Integrated Energy Storage Systems for Enhanced Grid Efficiency: A Comprehensive Review of Technologies and Applications

Abstract

:1. Introduction

1.1. Statement of Problem

1.2. Aim and Objectives

- To systematically analyze and categorize IESSs based on functional performance metrics, including grid applications (short-term vs. long-term storage), efficiency, power density, and response time.

- To develop an evaluation framework that integrates Multi-Criteria Decision Analysis (MCDA), considering technical, economic, and environmental factors for optimizing storage system selection.

- To assess real-world case studies and performance metrics from leading implementations worldwide, identifying successful integration patterns and challenges.

- To propose tailored solutions for emerging markets, addressing unique infrastructural and regulatory challenges in energy storage adoption.

- To provide policy and implementation recommendations for accelerating the deployment of optimized IESSs in different grid environments

1.3. Review Scope

2. Methodology

2.1. Literature Search and Selection Criteria

2.2. Thematic Analysis Approach

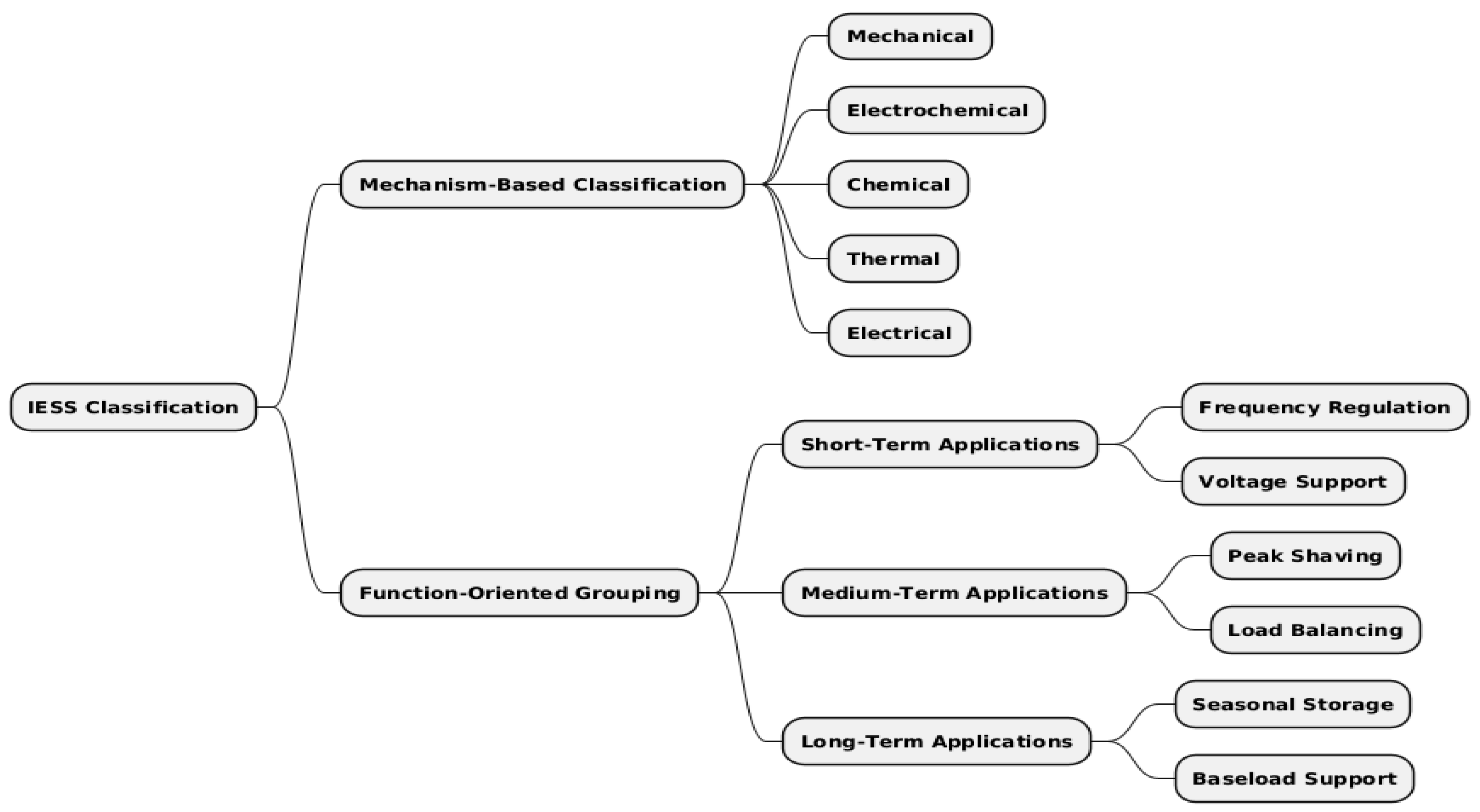

- Technology Classification—Analyzing mechanism-based and function-oriented groupings of IESSs for grid integration.

- Performance Metrics—Evaluating technical, economic, and environmental indicators such as efficiency, power density, CAPEX/OPEX, and lifecycle emissions.

- Integration Strategies—Reviewing centralized, decentralized, and hybrid approaches to storage deployment.

- Case Study Analysis—Examining global implementations (such as the Hornsdale Power Reserve, Leighton Buzzard, and Notrees Wind Farm) to extract success factors and challenges.

2.3. Analytical Framework

3. Classification of Energy Storage Systems

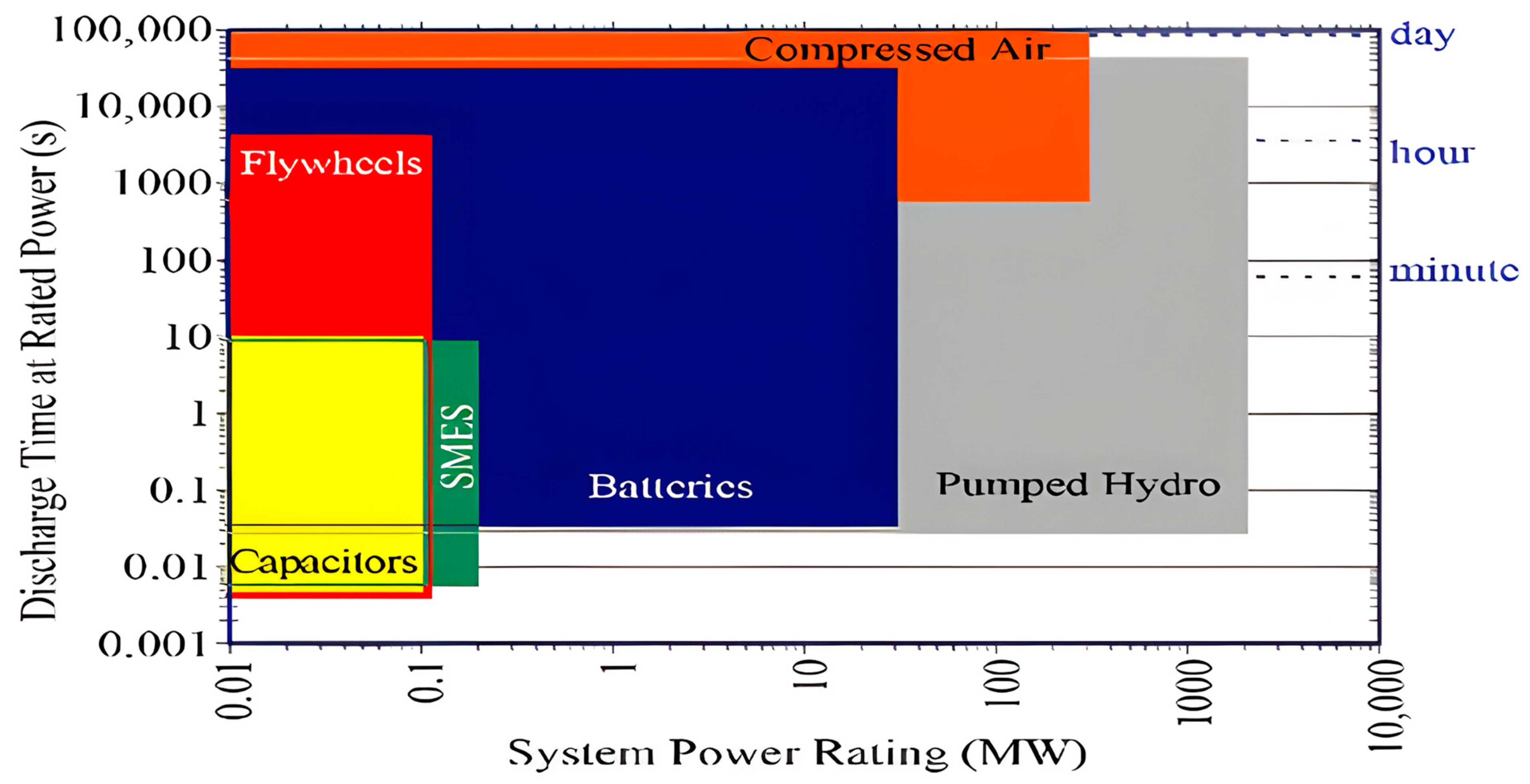

3.1. Storage Mechanism-Based Energy Storage System (ESS) Classification

- Mechanical Energy Storage Systems

- 2.

