Review Analysis for the Energy Performance of Integrated Air-Conditioning Systems

Abstract

:1. Introduction

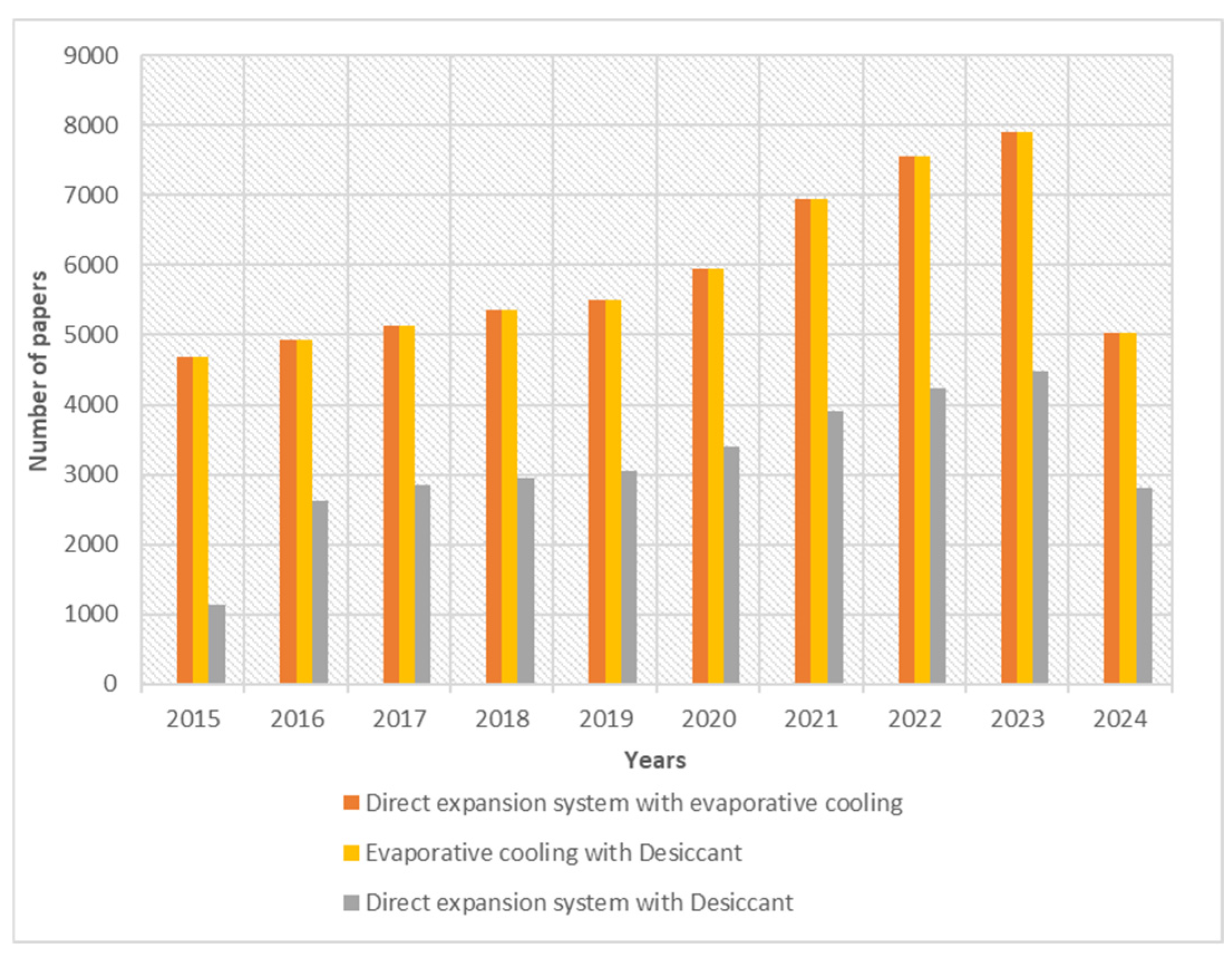

2. Literature Review Approach

- “Direct expansion system” and “DX system” are considered to cover studies on conventional refrigerant-based cooling systems.

- “Evaporative cooling” is combined with “DX system” and “direct expansion system” to identify research addressing hybrid cooling approaches aimed at enhancing energy efficiency of HVAC systems.

- “Desiccant” is paired with both DX and evaporative cooling technologies to identify studies that have evaluated dehumidification technologies used in conjunction with conventional and evaporative cooling strategies.

- Experimental or simulation-based evaluation of integrated cooling systems.

- Performance assessment metrics for evaluating energy efficiency, thermal comfort, and humidity control of the hybrid systems.

- Applications of hybrid systems in hot and humid climatic conditions.

