Enhancing Mining Enterprise Energy Resource Extraction Efficiency Through Technology Synthesis and Performance Indicator Development

Abstract

:1. Introduction

2. Research Methods for Studying

3. Results and Discussion

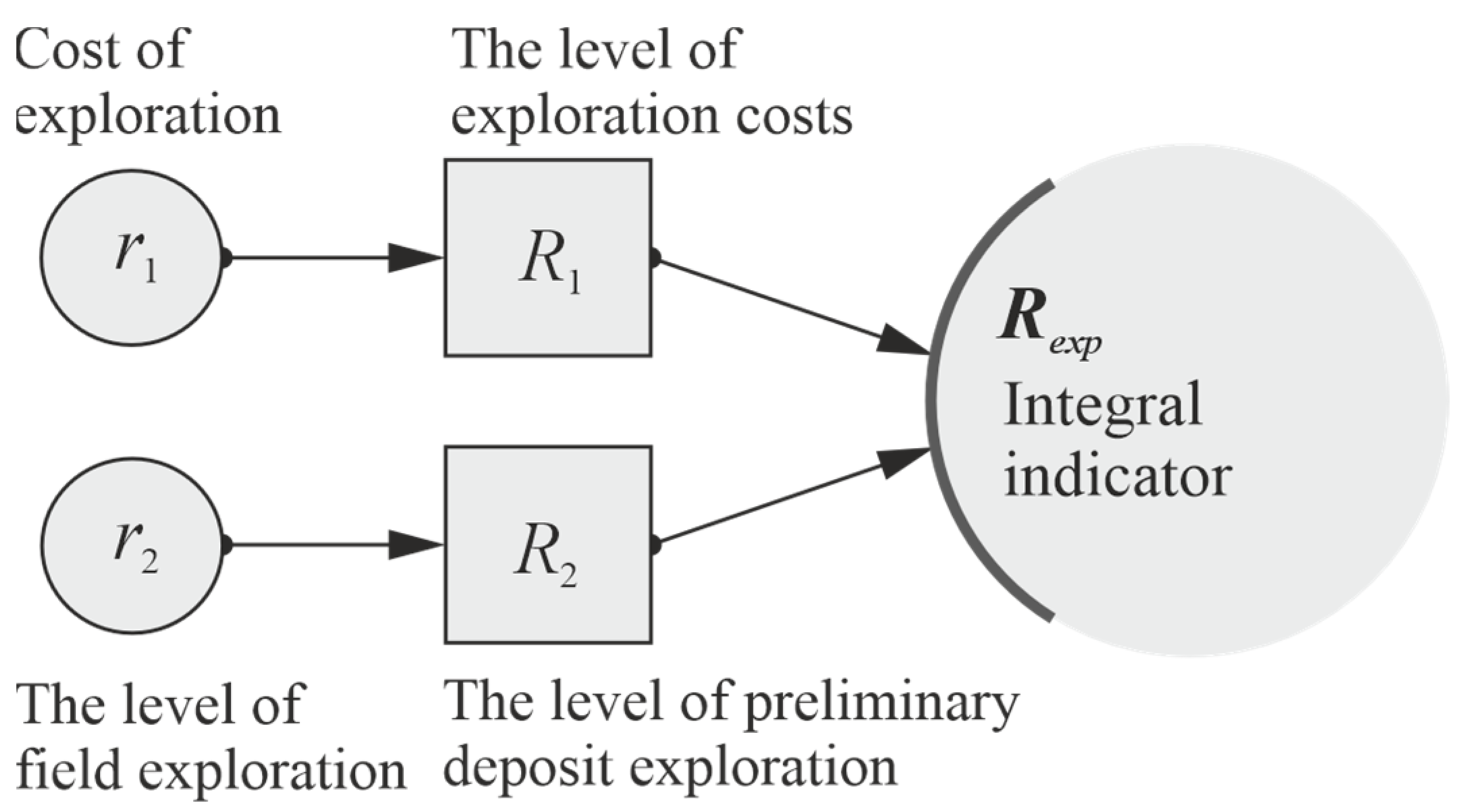

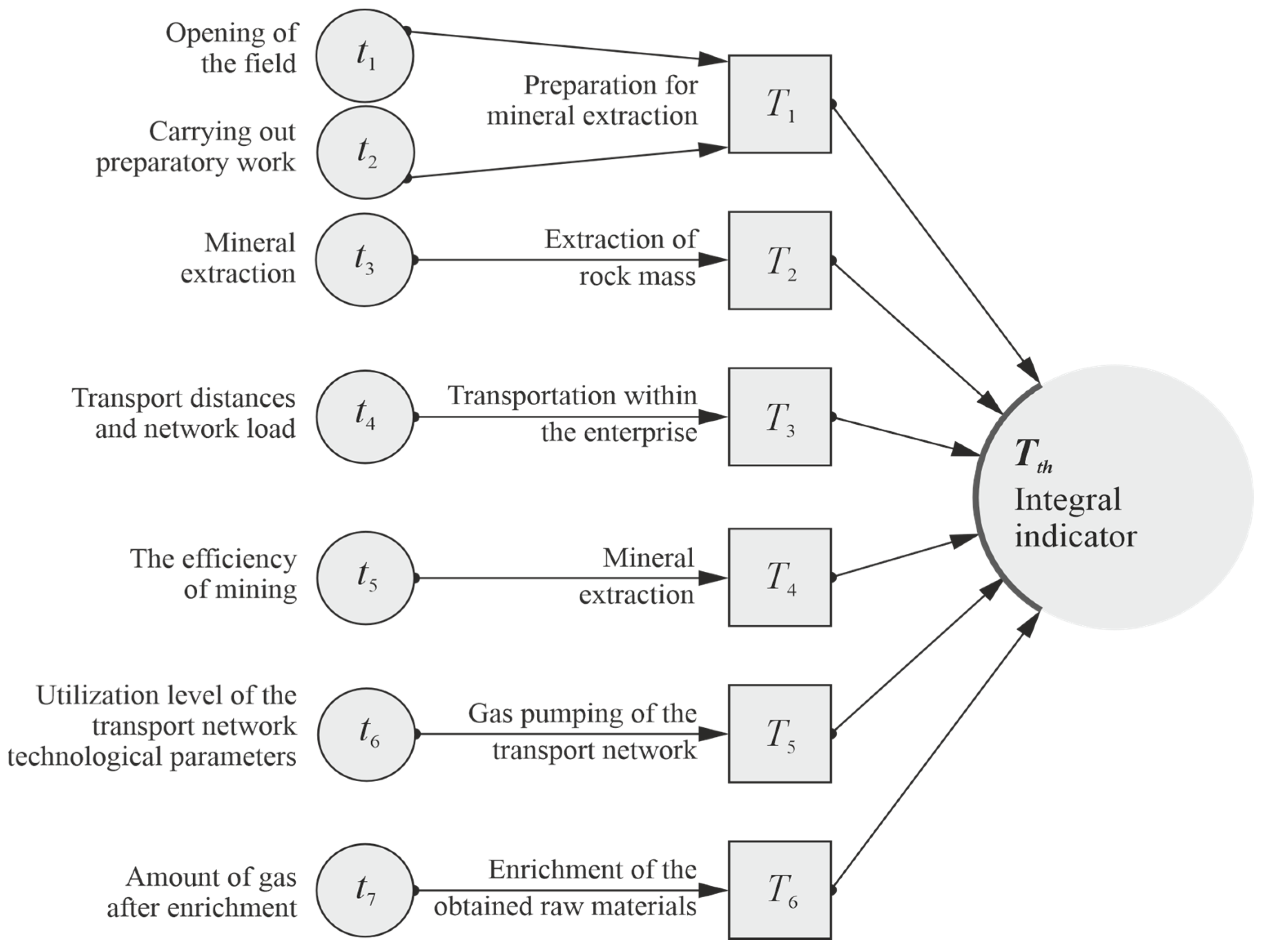

3.1. Geotechnological and Technological Indicators