- Electrochemical Energy Storage Systems

- 3.

- Chemical Storage Systems (CESSs)

- 4.

- Thermal Energy Storage (TES) Systems

- 5.

- Electric Energy Storage Systems

3.2. Function-Oriented Grouping

- 1.

- Short-Term Applications:

- 2.

- Medium-Term Applications:

- 3.

- Long-Term Applications:

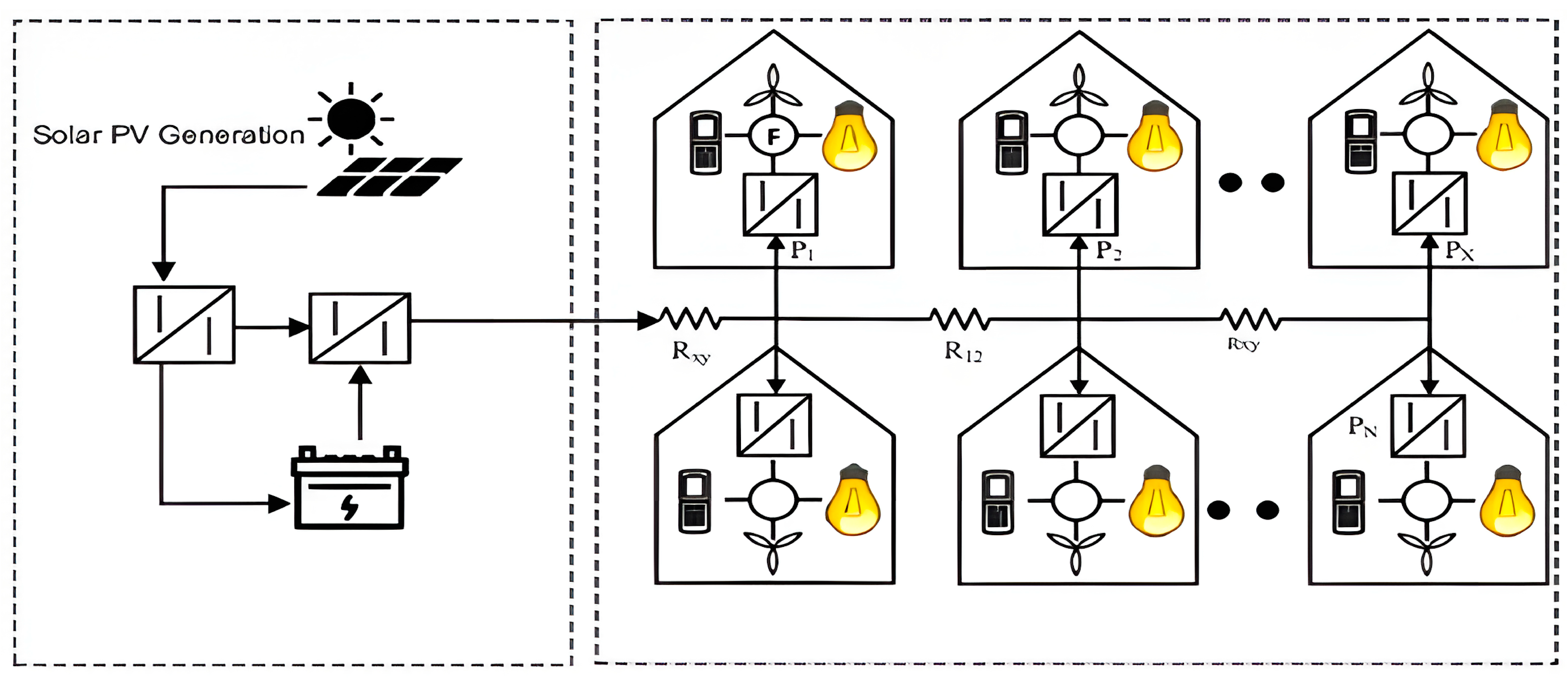

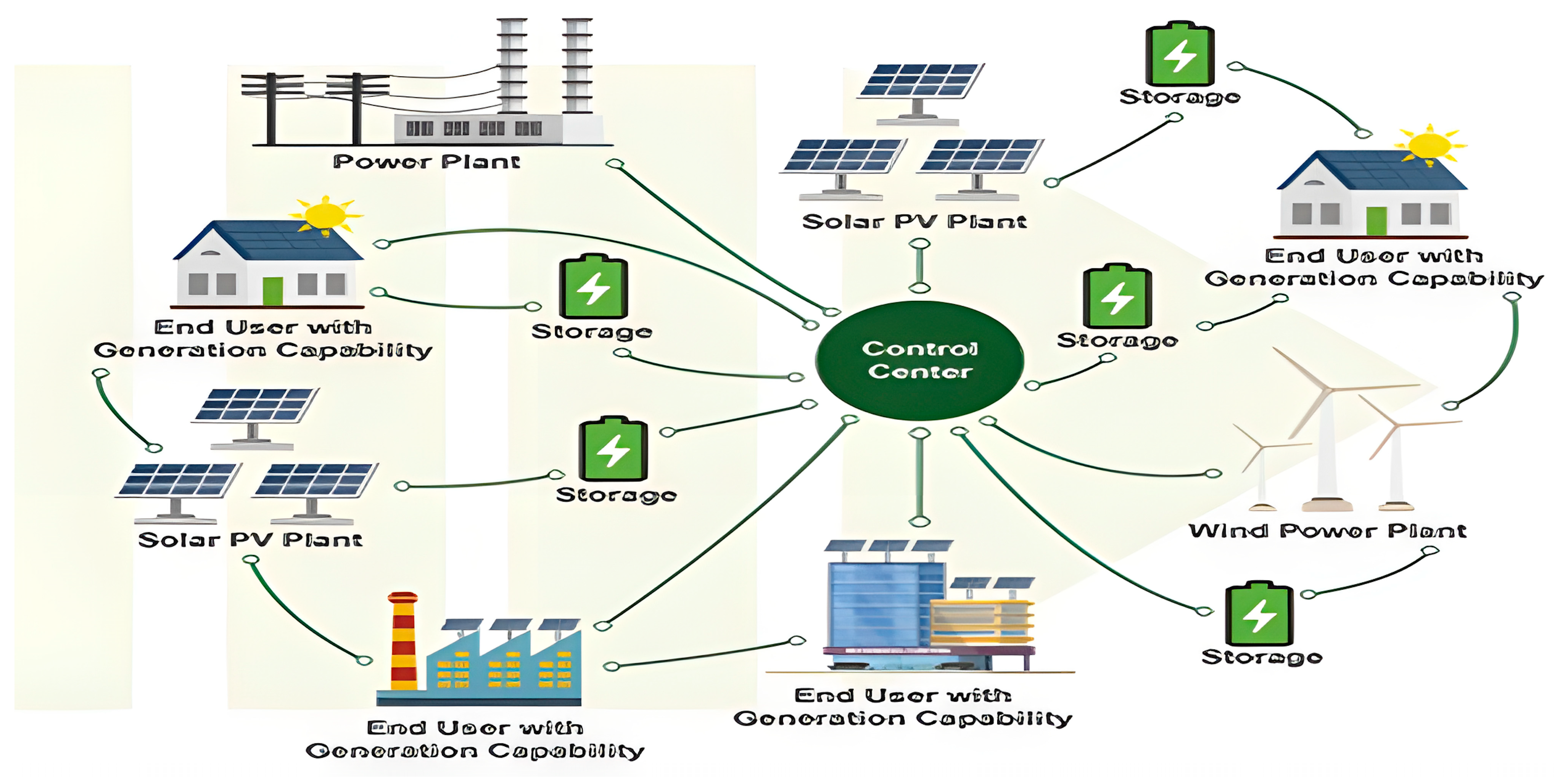

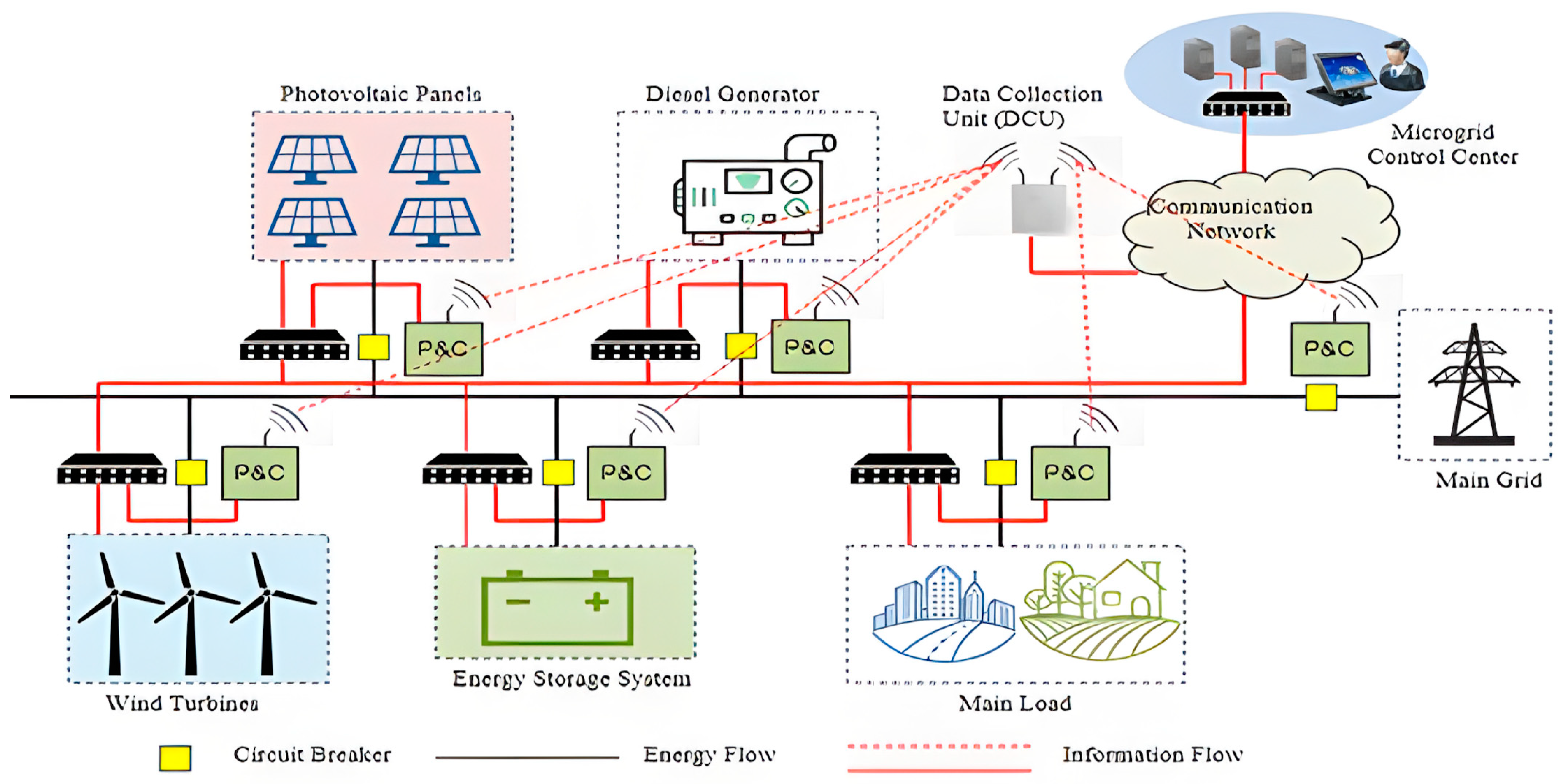

3.3. Integration Approaches for Energy Storage Systems

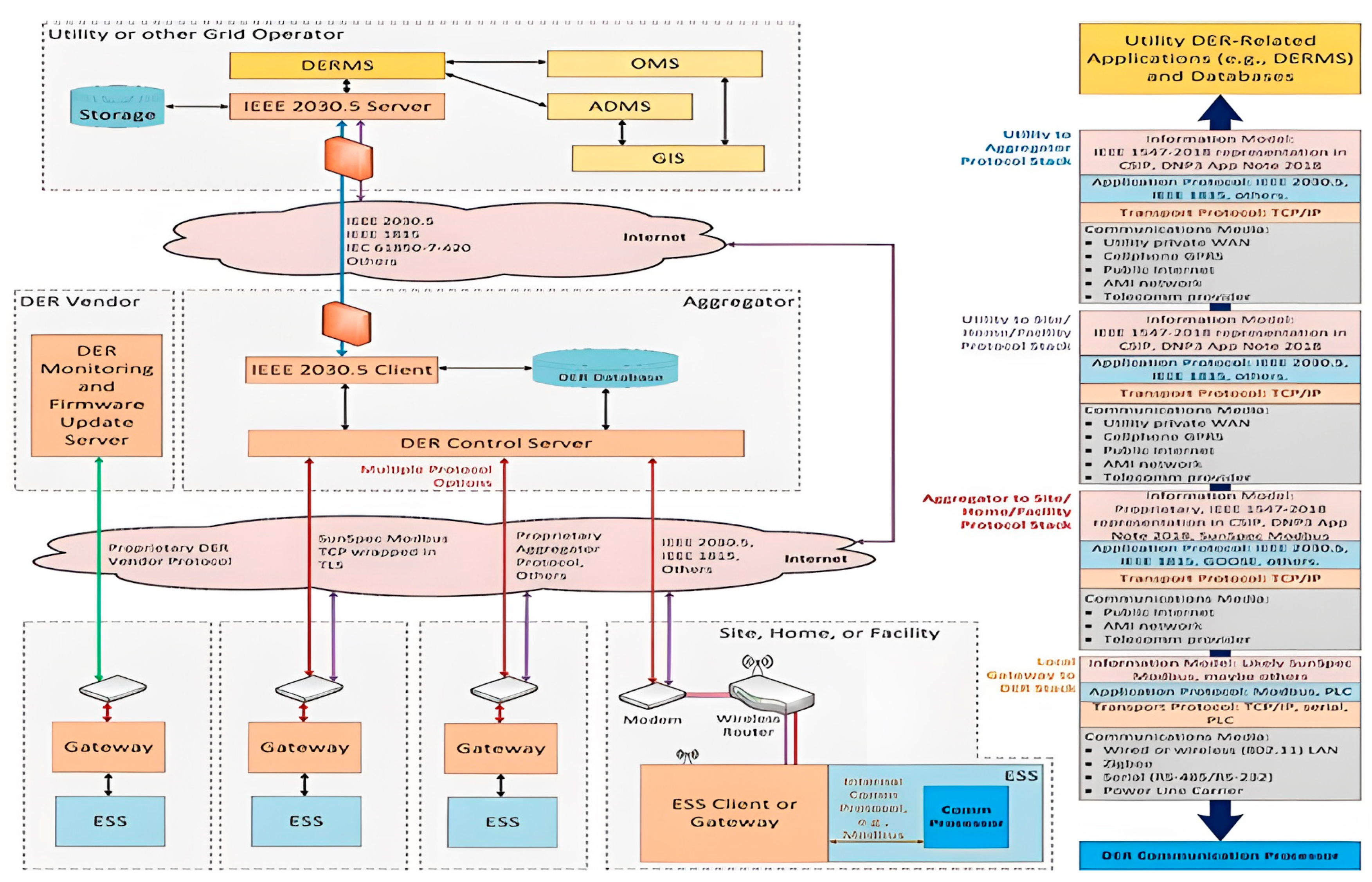

3.3.1. Centralized and Decentralized Integration Models

3.3.2. Direct and Indirect Grid Connection

3.3.3. Hybrid Integration Approaches

3.3.4. Role of Smart Grid Technologies, Communication Protocols, and Cybersecurity

- Primary Control: Provides immediate response to frequency fluctuations.

- Secondary Control: Balances power flows across interconnected systems.

- Tertiary Control: Manages economic dispatch and optimizes system-wide operations [122].

3.4. Hybrid Energy Storage Systems (HESSs)

3.4.1. Overview of Hybrid ESS Configurations

- Battery–Supercapacitor Systems: Combine the high energy density and long-term storage capability of lithium-ion or lead–acid batteries with the rapid charge–discharge performance of supercapacitors. Such configurations can capture transient surges and reduce degradation in batteries by offloading peak power demands [128,129].

- Hydrogen-Based Systems: Integrate hydrogen fuel cells with conventional batteries, offering very high energy density for long-term storage. While hydrogen production and storage incur additional costs, the approach enables seasonal storage and grid stabilization over extended periods [132].

- Hybrid Nanofluid Systems: Utilize advanced nanofluids to store thermal energy with high conductivity and responsiveness. These systems are emerging in industrial cooling applications and can be tuned for specific thermal management needs [133].