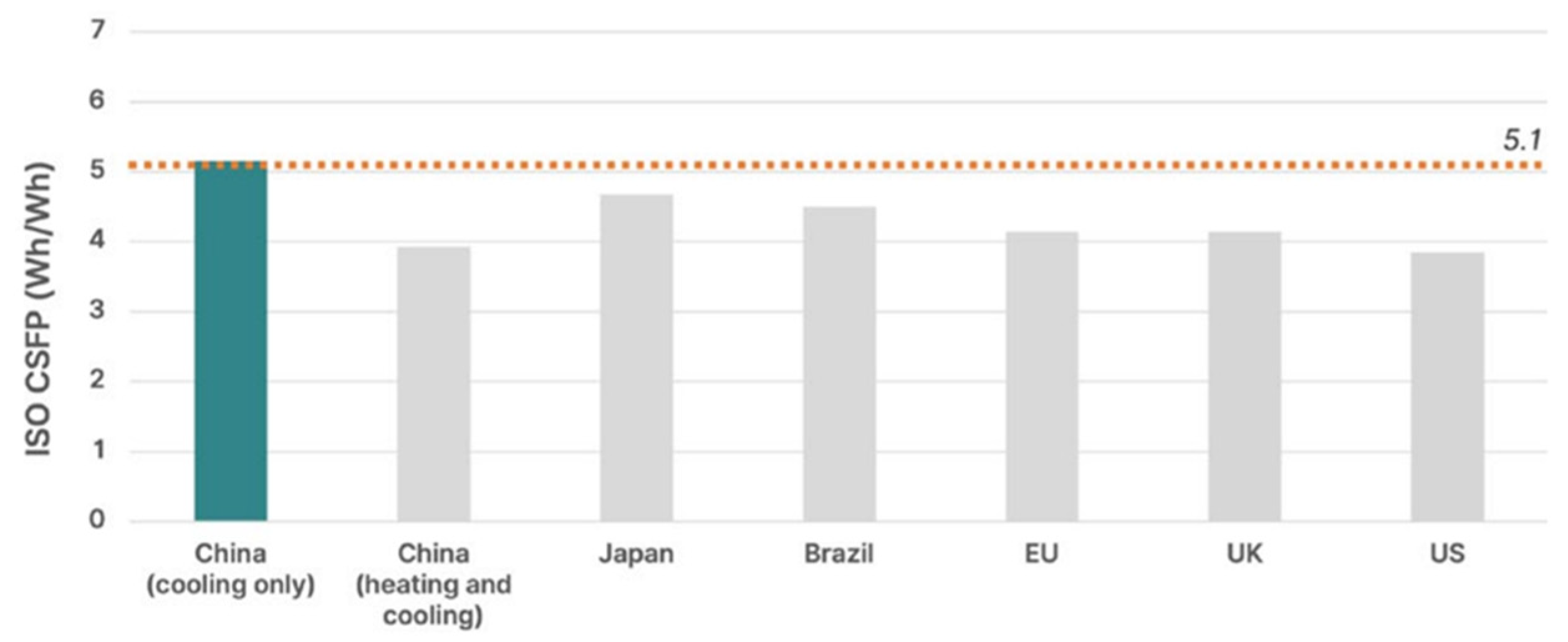

3. Energy Efficiency Standards

4. Overview of Integrated Air-Conditioning Systems

4.1. Integration of Two Cooling Systems

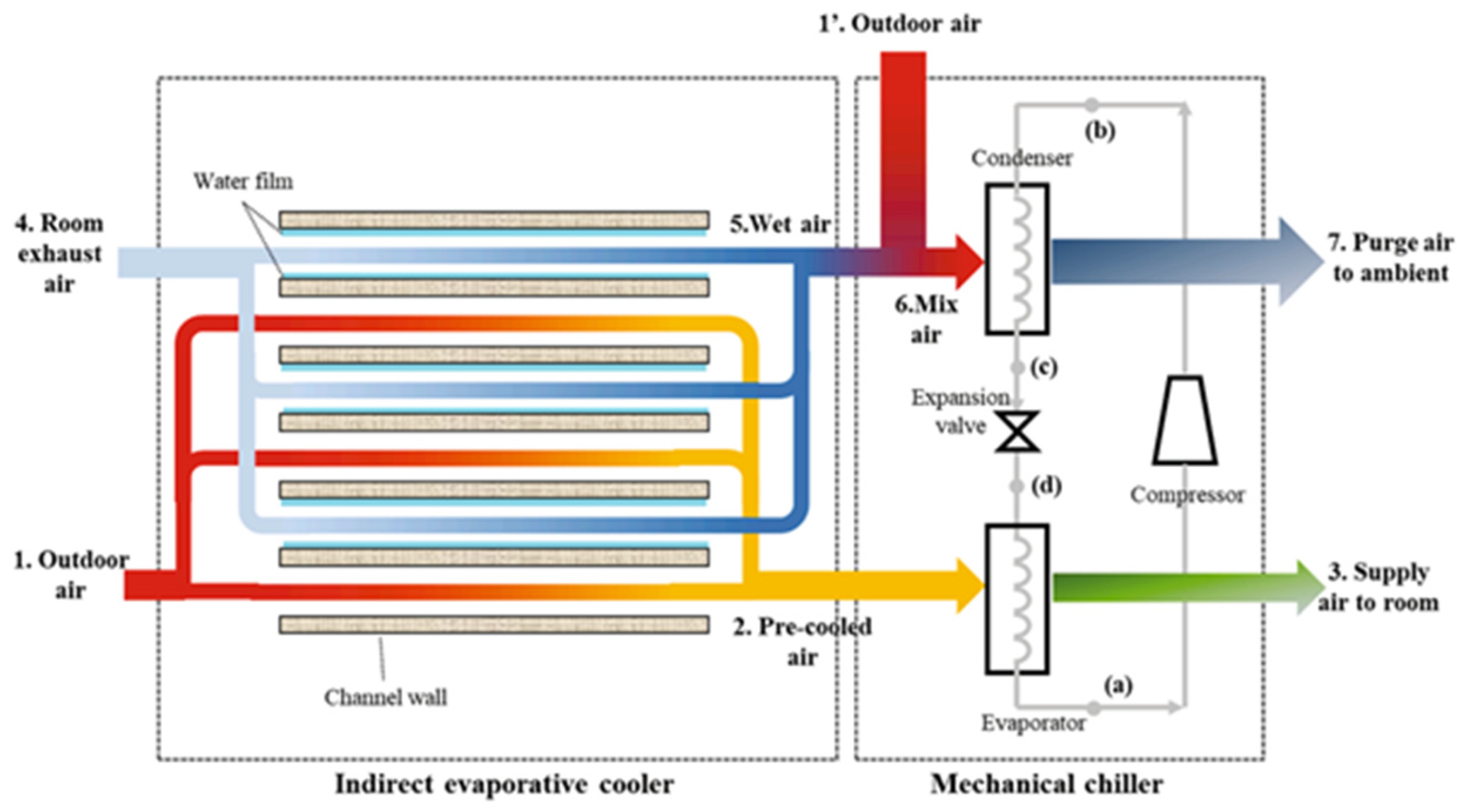

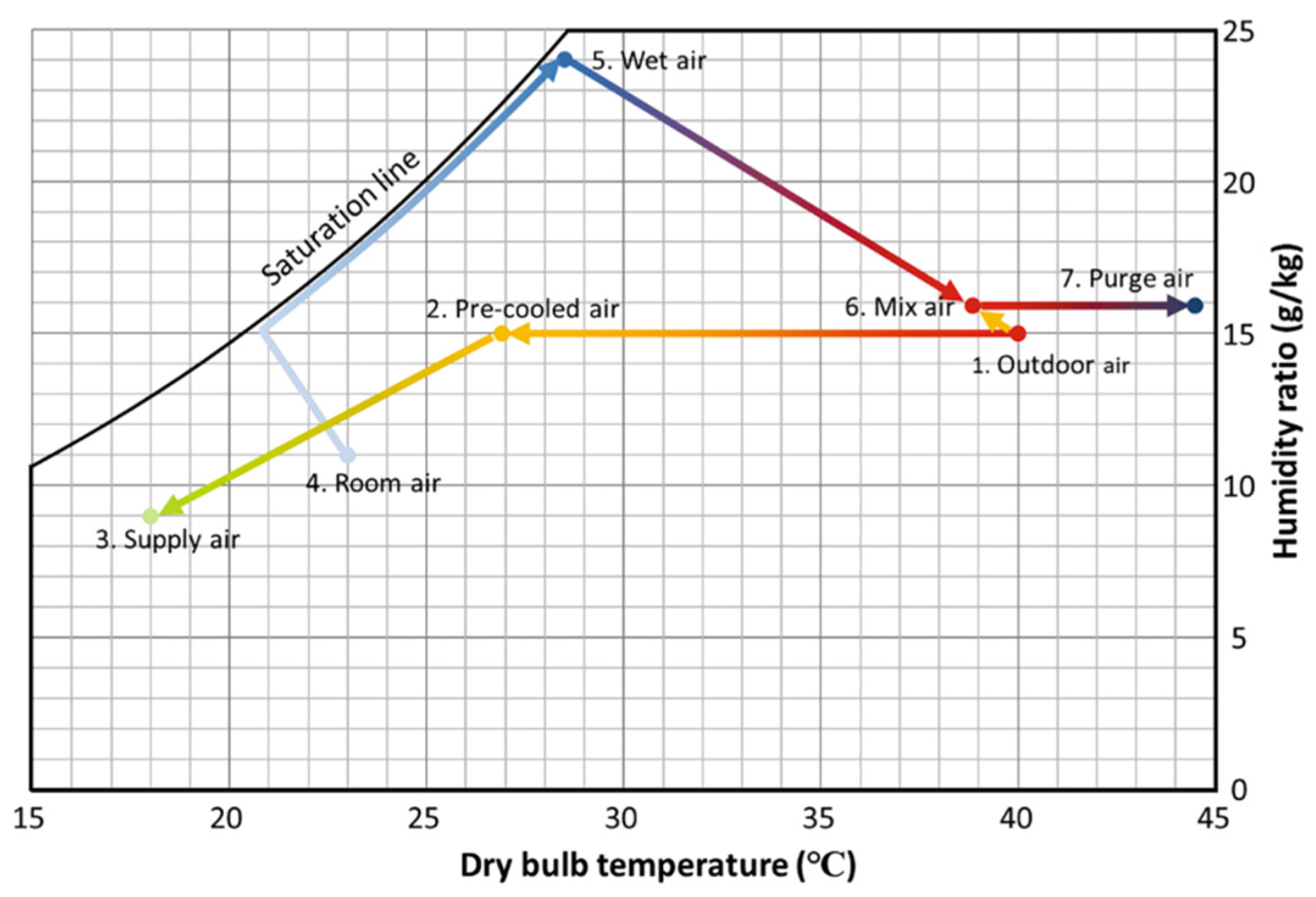

4.1.1. Direct Expansion System with Evaporative Cooling

4.1.2. Direct Expansion System with Desiccant

4.1.3. Evaporative Cooling System with Desiccant

4.2. Integrated HVAC Systems with Photovoltaic and Thermal Energy Storage

5. Discussion

6. Summary and Concussions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| 3E | Energy, economic, and environmental |

| ACE | Annual carbon dioxide emissions |

| ACOP | The average yearly coefficient of performance |

| AHRI | Air Conditioning, Heating, & Refrigeration Institute |

| ASHP | Air source heat pump |

| ASHRAE | American Society of Heating, Refrigerating, and Air-Conditioning Engineers |

| AWC | Annual water consumption |

| COP | Coefficient of performance |

| DAC | Desiccant air-conditioning system |

| DEC | Desiccant evaporative cooling |

| DEVap | Desiccant-Enhanced Indirect Evaporative Cooling |

| DOE | U.S. Department of Energy |

| DOF | Dry operation fraction |

| DW | Desiccant wheel |

| DW–IEC | Desiccant wheels and indirect evaporative coolers |

| DX | Direct expansion cooling |

| ECB | Electric chiller and boiler |

| EER | Energy Efficiency Ratio |

| EOO | Equation-based object-oriented |

| FAHU | Fresh-air-handling unit |

| GA | Genetic Algorithm |

| GHG | Greenhouse gas |

| HSPF | Heating Seasonal Performance Factor |

| HVAC | Heating, ventilation, and air conditioning |

| IDCS | Integrated Desiccant Cooling System |

| IEC | Indirect evaporative cooling |

| IECL | Indirect evaporative cooling combined with liquid dehumidification |

| LCC | Life-cycle cost |

| CSPF | cooling seasonal performance factor |

| LD | Liquid Dehumidification |

| LDAHU | Direct expansion air handling unit assisted by liquid desiccant |

| LDCH | Liquid Desiccant–Vapor Compression Hybrid |

| LDCS | Liquid desiccant cooling system |

| LDD–RIEC | Liquid desiccant dehumidifier and regenerative indirect evaporative cooling |

| LD-HP | Liquid desiccant–heat pump |

| LD-IDECOASs | Liquid desiccant and evaporative cooling-assisted 100% outdoor air systems |

| LHTES | Latent-heat thermal energy storage |

| M-cycle | Maisotsenko cycle |

| MEE | Membrane enthalpy exchanger |

| MEPS | Minimum Energy Performance Standard |

| MRR | Moisture removal rate |

| MVC | Mechanical vapor compression |

| PCMs | Phase change materials |

| PEC | Personalized evaporative cooler |

| PEC | Photovoltaic evaporative cooler |

| PV | Photovoltaic |

| PVT-SAH | Photovoltaic Thermal Collector-Solar Air Heater |

| REC | Regenerative evaporative cooling |

| RIEC | Regenerative indirect evaporative cooling |

| RSM | Response surface methodology |

| SASO | Saudi Standards, Metrology, and Quality Organization |

| SEER | Seasonal Energy Efficiency Ratio |

| SF | Solar Fraction |

| SHR | Sensible heat ratio |

| SLDAC | Solar-assisted liquid desiccant air conditioning |

| SSHE | Solution-saturated heat exchanger |

| TEC | Thermoelectric cooler |

| TES | Thermal energy storage |

| TOPSIS | Order Preference by Similarity to the Ideal Solution |

| VCAC | Vapor compression air conditioning |

| VRF | Variable refrigerant flow |

| meetMED | the Mitigation Enabling Energy Transition in the Mediterranean area |

| CLASP | Collaborative Labeling and Appliance Standards Program |

| T | Temperature |

| RH | Relative humidity |

References

- Heidarinejad, G.; Pasdarshahri, H. Potential of a Desiccant-Evaporative Cooling System Performance in a Multi-Climate Country. Int. J. Refrig. 2011, 34, 1251–1261. [Google Scholar]

- Alayed, E.; Bensaid, D.; O’Hegarty, R.; Kinnane, O. Thermal Mass Impact on Energy Consumption for Buildings in Hot Climates: A Novel Finite Element Modelling Study Comparing Building Constructions for Arid Climates in Saudi Arabia. Energy Build. 2022, 271, 112324. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Open Energy Data; U.S. Department of Energy: Washington, DC, USA, 2011.

- Chen, Y.; Yang, H.; Luo, Y. Investigation on Solar Assisted Liquid Desiccant Dehumidifier and Evaporative Cooling System for Fresh Air Treatment. Energy 2018, 143, 114–127. [Google Scholar] [CrossRef]

- Kharseh, M.; Altorkmany, L.; Al-Khawaj, M.; Hassani, F. Warming Impact on Energy Use of HVAC System in Buildings of Different Thermal Qualities and in Different Climates. Energy Convers. Manag. 2014, 81, 106–111. [Google Scholar] [CrossRef]

- Romero-Lara, M.J.; Comino, F.; Ruiz de Adana, M. Experimental Assessment of the Energy Performance of a Renewable Air-Cooling Unit Based on a Dew-Point Indirect Evaporative Cooler and a Desiccant Wheel. Energy Convers. Manag. 2024, 310, 118486. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.; Yang, H.; Zhang, H.; Leung, C.W. Experimental Performance Investigation on a Desiccant-Assisted Two-Stage Evaporative Cooling System in Hot and Humid Areas. Appl. Energy 2025, 377, 124704. [Google Scholar] [CrossRef]

- Izadi, M.; Afsharpanah, F.; Mohadjer, A.; Shobi, M.O.; Mousavi Ajarostaghi, S.S.; Minelli, F. Performance Enhancement of a Shell-and-Coil Ice Storage Enclosure for Air Conditioning Using Spiral Longitudinal Fins: A Numerical Approach. Heliyon 2025, 11, e42786. [Google Scholar] [CrossRef]

- Abd Manaf, I.; Durrani, F.; Eftekhari, M. A Review of Desiccant Evaporative Cooling Systems in Hot and Humid Climates. Adv. Build. Energy Res. 2021, 15, 1–42. [Google Scholar]

- Elsevier. Available online: https://www.elsevier.com/ (accessed on 14 March 2025).

- Springer Nature. Available online: https://www.springer.com/ (accessed on 14 March 2025).

- MDPI. Multidisciplinary Digital Publishing Institute. Available online: https://www.mdpi.com/ (accessed on 14 March 2025).

- Google Scholar. Available online: https://scholar.google.com/ (accessed on 14 March 2025).

- ASHRAE/ANSI Standard 90.1; Energy Standard for Buildings Except Low-Rise Residential Buildings. ASHRAE: Peachtree Corners, GA, USA, 2022.

- ASHRAE/ANSI Standard 90.2; Energy-Efficient Design of Low-Rise Residential Buildings. ASHRAE: Peachtree Corners, GA, USA, 2018.

- SASO 2663:2021; Saudi Standards, Metrology and Quality Organization (SASO). Air Conditioners-Minimum Energy Performance, Labelling and Testing Requirements for Low Capacity Window and Single-Split Types. SASO: Riyadh, Saudi Arabia, 2021.

- AHRI 210/240-2017; Performance Rating of Unitary Air-conditioning & Air-source Heat Pump Equipment. Air-Conditioning, Heating, and Refrigeration Institute (AHRI): Arlington, VA, USA, 2017.

- Multiple Benefits of Energy Efficiency. Available online: https://www.iea.org/reports/multiple-benefits-of-energy-efficiency/economic-benefits-2 (accessed on 12 December 2024).

- Minimum Energy Performance Standards. Available online: https://www.nea.gov.sg/our-services/climate-change-energy-efficiency/energy-efficiency/household-sector/minimum-energy-performance-standards (accessed on 12 December 2024).