3.2. Technological and Economic Performance Analysis

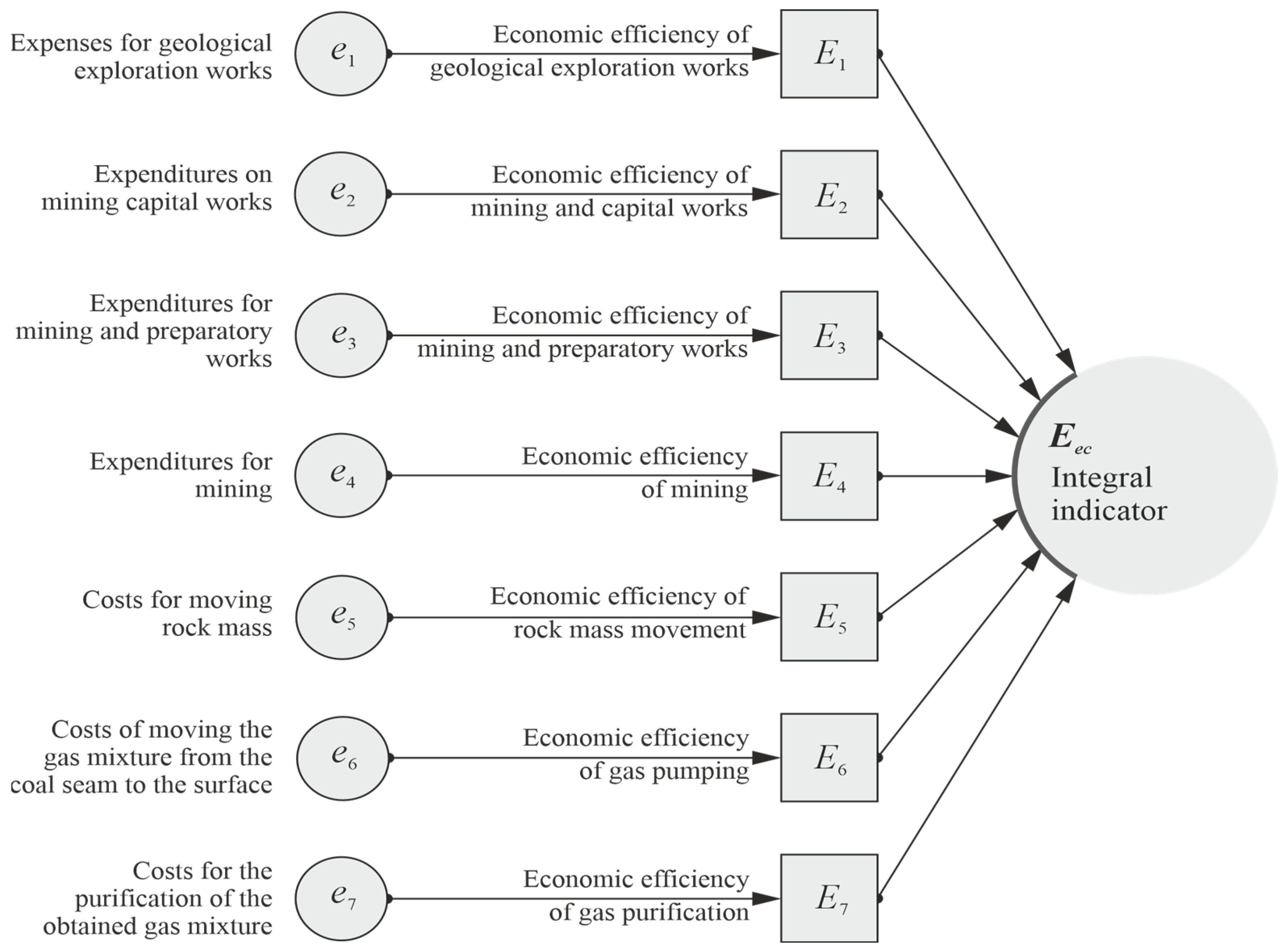

3.3. Economic Efficiency and Cost Evaluation

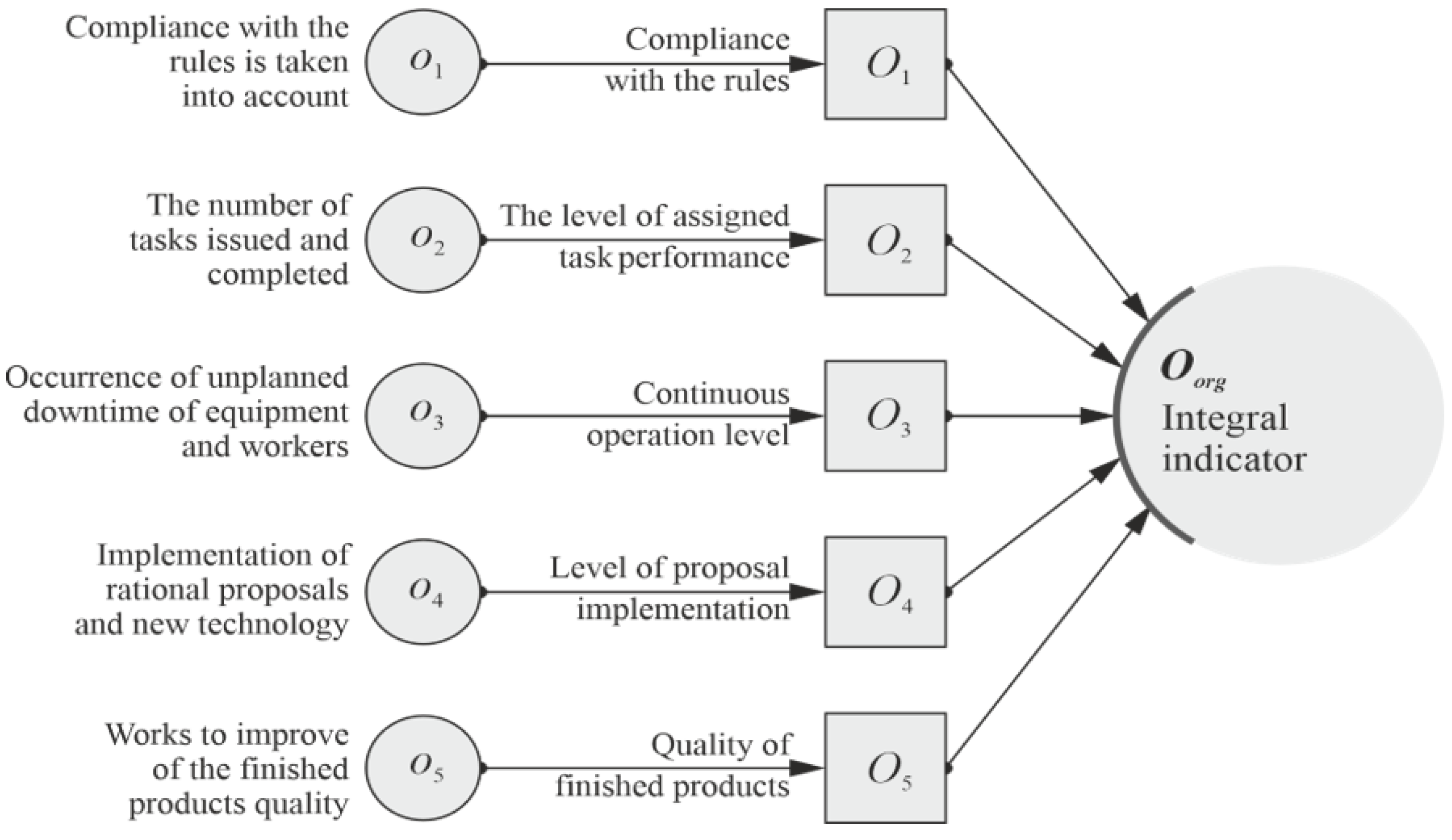

3.4. Organizational and Management Dynamics

- -

- 0.0–0.3—The mine does not invest funds and primarily utilizes existing technologies. Such enterprises are relatively stable but have been practically closed to innovation. In Ukraine, this situation is typical for state-owned mining enterprises.

- -

- 0.31–0.60—These enterprises fall into the category of mines with a moderate level of adoption of technical and technological innovations. Financially, such mining enterprises are also of a medium level. They focus their improvements primarily on implementing, and in many cases purchasing, used equipment from more stable mines, including foreign ones.

- -

- 0.61–1.0—Mines that rank among the top 10 in the national ranking. These are economically independent enterprises. They involve the most advanced mining equipment for production processes. Additionally, they invest in acquiring innovative solutions and services from leading global consulting firms.

