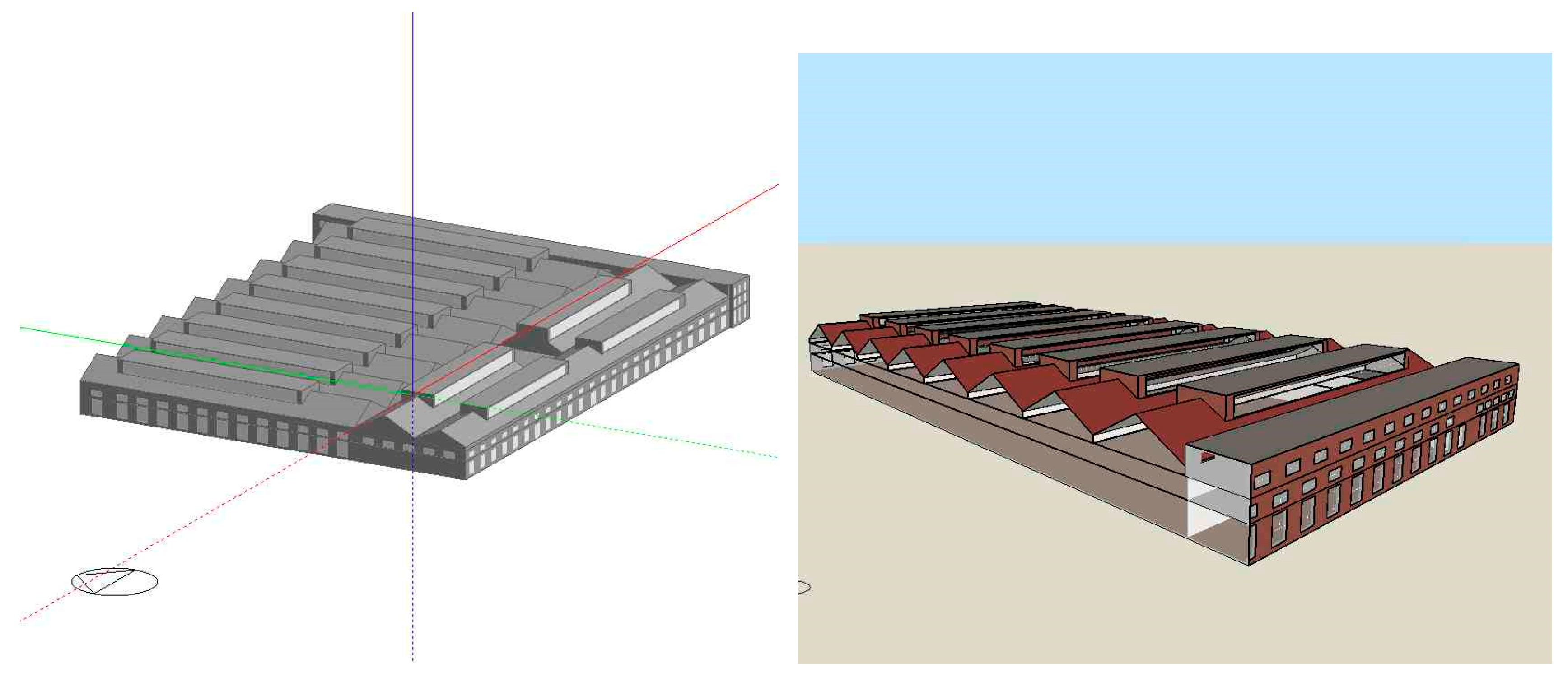

- Construction and Glazing Template: Factory No. 2 exhibits distinct characteristics of an industrial factory building in terms of structural form and internal space. According to China’s Code for Thermal Design of Civil Buildings (GB50176-2016) [46], the external opaque envelope consists entirely of 490 mm-thick red brick walls, is lightweight mortar masonry clay brick with a thermal conductivity of 0.76 (W/m·K), and exposed both internally and externally. The transparent envelope consists of double-layer ordinary glass, with a thermal conductivity of 0.76 (W/m·K). The roof is composed of prefabricated concrete slabs combined with composite steel plates. The thermal conductivity of the concrete slab is 1.74 (W/m·K), while that of the composite steel plate is approximately 0.04 (W/m·K). And the roof skylights are made of non-operable single-layer ordinary glass. Based on these features, the corresponding original structural model was established as shown in Figure 10.

- Climatic Conditions: The project is located in Changchun, the capital city of Northeast China, classified as a Severe Cold Zone C in China’s building thermal design zoning. The annual total solar radiation on a horizontal plane is 5000 MJ/m2, with an average annual outdoor temperature of 4.9 °C. The climate here is short and warm in summers, while cold and long in the winters, and there are significant daily temperature variations in spring and autumn. DesignBuilder software supports the CSWD’s (Chinese Standard Weather Data) weather database, which was developed by Dr. Jiang Yi, Department of Building Science and Technology at Tsinghua University and China Meteorological Bureau, and calculates heating and cooling loads using the heat balance method [48,49]. Therefore, the meteorological data of the Changchun area in the CSWD database selected for this project, detailed information, and outdoor temperature changes are shown in Table 4.

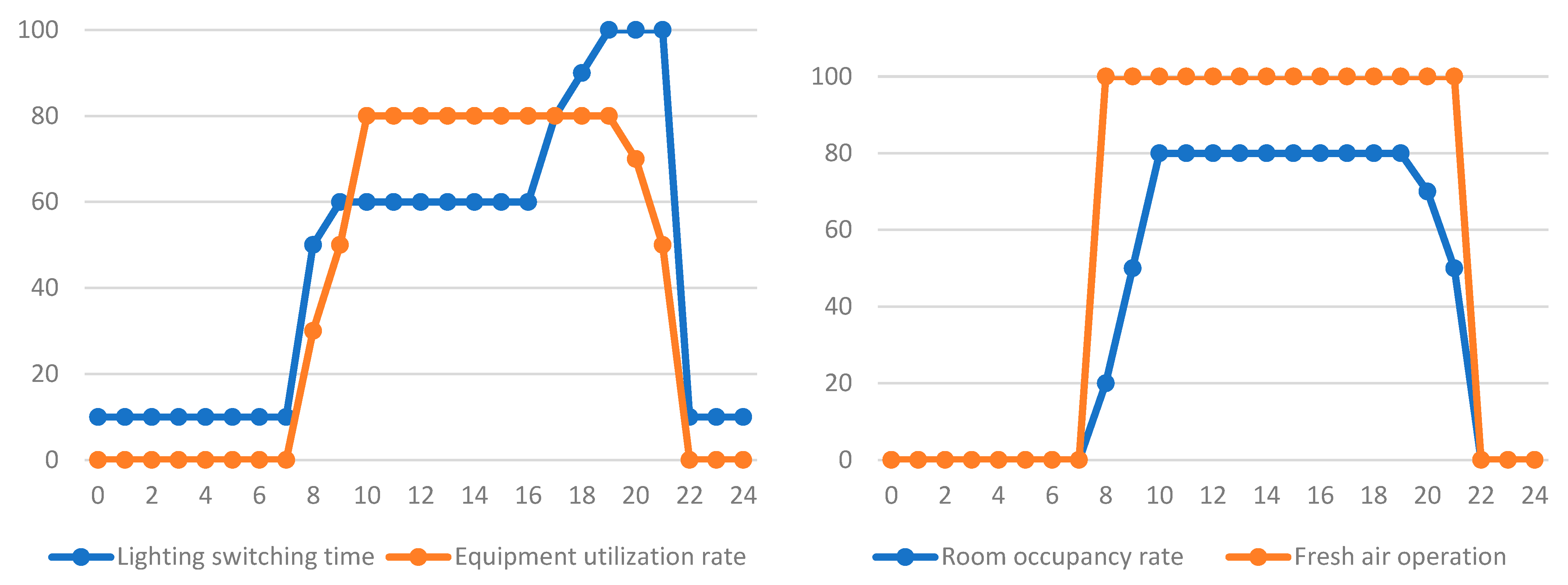

- Activity Template: This study combines the Design Standard for Energy Efficiency of Public Buildings by Jilin Province (energy efficiency 72%) (DB22/T 5160-2024) [50], the Design standard for Green Building by Jilin Province (DB22/T 5055-2021) [51], and other standards. Additionally, the surrounding Points of Interest (POIs) were considered and analyzed. Based on this, the project is preliminarily defined with a focus on a cultural and creative business and educational template, supported by flexible structural forms, to expand the building’s adaptability and enhance its sustainability, thereby meeting more diverse user needs. The time-by-time parameterization for various types of room use requirements are shown in Figure 11.