- Augustus de Melo, C.; Cunha, K.B.; Santiago Suárez, G.P. MEPS for Air Conditioners in Brazil: Regulatory Developments and Future Perspectives. Renew. Sustain. Energy Rev. 2022, 163, 112504. [Google Scholar] [CrossRef]

- Mitigation Enabling Energy Transition in the Mediterranean Region (MeetMED). Available online: https://south.euneighbours.eu/project/meetmed-mitigation-enabling-energy-transition-mediterranean-region/ (accessed on 12 December 2024).

- Mitigation Enabling Energy Transition in the MEDiterranean Region; Together We Switch to Clean Energy; Energy Efficiency for Appliances with A Focus on Air-Conditioning. 2020. Available online: https://meetmed.org/wp-content/uploads/2022/02/MeetMED_EE-in-Appliances.pdf (accessed on 10 December 2024).

- El Hafdaoui, H.; Khallaayoun, A.; Ouazzani, K. Activity and Efficiency of the Building Sector in Morocco: A Review of Status and Measures in Ifrane. AIMS Energy 2023, 11, 454–485. [Google Scholar]

- U4E Uses an Integrated Policy Approach to Accelerate Adoption of Energy-Efficient Lighting, Appliances and Equipment. Available online: https://united4efficiency.org/our-approach/ (accessed on 12 December 2024).

- Mavandad, S.; Malinowski, M. World’s Best MEPS: Assessing Top Energy Efficiency Standards for Priority Appliances; CLASP: Washington, DC, USA, 2022. [Google Scholar]

- Air Conditioners and Comfort Fans. Available online: https://energy-efficient-products.ec.europa.eu/product-list/air-conditioners-and-comfort-fans_en (accessed on 12 December 2024).

- Meng, L. MEPS and Energy Labeling for Room AC in China. 2020. Available online: https://iea.blob.core.windows.net/assets/e3e9ca64-df28-457d-9325-3ec6ab36030c/2.LiuMeng%2CAssociateresearchscholar%2CCNIS.ProgressonMEPSandenergylabellingforroomACinChina..pdf (accessed on 11 December 2024).

- Energy Efficiency Label for Air Conditioners Changed. 2022. Available online: https://www.meti.go.jp/english/press/2022/0901_002.html (accessed on 12 December 2024).

- Wiel, S. Energy Efficiency Standards and Labels in North America: Opportunities for Harmonization Introduction: Creation of NAEWG. Available online: https://www.aceee.org/files/proceedings/2002/data/papers/SS02_Panel9_Paper31.pdf (accessed on 10 December 2024).

- Kubiak, R.; Grönroos-Saikkala, I. Energy Labelling—State of Play and Conceptions for Future. Available online: https://www.rehva.eu/rehva-journal/chapter/energy-labelling-state-of-play-and-conceptions-for-future (accessed on 13 December 2024).

- Australian Government Department of the Environment. The New Zoned Energy Rating Label for Air Conditioners; What Installers and Retailers Need to Know; Australian Government Department of the Environment: Canberra, Australia, 2019.

- Guide on Minimum Energy Performance Standard Requirements for Air Conditioner with Cooling Capacity ≤7.1kW. 2018. Available online: https://www.st.gov.my/contents/2021/MEPS/20210108%20-Guide%20on%20MEPS%20for%20AC%20(UPDATED).pdf (accessed on 21 March 2025).

- Khalajzadeh, V.; Farmahini-Farahani, M.; Heidarinejad, G. A Novel Integrated System of Ground Heat Exchanger and Indirect Evaporative Cooler. Energy Build. 2012, 49, 604–610. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Abdelgaied, M.; Sathyamurthy, R.; Arunkumar, T. Performance Improvement of a Hybrid Air Conditioning System Using the Indirect Evaporative Cooler with Internal Baffles as a Pre-Cooling Unit. Alex. Eng. J. 2017, 56, 395–403. [Google Scholar] [CrossRef]

- Jain, V.; Mullick, S.C.; Kandpal, T.C. A Financial Feasibility Evaluation of Using Evaporative Cooling with Air-Conditioning (in Hybrid Mode) in Commercial Buildings in India. Energy Sustain. Dev. 2013, 17, 47–53. [Google Scholar] [CrossRef]

- Chauhan, S.S.; Rajput, S.P.S. Thermodynamic Analysis of the Evaporative-Vapour Compression Based Combined Air Conditioning System for Hot and Dry Climatic Conditions. J. Build. Eng. 2015, 4, 200–208. [Google Scholar] [CrossRef]

- Chen, Q.; Kum Ja, M.; Burhan, M.; Akhtar, F.H.; Shahzad, M.W.; Ybyraiymkul, D.; Ng, K.C. A Hybrid Indirect Evaporative Cooling-Mechanical Vapor Compression Process for Energy-Efficient Air Conditioning. Energy Convers. Manag. 2021, 248, 114798. [Google Scholar] [CrossRef]

- Zhang, L.; Zha, X.; Song, X.; Zhang, X. Optimization Analysis of a Hybrid Fresh Air Handling System Based on Evaporative Cooling and Condensation Dehumidification. Energy Convers. Manag. 2019, 180, 83–93. [Google Scholar] [CrossRef]

- Yan, H.; Chen, Y.; Min, Y. Performance Analysis of Small-Scale Direct Expansion Air Conditioning System with Indirect Evaporative Cooler as Dedicated Ventilator. Build. Environ. 2022, 208, 108603. [Google Scholar] [CrossRef]

- Venkateswara Rao, V.; Datta, S.P. A Feasibility Assessment of Single to Multi/Hybrid Evaporative Coolers for Building Air-Conditioning across Diverse Climates in India. Appl. Therm. Eng. 2020, 168, 114813. [Google Scholar] [CrossRef]

- Al-Horr, Y.; Tashtoush, B.; Chilengwe, N.; Musthafa, M. Performance Assessment of a Hybrid Vapor Compression and Evaporative Cooling Fresh-Air-Handling Unit Operating in Hot Climates. Processes 2019, 7, 872. [Google Scholar] [CrossRef]

- Duan, Z.; Zhao, X.; Liu, J.; Zhang, Q. Dynamic Simulation of a Hybrid Dew Point Evaporative Cooler and Vapour Compression Refrigerated System for a Building Using EnergyPlus. J. Build. Eng. 2019, 21, 287–301. [Google Scholar] [CrossRef]

- Rajski, K.; Sohani, A.; Jafari, S.; Danielewicz, J.; Sayegh, M.A. Energy Performance of a Novel Hybrid Air Conditioning System Built on Gravity-Assisted Heat Pipe-Based Indirect Evaporative Cooler. Energies 2022, 15, 2613. [Google Scholar] [CrossRef]

- Yogaraja, J.; Mohanraj, M.; Manikandan, J.; Muthusamy, P. Performance of Direct Expansion Photovoltaic-Thermal Evaporator Assisted Compression Heat Pump Water Heaters Using a Zeotropic Mixture. Sol. Energy 2024, 271, 112435. [Google Scholar] [CrossRef]

- Socci, L.; Rey-Hernandez, J.M.; Rocchetti, A.; Dominguez-Muñoz, F.; Rey-Hernandez, A.; Rey-Martínez, F.J. Use of Semi-Indirect Evaporative Cooling in HVAC Systems: Experimental Study. J. Build. Eng. 2024, 95, 110158. [Google Scholar] [CrossRef]

- Krarti, M.; Ybyraiymkul, D.; Kum Ja, M.; Burhan, M.; Chen, Q.; Shahzad, M.W.; Ng, K.C. Energy Performance of Hybrid Evaporative-Vapor Compression Air Conditioning Systems for Saudi Residential Building Stocks. J. Build. Eng. 2023, 69, 106344. [Google Scholar] [CrossRef]

- Krarti, M.; Aldubyan, M.; Williams, E. Residential Building Stock Model for Evaluating Energy Retrofit Programs in Saudi Arabia. Energy 2020, 195, 116980. [Google Scholar] [CrossRef]

- Cui, X.; Sun, L.; Zhang, S.; Jin, L. On the Study of a Hybrid Indirect Evaporative Pre-Cooling System for Various Climates. Energies 2019, 12, 4419. [Google Scholar] [CrossRef]

- Zanchini, E.; Naldi, C. Energy Saving Obtainable by Applying a Commercially Available M-Cycle Evaporative Cooling System to the Air Conditioning of an Office Building in North Italy. Energy 2019, 179, 975–988. [Google Scholar] [CrossRef]

- Dadi, M.J.; Jani, D.B. TRNSYS Simulation of an Evacuated Tube Solar Collector and Parabolic Trough Solar Collector for Hot Climate of Ahmedabad. SSRN 2020. [Google Scholar] [CrossRef]

- Jani, D.B.; Mishra, M.; Sahoo, P.K. Investigations on Effect of Operational Conditions on Performance of Solid Desiccant Based Hybrid Cooling System in Hot and Humid Climate. Therm. Sci. Eng. Prog. 2018, 7, 76–86. [Google Scholar] [CrossRef]

- Gorai, V.K.; Singh, S.K.; Jani, D.B. A Comprehensive Review on Solid Desiccant-Assisted Novel Dehumidification and Its Advanced Regeneration Methods. J. Therm. Anal. Calorim. 2024, 149, 8979–9000. [Google Scholar] [CrossRef]

- Liang, C.; Li, X.; Shi, W.; Wang, B. A Direct Expansion Air Handling Unit Assisted by Liquid Desiccant for Different Sensible and Latent Heat Ratios. Energy Build. 2021, 238, 110672. [Google Scholar] [CrossRef]

- Jani, D.B.; Mishra, M.; Sahoo, P.K. Performance Analysis of a Solid Desiccant Assisted Hybrid Space Cooling System Using TRNSYS. J. Build. Eng. 2018, 19, 26–35. [Google Scholar] [CrossRef]