3.4.2. Quantitative Comparison of HESSs

3.4.3. Applications of HESSs

3.4.4. Challenges in Implementing HESS

3.5. Performance Analysis of Integrated ESS

3.5.1. Technical Performance Metrics

- Storage Capacity: Measured in kilowatt-hours (kWh) or megawatt-hours (MWh), storage capacity indicates the total energy available for discharge. For example, a 1 MW/4 MWh system provides a four-hour discharge at full power. This metric is critical for applications ranging from short-term frequency regulation to seasonal storage [86,135].

- Power Rating: Expressed in kilowatts (kW) or megawatts (MW), power rating reflects the maximum rate at which energy can be charged or discharged. High power ratings are particularly important for grid services requiring rapid response, such as voltage support and frequency regulation. The ratio of power rating to storage capacity also defines the discharge duration, providing a direct measure of system responsiveness [136].

- Round-Trip Efficiency: This is defined as the ratio of energy delivered during discharge to the energy used during charging. For instance, lithium-ion systems typically achieve efficiencies of 90–95%, while pumped hydro systems may operate at 70–85%. High round-trip efficiency minimizes energy losses and maximizes economic benefits [5].

- Response Time: Response time, which includes both activation time (time to initiate a charge/discharge) and settling time (time to reach the desired output), is vital for applications such as frequency regulation. Technologies like supercapacitors and flywheels can respond in seconds, whereas others may require several minutes [137].

- Cycle Life: Cycle life represents the number of full charge–discharge cycles an ESS can undergo before its performance degrades below a specified threshold. For example, lithium-ion batteries may provide between 2000 and 5000 cycles, while flow batteries can exceed 10,000 cycles. A longer cycle life directly contributes to improved economic viability [138].

- Self-Discharge Rate: This metric quantifies the energy lost when an ESS is idle. Low self-discharge is especially important for long-duration storage, ensuring that minimal energy is wasted over time [69].

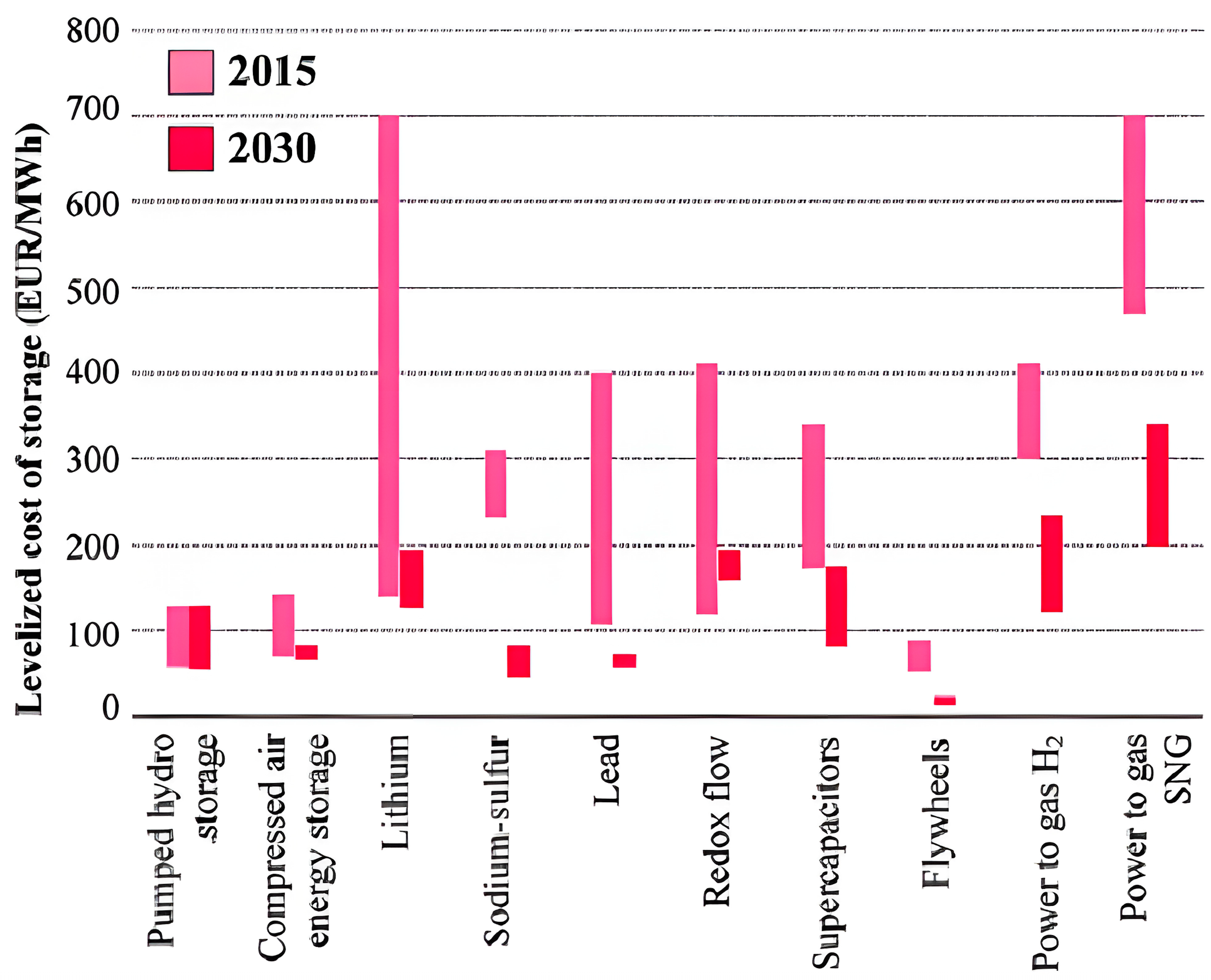

3.5.2. Economic Viability

- Capital Expenditure (CAPEX): CAPEX includes all upfront costs required to procure, install, and commission an ESS. For instance, recent studies indicate that lithium-ion battery systems now have CAPEX in the range of USD 300–USD 600 per kWh, while large-scale systems like pumped hydro storage may have higher initial costs but benefit from economies of scale.

- Operational Expenditure (OPEX): OPEX encompasses recurring costs such as maintenance, component replacement, and energy consumption for auxiliary systems (e.g., cooling and ventilation). Lithium-ion systems generally incur lower O&M costs—often around 1–2% of CAPEX annually—compared to more complex systems like hydrogen-based storage, which may require higher operational investments.

- Energy Costs and Revenue Streams: ESS economic performance is also influenced by the cost of charging during off-peak hours versus the revenue generated by discharging during peak demand. This price spread, along with revenue from ancillary services (e.g., frequency regulation, voltage support) and capacity market participation, is critical for determining overall profitability.

- Financial Metrics are used to evaluate the economic performance of ESS investments. These include the following:

- (a)

- Net Present Value (NPV): The present value of all future cash flows, discounted to the present time. A positive NPV indicates a profitable investment.

- (b)

- Internal Rate of Return (IRR): The discount rate at which the NPV of the project is equal to zero. An IRR higher than the required rate of return makes the investment attractive.

- (c)

- Payback period: The time it takes for the cumulative cash flows to equal the initial investment. A shorter payback period indicates a quicker return on investment.

- (d)

- Levelized Cost of Storage (LCOS): The average cost of storing one unit of energy over the lifetime of the ESS. This metric allows for comparing different storage technologies on a common basis. For example, advanced lithium-ion systems often report LCOS values of 8–12 cents per kWh, while hydrogen-based systems may exhibit an LCOS above 15 cents per kWh due to lower round-trip efficiencies [43,75,139].

3.6. Case Studies of Successful IESS Implementations

- Hornsdale Power Reserve (Australia):

- Leighton Buzzard (UK):

- Notrees Wind Farm (USA):

| Technology | Storage Capacity | Round-Trip Efficiency (%) | Response Time | Cycle Life (Cycles) | Typical DOD (%) | Self-Discharge (%/Day) |

|---|---|---|---|---|---|---|

| Lithium-Ion Battery [52,53] | 100–250 Wh/kg | 90–95 | <10 sec | 2000–5000 | 80–100 | <1% |

| Pumped Hydro | ~1–2 kWh/m3 | 70–85 | Minutes | >20,000 | 50–80 | N/A |

| Flow Battery [49] | 20–50 Wh/L | 70–85 | Seconds–Minutes | >10,000 | 80–90 | <2% |

| Supercapacitor [39,109] | 5–10 Wh/kg | 95–98 | <1 sec | >1,000,000 | 100 | 2–5% |

| Flywheel [64,65] | 10–20 Wh/kg | 85–90 | <5 sec | >100,000 | 100 | Negligible |

| Technology | CAPEX (USD/kWh) | OPEX (% of CAPEX per Year) | ROI (Years) | LCOS (Cents/kWh) |

|---|---|---|---|---|

| Lithium-Ion Battery | USD 300–USD 600 | 1–2% | 7–10 | 8–12 |

| Pumped Hydro | USD 200–USD 400 | 1–3% | 15–20 | 10–15 |

| Flow Battery | USD 400–USD 800 | 2–4% | 10–15 | 12–18 |

| Supercapacitor | USD 800–USD 1200 | 1–2% | 8–12 | 15–20 |

| Flywheel | USD 700–USD 900 | <1% | 8–10 | 9–13 |

| Hydrogen-Based | USD 800–USD 1000 (equiv.) | 3–5% | >10 | 12–16 |

- Other Emerging Market Examples:

3.7. Challenges and Emerging Trends in IESS Deployment

3.7.1. Key Challenges in Grid Integration

- Cost and Economic Viability: High capital expenditures (CAPEX) remain one of the primary challenges in IESS deployment. Despite recent declines in battery costs, technologies such as advanced lithium-ion, redox flow, and hydrogen-based storage still require significant upfront investments. These costs are further compounded by the need for supporting infrastructure and control systems, which can vary widely depending on the scale and location of the project [83,114].