- Other Templates: During the previous use of the factory building, the indoor temperature was maintained at the minimum standard to prevent freezing, primarily due to the heat generated by machinery, technical limitations, and cost-saving considerations. Human comfort limits and other requirements were not taken into account. Field investigations revealed that the building was originally equipped with a boiler heating system but lacked an air conditioning system. Therefore, the original model parameters exclude mechanical ventilation and cooling systems. Based on the average temperature during the heating period in Changchun, the heating temperature was set to 24 °C. The heating time was set to the annual heating cycle schedule of Changchun from October 20 of each year to April 6 of the following year.

3.4. Building a Reuse Strategy

3.4.1. Analysis of Current Situation

- Current status and development needs of the Changchun Tractor Factory surrounding: A data analysis was performed on six categories of POIs (Points of Interest) within a 5 km radius of the Changchun Tractor Factory, using data sourced from Gaode Map [52]. The project samples were visualized and organized into a dataset using Kepler.gl software, as illustrated in Figure 12. It can be observed that education categories in this area are distributed very densely, followed by sports categories and mall categories. Additionally, the data obtained from POIs after data analysis are shown in Table 5. To verify the accuracy of the data, we used the triple standard deviation method, and the guidelines were shown as follows:

- 2.

- Key concerns for the conservation and inheritance of industrial heritage: The U.S. Department of the Interior, through discussions with experts, identified windows as a consistently significant element of historical buildings. This point has also been recognized in European countries, where windows are considered a unique and integral part of historical architecture, warranting maximum restoration and preservation efforts [54,55,56,57]. Consequently, this project focuses on protecting the external envelope and overall form, specifically preserving historically valuable windows, red brick walls, and building façades. Meanwhile, reuse strategies are applied to enhance the adaptability and flexibility of internal spaces [48].

- 3.

- Sustainability of reuse projects: This study employs ultra-low energy concepts to reduce building energy consumption and extend the service life of the structure. However, due to the large spatial volume of factory buildings and the principle of preserving external enclosures, calculations using DesignBuilder indicate that achieving ultra-low energy performance while maintaining the existing enclosure is nearly impossible with current technologies. Consequently, this study incorporates the “loggias” retrofitting concept proposed by Reina Oki et al. from Waseda University in Japan [54,58] and combines it with the design of interior walking spaces, resulting in a sustainable, low-energy, and adaptable prefabricated design solution.

3.4.2. “Two Enhancements”: Increasing Functionality of Space and Diversity of Energy-Saving Materials

3.4.3. “Two Reductions”: Reducing Profile Sizes and Carbon Emissions

3.5. Model Construction and Simulation Settings Under the “Two Enhancements and Two Reductions” Strategy

4. Results

4.1. Analysis of the Original Model—Current Situation with No Modifications

4.2. Analysis of Modeling Results for the “Two Enhancements and Two Reductions” Strategy

5. Discussion

- Preservation of the external envelope, conserving the historical value of industrial heritage.

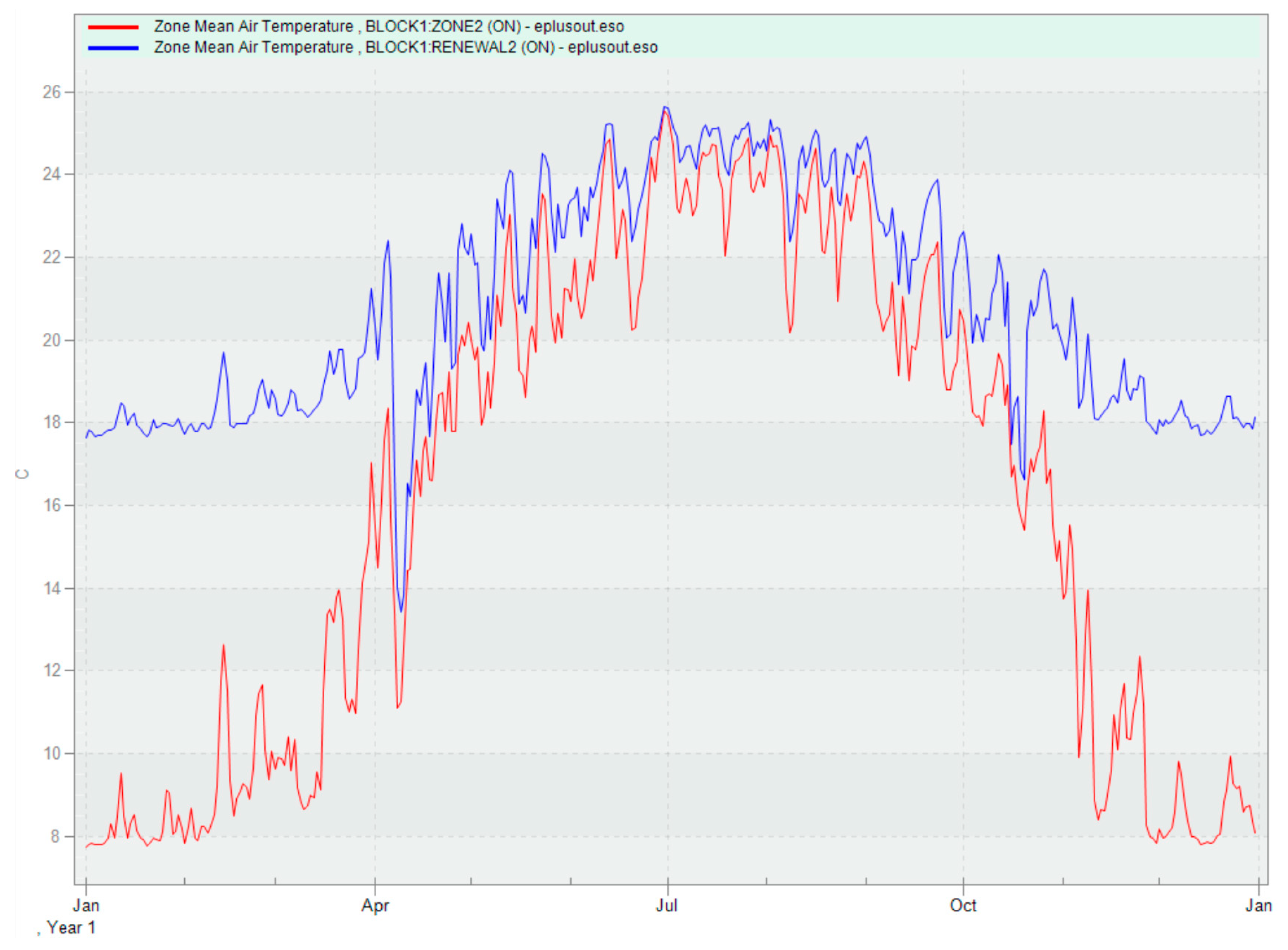

- Utilization of large spaces and high ceilings in factory buildings, transforming the indoor walking space into more than just a transitional commercial area. It also provides an improved walking environment during the five-month winter period in cold regions, with an annual temperature maintained between 8 °C and 26 °C (as shown in Figure 21).

- Significant reduction in total energy consumption—compared to Case 1, total energy consumption was reduced by approximately 95%, with an annual decrease in primary energy of 4,009,346 (kgce/tce).

- Ensuring the usability and thermal comfort of the mall space, with an annual temperature maintained between 18 °C and 26 °C (as shown in Figure 21), meeting human comfort standards.

6. Conclusions

- The high ceiling and large space provide a high level of flexibility for reuse, accommodating diverse functional needs.

- Most are located in the city center, offering excellent foot traffic and geographical location advantages.