- -

- To identify negative trends in the qualitative and quantitative indicators of the activity of the mining enterprise;

- -

- To establish the main groups of factors affecting the efficiency of the enterprise;

- -

- To justify development scenarios for the technological improvement of the company’s activity;

- -

- To determine the sequence of measures aimed at increasing the efficiency of the equipment at the enterprise;

- -

- To justify tactical and strategic management decisions to regulate the work of the enterprise.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kužvart, M.; Böhmer, M. Geophysical methods of prospecting for and exploration of metallic, non-metallic and coal deposits. Prospect. Explor. Miner. Depos. 1986, 21, 187–233. [Google Scholar] [CrossRef]

- Dychkovskyi, R.; Tabachenko, M.; Zhadiaieva, K.; Dyczko, A.; Cabana, E. Gas hydrates technologies in the joint concept of geoenergy usage. E3S Web Conf. 2021, 230, 01023. [Google Scholar] [CrossRef]

- Abelson, P. Cost-Benefit Evaluation of Mining Projects. Aust. Econ. Rev. 2015, 48, 442–452. [Google Scholar] [CrossRef]

- Dudek, M. The analysis of the low-cost flexibility corridors. In Proceedings of the 2017 IEEE International Conference on Innovations in Intelligent Systems and Applications (INISTA), Gdynia, Poland, 3–5 July 2017; pp. 478–483. [Google Scholar] [CrossRef]

- Kalas, M.S.; Deshpande, N.D. Implementation of Production Planning and Scheduling—A Data Mining Approach. Int. J. Sci. Res. (IJSR) 2022, 11, 1120–1126. [Google Scholar] [CrossRef]

- Polyanska, A.; Cichoń, D.; Verbovska, L.; Dudek, M.; Sala, D.; Martynets, V. Waste management skills formation in modern conditions: The example of Ukraine. Financ. Credit Act. Probl. Theory Pract. 2022, 4, 322–334. [Google Scholar] [CrossRef]

- Falshtynskyi, V.; Dychkovskyi, R.; Khomenko, O.; Kononenko, M. On the formation of a mine-based energy resource complex. E3S Web Conf. 2020, 201, 01020. [Google Scholar] [CrossRef]

- Dychkovskyi, R.; Saik, P.; Sala, D.; Cabana, E.C. The current state of the non-ore mineral deposits mining in the concept of the Ukraine reconstruction in the post-war period. Miner. Econ. 2024, 37, 589–599. [Google Scholar] [CrossRef]

- Polyanska, A.; Pazynich, Y.; Mykhailyshyn, K.; Buketov, V. Energy transition: The future of energy on the base of smart specialization. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2023, 4, 89–95. [Google Scholar] [CrossRef]

- Dudek, M. Utilisation of simulation modelling to coordinate of distributed logistic resources. In Proceedings of the Congress Proceedings—CLC 2012: Carpathian Logistics Congress, Jesenik, Czech Republic, 7–9 November 2012; pp. 151–159. [Google Scholar]

- Wilkey, M.L.; Macal, C.M. Coal Blending in Illinois (Compliance with SO/sub 2/ Emission Regulations); Office of Scientific and Technical Information (OSTI): Argonne, IL, USA, 1976; p. 80. [CrossRef]

- Kicki, J.; Sobczyk, E. Technical, Technological and Economic Aspects of Thin-Seam Coal Mining. International Mining Forum 2007; CRC Press: London, UK, 2007; p. 197. [Google Scholar] [CrossRef]

- Golosinski, T.S. Data mining uses in mining. In Computer Applications in the Mineral Industries; CRC Press: Boca Raton, FL, USA, 2020; pp. 763–766. [Google Scholar] [CrossRef]

- Li, Y.; Duan, B. Research on Enterprise Data Management Strategy Analysis System Based on Knowledge Mining Model. Mob. Inf. Syst. 2022, 2022, 6359293. [Google Scholar] [CrossRef]

- Vladyko, O.; Maltsev, D.; Cabana, E.C.; Shavarskyi, I.; Dychkovskyi, R. Formation of the models of mining enterprise management. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2022, 3, 30–36. [Google Scholar] [CrossRef]

- Polyanska, A.; Pazynich, Y.; Sabyrova, M.; Verbovska, L. Directions and prospects of the development of educational services in conditions of energy transformation: The aspect of the coal industry. Polityka Energetyczna Energy Policy J. 2023, 26, 195–216. [Google Scholar] [CrossRef]