- Regulatory Barriers: A fragmented regulatory landscape poses significant obstacles for IESS integration. Inconsistent standards and policies across regions can delay project approvals and complicate financing. Additionally, many regions lack clear guidelines for the participation of energy storage in ancillary service markets, which reduces potential revenue streams and discourages investment [85,98].

- Interoperability and Integration Complexity: As IESSs are increasingly integrated with renewable energy sources and smart grid technologies, ensuring interoperability between diverse systems becomes critical. Variations in communication protocols, control architectures, and legacy grid infrastructure can impede seamless integration, necessitating sophisticated control algorithms and robust communication networks to coordinate operation across multiple storage assets [76].

3.7.2. Advancements in Energy Storage Technologies

- Next-Generation Batteries and Solid-State Storage: Recent developments in battery technology, such as solid-state batteries, promise higher energy densities, improved safety, and longer cycle lives compared to conventional lithium-ion systems. Solid-state storage, with its reduced flammability and enhanced thermal stability, is poised to become a game changer for grid-scale applications [148].

- AI-Driven Grid Management and Digital Twin Technologies: Advances in artificial intelligence and machine learning are being leveraged to optimize the operation and maintenance of IESS. AI-driven grid management systems can predict demand fluctuations, optimize energy dispatch, and even forecast potential component failures. Digital twin technologies, which create virtual replicas of physical ESS assets, enable real-time monitoring and predictive maintenance, thereby improving reliability and reducing downtime [143].

- Enhanced Power Electronics and Control Systems: Modern power electronics, including advanced bidirectional converters and inverters, are essential for improving the efficiency and flexibility of ESS integration. New control strategies that employ hierarchical management structures and real-time communication protocols are being developed to ensure the seamless interaction between IESSs and the grid, ultimately enhancing overall system performance [28,109].

- Integration of Renewable Forecasting and Energy Markets: Emerging trends also include improved renewable energy forecasting, which allows storage systems to better anticipate fluctuations in generation. Coupled with innovative energy market models and dynamic pricing mechanisms, these advancements enable IESSs to participate more effectively in energy arbitrage and ancillary service markets, thus improving the economic case for storage deployment [21,115].

4. Implementation Strategy and Multi-Criteria Evaluation Framework

4.1. Policy and Implementation Strategies

4.1.1. Policy Recommendations

4.1.2. Regional Implementation Roadmaps

4.1.3. Actionable Steps for Stakeholders

4.1.4. Addressing Equity and Just Transition

4.2. Multi-Criteria Evaluation Framework for Optimizing IESS Deployment

4.2.1. Criteria Identification and Weighting

4.2.2. Aggregation and Normalization Methods

4.2.3. Validation Through Case Studies

4.2.4. Dynamic Adaptation and Sensitivity Analysis

4.2.5. Implementation Guidelines for Stakeholders

4.3. Limitations and Assumptions

4.3.1. Key Assumptions

- Uniform Regulatory Adoption: The framework assumes that policymakers can harmonize fragmented regulations (e.g., ancillary service market rules) across regions. However, as highlighted in the analysis of Cyprus’s insular energy system, regulatory gaps and monopolistic practices in emerging markets may delay standardization [144].

- Stakeholder Representativeness: The MCDA framework assumes that stakeholder input (e.g., weightings for criteria like the LCOS or resilience) is representative and unbiased. In reality, cognitive biases in eliciting trade-offs—such as framing effects or groupthink—can skew priorities, as noted in studies on MCDA methodologies [125].

- Static Cost Projections: Economic metrics like CAPEX (USD 300–USD 1200/kWh) and the LCOS (8–20 cents/kWh) are based on current technology trends. These projections assume linear cost reductions, overlooking potential disruptions (e.g., raw material shortages or geopolitical risks to cobalt supply chains) [113].

4.3.2. Methodological Limitations

- Synergy Quantification: The framework assigns synergy bonuses (e.g., 15% technical improvement for hybrid systems) based on pilot projects. However, long-term performance data for such configurations remain sparse, risking the overestimation of benefits in large-scale deployments [145].

- Dynamic Adaptation Constraints: While sensitivity analysis accounts for cost reductions (e.g., 20% CAPEX decline boosting lithium-ion viability), it assumes machine learning models can reliably predict future policy or market shifts. Historical data gaps in regions like sub-Saharan Africa limit algorithmic accuracy [13].

- Environmental Metric Simplification: Lifecycle emissions (e.g., 50–150 kg CO2-eq/MWh for lithium-ion) aggregate upstream and operational impacts but exclude indirect effects like land-use changes for mining, which are critical in holistic sustainability assessments [113].

4.3.3. Validation Challenges

- Case Study Generalizability: Retrospective validation using projects like Hornsdale (Australia) and KIUC (Hawaii) assumes these systems are broadly representative. However, island grids with high renewable penetration face unique challenges (e.g., cyclability demands) that may not translate to continental grids [145].

- Data Availability: Emerging markets often lack granular data on grid reliability indices or demand response potential, complicating LCOS calculations and regional prioritization [146].

4.3.4. Supporting References

- Regulatory and Technical Gaps: The Springer study on Cyprus’s energy storage challenges underscores the difficulty of standardizing policies in insular systems, aligning with the framework’s assumption limitations [134].

- MCDA Methodological Pitfalls: The health economics critique of MCDA highlights risks in stakeholder bias and non-orthogonal criteria, directly relevant to the framework’s weighting process [135].

- Optimization Realism: The capacity optimization study in smart parks emphasizes the need to balance carbon flow and demand response, validating the framework’s technical assumptions while exposing gaps in synergy quantification [145].

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pérez-Díaz, J.I.; Chazarra, M.; García-González, J. Renewable energy integration: Challenges and solutions for a sustainable future. Renew. Sustain. Energy Rev. 2021, 145, 111446. [Google Scholar]

- Lund, H.; Mathiesen, B.V. Energy system analysis of 100% renewable energy systems. Appl. Energy 2009, 86, 794–803. [Google Scholar]

- U.S. Department of Energy. Solar Energy Technologies. Available online: https://www.energy.gov/eere/solar/solar-energy-technologies-office (accessed on 6 July 2023).

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Renew. Sustain. Energy Rev. 2015, 41, 436–445. [Google Scholar] [CrossRef]

- Chen, H.; Cong, T.N.; Yang, W.; Tan, C.; Li, Y. Progress in electrical energy storage system: A critical review. Energy 2019, 187, 115001. [Google Scholar] [CrossRef]

- Zakeri, B.; Syri, S. Electrical energy storage systems: A comparative life cycle cost analysis. Renew. Sustain. Energy Rev. 2015, 42, 569–596. [Google Scholar]

- Kittner, N.; Lill, F.; Kammen, D.M. Energy storage deployment and innovation for the clean energy transition. Nat. Energy 2017, 2, 17125. [Google Scholar] [CrossRef]

- Blakers, A.; Lu, B.; Stocks, M. 100% renewable electricity in Australia. Energy 2018, 133, 471–482. [Google Scholar]

- Yang, Y.; Bremner, S.; Menictas, C.; Kay, M. Battery energy storage system size determination in renewable energy systems: A review. Renew. Sustain. Energy Rev. 2020, 91, 109982. [Google Scholar]

- IEA. Energy Storage; IEA—International Energy Agency: Paris, French, 2023. [Google Scholar]

- National Renewable Energy Laboratory (NREL). Renewable Electricity Futures Study | Energy Analysis | NREL. 2018. Available online: https://www.nrel.gov/analysis/re-futures.html (accessed on 15 January 2025).