- The large spaces result in excessively high demands for heating and cooling.

- To preserve the historical value of the industrial heritage, the factory’s envelope structure is retained, but these structures have poor thermal insulation properties.

- The large spans and multiple bays of these factories also impose significant limitations on natural daylight.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. Global ABC Roadmap for Buildings and Construction. 2020–2050. Available online: https://www.iea.org/reports/globalabc-roadmap-for-buildings-and-construction-2020-2050 (accessed on 15 October 2024).

- CPC Central Committee State Council. Oponions on Accelerating Comprehensive Green Transformation of Economic and Social Development. Available online: https://www.gov.cn/gongbao/2024/issue_11546/202408/content_6970974.html (accessed on 15 October 2024).

- Alsabry, A.; Szymański, K.; Backiel-Brzozowska, B. Analysis of the Energy, Environmental and Economic Efficiency of Multi-Family Residential Buildings in Poland. Energies 2024, 17, 2057. [Google Scholar] [CrossRef]

- Spandagos, C.; Ng, T.L. Equivalent full-load hours for assessing climate change impact on building cooling and heating energy consumption in large Asian cities. Appl. Energy 2017, 189, 352–368. [Google Scholar] [CrossRef]

- Blagojević, M.R.; Tufegdžić, A. The new technology era requirements and sustainable approach to industrial heritage renewal. Energ Build. 2016, 115, 148–153. [Google Scholar] [CrossRef]

- Douet, J. Industrial Heritage Re-Tooled: The TICCIH Guide to Industrial Heritage Conservation; Routledge: London, UK, 2016. [Google Scholar]

- Misirlisoy, D.; Günçe, K. Adaptive reuse strategies for heritage buildings: A holistic approach. Sustain. Cities Soc. 2016, 26, 91–98. [Google Scholar] [CrossRef]

- Vardopoulos, I. Critical sustainable development factors in the adaptive reuse of urban industrial buildings. A fuzzy DEMATEL approach. Sustain. Cities Soc. 2019, 50, 101684. [Google Scholar] [CrossRef]

- Scaffidi, F. Average social and territorial innovation impacts of industrial heritage regeneration. Cities 2024, 148, 104907. [Google Scholar] [CrossRef]

- Guidetti, E.; Ferrara, M. Embodied energy in existing buildings as a tool for sustainable intervention on urban heritage. Sustain. Cities Soc. 2023, 88, 104284. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J.; Wang, F.; Dong, Y. How to achieve a balance between functional improvement and heritage conservation? A case study on the renewal of old Beijing city. Sustain. Cities Soc. 2023, 98, 104790. [Google Scholar] [CrossRef]

- Banti, N. Existing industrial buildings—A review on multidisciplinary research trends and retrofit solutions. J. Build. Eng. 2024, 84, 108615. [Google Scholar] [CrossRef]

- Yue, J.; Lu, J.; Yan, C.; Liu, J.; Pan, Y. Dynamic Simulation Analysis of Influencing Factors of Energy Consumption of Public Building Envelope in Central China. Sustainability 2023, 15, 14982. [Google Scholar] [CrossRef]

- Harish, V.S.K.V.; Kumar, A. A review on modeling and simulation of building energy systems. Renew. Sustain. Energy Rev. 2016, 56, 1272–1292. [Google Scholar] [CrossRef]

- Gan, V.J.L.; Lo, I.M.C.; Ma, J.; Tse, K.T.; Cheng, J.C.P.; Chan, C.M. Simulation optimisation towards energy efficient green buildings: Current status and future trends. J. Clean. Prod. 2020, 254, 120012. [Google Scholar] [CrossRef]

- Tian, Z.C.; Zhang, X.K.; Jin, X.; Zhou, X.; Si, B.H.; Shi, X. Towards adoption of building energy simulation and optimization for passive building design: A survey and a review. Energy Build. 2018, 158, 1306–1316. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Gao, W.; Wang, F.; Zhou, N.; Kammen, D.M.; Ying, X. A survey of the status and challenges of green building development in various countries. Sustainability 2019, 11, 5385. [Google Scholar] [CrossRef]

- Cucuzzella, C. Analyzing Eco-Architecture Beyond Performance; Editions JFD: Montreal, QC, Canada, 2020. [Google Scholar]

- Esbensen, T.V.; Korsgaard, V. Dimensioning of the solar heating system in the zero energy house in Denmark. Sol. Energy 1977, 19, 195–199. [Google Scholar] [CrossRef]

- Ding, Z.; Fan, Z.; Tam, V.W.Y.; Bian, Y.; Li, S.; Illankoon, I.M.C.S.; Moon, S. Green building evaluation system implementation. Build. Environ. 2018, 133, 32–40. [Google Scholar] [CrossRef]

- Bere, J. An introduction to Passive House; Riba Publishing: London, UK, 2019. [Google Scholar]

- Martiskainen, M.; Kivimaa, P. Creating innovative zero carbon homes in the United Kingdom—Intermediaries and champions in building projects. Environ. Innov. Soc. Transit. 2018, 26, 15–31. [Google Scholar] [CrossRef]

- Dang, M.; van den Dobbelsteen, A.; Voskuilen, P. A Parametric Modelling Approach for Energy Retrofitting Heritage Buildings: The Case of Amsterdam City Centre. Energies 2024, 17, 994. [Google Scholar] [CrossRef]

- Xiaoxiang, Q.; Junjia, Y.; Haron, N.A.; Alias, A.H.; Law, T.H.; Abu Bakar, N. Status, Challenges and Future Directions in the Evaluation of Net-Zero Energy Building Retrofits: A Bibliometrics-Based Systematic Review. Energies 2024, 17, 3826. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Hu, F.; Wang, Y. Comparison of evaluation standards for green building in China, Britain, United States. Renew. Sustain. Energy Rev. 2017, 68, 262–271. [Google Scholar] [CrossRef]

- Collection of Building Energy Effciency Standards; China Architecture & Building Press: Beijing, China, 2017.

- CECC. National Standard E-Book Library. Available online: https://ebook.chinabuilding.com.cn/zbooklib/index?SiteID=1&IsSiteUrl=Y (accessed on 31 October 2024).

- Francioni, F.; Lenzerini, F. The 1972 World Heritage Convention: A Commentary; Oxford University Press: Oxford, UK, 2023. [Google Scholar]

- Unesco. World Heritage Convention. Available online: https://whc.unesco.org/ (accessed on 10 October 2024).

- Chen, J.; Judd, B.; Hawken, S. Adaptive reuse of industrial heritage for cultural purposes in Beijing, Shanghai and Chongqing. Struct. Surv. 2016, 34, 331–350. [Google Scholar] [CrossRef]

- Bandarin, F.; Van Oers, R. The Historic Urban Landscape: Managing Heritage in an Urban Century; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Mo, C.; Wang, L.; Rao, F. Typology, preservation, and regeneration of the post-1949 industrial heritage in China: A case study of Shanghai. Land 2022, 11, 1527. [Google Scholar] [CrossRef]

- Alfrey, J.; Putnam, T. The Industrial Heritage: Managing Resources and Uses; Routledge: London, UK, 2003. [Google Scholar]

- Jankovich, B.; Puccetti, P. Building rehabilitation with retrofit of passive and low energy systems. In Passive and Low Energy Architecture; Yannas, S., Ed.; Pergamon: Oxford, UK, 1983; pp. 177–181. [Google Scholar]

- Attia, S. State of the Art of Existing Early Design Simulation Tools for Net Zero Energy Buildings: A Comparison of Ten Tools; Architecture et climat: Ottignies-Louvain-la-Neuve, Belgium, 2011. [Google Scholar]

- Sagdiçoglu, M.S.; Yenice, M.S.; Tel, M.Z. The Use of Energy Simulations in Residential Design: A Systematic Literature Review. Sustainability 2024, 16, 8138. [Google Scholar] [CrossRef]

- Wang, H.D.; Zhai, Z. Advances in building simulation and computational techniques: A review between 1987 and 2014. Energy Build. 2016, 128, 319–335. [Google Scholar] [CrossRef]