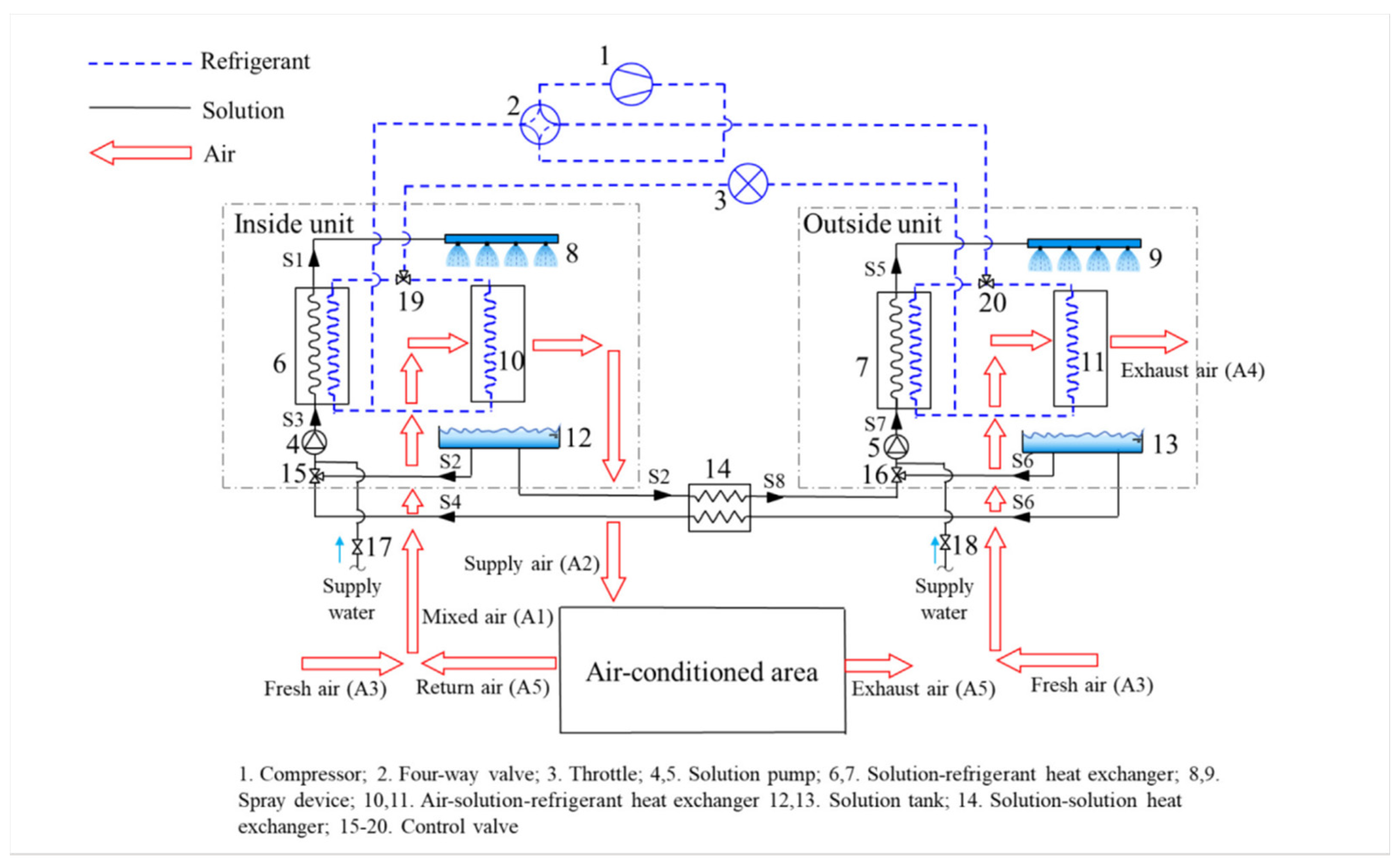

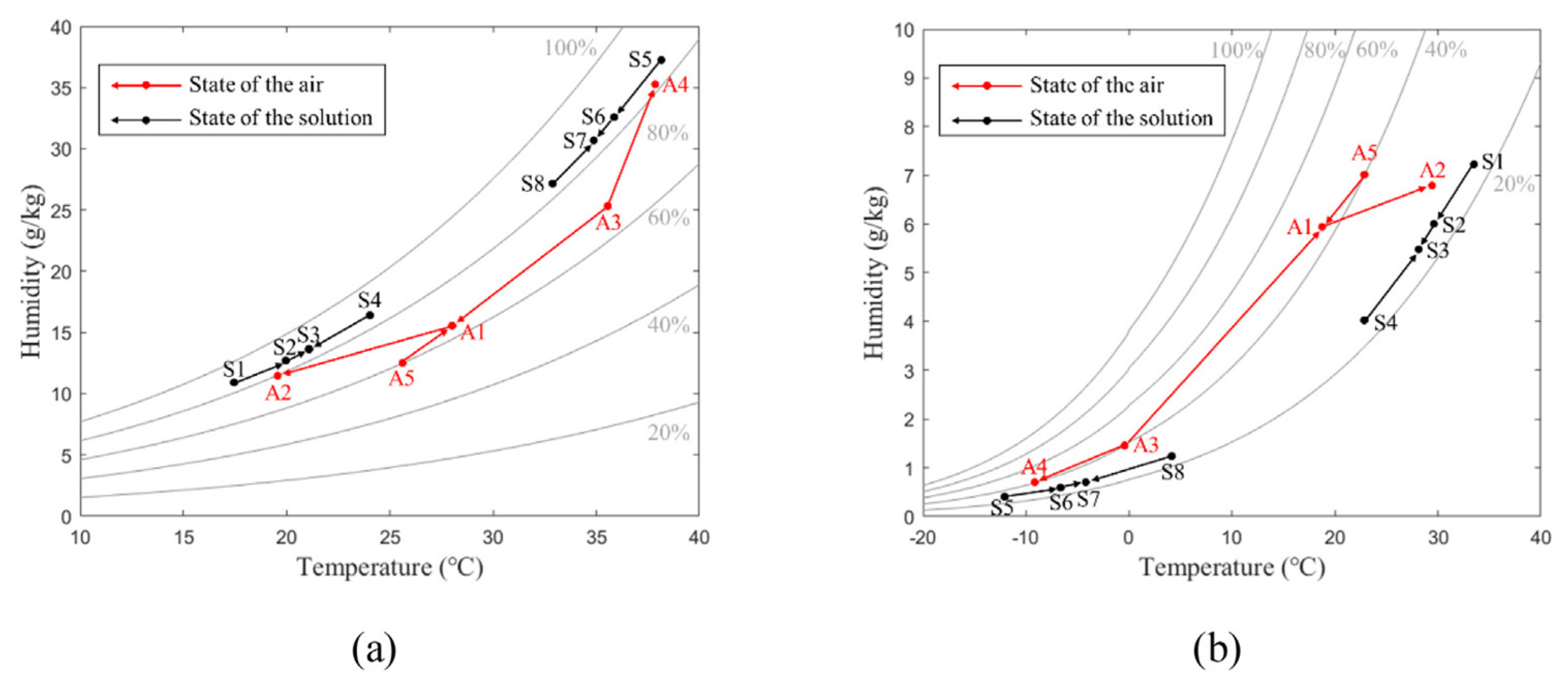

- Yinglin, L.; Xiaosong, Z.; Laizai, T.; Zhongbin, Z.; Wei, W.; Xueying, X. Performance Analysis of a Novel Liquid Desiccant-Vapor Compression Hybrid Air-Conditioning System. Energy 2016, 109, 180–189. [Google Scholar] [CrossRef]

- Yamaguchi, S.; Jeong, J.; Saito, K.; Miyauchi, H.; Harada, M. Hybrid Liquid Desiccant Air-Conditioning System: Experiments and Simulations. Appl. Therm. Eng. 2011, 31, 3741–3747. [Google Scholar]

- Sanaye, S.; Taheri, M. Modeling and Multi-Objective Optimization of a Modified Hybrid Liquid Desiccant Heat Pump (LD-HP) System for Hot and Humid Regions. Appl. Therm. Eng. 2018, 129, 212–229. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, X.; Zhang, T.; Xie, Y. Performance Optimization of a Heat Pump Driven Liquid Desiccant Dehumidification System Using Exergy Analysis. Energy 2020, 204, 117891. [Google Scholar] [CrossRef]

- Fatouh, M.; Abou-Ziyan, H.; Mahmoud, O.; Abd El-Raheim, D. Experimental Analysis of Hybrid and Conventional Air Conditioning Systems Working in Hot-Humid Climate. Appl. Therm. Eng. 2017, 118, 570–584. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, T.; Liu, X. Model-Based Investigation of a Heat Pump Driven, Internally Cooled Liquid Desiccant Dehumidification System. Build. Environ. 2018, 143, 431–442. [Google Scholar] [CrossRef]

- Li, W.; Yin, Y.; Wang, Y. Performance Evaluation of a Heat Pump-Driven Liquid Desiccant Dehumidification System Integrated with Fresh Air Supply. Energy Build. 2022, 275, 112473. [Google Scholar] [CrossRef]

- Erkek, T.U.; Gungor, A.; Fugmann, H.; Morgenstern, A.; Bongs, C. Performance Evaluation of a Desiccant Coated Heat Exchanger with Two Different Desiccant Materials. Appl. Therm. Eng. 2018, 143, 701–710. [Google Scholar] [CrossRef]

- Liu, J.; Sun, C.; Chen, Q. Experimental Study of Desiccant-Coated Heat Exchangers for Deep Dehumidification. Energy Build. 2024, 319, 114554. [Google Scholar] [CrossRef]

- Aboelala, A.N.; Kassem, M.A.; Hassan, M.A.; Hamed, A. A Preliminary Investigation of a Novel Solar-Powered Absorption-Desiccant-Radiant Cooling System for Thermally Active Buildings. Sol. Energy 2024, 275, 112642. [Google Scholar] [CrossRef]

- Kosar, D.; Golubovic, M.; Khadir, M.; Swami, M.; Shirey, D.; Basarkar, M.; Raustad, R.; Judge, J. National Center for Energy Management and Building Technologies Task 6: Integrating Advanced Humidty Control to Reduce Energy Use; National Center for Energy Management and Building Technologies: Alexandria, VA, USA, 2007.

- Mohammad, A.T.; Mat, S.B.; Sopian, K.; Al-Abidi, A.A. Review: Survey of the Control Strategy of Liquid Desiccant Systems. Renew. Sustain. Energy Rev. 2016, 58, 250–258. [Google Scholar] [CrossRef]

- Yang, L.; Deng, S.; Fang, G.; Li, W. Improved Indoor Air Temperature and Humidity Control Using a Novel Direct-Expansion-Based Air Conditioning System. J. Build. Eng. 2021, 43, 102920. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, X.; Ma, X. Development of a New Control Method for the Dynamic Liquid Desiccant Dehumidification Process. Energy Build. 2022, 269, 112239. [Google Scholar] [CrossRef]

- Demir, M.H.; Cetin, S.; Haggag, O.; Gursoy Demir, H.; Worek, W.; Premer, J.; Pandelidis, D. Design of a Proportional-Control-Based Advanced Control Strategy for Independent Temperature and Humidity Control of a Pre-Cooled Desiccant Air Cooling System. Appl. Sci. 2022, 12, 9745. [Google Scholar] [CrossRef]

- Lee, S.J.; Kim, H.J.; Dong, H.W.; Jeong, J.W. Energy Saving Assessment of a Desiccant-Enhanced Evaporative Cooling System in Variable Air Volume Applications. Appl. Therm. Eng. 2017, 117, 94–108. [Google Scholar] [CrossRef]

- Chen, Q.; Burhan, M.; Ja, M.K.; Shahzad, M.W.; Ybyraiymkul, D.; Zheng, H.; Cui, X.; Ng, K.C. Hybrid Indirect Evaporative Cooling-Mechanical Vapor Compression System: A Mini-Review. Energies 2022, 15, 7810. [Google Scholar] [CrossRef]

- Peng, D.; Zhou, J.; Luo, D. Analyse Exergétique d’un Système de Refroidissement Évaporatif à Déshydratant Liquide. Int. J. Refrig. 2017, 82, 495–508. [Google Scholar] [CrossRef]

- Heidari, A.; Roshandel, R.; Vakiloroaya, V. An Innovative Solar Assisted Desiccant-Based Evaporative Cooling System for Co-Production of Water and Cooling in Hot and Humid Climates. Energy Convers. Manag. 2019, 185, 396–409. [Google Scholar] [CrossRef]

- Kashif Shahzad, M.; Ali, M.; Ahmed Sheikh, N.; Qadar Chaudhary, G.; Shahid Khalil, M.; Rashid, T.U. Experimental Evaluation of a Solid Desiccant System Integrated with Cross Flow Maisotsenko Cycle Evaporative Cooler. Appl. Therm. Eng. 2018, 128, 1476–1487. [Google Scholar] [CrossRef]

- Comino, F.; Ruiz de Adana, M.; Peci, F. Energy Saving Potential of a Hybrid HVAC System with a Desiccant Wheel Activated at Low Temperatures and an Indirect Evaporative Cooler in Handling Air in Buildings with High Latent Loads. Appl. Therm. Eng. 2018, 131, 412–427. [Google Scholar] [CrossRef]

- Bleibel, N.; Ismail, N.; Ghaddar, N.; Ghali, K. Solar-Assisted Desiccant Dehumidification System to Improve Performance of Evaporatively Cooled Window in Hot and -Humid Climates. Appl. Therm. Eng. 2020, 179, 115726. [Google Scholar] [CrossRef]