- Krot, K.; Lewicka, D. Relationship between Impersonal Trust and Innovative Culture: An Empirical Study. E+M Ekon. Manag. 2020, 23, 82–100. [Google Scholar] [CrossRef]

- Sokolov, N.V. Technological Process as an Object of Optimization and Management; Vistnyk of State University of Transport: Kharkiv, Ukraine, 2004; pp. 68–74. [Google Scholar]

- Dychkovskyi, R.; Tabachenko, M.; Zhadiaieva, K.; Cabana, E. Some aspects of modern vision for geoenergy usage. E3S Web Conf. 2019, 123, 01010. [Google Scholar] [CrossRef]

- Vladyko, O.; Maltsev, D.; Sala, D.; Cichoń, D.; Buketov, V.; Dychkovskyi, R. Simulation of leaching processes of polymetallic ores using the similarity theorem. Rud. Geol.-Naft. Zb. 2022, 37, 169–180. [Google Scholar] [CrossRef]

- Surgay, M.S. Methodological Bases for Ensuring the Reliability of Coal Mine Operations as a Single Technological Complex with a Computerized Control System: Doctoral Dissertation in Technical Sciences. Ph.D. Thesis, Institute of Geotechnical Mechanics of the National Academy of Sciences of Ukraine, Dnipro, Ukraine, 2002; p. 280. [Google Scholar]

- Honcharenko, S.N.; Bayarsaihan, Y. Economic evaluation of strategic alternatives for the development of non-ferrous metal mining enterprises. Min. Inf. Anal. Bull. 2001, 8, 53–57. [Google Scholar]

- Sokolovsky, A.V. Methodology for Designing the Technological Development of Operating Quarries. Ph. D. Thesis, State Mining University, Moscow, Russia, 2009; p. 332. [Google Scholar]

- Grigoriev, I.Y. Methodology of Designing Careers in Modern Conditions. Bull. Kryvorizk Natl. Univ. 2012, 32, 6–10. Available online: http://nbuv.gov.ua/UJRN/Vktu_2012_32_4 (accessed on 12 November 2024).

- Shapar, A.G. Resource-Saving Technologies of Mineral Extraction in Quarries of Ukraine; Naukova Dumka: Kyiv, Ukraine, 1998; p. 91. [Google Scholar]

- Zakrzewska-Bielawska, A.; Lewicka, D. A company’s relational strategy: Linkage between strategic choices, attributes, and outcomes. PLoS ONE 2021, 16, e0254531. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S.; Petrenko, A.; Barkova, O.; Kobylianskyi, B. Numerical simulation of the surface subsidence evolution caused by the flooding of the longwall goaf during excavation of thin coal seams. IOP Conf. Ser. Earth Environ. Sci. 2023, 1254, 012057. [Google Scholar] [CrossRef]

- Merzlikina, G.; Oleinik, O.; Mogharbel, N. Sustainable Innovative Development of a Regional Enterprise: Strategic and Operational Potential. In Proceedings of the International Scientific and Practical Conference on Sustainable Development of Regional Infrastructure, Yekaterinburg, Russia, 14–15 March 2021; Volume 1, pp. 501–506. [Google Scholar] [CrossRef]

- Piletska, S.T. Anti-Crisis Management National Aviation University Economic Stability Industrial Aviation Enterprise; National Aviation University: Kyiv, Ukraine, 2014; p. 314. [Google Scholar]

- Ramazanovna, G.D. Methodology for Evaluating the Management of Innovative Processes in the Field of Information and Communication Technologies. Webology 2020, 17, 365–376. [Google Scholar] [CrossRef]

- Aroshidze, A. Criterial code of sustainable enterprise development. CITISE 2022, 32, 135–146. [Google Scholar] [CrossRef]

- Dychkovskyi, R.O. Determination of the rock subsidence spacing in the well underground coal gasification. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2015, 6, 30–36. [Google Scholar]

- Kononenko, M.; Khomenko, O.; Sadovenko, I.; Sobolev, V.; Pazynich, Y.; Smoliński, A. Managing the rock mass destruction under the explosion. J. Sustain. Min. 2023, 22, 240. [Google Scholar] [CrossRef]

- Zdonek, D. Identification of technologies in Industry 4.0 with the use of text mining. Scientific Papers of Silesian University of Technology. Organ. Manag. Ser. 2020, 2020, 45–57. [Google Scholar] [CrossRef]