- Bevilacqua, P.; Bruno, R.; Szyszka, J.; Cirone, D.; Rollo, A. Summer and winter performance of an innovative concept of Trombe wall for residential buildings. Energy 2022, 258, 124798. [Google Scholar] [CrossRef]

- Rahman, M.M.; Rasul, M.; Khan, M.M.K. Energy conservation measures in an institutional building in sub-tropical climate in Australia. Appl. Energy 2010, 87, 2994–3004. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, H.; Zhang, L.; Feng, Z. Enhancing building energy efficiency using a random forest model: A hybrid prediction approach. Energy Rep. 2021, 7, 5003–5012. [Google Scholar] [CrossRef]

- Goenaga-Pérez, A.; Álvarez-Sanz, M.; Terés-Zubiaga, J.; Campos-Celador, A. Cost-effectiveness and minimum requirements of nZEB for residential buildings under the new Spanish Technical Building Code. Energ Build. 2023, 287, 112986. [Google Scholar] [CrossRef]

- Hosseini, S.M.A.; Farahzadi, L.; Pons, O. Assessing the sustainability index of different post-disaster temporary housing unit configuration types. J. Build. Eng. 2021, 42, 102806. [Google Scholar] [CrossRef]

- Martinaitis, V.; Zavadskas, E.K.; Motuzienė, V.; Vilutienė, T. Importance of occupancy information when simulating energy demand of energy efficient house: A case study. Energy Build. 2015, 101, 64–75. [Google Scholar] [CrossRef]

- Zhang, A.; Bokel, R.; van den Dobbelsteen, A.; Sun, Y.; Huang, Q.; Zhang, Q. An integrated school and schoolyard design method for summer thermal comfort and energy efficiency in Northern China. Build. Environ. 2017, 124, 369–387. [Google Scholar] [CrossRef]

- Development and Reform Commission. Circular on the Issuance of the National Plan for the Adjustment and Transformation of Old Industrial Bases. Available online: https://www.gov.cn/gongbao/content/2013/content_2441018.htm (accessed on 15 October 2024).

- GB 50176-2016; Code for Thermal Design of Civil Building. China Architecture & Building Press: Beijing, China, 2016.

- Zhu, G. Resource Conservation Study of Changchun Tractor Works Industrial Heritage Under the Concept of Urban Micro-Renewal. Master’s Thesis, Jilin Jianzhu University, Changchun, China, 2022. [Google Scholar]

- Anderson, K. Design Energy Simulation for Architects: Guide to 3D Graphics, 1st ed.; Routledge: London, UK, 2014. [Google Scholar]

- Wilcox, S. Users Manual for TMY3 Data Sets; NREL/TP-581-43156; National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- DB22/T 5160-2024; Design Standard for Energy Efficiency of Public Buildings (Energy Efficiency 72%). Housing and Urban-Rural Development Department of Jilin Province: Changchun, China, 2024.

- DB22/T 5055-2021; Design standard for Green Building. Housing and Urban-Rural Development Department of Jilin Province: Changchun, China, 2021.

- Han, R.; Yang, S. A study on industrial heritage renewal strategy based on hybrid Bayesian network. Sustainability 2023, 15, 10707. [Google Scholar] [CrossRef]

- Felipe, C.A.S.; Rocha, S.C.S. Prediction of minimum fluidization velocity of gas–solid fluidized beds by pressure fluctuation measurements—Analysis of the standard deviation methodology. Powder Technol. 2007, 174, 104–113. [Google Scholar] [CrossRef]

- Welch, S.; Obonyo, E.; Memari, A.M. A review of the previous and current challenges of passive house retrofits. Build. Environ. 2023, 245, 110938. [Google Scholar] [CrossRef]

- Hensley, J.E.; Aguilar, A. Preservation Brief 3: Improving Energy Efficiency in Historic Buildings, National Park Service. 2011. Available online: https://www.nps.gov/orgs/1739/index.htm (accessed on 15 October 2024).

- Kertsmik, K.-A.; Arumägi, E.; Hallik, J.; Kalamees, T. Low carbon emission renovation of historical residential buildings. Energy Rep. 2024, 11, 3836–3847. [Google Scholar] [CrossRef]

- Menconi, M.; Painting, N.; Piroozfar, P. Modelling and simulation of low-risk energy retrofit measures for Traditional Listed Dwellings in the UK. J. Build. Eng. 2024, 82, 108346. [Google Scholar] [CrossRef]

- Oki, R.; Tsuneoka, Y.; Yamaguchi, S.; Sugano, S.; Watanabe, N.; Akimoto, T.; Hayashi, Y.; Wakao, S.; Tanabe, S.-i. Renovating a house to aim for net-zero energy, thermal comfort, energy self-consumption and behavioural adaptation: A method proposed for ENEMANE HOUSE 2017. Energy Build. 2019, 201, 183–193. [Google Scholar] [CrossRef]

- Hao, L.; Chengyuan, Z. Regional Linkage, Strategic Reserve, and the Dual Track of Peacetime and Wartime: Reflections on the Architectural Design of Contemporary Infectious Disease Hospitals Based on Historical Study and the Current Outbreak of Pandemics. Archit. J. 2020, 3, 41–48. [Google Scholar] [CrossRef]

- Chwieduk, D. Towards sustainable-energy buildings. Appl. Energy 2003, 76, 211–217. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, Z.; Yang, T.; Qin, D.; Li, S.; Zhang, G.; Haghighat, F.; Joybari, M.M. A review on macro-encapsulated phase change material for building envelope applications. Build. Environ. 2018, 144, 281–294. [Google Scholar] [CrossRef]

- Brigante, D. New Composite Materials: Selection, Design, and Application; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- Sah, T.P.; Lacey, A.W.; Hao, H.; Chen, W. Prefabricated concrete sandwich and other lightweight wall panels for sustainable building construction: State-of-the-art review. J. Build. Eng. 2024, 89, 109391. [Google Scholar] [CrossRef]

- Tripathi, B.M.; Shukla, S.K. A comprehensive review of the thermal performance in energy efficient building envelope incorporated with phase change materials. J. Energy Storage 2024, 79, 110128. [Google Scholar] [CrossRef]

- Sharafi, P.; Samali, B.; Ronagh, H.; Ghodrat, M. Automated spatial design of multi-story modular buildings using a unified matrix method. Autom. Constr. 2017, 82, 31–42. [Google Scholar] [CrossRef]

- Building Energy Efficiency Research Center, Tsinghua University. China Annual Development Report on Building Energy Efficiency 2022 (Public Building Edition); China Building Industry Press: Beijing, China, 2022. [Google Scholar]

- Zhao, Y.; Sun, Q.; Wei, W.; Xiao, C.; Ren, J.; Wang, Z.; Gao, S.; Dai, Y. Research on the impact of building structure type and scheme on carbon emission. Build. Struct. 2023, 53, 14–18. [Google Scholar]

- JGJ/T 449-2018; Standard for Green Performance Calculation of Civil Buildings. China Architecture & Building Press: Beijing, China, 2018.

- GB 55015-2021; General Code for Energy Efficiency and Renewable Energy Application in Buildings. China Architecture & Building Press: Beijing, China, 2021.

- GB 21455-2019; Minimum Allowable Values of the Energy Efficiency and Energy Efficiency Grades for Room Air Conditioners. State Administration for Market Regulation of the People’s Republic of China: Beijing, China, 2019.

- Arakawa Martins, L.; Soebarto, V.; Williamson, T. A systematic review of personal thermal comfort models. Build. Environ. 2022, 207, 108502. [Google Scholar] [CrossRef]

- Fanger, P. Thermal Comfort: Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970. [Google Scholar]

- Kim, J.; Schiavon, S.; Brager, G. Personal comfort models—A new paradigm in thermal comfort for occupant-centric environmental control. Build. Environ. 2018, 132, 114–124. [Google Scholar] [CrossRef]

- GB/T 50785-2012; Evaluation Standard for Indoor Thermal Environment in Civil Buildings. China Architecture & Building Press: Beijing, China, 2012.