- Kalpana; Subudhi, S. Developments in Liquid Desiccant Dehumidification System Integrated with Evaporative Cooling Technology. Int. J. Energy Res. 2022, 46, 61–88. [Google Scholar]

- Sohani, A.; Sayyaadi, H.; Azimi, M. Employing Static and Dynamic Optimization Approaches on a Desiccant-Enhanced Indirect Evaporative Cooling System. Energy Convers. Manag. 2019, 199, 112017. [Google Scholar] [CrossRef]

- Zhang, H.; Ma, H.; Ma, S. Investigation on Indirect Evaporative Cooling System Integrated with Liquid Dehumidification. Energy Build. 2021, 249, 111179. [Google Scholar] [CrossRef]

- Cuce, P.M. Thermal Performance Assessment of a Novel Liquid Desiccant-Based Evaporative Cooling System: An Experimental Investigation. Energy Build. 2017, 138, 88–95. [Google Scholar] [CrossRef]

- Elmer, T.; Worall, M.; Wu, S.; Riffat, S. An Experimental Study of a Novel Integrated Desiccant Air Conditioning System for Building Applications. Energy Build. 2016, 111, 434–445. [Google Scholar] [CrossRef]

- Elgendy, E.; Mostafa, A.; Fatouh, M. Performance Enhancement of a Desiccant Evaporative Cooling System Using Direct/Indirect Evaporative Cooler. Int. J. Refrig. 2015, 51, 77–87. [Google Scholar] [CrossRef]

- Qi, R.; Lu, L.; Huang, Y. Energy Performance of Solar-Assisted Liquid Desiccant Air-Conditioning System for Commercial Building in Main Climate Zones. Energy Convers. Manag. 2014, 88, 749–757. [Google Scholar] [CrossRef]

- Park, J.Y.; Dong, H.W.; Cho, H.J.; Jeong, J.W. Energy Benefit of a Cascade Liquid Desiccant Dehumidification in a Desiccant and Evaporative Cooling-Assisted Building Air-Conditioning System. Appl. Therm. Eng. 2019, 147, 291–301. [Google Scholar] [CrossRef]

- Kim, M.H.; Yoon, D.S.; Kim, H.J.; Jeong, J.W. Retrofit of a Liquid Desiccant and Evaporative Cooling-Assisted 100% Outdoor Air System for Enhancing Energy Saving Potential. Appl. Therm. Eng. 2016, 96, 441–453. [Google Scholar] [CrossRef]

- El Hourani, M.; Ghali, K.; Ghaddar, N. Effective Desiccant Dehumidification System with Two-Stage Evaporative Cooling for Hot and Humid Climates. Energy Build. 2014, 68, 329–338. [Google Scholar] [CrossRef]

- Ali, M.; Vukovic, V.; Sheikh, N.A.; Ali, H.M. Performance Investigation of Solid Desiccant Evaporative Cooling System Configurations in Different Climatic Zones. Energy Convers. Manag. 2015, 97, 323–339. [Google Scholar] [CrossRef]

- Luo, J.; Shen, Y.; Yang, H. Investigations on an Integrated Air-Conditioning System Using Technologies of Desiccant Dehumidification, Indirect Evaporative Cooling and CO2 Capture. Appl. Energy 2024, 369, 123601. [Google Scholar] [CrossRef]

- Shi, W.; Ma, X.; Min, Y.; Yang, H. Feasibility Analysis of Indirect Evaporative Cooling System Assisted by Liquid Desiccant for Data Centers in Hot-Humid Regions. Sustainability 2024, 16, 2011. [Google Scholar] [CrossRef]

- Buker, M.S.; Riffat, S.B. Recent Developments in Solar Assisted Liquid Desiccant Evaporative Cooling Technology—A Review. Energy Build. 2015, 96, 95–108. [Google Scholar]

- Kashif, M.; Niaz, H.; Sultan, M.; Miyazaki, T.; Feng, Y.; Usman, M.; Shahzad, M.W.; Niaz, Y.; Waqas, M.M.; Ali, I. Study on Desiccant and Evaporative Cooling Systems for Livestock Thermal Comfort: Theory and Experiments. Energies 2020, 13, 2675. [Google Scholar] [CrossRef]

- Karimi, M.T.; Ghorbani, G.R.; Kargar, S.; Drackley, J.K. Late-Gestation Heat Stress Abatement on Performance and Behavior of Holstein Dairy Cows. J. Dairy. Sci. 2015, 98, 6865–6875. [Google Scholar] [CrossRef]

- Ashraf, H.; Sultan, M.; Shamshiri, R.R.; Abbas, F.; Farooq, M.; Sajjad, U.; Md-Tahir, H.; Mahmood, M.H.; Ahmad, F.; Taseer, Y.R.; et al. Dynamic Evaluation of Desiccant Dehumidification Evaporative Cooling Options for Greenhouse Air-Conditioning Application in Multan (Pakistan). Energies 2021, 14, 1097. [Google Scholar] [CrossRef]

- Yuan, X.; Zhou, X.; Pan, Y.; Kosonen, R.; Cai, H.; Gao, Y.; Wang, Y. Phase Change Cooling in Data Centers: A Review. Energy Build. 2021, 236, 110764. [Google Scholar] [CrossRef]

- Lai, L.; Wang, X.; Kefayati, G.; Hu, E. Evaporative Cooling Integrated with Solid Desiccant Systems: A Review. Energies 2021, 14, 5982. [Google Scholar] [CrossRef]

- Saedpanah, E.; Pasdarshahri, H. Performance Assessment of Hybrid Desiccant Air Conditioning Systems: A Dynamic Approach towards Achieving Optimum 3E Solution across the Lifespan. Energy 2021, 234, 121151. [Google Scholar] [CrossRef]

- El Loubani, M.; Ghaddar, N.; Ghali, K.; Itani, M. Hybrid Cooling System Integrating PCM-Desiccant Dehumidification and Personal Evaporative Cooling for Hot and Humid Climates. J. Build. Eng. 2021, 33, 101580. [Google Scholar] [CrossRef]

- Wan, Y.; Huang, Z.; Soh, A.; Jon Chua, K. On the Performance Study of a Hybrid Indirect Evaporative Cooling and Latent-Heat Thermal Energy Storage System under Commercial Operating Conditions. Appl. Therm. Eng. 2023, 221, 119902. [Google Scholar] [CrossRef]