- Eberhard, A.; Gratwick, K.; Morella, E.; Antmann, P. Independent power projects in sub-Saharan Africa: Investment trends and policy lessons. Energy Policy 2018, 120, 394–408. [Google Scholar] [CrossRef]

- Schmidt, O.; Melchior, S.; Hawkes, A.; Staffell, I. Projecting the future levelized cost of electricity storage technologies. Joule 2019, 3, 81–100. [Google Scholar] [CrossRef]

- Hossain, E.; Faruque, H.M.R.; Sunny, M.S.; Sami, N.M.; Nawar, N. A Comprehensive Review on Energy Storage Systems: Types, Comparison, Current Scenario, Applications, Barriers, and Potential Solutions, Policies, and Future Prospects. Energies 2020, 13, 3651. [Google Scholar] [CrossRef]

- International Energy Agency. International Energy Agency (IEA) World Energy Outlook. 2022. Available online: https://www.iea.org/reports/world-energy-outlook-2022/executive-summary (accessed on 16 January 2025).

- Guney, M.S.; Tepe, Y. Classification and assessment of energy storage systems. Renew. Sustain. Energy Rev. 2017, 75, 1187–1197. [Google Scholar]

- Krishan, O.; Suhag, S. An updated review of energy storage systems: Classification and applications in distributed generation power systems incorporating renewable energy resources. Int. J. Energy Res. 2018, 43, 6171–6210. [Google Scholar]

- Sterner, M.; Bauer, F. Definition and Classification of Energy Storage Systems. Energy Storage Syst. 2019, 1, 23–47. [Google Scholar]

- Kandhasamy, M.; Duvaragan, B.K. An Overview on Classification of Energy Storage Systems. ACS Symp. Ser. 2024, 1, 1–25. [Google Scholar]

- Lin, J.; Zhao, Q.; Huang, H.; Mao, H.; Liu, Y.; Xiao, Y. Applications of low-temperature thermochemical energy storage systems for salt hydrates based on material classification: A review. Sol. Energy 2021, 214, 149–178. [Google Scholar]

- Enasel, E.; Dumitrascu, G. Storage solutions for renewable energy: A Review. Energy Nexus 2025, 17, 100391. [Google Scholar] [CrossRef]

- Haddad, M.; Javani, N.; Rezaie, B. Energy storage management using Li-ion, lead-acid, flywheel, and photovoltaic systems integrated to a near zero energy building using TRNSYS simulation. Process Saf. Environ. Prot. 2025, 196, 106898. [Google Scholar] [CrossRef]

- Deshmukh, K.; Varade, K.; Rajesh, S.M.; Sharma, V.; Kabudake, P.; Nehe, S.; Lokawar, V. Sodium-ion batteries: State-of-the-art technologies and future prospects. J. Mater. Sci. 2025, 60, 3609–3633. [Google Scholar] [CrossRef]

- Bonilla, O.; Le, H.T. Multi-functional energy storage system for supporting solar PV plants and host power distribution system. J. Energy Storage 2023, 73, 108933. [Google Scholar] [CrossRef]

- Zhang, H.; Baeyens, J.; Cáceres, G.; Degrève, J.; Lv, Y. Thermal energy storage: Recent developments and practical aspects. Prog. Energy Combust. Sci. 2016, 2, 1–40. Available online: https://consensus.app/papers/thermal-energy-storage-recent-developments-and-practical-zhang-baeyens/1d8b267a4a875221a950d0293c0968ea (accessed on 1 March 2016).

- Gautam, K.R.; Andresen, G.B.; Victoria, M. Review and techno-economic analysis of emerging thermo-mechanical energy storage technologies. Energies 2022, 15, 6328. [Google Scholar] [CrossRef]

- Salkuti, S.R. Techno-economic analysis of renewable energy, storage, and electric vehicles for sustainable development. Energies 2025, 18, 238. [Google Scholar] [CrossRef]

- Pengonda, H.B.; Rotte, N.K.; Puttapati, S.K.; Yerramala, S. Developing Energy Storage Applications for Next Generation; Spinger: Berlin/Heidelberg, Germany, 2024; pp. 297–317. [Google Scholar] [CrossRef]

- McLeod, W.T.; Sheelam, A.; Kroiss, A.K.; Bell, J.G. Affecting the Electropolymerization of Aniline with Permanent Magnets. ECS Meet. Abstr. 2024, MA2024-01, 128. [Google Scholar] [CrossRef]

- Mahmoud, M.; Ramadan, M.; Olabi, A.G.; Pullen, K. A review of mechanical energy storage systems combined with wind and solar applications. Energy Convers. Manag. 2020, 210, 112670. [Google Scholar]

- Rehman, S.; Al-Hadhrami, L.M.; Alam, M.D.M. Pumped Hydro Energy Storage System: A Technological Review. Renew. Sustain. Energy Rev. 2015, 44, 586–598. [Google Scholar]

- Deane, J.P.; Gallachóir, B.Ó.; McKeogh, E.J. Techno-economic Review of Existing and New Pumped Hydro Energy Storage Plant. Renew. Sustain. Energy Rev. 2010, 14, 1293–1302. [Google Scholar]

- Vilanova, M.R.N.; Flores, A.T.; Balestieri, J.A.P. Pumped Hydro Storage Plants: A Review. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 415. [Google Scholar]

- National Renewable Energy Laboratory. Pumped Storage Hydropower Electricity 2022—ATB. 2022. Available online: https://atb.nrel.gov/electricity/2022/pumped_storage_hydropower (accessed on 15 January 2025).

- Amirante, R.; Cassone, E.; Distaso, E. Overview on recent developments in energy storage: Mechanical, electrochemical and hydrogen technologies. Energy Convers. Manag. 2017, 132, 372–387. [Google Scholar]

- U.S. Department of Energy. Compressed-Air Energy Storage Technology Strategy Assessment. 2023. Available online: https://www.energy.gov/sites/default/files/2023-07/Technology%20Strategy%20Assessment%20-%20Compressed%20Air%20Energy%20Storage_0.pdf (accessed on 3 January 2025).

- Matos, C.R.; Silva, P.P.; Carneiro, J.F. Overview of Compressed Air Energy Storage Projects and Regulatory Framework for Energy Storage. J. Energy Storage 2022, 55, 105862. [Google Scholar] [CrossRef]

- Amirlatifi, A.; Vahedifard, F.; Degtyareva, M.; Esposito, R.A. Reusing Abandoned Natural Gas Storage Sites for Compressed Air Energy Storage. Energy Procedia 2021, 155, 323–330. [Google Scholar] [CrossRef]

- Liu, C.; Su, X.; Yin, Z.; Sheng, Y.; Zhou, X.; Chen, H. Experimental Study on the Feasibility of Isobaric Compressed Air Energy Storage as a Wind Power Side Energy Storage Solution. Appl. Energy 2024, 364, 123129. [Google Scholar] [CrossRef]

- Raju, M.; Khaitan, S.K. Modeling and Simulation of Compressed Air Storage in Caverns: A Case Study of the Huntorf Plant. Appl. Energy 2012, 89, 474–481. [Google Scholar] [CrossRef]

- Sabihuddin, S.; Kiprakis, A.E.; Mueller, M. A numerical and graphical review of energy storage technologies. Energies 2015, 8, 172–216. [Google Scholar] [CrossRef]

- Li, X.-S.; Liang, J.; Cao, X.; Zhu, S.-Y.; Bai, Y.-F.; Sun, J.-W.; Luo, H.-B.; Kong, J. Research progress of inorganic solid electrolyte materials for all-solid-state sodium-ion batteries. Rare Met. 2025, 1, 1–29. [Google Scholar] [CrossRef]

- Li, D.; Mo, Z.; Fane, A.G.; She, Q. Improving both energetic and kinetic performances of osmotic battery for grid energy storage. Desalination 2024, 597, 118389. [Google Scholar] [CrossRef]

- Reddy Salkuti, S. Overview and tools of asset management in renewable energy based smart grid. Int. J. Electr. Comput. Eng. 2018, 8, 2849–2856. [Google Scholar] [CrossRef]

- Olympios, A.V.; McTigue, J.D.; Farres-Antunez, P. Progress and prospects of thermo-mechanical energy storage—A critical review. J. Phys. Energy 2021, 3, 022001. [Google Scholar] [CrossRef]

- Steinmann, W.D. Thermo-mechanical concepts for bulk energy storage. Renew. Sustain. Energy Rev. 2017, 75, 205–219. [Google Scholar] [CrossRef]

- NASA. Liquid Hydrogen Storage for Aerospace Applications. 2020. Available online: https://ntrs.nasa.gov/citations/20200005196 (accessed on 5 January 2025).