- GB/T 2589-2020; General Rules for Calculation of the Comprehensive Energy Consumption. State Administration for Market Regulation of the People’s Republic of China: Beijing, China, 2020.

- DB22/T 5128-2022; Ultra-Low Energy Consumption Requirements for Public Buildings in Jilin Province. Housing and Urban-Rural Development Department of Jilin Province: Changchun, China, 2022.

| TRNSYS | PHPP | EnergyPlus | eQUEST | DeST | DesignBuilder | |

|---|---|---|---|---|---|---|

| Country | United States | Germany | United States | United States of America | China | United Kingdom |

| Development Company | University of Wisconsin | Passive House Institute | U.S. Department of Energy (DOE) | JB Engineering | Tsinghua University | DesignBuilder Software Ltd. |

| Development | 1975 | 1996 | 1999 | 2000 | 2004 | 2006 |

| Load Simulation Methods | Modular Thermodynamic Modeling | Heat Balance Method | Heat Balance and Fluid Dynamics | Simplified Models | Heat Balance Method | Heat Balance and Fluid Dynamics |

| Model Complexity | high | medium | high | low | medium | medium |

| System Restructuring | highly flexible | limited | flexible | limited | limited | flexible |

| Accurate Temperature Calculations | accurate | accurate | accurate | accurate | accurate | accurate |

| Applicable Structures | all types of complex systems | primarily for passive houses | all types of buildings | residential and small businesses | Chinese buildings | all types of buildings |

| Photovoltaic Module | support | partial support | support | partial support | partial support | support |

| Data Input Method | manual or script | manual | manual or batch input | simple import | manual | graphical input |

| Output of Results | reports and data output | reports | graphs and data tables | graphs and reports | reports | graphs and reports |

| Name of the First-Level Zone | Main Indexes of the Classification | Name of the Second-Level Zone | Main Indexes of the Classification |

|---|---|---|---|

| Severe cold zone | tmin·m ≤ −10 °C | Severe cold zone A (1A) | 6000 ≤ HDD18 |

| Severe cold zone B (1B) | 5000 ≤ HDD18 < 6000 | ||

| Severe cold zone C (1C) | 3800 ≤ HDD18 < 5000 | ||

| Cold zone | −10 °C < tmin·m ≤ 0 °C | Cold zone A (2A) | 2000 ≤ HDD18 < 3800 CDD26 ≤ 90 |

| Cold zone B (2B) | 2000 ≤ HDD18 < 3800 CDD26 > 90 |

| Provinces in Northeast China | Number and Percentage of 1A | Number and Percentage of 1B | Number and Percentage of 1C | Number and Percentage of 2A |

|---|---|---|---|---|

| Heilongjiang Province | 6; 30% | 14; 70% | 0 | 0 |

| Jilin Province | 0 | 3; 30% | 7; 70% | 0 |

| Liaoning Province | 0 | 0 | 5; 50% | 5; 50% |

| Total number | 6 | 17 | 12 | 5 |

| Total Percentage | 15% | 42.5% | 30% | 12.5% |

| Location Templates | Daily Frequency of Site Outdoor Air Dewpoint Temperature and Dry Bulb Temperature in Changchun | |

|---|---|---|

| Location |  | |

| Source | ASHRAE/CSWD | |

| WMO | 541,610 | |

| ASHRAE climate zone | 6A | |

| Latitude | 43.90 | |

| Longitude | 125.22 | |

| Elevation (m) | 238.0 | |

| Standard pressure (kPa) | 98.5 | |

| Time zone | (GMT+8:00) Beijing | |

| Winter design weather | ||

| Outside design temperature | −25 °C | |

| Wind speed | 2.0 | |

| Wind direction | 220.0 | |

| Categories Name | Area | Number | Deviation Average (Di) | Normalized Percentage | |

|---|---|---|---|---|---|

| sports | Surrounding | 197 | 5.04% | −0.0317 | 10.23% |

| Citywide | 3912 | ||||

| malls | Surrounding | 94 | 12.00% | −0.0380 | 24.37% |

| Citywide | 783 | ||||

| parks | Surrounding | 15 | 6.73% | −0.0148 | 13.66% |

| Citywide | 223 | ||||

| tourism | Surrounding | 26 | 4.20% | −0.0401 | 8.53% |

| Citywide | 619 | ||||

| education | Surrounding | 435 | 9.44% | 0.0123 | 19.17% |

| Citywide | 4610 | ||||

| exhibition hall | Surrounding | 9 | 11.84% | 0.0363 | 24.03% |

| Citywide | 76 |

| Reuse Strategy Deconstruction | Technology Pathway | Technology Support |

|---|---|---|

| Increase the functionality of the space | Constructing Variable Composite Structure System | Movable wall panel track system Foldable three-glass, two-cavity inert gas-filled windows Removable dual-cavity ultra-low-energy light steel composite panels |

| Increase the diversity of energy-saving materials | Reducing the energy consumption of renewed buildings | Reduction of heating (cooling) loss through the high performance of new energy-saving materials themselves |

| reducing profile sizes | Modular architecture | Reduced profile sizes of modularized buildings 4.5 m × 3 Nm as the standard module size |

| reducing carbon emissions | New energy-saving materials and standardization | Carbon reduction advantages and reuse of energy-saving materials |

| Program Level | Characterization | Validation Objectives | |

|---|---|---|---|

| Case 1 | L0—Baseline model | Partial area of the original plant | Establishing a Baseline for building energy consumption |

| Case 2 | L1—Energy Complement Model | +The structural system of the “Two Enhancements and Two Reductions” strategy + Solar panel | Effectiveness of spatial reconfiguration and renewable energy |

| Case 3 | L2—Thermal control model with spatial reconfiguration zoning | +The structural system of the “Two Enhancements and Two Reductions” strategy + Solar panel + Zone temperature control | Effectiveness of spatial reconfiguration, renewable energy, and zonal temperature control |

| Case 4 | L3—Comfort Optimization Model | +The structural system of the “Two Enhancements and Two Reductions” strategy + Solar panel + Zone temperature control + Dynamic natural lighting | Dynamic optimization of energy consumption changes and comfort |

| Cooling System | Solar Panels | Zone Temperature Control | Internal Space | ||

|---|---|---|---|---|---|

| Internal Enclosure Dividing | Interior Structure Roof Lighting | ||||

| Case 1 | Applicable | - | - | - | - |

| Case 2 | Applicable | 16 groups | - | - | - |

| Case 3 | Applicable | 30 groups | Applicable | Applicable | - |

| Case 4 | Applicable | 30 groups | Applicable | Applicable | Applicable |

| Roof Material | Envelope (Restoration Only) | Internal Space | ||||

|---|---|---|---|---|---|---|

| Removable Dividing Wall | Interior Side Windows | Interior Roof | Internal Roof Windows | |||

| Case 1 | 250 mm prefabricated concrete panel + 80 mm laminated steel panel | 490 mm red brick repair | - | - | - | - |

| Case 2 | - | - | - | - | ||

| Case 3 | Rockwool composite panel | Triple-glazed, double-cavity inert gas-filled windows | Double-cavity ultra-low energy consumption light steel composite panel | - | ||

| Case 4 | Double-cavity inert gas-filled windows | |||||

| Spaces | Lighting Power Density for Different Functional Spaces (W/m2) | Lighting Power Density with Full-Coverage Design (W/m2) | Equipment Power Density for Different Functional Spaces (W/m2) | Equipment Power Density with Full-Coverage Design (W/m2) | Fresh Air Volume for Different Functional Spaces (m3/h·person) | Fresh Air Volume with Full-Coverage Design (m3/h·Person) |

|---|---|---|---|---|---|---|

| Usage spaces of Case 1–4 | General commercial = 10 Upscale commercial = 16 General classroom = 9 Art classroom = 15 Exhibition = 10 | 16 | General commercial = 13 Upscale commercial = 13 General classroom = 5 Art classroom = 5 Exhibition = 10 | 13 | General commercial = 19 Upscale commercial = 19 General classroom = 24 Art classroom = 20 Exhibition = 20 | 24 |