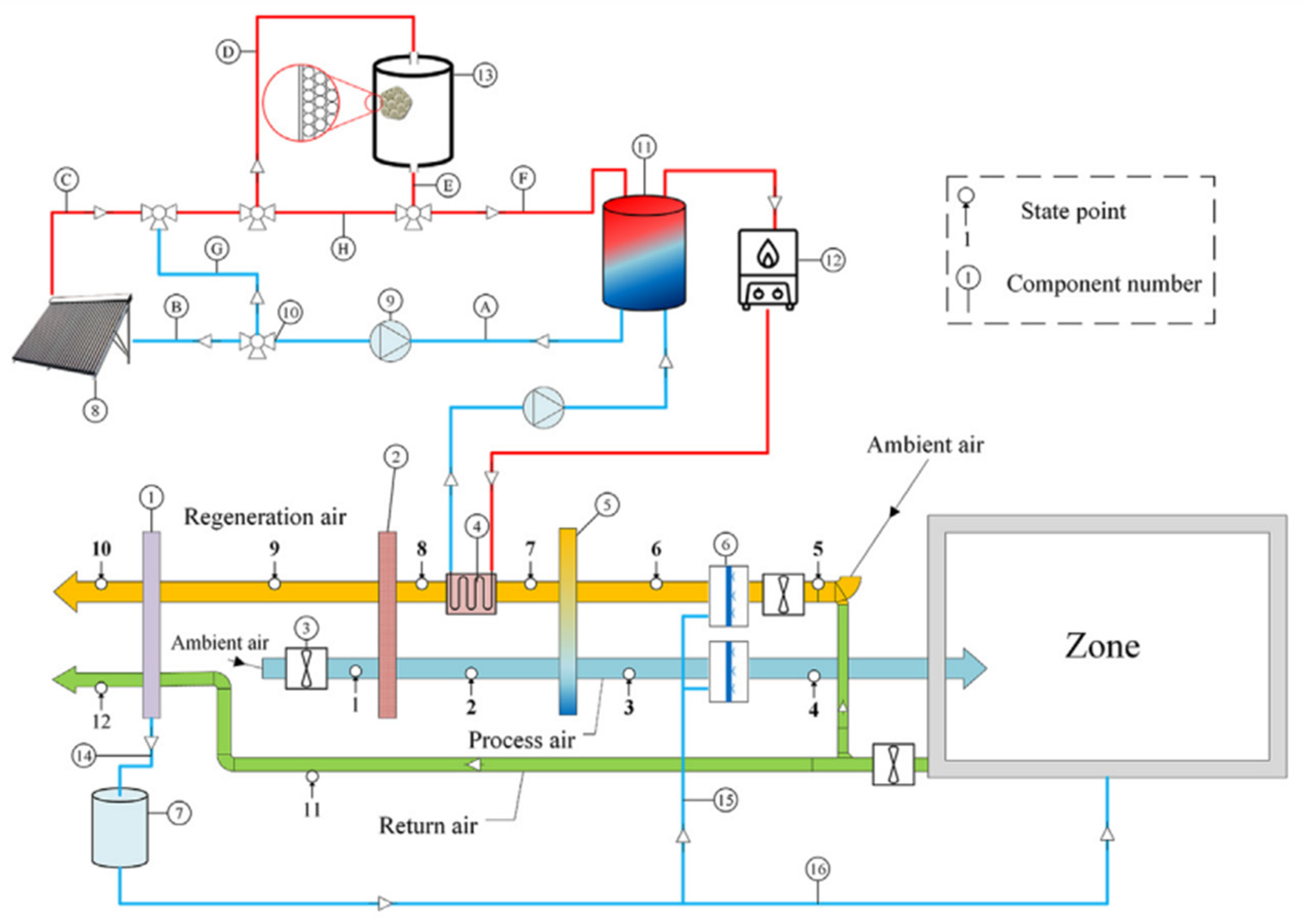

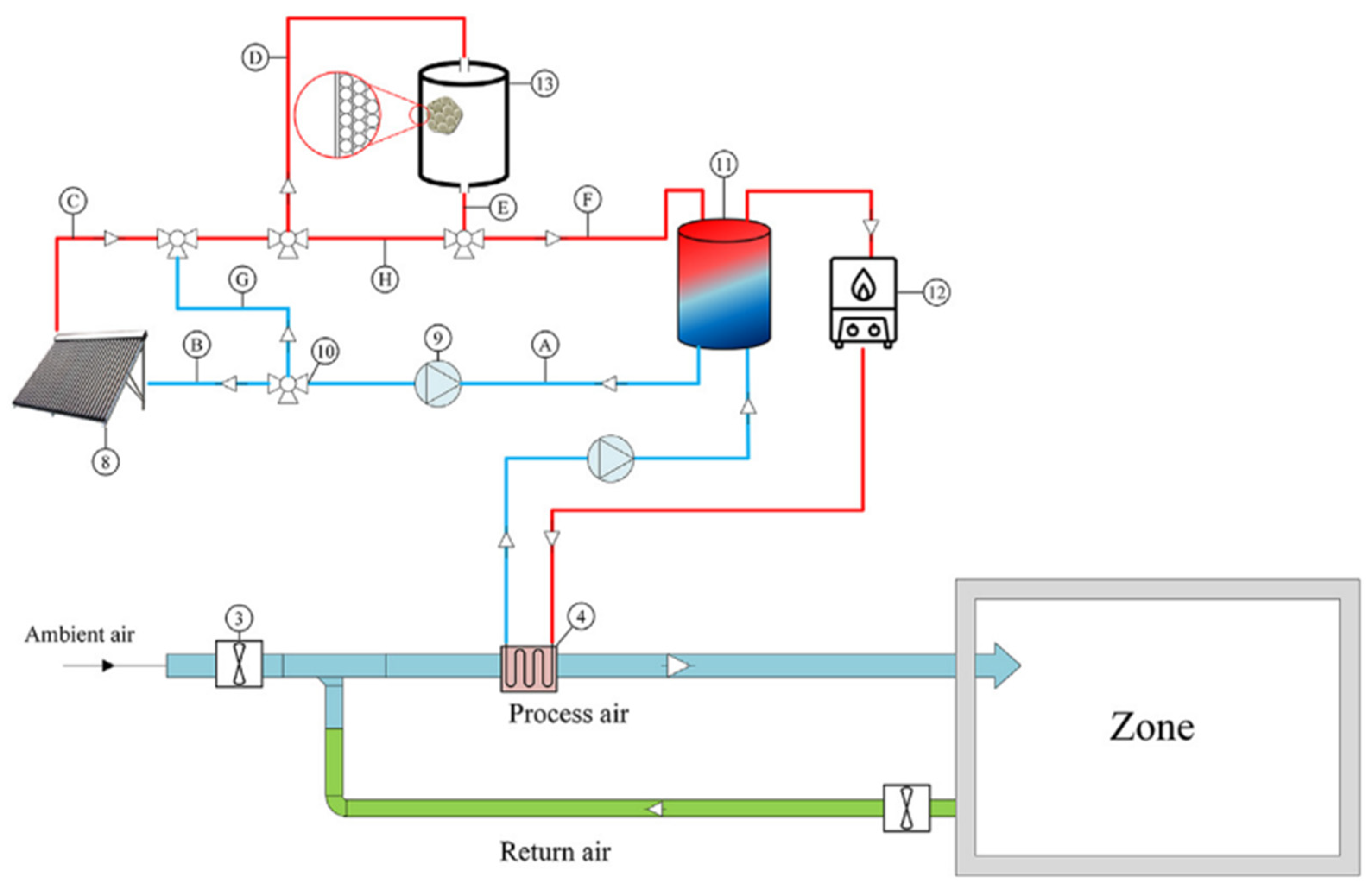

- Fan, W.; Kokogiannakis, G.; Ma, Z. Integrative Modelling and Optimisation of a Desiccant Cooling System Coupled with a Photovoltaic Thermal-Solar Air Heater. Sol. Energy 2019, 193, 929–947. [Google Scholar] [CrossRef]

- Zhou, Y.; Yan, Z.; Dai, Q.; Yu, Y. Experimental Study on the Performance of a Novel Hybrid Indirect Evaporative Cooling/Thermoelectric Cooling System. Build. Environ. 2022, 207, 108539. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, Y.; Wang, D.; Luo, X.; Liu, J.; Liu, J.; Wang, Y.; Liu, J. Performance and Optimization of a Novel Solar-Driven Liquid Desiccant Air Conditioning System Suitable for Extremely Hot and Humid Climates. Energy Convers. Manag. 2020, 215, 112899. [Google Scholar] [CrossRef]

- Beigi, M.; Jalalizadeh, M.; Karami, M.; Fayaz, R.; Jalalizadeh, M.; Sadeghi, S.; Deb Mondol, J. A Novel Liquid Desiccant-Based Hybrid System of Building Integrated Photovoltaic-Thermal System and Ground Heat Exchanger for Buildings in Hot and Humid Climate. Energy Convers. Manag. 2024, 317, 118807. [Google Scholar] [CrossRef]

- Shehram, M.; Hamidi, M.N.; Abdul Wahab, A.A.; Mat Desa, M.K. Comprehensive Review of Hybrid Solar Cooling Systems for Buildings: Integrating PV and Thermal Energy Storage in Phase Change Materials. J. Therm. Anal. Calorim. 2025. [Google Scholar] [CrossRef]

- Aljashaami, B.A.; Ali, B.M.; Salih, S.A.; Alwan, N.T.; Majeed, M.H.; Ali, O.M.; Alomar, O.R.; Velkin, V.I.; Shcheklein, S.E. Recent Improvements to Heating, Ventilation, and Cooling Technologies for Buildings Based on Renewable Energy to Achieve Zero-Energy Buildings: A Systematic Review. Results Eng. 2024, 23, 102769. [Google Scholar]

- Xue, T.; Wan, Y.; Huang, Z.; Chen, P.; Lin, J.; Chen, W.; Liu, H. A Comprehensive Review of the Applications of Hybrid Evaporative Cooling and Solar Energy Source Systems. Sustainability 2023, 15, 16907. [Google Scholar] [CrossRef]

- Olmuş, U.; Güzelel, Y.E.; Pınar, E.; Özbek, A.; Büyükalaca, O. Performance Assessment of a Desiccant Air-Conditioning System Combined with Dew-Point Indirect Evaporative Cooler and PV/T. Sol. Energy 2022, 231, 566–577. [Google Scholar] [CrossRef]

- Shukla, A.; Shrivastava, P.K.; Sharma, P.; Sharma, A.K. Experimental Investigations on a Hybrid Solar Assisted Phase Change Enhanced Liquid Desiccant Cooling System. Energy Sources Part A Recovery Util. Environ. Eff. 2025, 47, 21–43. [Google Scholar] [CrossRef]

- Tian, S.; Su, X.; Shao, X.; Wang, L. Optimization and Evaluation of a Solar Energy, Heat Pump and Desiccant Wheel Hybrid System in a Nearly Zero Energy Building. Build. Simul. 2020, 13, 1291–1303. [Google Scholar] [CrossRef]

- Patel, J.H.; Qureshi, M.N.; Darji, P.H. Experimental Analysis of Thermal Energy Storage by Phase Change Material System for Cooling and Heating Applications. Mater. Today Proc. 2018, 5, 1490–1500. [Google Scholar] [CrossRef]

- Panchal, H.; Patel, K.; Elkelawy, M.; Bastawissi, H.A.-E. A Use of Various Phase Change Materials on the Performance of Solar Still: A Review. Int. J. Ambient Energy 2021, 42, 1575–1580. [Google Scholar] [CrossRef]

| Direct Expansion System with Evaporative Cooling | Direct Expansion System with Desiccant | Evaporative Cooling with Desiccant |

|---|---|---|

| “Direct expansion system” “Evaporative cooling” | “Direct expansion system” “Desiccant” | “Evaporative cooling” “Desiccant” |

| “DX system” “Evaporative cooling” | “DX system” “Desiccant” |

| Product Class | Capacity Range | National Standards | Southeastern Region Standards | Southwestern Region Standards |

|---|---|---|---|---|

| Split-system air conditioners | <45,000 Btu/h single phase | SEER1 = 13.0 (COP1 = 3.8) | SEER1 = 14.0 (COP1 = 4.1) | |

| SEER2 = 13.4 (COP2 = 3.9) | SEER2 = 14.3 (COP2 = 4.2) | |||

| PwOFF ≤ 30 W | PwOFF ≤ 30 W | |||

| Split-system air conditioners | >45,000 Btu/h and <65,000 Btu/h single phase | SEER1 = 13.0 (COP1 = 3.8) | SEER1 = 14.0 (COP1 = 4.1) | |

| SEER2 = 13.4 (COP2 = 3.9) | SEER2 = 13.8 (COP2 = 4.0) | |||

| PwOFF ≤ 30 W | PwOFF ≤ 30 W | |||

| Split-system heat pumps | <65,000 Btu/h single phase | SEER1 = 14.0 (COP1 = 4.1) for cooling mode | ||

| HSPF1 = 8.2 (COP1= 2.4) for heating mode | ||||

| SEER2 = 14.3 (COP2 = 4.2) for cooling mode | ||||

| HSPF2 = 7.5 (COP2 = 2.2) for heating mode | ||||

| PwOFF ≤ 33 W | ||||

| Single-package air conditioners | <65,000 Btu/h single phase | SEER1 = 14.0 (COP1 = 4.1) | ||

| SEER2 = 13.4 (COP = 3.9) | ||||

| PwOFF ≤ 30 W | ||||

| Single-package heat pumps | <65,000 Btu/h single phase | SEER1 = 14.0 (COP1 = 4.1) for cooling mode | ||

| HSPF1 = 8.0 (COP1 = 2.3) for heating mode | ||||

| SEER2 = 13.4 (COP2 = 3.9) for cooling mode | ||||

| HSPF2 = 6.7 (COP2 = 2.0) for heating mode | ||||

| PwOFF ≤ 33 W | ||||

| Small-duct high-velocity systems | <65,000 Btu/h single phase | SEER1 = 12.0 (COP1 = 3.5) for cooling mode | ||

| HSPF2 = 7.2 (COP1 = 2.1) for heating mode | ||||

| SEER2 = 12.0 (COP2 = 3.5) for cooling mode | ||||

| HSPF2 = 6.1 (COP2 = 1.8) for heating mode | ||||

| PwOFF ≤ 30 W | ||||

| Space-constrained air conditioners | <65,000 Btu/h single phase | SEER1 = 12.0 (COP1 = 3.5) | ||

| SEER2 = 11.7 (COP2 = 3.4) | ||||

| PwOFF ≤ 30 W | ||||

| Space-constrained heat pumps | <65,000 Btu/h single phase | SEER1 = 12.0 (COP1 = 3.5) for cooling mode | ||

| HSPF1 = 7.4 (COP1 = 2.2) for heating mode | ||||

| SEER2 = 11.9 (COP2 = 3.5) for cooling mode | ||||

| HSPF2 = 6.3 (COP2 = 1.9) for heating mode | ||||

| PwOFF ≤ 33 W | ||||

| Cooling Testing Conditions | Temperature T1 | Temperature T3 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Indoor Section | Outdoor Section | Indoor Section | Outdoor Section | |||||||

| Dry-Bulb (°C) | Wet-Bulb (°C) | Dry-Bulb (°C) | Wet-Bulb (°C) | Dry-Bulb (°C) | Wet-Bulb (°C) | Dry-Bulb (°C) | Wet-Bulb (°C) | |||

| 27 | 19 | 35 | 24 | 29 | 19 | 46 | 24 | |||

| Rated Cooling Capacity (CC) categories at test condition (T1) in Btu/h [W] | EER Values (Btu/h/W) [COP] | |||||||||

| HVAC type | Single package of Window type—category A | CC ≤ 24,000 [7020] | 9.8 [2.9] | 7.0 [2.1] | ||||||

| Single package of Window type—category B | 24,000 [7020] < CC ≤ 65,000 [19,050] | 9.0 [2.6] | 6.2 [1.8] | |||||||

| Split type ducted and non-ducted using air-cooled condensers, heat pumps using air-cooled condensers | CC ≤ 65,000 [19,050] | 11.8 [3.5] | 8.3 [2.4] | |||||||

| Bar Color | Energy Class | SEER Limits (Btu/W.h) [COP LiMITS] |

|---|---|---|

| Dark green | A | SEER ≥ 18.0 [COP ≥ 5.3] |

| Green | B | 18.0 > SEER ≥ 15.0 [5. 3 > COP ≥ 4.4] |

| Light green | C | 15.0 > SEER ≥ 12.5 [4.4 > COP ≥ 3.7] |

| Yellow | D | 12.5 > SEER ≥ 10.0 [3.7 > COP ≥ 2.9] |

| Orange | E | 10.0 > SEER ≥ 9.0 [2.9 > COP ≥ 2.6] |

| Red | F | 9.0 > SEER ≥ 8.0 [2.6 > SEER ≥ 2.3] |

| Dark Red | G | 8.0 > SEER [2.3 > COP] |

| No. | REF | Year | System | Methodology | Finding |

|---|---|---|---|---|---|

| 1 | [37] | 2021 | A hybrid indirect evaporative cooling-mechanical vapor compression (IEC–MVC) | Experimental and analytical | Tests showed that a cross-flow IEC could reduce the outdoor air temperature by 6–15 °C and humidity by 0.5–4 g/kg. Enthalpy recovery was 27–36% and increased with airflow, higher humidity, and lower temperatures. The IEC had a COP of 6–16 and could handle 34–77% of the cooling load. The overall COP was increased to 4.96–6.05 by the hybrid IEC–MVC system, exceeding standalone MVC by 19–135%. |