- Magdziarczyk, M.; Chmiela, A.; Dychkovskyi, R.; Smoliński, A. The Cost Reduction Analysis of Green Hydrogen Production from Coal Mine Underground Water for Circular Economy. Energies 2024, 17, 2289. [Google Scholar] [CrossRef]

- Gumiński, A.; Kurek, M. The concept of the main dewatering model in a coal mine considering technical, managerial, and economic criteria. Zesz. Naukowe. Organ. Zarz./Politech. Śląska 2022, 160, 227–243. [Google Scholar] [CrossRef]

| No. | Complex Indicator | Components of the Complex Indicator | Value/ Weight | Rexp |

|---|---|---|---|---|

| 1 | Level of exploration costs, R1, units | Cost of exploration | 0.9/0.3 | 0.885 |

| Level of total costs from the extraction of minerals | ||||

| 2 | Level of preliminary exploration, R2, units | Exploration level | 0.8/0.7 | |

| Ratio of mineral exploration to production for the year | ||||

| No. | Complex Indicator | Components of the Complex Indicator | Value/ Weight | Ceq |

|---|---|---|---|---|

| 1 | Extraction of minerals, C1, units | Productivity of mining operations | 0.8/0.3 | 0.421 |

| Efficiency of using mining equipment for the main technology | ||||

| 2 | Carrying out preparatory work, C2, units | Productivity of preparatory works | 0.7/0.2 | |

| Effectiveness of the use of drilling equipment during mining operations for the main technology | ||||

| 3 | Transportation of minerals, C3, units | Productivity of transport vehicles | 0.7/0.1 | |

| Efficiency of using the transport network for the main technology with an average transport length of 4500 m | ||||

| 4 | Massif drilling, C4, units | Productivity of drilling machines | 0.7/0.2 | |

| Effectiveness of using drilling machines for additional technology | ||||

| 5 | Pumping through pipelines, C5, units | Pumping through pipelines | 0.7/0.2 | |

| Efficiency of using mineral transportation through pipelines for additional technology | ||||

| No. | Complex Indicator | Components of the Complex Indicator | Value/ Weight | Tth |

|---|---|---|---|---|

| 1 | Preparation for opening and carrying out mine workings, T1, units | Preparation for opening and carrying out mine workings | 0.7/0.1 | 0.332 |

| Effectiveness of the use of the technological subsystem before opening and production using the main technology | ||||

| 2 | Extraction of rock mass, T2, units | Mining productivity | 0.8/0.2 | |

| Efficiency of mineral extraction using the main technology | ||||

| 3 | Efficiency of transportation technology within the enterprise, T3, units | Congestion of the transport network | 0.6/0.2 | |

| Load of the transport network according to the main technology | ||||

| 4 | Mineral extraction, T4, units | Technological efficiency of mineral extraction | 0.8/0.1 | |

| Efficiency of mineral extraction by the additional technology | ||||

| 5 | Gas pumping of the transport network, T5, units | Level of use of technological parameters in the transport network | 0.6/0.2 | |

| Efficiency of using the transport network for the additional technology | ||||

| 6 | Enrichment of the obtained raw materials, T6, units | Amount of gas obtained after purification | 0.7/0.2 | |

| Efficiency of gas purification by additional technology | ||||

| No. | Complex Indicator | Components of the Complex Indicator | Value/ Weight | Eec |

|---|---|---|---|---|

| 1 | Economic efficiency of geological exploration works, E1, units | Expenditures for geological exploration work, which are determined by the costs of work and attributed to the unit of volume of mineral in the massif | 0.7/0.1 | 0.274 |

| Ratio of costs to the maximum in the industry | ||||

| 2 | Economic efficiency of mining and capital works, E2, units | Expenditures for mining and capital works, which are determined by the costs of carrying out production over a unit of mine working length and are added to general costs | 0.9/0.1 | |

| Ratio of costs to the maximum in the industry | ||||

| 3 | Economic efficiency of mining and preparatory works, E3, units | Expenditures for mining preparatory work, which is determined by the costs of excavation work and maintenance over a unit length of production, added to the general costs | 0.8/0.1 | |