| Spaces | Personnel Density for Different Functional Spaces (m2/h·Person) | Personnel Density with Full-Coverage Design (m2/h·Person) | Room Summer Set Temperature for Different Functional Spaces (°C) | Room Summer Set Temperature with Full-Coverage Design (°C) | Room Winter Set Temperature for Different Functional Spaces (°C) | Room Winter Set Temperature with Full-Coverage Design (°C) |

| Usage spaces of Case 1–4 | General commercial = 4 Upscale commercial = 4 General classroom = 1.39 Art classroom = 4 Exhibition = 4 | 4 | General commercial = 26 Upscale commercial = 26 General classroom = 26 Art classroom = 26 Exhibition = 20 | 26 | General commercial = 20 Upscale commercial = 20 General classroom = 18 Art classroom = 18 Exhibition = 20 | 20 |

| Name | Lighting Power Density (W/m2) | Equipment Power Density (W/m2) | Personnel Density (m2/Person) | Fresh Air | Lighting Power Density (W/m2) | Equipment Power Density (W/m2) |

|---|---|---|---|---|---|---|

| Case 2 hallway | 7 | 13 | 4 | 19 | 26 | 20 |

| Cases 3–4 hallway | 7 | 13 | 4 | 19 | 26 | 10 |

| Type | Nominal Efficiency |

|---|---|

| Heating system: coal-fired boiler | η = 85% |

| LED lighting | η = 95% |

| Cooling system: inverter air conditioner (GB 21455-2019 standard) [70] | Annual Performance Factor: APF = 4.8 |

| Domestic Hot Water systems (DHW) | CoP = 0.85 |

| Solar Panel | PV Constant Efficiency = 20% |

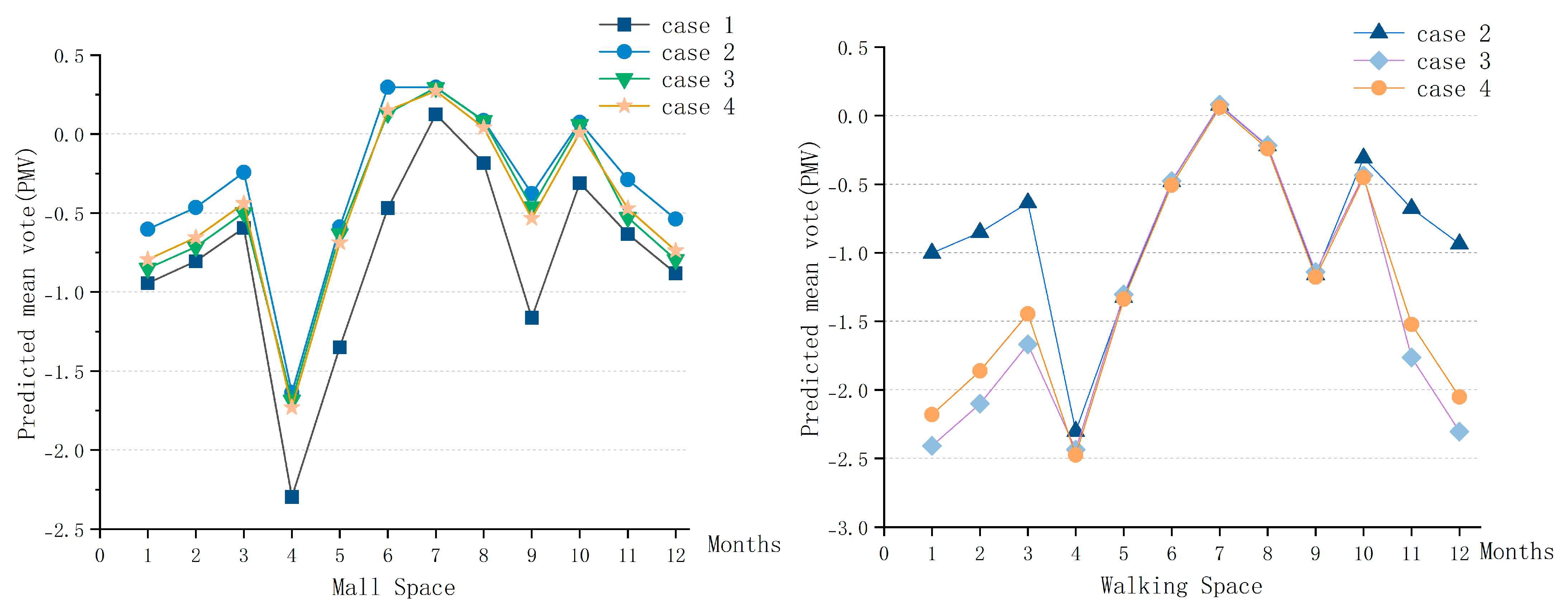

| Date | Relative Humidity (%) | Fanger PMV | Fanger PPD (%) | Air Temperature | Radiant Temperature | Operative Temperature | Outside Dry-Bulb Temperature |

|---|---|---|---|---|---|---|---|

| Jan | 12.11028 | −1.83746 | 53.03131 | 14.68633 | 12.92066 | 13.80349 | −15.3989 |

| Feb | 12.35588 | −1.64383 | 49.12699 | 15.3051 | 14.26906 | 14.78708 | −9.48382 |

| Mar | 20.13476 | −1.33774 | 42.95947 | 16.39322 | 15.94101 | 16.16712 | −3.31946 |

| Apr | 27.02408 | −2.21599 | 68.80729 | 17.31706 | 18.46242 | 17.88974 | 7.259167 |

| May | 35.56598 | −1.04275 | 34.4886 | 21.04499 | 22.70672 | 21.87586 | 15.05538 |

| Jun | 50.80415 | 2.65 × 10−2 | 21.27699 | 24.16246 | 25.99894 | 25.0807 | 20.20503 |

| Jul | 64.01617 | 0.660134 | 20.49438 | 25.74809 | 27.90072 | 26.8244 | 22.94425 |

| Aug | 61.84307 | 0.349352 | 19.19988 | 24.87872 | 26.87755 | 25.87814 | 21.30336 |

| Sept | 45.78144 | −0.798 | 27.5013 | 21.51686 | 23.48149 | 22.49918 | 15.21132 |

| Oct | 36.45867 | −0.67075 | 22.966 | 18.53919 | 19.57963 | 19.05941 | 7.616667 |

| Nov | 21.47486 | −1.39804 | 43.77863 | 16.21113 | 15.43637 | 15.82375 | −5.01031 |

| Dec | 16.05555 | −1.75822 | 51.64983 | 14.96786 | 13.30296 | 14.13541 | −11.6448 |