| 2 | [38] | 2019 | Evaporative cooling and condensation dehumidification | Experimental | The system’s COP increased by 8.5% due to the addition of a single-stage total heat recovery module. A single-stage sensible heat recovery module was added to improve the system further, increasing the COP by 3.3% and enabling direct room supply air without reheating. The system’s efficiency increased with higher humidity and fresh air temperature due to increased total heat recovery. |

| 3 | [39] | 2022 | Direct expansion system with indirect evaporative cooler | Experimental and analytical | As ambient temperature, humidity, and SHR increase, the COP decreases. The COP and indoor air quality may increase using the IEC ventilator in suitable outdoor conditions. When the ambient temperature and humidity are lower, a higher fresh air flow ratio should be used to achieve a larger COP. |

| 4 | [40] | 2020 | Direct expansion system with direct and indirect evaporative cooler | Simulation | Although hybrid systems use more power, they perform well in all climatic zones. The IEC–DEC–DX system balances wet-bulb effectiveness, thermal comfort, and cooling capacity. However, it consumes more water and power, has a lower COP, and has greater lifespan costs. |

| 5 | [41] | 2019 | Direct expansion system with evaporative cooler | Experimental | With the ‘triple-effect’ mode, significant energy savings were achieved, with a reduction of 60.4% when compared to DX cooling for ambient temperatures below 40 °C. However, for ambient temperatures greater than 40 °C, the energy savings decreased to 40.5%. The COP of the FAHU was doubled for ambient temperatures under 40 °C when using IEC combined with the DX cooling system. The ’triple-effect’ DX mode outperformed the single-effect DX mode for ambient temperatures over 40 °C, achieving 2.16 times better COP. |

| 6 | [42] | 2019 | Hybrid dew point evaporative cooler and vapor compression refrigerated | Simulation | Compared to the conventional DX and IEC/DX systems, the REC/DX hybrid system significantly improved energy savings, saving 38.2% more energy. The system also reduced GHG emissions by 28.5% compared to the DX and 4.3% compared to the IEC/DX systems. |

| 7 | [43] | 2022 | Gravity-assisted heat pipe (GAHP)-based indirect evaporative cooler and direct expansion | Mathematical model | When compared to a conventional hybrid HVAC system, the proposed system showed a 39.2% increase in the COP, along with reductions of 45% and 51.7% in energy consumption and total operating cost, respectively. |

| 8 | [44] | 2024 | Direct expansion photovoltaic-thermal evaporator assisted compression heat pump water heaters using a zeotropic mixture | Experimental | The study experimentally compared a direct expansion photovoltaic-thermal evaporator assisted a compression heat pump water heater using R134a and R290/R600a. The R290/R600a mixture showed better miscibility, system compatibility, lower charge requirement, improved panel cooling, lower pressure ratio, enhanced compressor efficiency, reduced power consumption, and 3.5–7.9% higher COP than R134a. |

| 9 | [45] | 2024 | Semi-Indirect Evaporative Cooler | Experimental | Explores the use of a ceramic Semi-Indirect Evaporative Cooler in a Decarbonised Evaporative-Based Air-Conditioning System to enhance HVAC energy efficiency. Experimental tests showed that the system, operating in both dry and wet modes, achieved 50–70% efficiency in dry mode and nearly 100% in wet mode, with a 30–50% efficiency boost. |

| No. | REF | Year | System | Methodology | Finding |

|---|---|---|---|---|---|

| 10 | [53] | 2021 | A direct expansion unit and liquid desiccant | Simulation | Increases in building load and fresh air humidity led to an improvement in the LDAHU system’s performance. The LDAHU system had a seasonal system COP that was significantly higher than that of the ECB and ASHP systems, resulting in lower annual operating costs and a shorter payback period. Comparing the LDAHU system to the ECB and ASHP systems, the overall cost of operation over a 15-year lifecycle was much lower with the LDAHU system. |

| 11 | [54] | 2018 | Desiccant with DX | Simulation | The COP decreases when the regeneration air temperatures increase because of the rise in process air outlet temperatures and higher cooling demands on the enthalpy wheel and vapor compression cooling unit. Higher outdoor temperatures also reduce the efficiency of the MRR and dehumidifier, which increases the latent cooling load on the sensible cooling coil and lowers the COP. |

| 12 | [55] | 2016 | Liquid desiccant–vapor compression hybrid | Experimental | The performance enhancement of the conventional LDCH system is limited due to the experience of cooling capacity loss (over 10%) due to temperature and concentration differences in the system. The cooling capacity loss of the evaporator is reduced to approximately 1.5% by utilizing a novel LDCH system that uses an auxiliary regenerator. A larger concentration difference in the liquid desiccant enhances the cooling capacity of the evaporator and the dehumidification effect. |

| 13 | [56] | 2011 | Conventional liquid desiccant system and a vapour compression heat pump | Experiments and simulations | Increasing the temperature efficiency of the solution heat exchanger and the compressor’s isentropic efficiency can further improve the system’s COP. The system overall COPsys and the heat pump alone COPhp were 2.7 and 3.8, respectively |

| 14 | [57] | 2018 | Liquid desiccant heat pump (LD–HP) | Simulation | The improved LD–HP system used 33.2% less power over seven months than a conventional heat pump system, which decreased by 33.2% in annual CO2 emissions. The COP of the system was about 4.83 at the optimum point, which is much higher than the 2.74 COP of a conventional heat pump system with an electric heater. For the additional hardware required for the LD-HP system, a payback period of 3.04 years was predicted. |

| 15 | [58] | 2020 | Heat pump-driven liquid desiccant dehumidification system | Simulation | Modifications that created an improved cross-flow system decreased the uniformity coefficients, raising the system’s COPsys from 5.7 to 6 and its exergy efficiency from 20.1% to 21%. The system’s exergy efficiency increased to 25% and its COPsys to 7.4 due to further adjustments to lower the uniformity coefficients that further reduced exergy destruction. |

| 16 | [59] | 2017 | VAC system thin-multilayer activated alumina bed. | Experimental | The conventional vapor compression system with a thin-multilayer activated alumina bed was found to consume less power and operate more efficiently than the conventional system, with an average COP that is 7.52% higher. The system’s COP increased by 12.4% in extremely hot, humid environments, while the degree of superheating dropped by 14.5%. Longer desiccant cycles enhanced the COP and required less power from the compressor, while shorter cycles resulted in a more compact system. |

| 17 | [60] | 2018 | A heat pump-driven, internally cooled liquid desiccant dehumidification system | Simulation | The basic system’s cooling and heating capacities varied based on the properties of each fluid in the dehumidifier, limiting its overall COP, which was 5.96. An improved design decreased the mismatching ratios and increased COP by 12% to 6.68. |

| 18 | [61] | 2022 | Heat pump-driven liquid desiccant dehumidification system integrated with fresh air supply | Simulation | The use of residual heat in the regenerator for air heating, compared to processes without air heating, led to a decrease in condenser temperature and an increase in the COP of the air process by 3.19–10.57% The COP of the air process might be increased by 6.8% and 5.0% with the optimal air volume selection. The supply air’s absolute humidity greatly influences the system’s COP in the summer. In winter, the system’s energy-saving ratio could increase by 25.9% to 30.4%, directly proportionate to the work done by the compressor. |

| 19 | [62] | 2018 | Desiccant coated heat exchanger | Simulation | Exchangers coated with aluminum fumarate have an 11% greater regeneration capacity and an 8% greater dehumidification capacity compared to silica gel. However, silica gel-coated exchangers remove 17% more adsorbate in water-cooled conditions and 66.6% more in adiabatic conditions compared to aluminum fumarate-coated exchangers. |

| 20 | [63] | 2024 | Desiccant-coated heat exchanger | Experimental | The study indicates that deep dehumidification using desiccant-coated heat exchangers requires longer processing time due to slower adsorption kinetics. Lower cooling water temperature enhances performance in both normal and deep dehumidification modes, but the deep demands more cooling power. Higher inlet humidity improves dehumidification in deep mode, while air velocity has differing effects, boosting moisture removal and COP in the deep mode but having an optimal limit in the normal mode. The system achieves a dew point of −23.44 °C while maintaining a 23.11 °C dry bulb temperature, surpassing conventional dehumidification methods. |

| 21 | [64] | 2024 | Hybrid desiccant-dehumidification-absorption system, driven by external compound parabolic concentrators | Simulation | The hybrid desiccant-dehumidification-absorption system is found to achieve superior thermal comfort lowering dissatisfaction of people by 5.6%, a 49% average solar fraction, and a seasonal COP ranging from 0.46 to 1.38. While life cycle costs rise by $6824, each $1000 investment cuts 4619 kg of CO2. |

| No. | REF | Year | System | Methodology | Finding |

|---|---|---|---|---|---|

| 22 | [4] | 2017 | A liquid desiccant dehumidifier and regenerative indirect evaporative cooling | Simulation-based | Inlet air temperature primarily affects the sensible cooling capacity, while air humidity affects both sensible and latent cooling capacities. The energy saving ratio and COP range from 22.4% to 53.2% and 4.3 to 7.1 under various inlet air conditions. The system’s energy efficiency is higher when FCU operates in dry-coil conditions. |

| 23 | [72] | 2017 | Liquid desiccant evaporative cooling system | Simulation | Increasing the hot water temperature, mass flow of hot water, and ambient air relative humidity improves system efficiency, but to varying degrees. However, cooling capacity exergy and exergy efficiency decrease with an increase in ambient air relative humidity. Increasing the hot water temperature results in more significant exergy destruction in each component; hence the recommended temperature is 75 °C. Increasing the gas-liquid ratio reduces exergy destruction, but the effect weakens when the ratio surpasses 1 kg·kg−1. Considering both exergy destruction and component efficacy, the system’s weak links are the regenerator, dehumidifier, and solution total heat recovery system. Furthermore, these components must perform better to increase the entire system’s performance. |

| 24 | [73] | 2019 | Desiccant evaporative cooling system | Simulation | The system has higher energy efficiency than the reference system. It uses more natural gas due to high regional humidity and emits 18.71% less CO2 Compared to the reference system. The system’s payback period is approximately three years, making it financially attractive for implementation. |

| 25 | [74] | 2018 | Solid desiccant system integrated with cross flow Maisotsenko cycle evaporative cooler | Experimental | Based on parametric testing done under the same conditions, the MC–DAC system has a 60–65% higher COP than the DAC system. The system works well in hot climates but is sensitive to the ratio of inlet ambient humidity. |

| 26 | [75] | 2018 | Desiccant wheels, DW, and indirect evaporative coolers | Simulation | The DW–IEC system showed lower annual energy consumption than the DX system across all studied climate zones, with notable energy savings in hot climate zones with high dehumidification demand. With a peak SCOP value of 2.8 in an extremely hot climate zone, the DW–IEC system consistently outperformed the DX system, which is always greater than a 25% difference om SCOPs. With a high demand for dehumidification in extremely hot climate zones, the DW–IEC system achieved up to 34.6% of energy savings. In cooler and colder climate zones with low dehumidification and high heating demand, energy savings were only 4.4% and 1.7%, respectively. |