| Ratio of costs to the maximum in the industry | ||||

| 4 | Economic efficiency of cleaning works, E4, units | Expenditures for clean mining at the expense of materials, current repairs, electricity, transportation within the mining area | 0.8/0.2 | |

| Ratio of costs to the maximum in the industry | ||||

| 5 | Economic efficiency of mining mass movement, E5, units | Costs for the movement of rock mass, storage, and separation of the movement of rock mass into streams attributed to the unit of the length of production, added to the general costs | 0.8/0.1 | |

| Ratio of costs to the maximum in the industry | ||||

| 6 | Economic efficiency of gas pumping, E6, units | Costs for moving the mixture of gases from the coal seam to the surface, per unit length | 0.8/0.2 | |

| Ratio of costs to the maximum in the industry | ||||

| 7 | Economic efficiency of gas purification, E7, units | Costs for cleaning the resulting mixture of gases from non-combustible impurities per unit volume of the final product | 0.4/0.2 | |

| Efficiency of gas purification after enrichment compared to the maximum in the industry | ||||

| No. | Complex Indicator | Components of the Complex Indicator | Value/ Weight | Oorg |

|---|---|---|---|---|

| 1 | Level of compliance with the rules, O1, units | Compliance with the rules of mineral extraction and labor protection is taken into account | 0.9/0.3 | 0.472 |

| Level of compliance with the rules of mineral extraction and labor protection is among the best enterprises in the industry | ||||

| 2 | Level of assigned tasks performance, O2, units | Number of issued and completed tasks is taken into account | 0.8/0.2 | |

| Ratio of the number of issued to the number of completed tasks | ||||

| 3 | Level of continuous operation, O3, units | Occurrence of unplanned downtime of equipment and workers that affects continuous work | 0.9/0.1 | |

| Ratio of continuous work of equipment and workers | ||||

| 4 | Level of proposal implementation, O4, units | Implementation of rational proposals and new technology, which includes a corresponding increase in work efficiency | 0.7/0.2 | |

| Effectiveness of implementation of rational proposals regarding technologies and new equipment | ||||

| 5 | Grade of finished products, O5, units | Work on improving the quality of finished products, which includes the number of defects from the total number of products | 0.9/0.2 | |

| Effectiveness of work on improving the quality of finished products | ||||

| No. | Integral Indicator Name | Calculated Value of the Integral Indicator | Coefficient of Consistency | Integral Indicator Value |

|---|---|---|---|---|

| 1 | Mineral exploration, Rexp | 0.885 | 1.0 | 0.885 |

| 2 | Equipment productivity, Ceq | 0.421 | 1.4 | 0.589 |

| 3 | Technological subsystem indicators, Tth | 0.332 | 2.5 | 0.831 |

| 4 | Economic subsystem indicators, Eec | 0.274 | 3.0 | 0.823 |

| 5 | Organizational subsystem indicators, Oorg | 0.472 | 1.7 | 0.802 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vladyko, O.; Maltsev, D.; Gliwiński, Ł.; Dychkovskyi, R.; Stecuła, K.; Dyczko, A. Enhancing Mining Enterprise Energy Resource Extraction Efficiency Through Technology Synthesis and Performance Indicator Development. Energies 2025, 18, 1641. https://doi.org/10.3390/en18071641

Vladyko O, Maltsev D, Gliwiński Ł, Dychkovskyi R, Stecuła K, Dyczko A. Enhancing Mining Enterprise Energy Resource Extraction Efficiency Through Technology Synthesis and Performance Indicator Development. Energies. 2025; 18(7):1641. https://doi.org/10.3390/en18071641

Chicago/Turabian StyleVladyko, Oleksandr, Dmytro Maltsev, Łukasz Gliwiński, Roman Dychkovskyi, Kinga Stecuła, and Artur Dyczko. 2025. "Enhancing Mining Enterprise Energy Resource Extraction Efficiency Through Technology Synthesis and Performance Indicator Development" Energies 18, no. 7: 1641. https://doi.org/10.3390/en18071641

APA StyleVladyko, O., Maltsev, D., Gliwiński, Ł., Dychkovskyi, R., Stecuła, K., & Dyczko, A. (2025). Enhancing Mining Enterprise Energy Resource Extraction Efficiency Through Technology Synthesis and Performance Indicator Development. Energies, 18(7), 1641. https://doi.org/10.3390/en18071641