- Ayeng’o, S.P.; Kimambo, C.Z.M. Selection of Electrochemical and Electrical Energy Storage Systems for Off-Grid Renewable Energy Mini-Grids: A Review. Clean. Eng. Technol. 2025, 14, 100029. [Google Scholar]

- Zuo, Y.; Fu, W.; Leung, P.; Wondimu, T.H.; Mohamed, M.R.; Flox, C.; Shah, A.; Xu, Q.; Liao, Q. Sustainable Recycling and Regeneration of Redox Flow Battery Components. Future Batter. 2025, 5, 100044. [Google Scholar] [CrossRef]

- McConnell, D. Grid stabilisation through lithium-ion battery storage: A South Australian case study. Renew. Sustain. Energy Rev. 2020, 109, 109382. [Google Scholar] [CrossRef]

- Biswas, R.; Dutta, A.; Barman, M.; Pal, M. A Comprehensive Review of Metal-Air Batteries: Mechanistic Aspects, Advantages, and Challenges. Catal. Today 2025, 408, 471. [Google Scholar]

- Ren, H.; McCulloch, M.; Wallom, D. Optimal sizing of solar photovoltaic and lithium battery storage to reduce grid electricity reliance in buildings. arXiv 2023, arXiv:2306.03581. [Google Scholar]

- Kim, H.W.; Son, Y. Two-Phase Electrolytes for Lithium Metal Batteries. Korean J. Chem. Eng. 2025, 42, 395–421. [Google Scholar]

- Kale, A.; Reddy, B.; Kumar, V. Voice-based commands for energy management in IoT-enabled smart meters. Int. J. Smart Technol. 2021, 12, 65–78. [Google Scholar]

- Ahmed, M.A.; Reddy, K.S.; Prakash, J.; Rai, A.; Singh, B. Statistical analysis of load and its frequency response for load forecasting in a medium voltage distribution system. In Proceedings of the 2017 International Conference on Energy, Communication, Data Analytics and Soft Computing (ICECDS), Chennai, India, 1–2 August 2017. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Zhang, Q.; Chen, H. A Comprehensive Review of Cost Reduction Strategies in Lithium-Ion Battery Manufacturing. J. Energy Storage 2023, 50, 105034. [Google Scholar]

- Kim, S.; Park, J.; Lee, D. Thermal Management and Safety Considerations in Large-Scale Lithium-Ion Battery Systems. J. Clean. Prod. 2023, 400, 137770. [Google Scholar] [CrossRef]

- Cole, W.; Karmakar, A. Cost Projections for Utility-Scale Battery Storage: 2023 Update. 2023. Available online: https://www.nrel.gov/docs/fy23osti/85332.pdf (accessed on 5 January 2025).

- Ziegler, M.S.; Trancik, J.E. Re-examining rates of lithium-ion battery technology improvement and cost decline. Energy Environ. Sci. 2021, 14, 1635–1651. [Google Scholar]

- Palomares, V.; Casas-Cabanas, M.; Castillo-Mart’inez, E.; Han, M.H.; Rojo, T. Update on Na-ion batteries: Status, challenges and future trends. Energy Environ. Sci. 2013, 6, 2312–2337. [Google Scholar] [CrossRef]

- Slater, M.D.; Kim, D.; Lee, E.; Johnson, C.S. Sodium-ion batteries. Adv. Funct. Mater. 2013, 23, 947–958. [Google Scholar]

- Gao, Y.; Yu, Q.; Yang, H.; Zhang, J.; Wang, W. The Enormous Potential of Sodium/Potassium-Ion Batteries as the Mainstream Energy Storage Technology for Large-Scale Commercial Applications. Adv. Mater. 2024, 36, 2405989. [Google Scholar]

- Zhao, Q.; Li, Y.; Chen, H. Recent advances in sodium-ion batteries for stationary energy storage applications. J. Power Sources 2023, 546, 1–23. [Google Scholar]

- Zhang, W.; Zhang, F.; Ming, F.; Alshareef, H.N. Sodium-ion battery anodes: Status and future trends. EnergyChem 2019, 1, 100012. [Google Scholar] [CrossRef]

- Han, J.; Lee, H.; Park, S. Visualising energy consumption data for non-technical users in IoT-based smart meters. Appl. Energy 2021, 290, 1–27. [Google Scholar]

- May, G.J.; Davidson, A.; Monahov, B. Lead batteries for utility energy storage: A review. J. Energy Storage 2018, 16, 186–200. [Google Scholar]

- Wang, Y.; Li, X.; Chen, Z. Advanced lead–acid battery technology for stationary energy storage: A review. Renew. Sustain. Energy Rev. 2016, 63, 750–764. [Google Scholar]

- Mohammad, S.; Khodabakhshian, A.; Salari, M.M. Environmental impact assessment of lead–acid batteries: A critical review. J. Hazard. Mater. 2020, 387, 121701. [Google Scholar]

- U.S. Environmental Protection Agency. Toxicological Profile for Lead. 2020. Available online: https://www.atsdr.cdc.gov/toxprofiles/tp13.pdf (accessed on 15 January 2025).

- Sun, C.; Zhang, Z.; Ding, Y.; Li, C. Recent progress in vanadium redox flow batteries for energy storage. J. Energy Storage 2018, 18, 234–250. [Google Scholar]

- Zhang, W.; Chen, L.; Guo, X. Scaling-up vanadium redox flow batteries for grid storage applications: A review. Renew. Sustain. Energy Rev. 2020, 119, 109556. [Google Scholar]

- Li, M.; Liu, Q.; Li, W. Recent advances in zinc–bromine flow batteries for energy storage: A review. Electrochim. Acta 2019, 301, 123–135. [Google Scholar]

- Choi, D.; Lee, H.; Park, H. Techno-economic analysis of flow battery systems for large-scale energy storage. Appl. Energy 2019, 235, 141–150. [Google Scholar]

- Wang, J.; Xu, F. Challenges and prospects for flow battery commercialization in grid-scale energy storage. Energy Convers. Manag. 2021, 243, 1–24. [Google Scholar]

- Goel, P. Aluminum-air batteries: A viability review. J. Energy Storage 2020, 28, 101258. [Google Scholar]

- Sherman, S.B.; Cano, Z.P.; Fowler, M.; Chen, Z. Range-extending zinc–air battery for electric vehicle. AIMS Energy 2018, 6, 121–145. [Google Scholar] [CrossRef]

- Li, Y.; Gong, M.; Liang, Y.; Feng, J.; Kim, J.E. Advanced zinc–air batteries based on high-performance hybrid electrocatalysts. Nat. Commun. 2019, 10, 1805. [Google Scholar] [CrossRef]

- Park, I.-J.; Choi, H.; Kim, D. Aluminum anode for aluminum–air battery—Part II: Influence of indium addition on the electrochemical characteristics of Al–Zn alloy in alkaline solution. J. Power Sources 2017, 343, 144–150. [Google Scholar] [CrossRef]

- Mutlu, R.N.; Yazıcı, N. Copper-deposited aluminum anode for aluminum–air battery. J. Solid State Electrochem. 2019, 23, 393–400. [Google Scholar] [CrossRef]

- Shin, D.; Lee, J.; Kim, S. Chemical energy storage systems for grid-scale applications: An overview of technologies and challenges. Renew. Sustain. Energy Rev. 2020, 119, 109552. [Google Scholar]

- Goodenough, J.B.; Kim, Y. Challenges for rechargeable Li batteries. Chem. Mater. 2018, 30, 3483–3495. [Google Scholar] [CrossRef]

- Khan, M.J.; Chen, Y.; Zhang, S. Recent advancements in vanadium redox flow batteries for grid-scale energy storage: A review. Renew. Sustain. Energy Rev. 2020, 122, 109710. [Google Scholar] [CrossRef]

- Recknagel, S.; Baumer, M.; Winter, M. Sustainable lithium extraction and recycling: Challenges and perspectives. Nat. Sustain. 2020, 3, 354–362. [Google Scholar]

- Liu, J.; Li, Y.; Chen, L. Recent advances in sodium-ion batteries: Materials, design and performance. J. Mater. Chem. A Mater. 2019, 7, 17341–17360. [Google Scholar]

- Haider, M.; Khan, S.; Mahmood, A. Emerging sodium-ion battery technologies for grid storage: Performance and challenges. Energy Storage Mater. 2021, 35, 409–428. [Google Scholar]

- Bai, Y.; Zhou, Y.; Wang, J. Recent advances in vanadium redox flow batteries for large-scale energy storage. J. Energy Storage 2019, 25, 100–115. [Google Scholar] [CrossRef]

- Dash, R.; Kumar, P.; Singh, A. Liquid hydrogen storage: Advances in cryogenic technologies and challenges. Int. J. Hydrogen Energy 2020, 45, 8900–8912. [Google Scholar] [CrossRef]

- Haider, R.; Sagadevan, S.; Cameron, N.R. Biomass-Derived Activated Carbon for High-Performance Energy Storage Devices. J. Power Sources 2025, 550, 240X. [Google Scholar]

- Mohammed, S.; Li, X.; Zhang, Y. Advances in metal hydride-based solid-state hydrogen storage: Materials, kinetics, and prospects. J. Alloys Compd. 2020, 832, 154995. [Google Scholar]