| 27 | [76] | 2020 | Desiccant with evaporative cooling system | Simulation | In the summer, the DDS-ECW system significantly decreased the inner window temperature, especially in September when humid conditions reduced the efficiency of the ECW system alone. The integrated system decreased an 11% summer cooling load, compared to a 7% decrease in the system without dehumidification. The integrated system has a life-cycle cost Net Present Value (NPV) of $12,600, which is a 14% decrease over the conventional system’s $14,660 NPV over 20 years. |

| 28 | [77] | 2021 | Desiccant evaporative cooling system | - | The LDCS effectively controls latent air loads, collect low-grade energy sources, and significantly reduces wasted electric energy. LDCS can save up to 40% more energy than traditional VRF systems. Compared to alternative configurations, using an LD and M-cycle IEC provides greater dehumidification and supply air temperature performance. |

| 29 | [78] | 2019 | Desiccant enhanced indirect evaporative cooling system | - | Dynamic retrofit optimization improved LCC by 23.7%, ACOP by 50.5%, AWC by 153.2%, and ACE by 57.8% compared to static retrofit optimization, and the improvements in dynamic design optimization were 34.6%, 60.1%, 390.0%, and 69.9%, respectively. |

| 30 | [79] | 2021 | Evaporative cooling system integrated with liquid dehumidification | Experimental | The IECL system significantly enhanced heat transfer performance, improving overall efficiency. Despite the added complexity and larger size of the integrated system, it greatly reduces energy consumption in air treatment processes. |

| 31 | [80] | 2017 | Liquid desiccant-based evaporative cooling system | Experimental | The system had a dehumidification efficiency of 63.7% and decreased air temperature by 5.3 °C at 0.3 m/s air velocity. The system’s dehumidification effectiveness dropped to 56.1% when the air velocity reached 0.5 m/s. The system maintained a high COP range by utilizing external power derived from renewable sources, with an average COP of 5.5 at 0.3 m/s air velocity and 4.8 at 0.5 m/s. |

| 32 | [81] | 2016 | Desiccant and evaporative inter-cooler | Experimental | The COPth, adj was computed due to the moisture imbalance between the regenerator and dehumidifier, and the values reached 1.26 and an average of 0.72, indicating the need for additional work to address the imbalance issue. The electrical COPel averaged 2.5 and reached a peak of 3.67. |

| 33 | [82] | 2015 | Desiccant evaporative cooling system | Simulation | The study shows that the COP of three novel configurations of a desiccant evaporative cooling system is greatly affected by the ambient air humidity ratio more than the ambient air temperature for the considered ranges. Energetic analysis showed that the first design has the most significant cooling capacity. In contrast, the second configuration is easier to build and delivers a 28% higher system COP than the standard system. The third configuration provides the highest thermal and air handling COP. Moreover, its average exergetic efficiency is 54% higher compared to the conventional system. |

| 34 | [83] | 2014 | Solar-assisted liquid desiccant air-conditioning system | Simulation | The SLDAC system performs best in humid environments and is less efficient in regions with low outdoor humidity. In humid climates, the system consumes 40% less electricity and has a payback period of approximately seven years. In dry climates, an enhanced chiller COP can reduce energy use by up to 45%, but the cost payback period is around 22 years. |

| 35 | [84] | 2019 | Cascade liquid desiccant dehumidification in a desiccant and evaporative cooling-assisted system | Simulation | Findings indicated that a retrofitted system with a two-stage liquid desiccant dehumidifier (cascade liquid desiccant section) was more energy-efficient than a conventional liquid desiccant and an indirect/direct evaporative cooling-assisted outdoor air system with a single-stage liquid desiccant dehumidifier, using 12% less primary energy at peak load and 17.4% less during the cooling season. The retrofitted system had better total thermal and primary performance coefficients, 0.78 and 2.05, respectively, compared to the other system, 0.65 and 1.45. |

| 36 | [85] | 2016 | Liquid desiccant and evaporative cooling-assisted 100% outdoor air system | Simulation | Simulation results showed that Case 1, integrating a dew-point IEC, could increase cooling capacity by 41% over the base case. Because more energy was required to heat the desiccant solution, the thermal COP remained about the same. MEE was added to Case 1 to generate Case 2. The COP for Case 2 was double that of the other cases due to significant increases in cooling capacity and energy conservation from the regeneration process. |

| 37 | [86] | 2014 | Desiccant dehumidification system with two-stage evaporative cooling | Simulation | The system reduces water usage and keeps ideal humidity by cooling a portion of the dehumidified air, mixing it with bypassed air, and circulating it in the room. Then, uses a PEC to provide localized cooling. These help to reduce energy use by 16.15% and water use by 26.93% compared to a conventional single-stage evaporative cooling system. |

| 38 | [87] | 2015 | Solid desiccant evaporative cooling system | Simulation | The ventilated-dunkle cycle configuration provided the greatest results for Vienna, Sao Paulo, and Adelaide, representing continental, temperate, and dry-summer subtropical climates, with COPs of 0.405, 0.89, and 1.01, respectively. Contrarily, the ventilation cycle DEC was most effective in dry, semi-arid, and varied temperate regions, such as Karachi and Shanghai, with average COPs of 2.43 and 3.03, respectively. |

| 39 | [88] | 2024 | Desiccant dehumidification, indirect evaporative cooling and CO2 capture | Simulation | The system demonstrated improved energy efficiency under various conditions, achieving over 30% energy savings and a 53.3% improvement in COP. Efficiency increased with occupancy levels (2 to 22 occupants), ranging from 50.7% to 85.6%, while effectively addressing indoor air quality concerns through CO2 capture. |

| 40 | [89] | 2024 | Indirect Evaporative Cooling System Assisted by Liquid Desiccant | Simulation | The system operates through a two-stage process designed for extreme weather conditions in Hong Kong, addressing the high cooling demand of data centers. The case study demonstrated that the proposed system achieves a remarkable 72.7% improvement in temperature drop compared to a single IEC. |

| 41 | [6] | 2024 | A dew-point indirect evaporative cooler and a desiccant wheel | Experimental | This study experimentally evaluates a hybrid system combining a desiccant wheel and a dew-point indirect evaporative cooler for independent control of temperature, humidity, and CO2. The system achieves a high COP of up to 11.0 under extreme conditions, outperforming traditional systems. The results support the system’s potential for energy-efficient cooling, improved thermal comfort, and better indoor air quality, especially in heat waves and climate change scenarios. |

| No. | REF | Year | System | Methodology | Finding |

|---|---|---|---|---|---|

| 42 | [96] | 2021 | Hybrid desiccant air-conditioning systems with thermal energy storage | Simulation | The proposed optimum system consumes 55.8 and 4.9% less electricity than CS conventional system and baseline system, respectively. The proposed optimum system enhanced thermal comfort by 13.9% and significantly lowered electricity and natural gas consumption compared to conventional systems. The proposed optimum system production of water from moisture harvesting exceeded its usage by 70% annually, providing water for the system and other residential uses. |

| 43 | [97] | 2021 | PCM-desiccant dehumidification and personal evaporative cooling | Simulation | The findings show an 87% decrease in overall energy costs compared to a conventional air conditioner. In addition, the Trombe wall was used in the system, resulting in energy savings of 55% compared to a system that just used the auxiliary heater. |

| 44 | [98] | 2023 | Hybrid indirect evaporative cooling and latent-heat thermal energy storage system | Experiments and modeling | The proposed system effectively achieves the required thermal condition by utilizing the peak load-shifting ability of the LHTES and the high cooling efficiency of the IEC. The study found that increasing the chilled water system’s temperature from 7 °C to 11 °C increased the chiller’s COP from 3.39 to 3.84, indicating possible energy savings with this approach. |

| 45 | [99] | 2019 | Desiccant cooling system coupled with a photovoltaic thermal-solar air heater | Simulation | The optimized system design for a commercial building in a hot and humid climate achieved a very high SF of 96.6%, meaning that solar energy provided most of the required energy. Additionally, the system had a high electrical COP of 19.8, significantly higher than the typical COP range for commercial buildings (2.6–3.0). It was calculated that 0.35 m2 of PVT-SAH was needed for every m2 of conditioned floor area to achieve this performance. |

| 46 | [100] | 2022 | Hybrid indirect evaporative cooling/thermoelectric cooling system | Experimental | Depending on the climate, the system’s COP can exceed 10, significantly higher than the typical COP of a vapor compression system (2–5). Even though the system’s COP slightly declines when spray water is used, dew point effectiveness increases. |

| 47 | [101] | 2020 | Solar-driven liquid desiccant air-conditioning system | Mathematical model | The system integrates photovoltaic and thermal solar power, dehumidification, and active cooling, aiming to optimize energy performance and the PV area ratio in very hot and humid conditions. Results show that the regeneration temperature is lowered by 2.8 °C, and the heat demand is reduced by 62.08 kW, with a 2% increase in indoor relative humidity. Conversely, a 10 °C rise in condensation temperature increases waste condensation heat by 173.7 kW. When the heat humidity ratio and cold load index are constant, the required PV/collector area ratio decreases. |

| 48 | [102] | 2024 | Liquid desiccant-based hybrid system integrated photovoltaic-thermal system and ground heat exchanger | TRNSYS-MATLAB co-simulator | The system demonstrates a payback period of 8 years with a 49% probability, achieving an efficiency of 45% and reducing energy consumption by 32%. |

| 49 | [103] | 2025 | Hybrid solar cooling systems for buildings: integrating PV and thermal energy storage in phase change materials | Review | This review highlights the potential of hybrid solar cooling systems, which integrate photovoltaic and thermal energy with phase change materials for efficient thermal energy storage. These systems utilize PV-generated energy to power adsorption chillers while storing excess thermal energy using PCMs for continuous cooling. When combined with PV panels and flat plate collectors, these advancements enhance energy efficiency, increasing PV output by up to 20%, and improving flat plate collector performance by 90%, offering a sustainable and effective cooling solution. |

| System Type | Best Performance | Energy Efficiency | Cost–Benefit Ratio | Climate Suitability |

|---|---|---|---|---|

| DX + Evaporative Cooling | IEC–MVC hybrid, [37] | COP increased by 19–135% | Moderate, might consumes more water and power | Best for hot-dry and mixed climates |

| DX + Desiccant | Heat pump-driven desiccant, [57] | Seasonal COP improved, CO2 reduced by 33.2% | High; reduces operational costs significantly | Best for hot-humid climates |

| Evaporative Cooling + Desiccant | DW–IEC system, [75] | Up to 34.6% energy savings | High; short payback period | Effective in humid and mixed climates |

| DX + Renewable Energy (PV/Thermal Storage) | PCM-desiccant dehumidification and personal evaporative cooling, [97] | 87% reduction in energy demand | High; long-term sustainability | Suitable for extreme climates with high cooling demand |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alghamdi, F.; Krarti, M. Review Analysis for the Energy Performance of Integrated Air-Conditioning Systems. Energies 2025, 18, 1611. https://doi.org/10.3390/en18071611

Alghamdi F, Krarti M. Review Analysis for the Energy Performance of Integrated Air-Conditioning Systems. Energies. 2025; 18(7):1611. https://doi.org/10.3390/en18071611

Chicago/Turabian StyleAlghamdi, Faisal, and Moncef Krarti. 2025. "Review Analysis for the Energy Performance of Integrated Air-Conditioning Systems" Energies 18, no. 7: 1611. https://doi.org/10.3390/en18071611

APA StyleAlghamdi, F., & Krarti, M. (2025). Review Analysis for the Energy Performance of Integrated Air-Conditioning Systems. Energies, 18(7), 1611. https://doi.org/10.3390/en18071611