| Date/Time | Room Electricity (kWh) | Lighting (kWh) | Heating (kWh) |

|---|---|---|---|

| Jan | 134,958.4 | 114,195.5 | 1.00 × 108 |

| Feb | 121,897.9 | 103,144.4 | 6.51 × 107 |

| Mar | 134,958.4 | 114,195.5 | 4.63 × 107 |

| Apr | 130,604.9 | 110,511.8 | 4,406,595 |

| May | 134,958.4 | 114,195.5 | 0 |

| Jun | 130,604.9 | 110,511.8 | 0 |

| Jul | 134,958.4 | 114,195.5 | 0 |

| Aug | 134,958.4 | 114,195.5 | 0 |

| Sept | 130,604.9 | 110,511.8 | 0 |

| Oct | 134,958.4 | 114,195.5 | 7,094,450 |

| Nov | 130,604.9 | 110,511.8 | 5.27 × 107 |

| Dec | 134,958.4 | 114,195.5 | 8.21 × 107 |

| Annual all | 1,589,026 | 1,344,561 | 3.58 × 108 |

| Energy consumption per unit area (kWh/m2) | 86.83 | 73.47 | 19,562.84 |

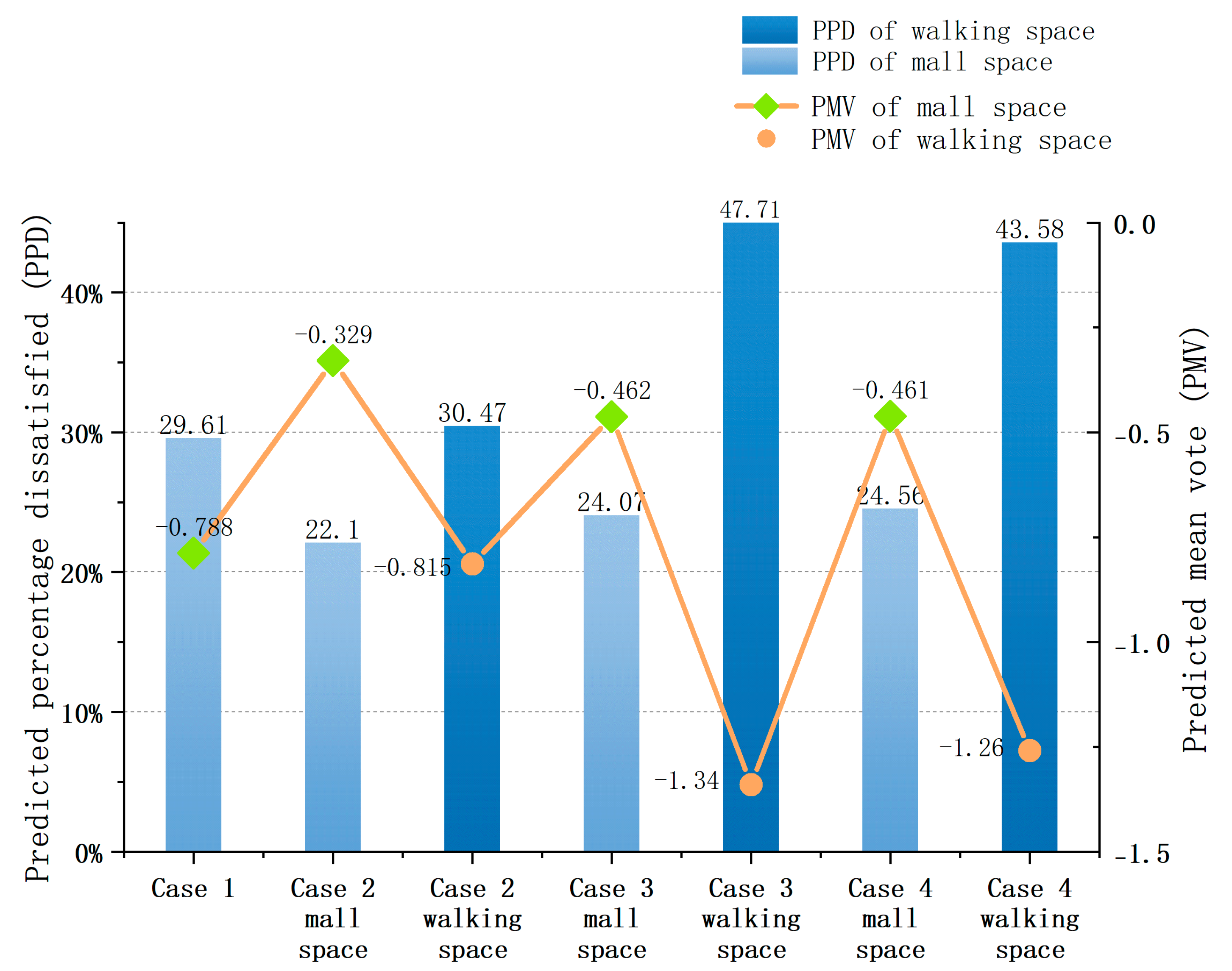

| Level | Evaluation Indicator 1 | Evaluation Indicator 2 | Explanation |

|---|---|---|---|

| Level I | −0.5 ≤ PMV ≤ +0.5 | PPD ≤ 10% | Thermal environment in which 90% of the population is satisfied |

| Level II | −1 ≤ PMV < −0.5 or +0.5 < PMV ≤ +1 | 10% < PPD ≤ 25% | Thermal environment in which 75% of the population is satisfied |

| Level III | PMV < −1 or PMV < +1 | PPD > 25% | Thermal environment in which less than 75% of the population is satisfied |

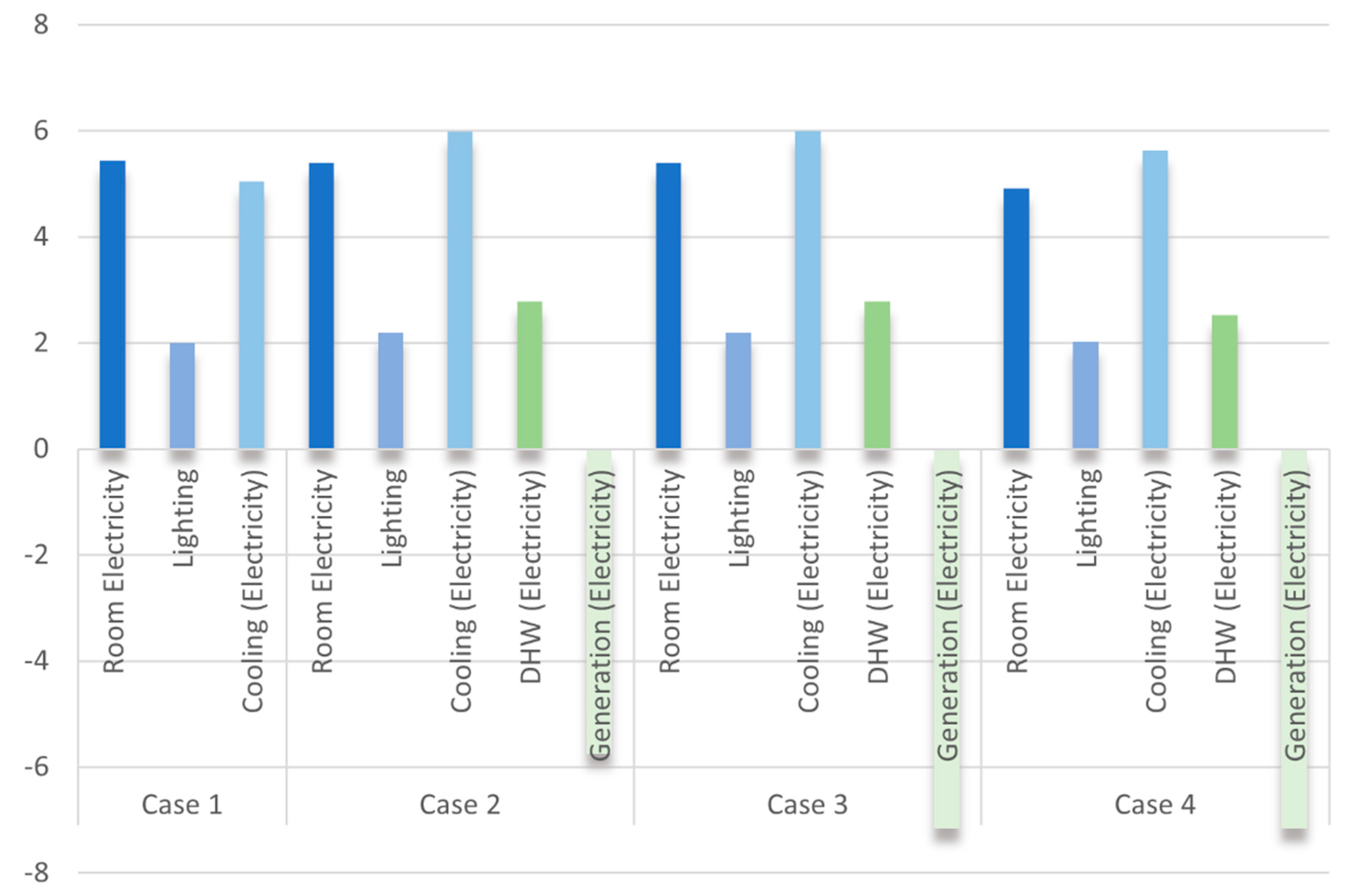

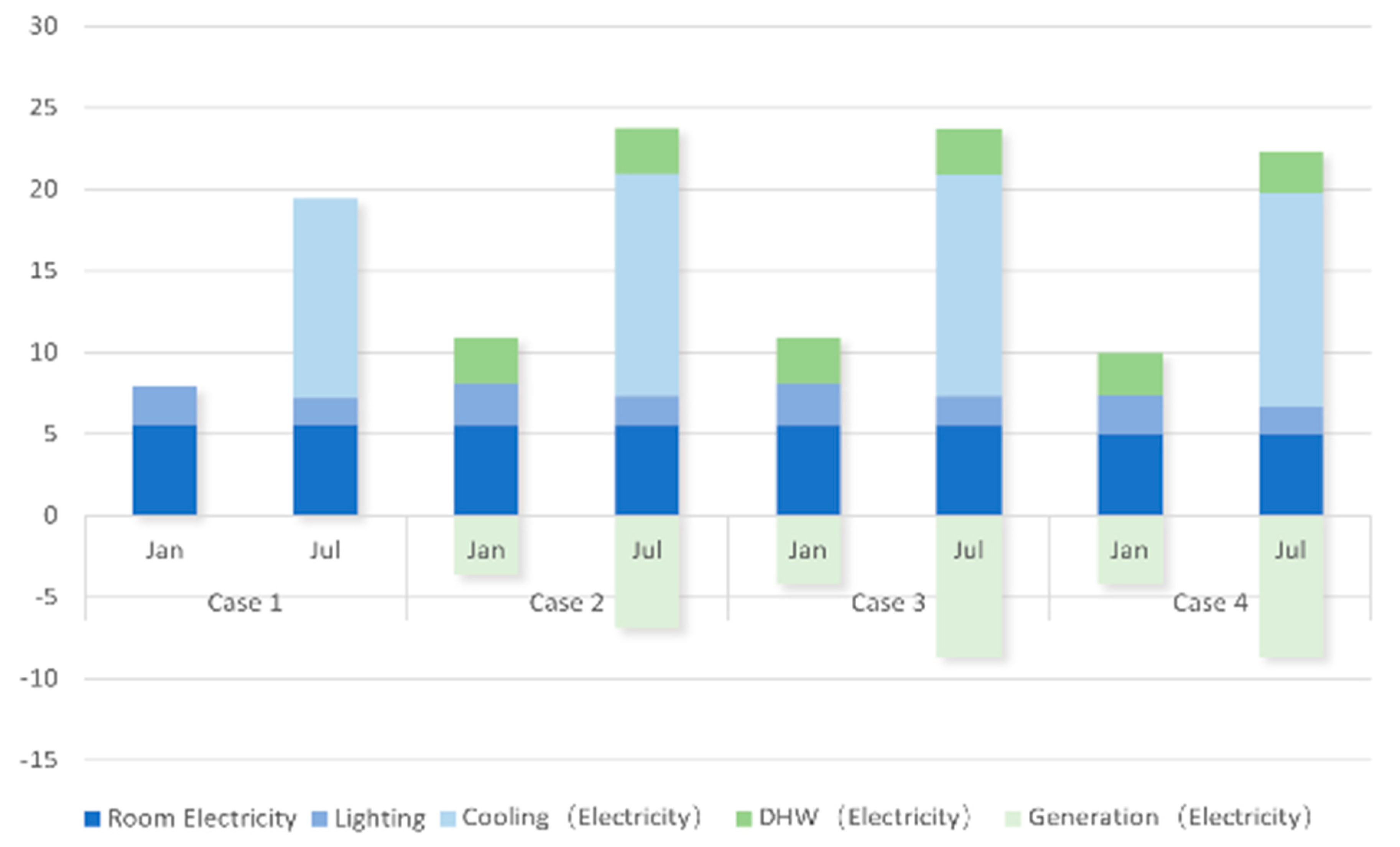

| Category | Indicator | Original Model | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|---|---|

| Room | Energy consumption (kWh) | 1,589,026 | 155,024 | 153,890 | 153,890 | 139,916 |

| Energy consumption per unit area (kWh/m2) | 86.832 | 65.49 | 65.01 | 65.01 | 59.11 | |

| Percentage | 0.44% | 0.5445% | 0.5408% | 19.0981% | 15.5237% | |

| PEC | 1,966,692.91 | 191,868.86 | 190,465.34 | 190,465.34 | 173,170.11 | |

| Lighting | Energy consumption (kWh) | 1,344,561 | 56,926 | 62,509 | 62,532 | 57,713 |

| Energy consumption per unit area (kWh/m2) | 73.47 | 24.05 | 26.41 | 26.42 | 24.38 | |

| Percentage | 0.37% | 0.1999% | 0.2196% | 7.7604% | 6.4032% | |

| PEC | 1,664,125.44 | 70,455.71 | 77,365.64 | 77,394.10 | 71,429.76 | |

| Heating | Energy consumption (kWh) | 358,000,000 | 28,186,467 | 28,077,519 | 424,385 | 551,408 |

| Energy consumption per unit area (kWh/m2) | 19,562.84 | 11,908.10 | 11,862.07 | 179.29 | 232.96 | |

| Percentage | 99.19% | 99.0029% | 98.6612% | 52.6673% | 61.1787% | |

| PEC | 51,736,260.18 | 4,073,358.63 | 4,057,614.05 | 61,329.87 | 79,686.56 | |

| Cooling | Energy consumption (kWh) | 71,934 | 85,452 | 85,824 | 80,303 | |

| Energy consumption per unit area (kWh/m2) | 30.39 | 36.10 | 36.26 | 33.93 | ||

| Percentage | 0.2527% | 0.3003% | 10.6510% | 8.9096% | ||

| PEC | 17,620.66 | 20,931.97 | 21,023.10 | 19,670.69 | ||

| DHW | Energy consumption (kWh) | - | - | 79,154 | 79,154 | 71,967 |

| Energy consumption per unit area (kWh/m2) | 33.44 | 33.44 | 30.40 | |||

| Percentage | 0.2781% | 9.8232% | 7.9847% | |||

| PEC | 116,335.44 | 116,335.4 | 105,772.5 | |||

| All | Energy consumption (kWh) | 360,933,587 | 28,470,350 | 28,458,524 | 805,784 | 901,307 |

| Energy consumption per unit area (kWh/m2) | 19,723.15 | 12,028 | 12,023 | 340.42 | 380.78 | |

| PEC | 55,367,078.53 | 4,353,303.86 | 4,346,376.99 | 350,212.40 | 343,957.12 | |

| Generation (Electricity) | - | - | −163,978 | −203,946 | −203,946 | |

| Energy Efficiency Requirements for Public Buildings with Low Energy Consumption | Limit Values | This Project |

|---|---|---|

| Building envelope’s airtightness (N50, h−1) | ≤1.0 | New structures under the “Two Enhancements and Two Reductions” reuse strategy (Case 3,4) Original factory > 1.0 |

| Comprehensive energy-saving rate η | ≥50% | 92% (Case 3,4) |

| Energy-saving of the building itself | ≥25% | 10% |

| Renewable energy utilization rate | ≥10% | 14.82% (Case 3,4) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Ma, H.; Li, N.; Xu, S.; Guo, F. Energy-Saving Design Strategies for Industrial Heritage in Northeast China Under the Concept of Ultra-Low Energy Consumption. Energies 2025, 18, 1289. https://doi.org/10.3390/en18051289

Yang S, Ma H, Li N, Xu S, Guo F. Energy-Saving Design Strategies for Industrial Heritage in Northeast China Under the Concept of Ultra-Low Energy Consumption. Energies. 2025; 18(5):1289. https://doi.org/10.3390/en18051289

Chicago/Turabian StyleYang, Shiqi, Hui Ma, Na Li, Sheng Xu, and Fei Guo. 2025. "Energy-Saving Design Strategies for Industrial Heritage in Northeast China Under the Concept of Ultra-Low Energy Consumption" Energies 18, no. 5: 1289. https://doi.org/10.3390/en18051289

APA StyleYang, S., Ma, H., Li, N., Xu, S., & Guo, F. (2025). Energy-Saving Design Strategies for Industrial Heritage in Northeast China Under the Concept of Ultra-Low Energy Consumption. Energies, 18(5), 1289. https://doi.org/10.3390/en18051289