- Yang, J.; Zhang, X. Challenges in solid-state hydrogen storage: Kinetics and reversibility. Energy Storage Mater. 2019, 23, 34–45. [Google Scholar] [CrossRef]

- Phogat, A.; Sharma, R.; Gupta, S. Renewable ammonia synthesis: A sustainable pathway for synthetic fuels. ACS Sustain. Chem. Eng. 2018, 6, 3452–3461. [Google Scholar]

- Biswas, S.; Paul, S.; Chatterjee, S. Power-to-liquid technologies: Advances in CO2 hydrogenation for methanol synthesis. Energy Convers. Manag. 2019, 198, 111–123. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Q.; Wei, Y.M.; Li, Z.P. Role of renewable energy in China’s energy security and climate change mitigation: An index decomposition analysis. Renew. Sustain. Energy Rev. 2018, 90, 187–194. [Google Scholar] [CrossRef]

- Soni, V.; Panwar, N.L. Advancements in Thermal Energy Storage for Efficient Energy Management. Energy Rep. 2019, 5, 190–203. [Google Scholar] [CrossRef]

- Jouhara, H.; Żabnieńska-Góra, A.; Khordehgah, N.; Ahmad, D.; Lipinski, T. Latent thermal energy storage technologies and applications: A review. Int. J. Thermofluids 2020, 5, 100039. [Google Scholar] [CrossRef]

- Khor, J.O.; Yang, L.; Akhmetov, B.; Leal, A.B.; Romagnoli, A. Application of granular materials for void space reduction within packed bed thermal energy storage system filled with macro-encapsulated phase change materials. Energy Convers. Manag. 2020, 222, 113118. [Google Scholar] [CrossRef]

- Palomba, V.; Frazzica, A. Comparative analysis of thermal energy storage technologies through the definition of suitable key performance indicators. Energy Build. 2019, 185, 88–102. [Google Scholar] [CrossRef]

- Deepak, K.; Behura, S.K. Review on Sensible Heat Storage Systems for Solar Thermal Applications. Sol. Energy 2019, 184, 213–224. [Google Scholar] [CrossRef]

- Han, J.; Lu, J. Improving Thermal Conductivity in Phase Change Materials for Latent Heat Storage. J. Mater. Sci. 2018, 53, 5674–5685. [Google Scholar]

- Chang, Y.; Storage, T.E. Systems, and Applications. J. Energy Chem. 2019, 38, 45–56. [Google Scholar] [CrossRef]

- Steinmann, W.D.; Prieto, C. Thermal Storage for Concentrating Solar Power Plants; Elsevier eBooks: Amsterdam, The Netherlands, 2021; Volume 3, pp. 673–697. [Google Scholar] [CrossRef]

- Rahbari, H.R.; Elmegaard, B.; Bellos, E.; Tzivanidis, C.; Arabkoohsar, A. Thermochemical technologies for industrial waste heat recovery: A comprehensive review. Renew. Sustain. Energy Rev. 2025, 215, 115598. [Google Scholar] [CrossRef]

- Jamali, A.; Li, X.; Wang, Y.; Zhao, H. A comprehensive review on electrical energy storage systems: Technologies and applications. J. Energy Storage 2020, 29, 101235. [Google Scholar]

- Guo, S.; Zhang, Y. Electrical energy storage: Principles, technologies, and applications. Energy Storage Mater. 2021, 34, 129–146. [Google Scholar] [CrossRef]

- Núñez-Gutiérrez, J.; Morales, M.; Garcia, R. Graphene-based supercapacitors: Recent progress and perspectives. Carbon. N. Y. 2019, 145, 199–222. [Google Scholar] [CrossRef]

- Wang, G.; Li, Y.; Chen, H. Recent advances in pseudocapacitive materials for high-performance energy storage. Nano Energy 2020, 70, 104527. [Google Scholar] [CrossRef]

- Manzo, F.; Rinaldi, M.; Spadaccini, C. Superconducting magnetic energy storage for grid applications. Supercond. Sci. Technol. 2018, 31, 43001. [Google Scholar]

- Aklujkar, M.; Choi, J.; Lee, S. High-energy density dielectric capacitors: Materials and design strategies. Adv. Mater. 2019, 31, 1805502. [Google Scholar]

- Maruf, M.N.I.; Morales-España, G.; Sijm, J.; Helistö, N.; Kiviluoma, J. Classification, potential role, and modelling of power-to-heat and thermal energy storage in energy systems: A review. Sustain. Energy Technol. Assess. 2022, 53, 102553. [Google Scholar]

- Sahoo, S.; Timmann, P. Energy Storage Technologies for Modern Power Systems: A Detailed Analysis of Functionalities, Potentials, and Impacts. IEEE Access 2023, 11, 12345–12360. [Google Scholar] [CrossRef]

- Phogat, P.; Chand, B.; Jha, R. Hydrogen and Methanol Fuel Cells: A Comprehensive Analysis of Challenges, Advances, and Future Prospects in Clean Energy. Int. J. Hydrogen Energy 2025, 60, 6998. [Google Scholar]

- Nasir, M.; Iqbal, S.; Khan, H.; Vasquez, J.C.; Guerrero, J. Sustainable Rural Electrification Through Solar PV DC Microgrids-An Architecture-Based Assessment. Processes 2020, 8, 1417. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Y. Energy strategy reviews for grid stability and renewable integration. Energy Strategy Rev. 2025, 50, 103345. [Google Scholar]

- Xie, J.; Li, A.; Jin, Y.; Li, Y. Advancements in large-scale energy storage technologies for power systems. IET Energy Syst. Integr. 2025, 7, e12179. [Google Scholar] [CrossRef]

- Varhegyi, G.; Nour, M. Integrating fast frequency response ancillary services: A global review of technical, procurement, and market integration challenges. Clean Energy 2025, 12, zkae105. [Google Scholar] [CrossRef]

- Eltamaly, A.; Alotaibi, M.; Alolah, A.; Ahmed, M.A. IoT-Based Hybrid Renewable Energy System for Smart Campus. Sustainability 2021, 13, 8555. [Google Scholar] [CrossRef]

- Tsao, Y.C.; Banyupramesta, I.G.A.; Lu, C.J. Optimal operation and capacity sizing for a sustainable shared energy storage system with solar power and hydropower generator. J. Energy Storage 2025, 62, 104835. [Google Scholar]

- Shaier, A.A.; Elymany, M.M.; Enany, M.A.; Elsonbaty, N.A. Multi-objective optimisation and algorithmic evaluation for EMS in a hybrid renewable energy system integrating PV, wind, and backup storage. Sci. Rep. 2025, 15, 1147. [Google Scholar] [CrossRef]

- Alnaqi, A.; Alsarraf, J.; Al-Rashed, A.A. Thermodynamic and economic evaluation with multi-objective optimisation of a novel thermally integrated pumped thermal energy storage system. Therm. Sci. Eng. Prog. 2025, 34, 101234. [Google Scholar]

- Elalfy, D.A.; Gouda, E.; Kotb, M.F.; Bureš, V. Frequency and voltage regulation enhancement for microgrids with electric vehicles based on red panda optimizer. Energy Convers. Manag. 2025, 256, 115450. [Google Scholar]

- Johnson, J.; Hoaglund, J.; Nguyen, T. Chapter 18: Physical Security and Cybersecurity of Energy Storage Systems; US DOE Energy Storage Handbook; Sandia National Laboratories: Albuquerque, NM, USA, 2021. [Google Scholar]

- Grijpink, P.M. Optimisation in Hybrid Renewable Energy Systems. 2024. Available online: https://repository.tudelft.nl/record/uuid:3b587a55-6cc1-4a24-b1ec-8e5781ac0a88 (accessed on 3 January 2025).

- Singh, A.K.; Dhamodharan, K. Hybrid nanosheets for high-performance capacitors. Diam. Relat. Mater. 2025, 152, 111976. [Google Scholar]

- Nawaz, F.; Pashajavid, E.; Fan, Y.; Batool, M. Enhanced Distributed Coordinated Control Strategy for DC Microgrid Hybrid Energy Storage Systems. 2025. Available online: https://www.preprints.org/manuscript/202501.0811/v1 (accessed on 15 December 2024).

- Zeb, O.; Ahmad, I. Adaptive Barrier Synergetic Super-Twisting Control for Hybrid Energy Storage in Smart Electric Vehicle Charging Stations. 2025. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5088771 (accessed on 14 December 2024).

- Ghanbari, K.; Maleki, A.; Ochbelagh, D.R. Investigating the effect of components in solar/wind/storage hybrid systems. J. Energy Storage 2025, 110, 115273. [Google Scholar]

- Lin, L.; Sun, M.; Wu, Y.; Huang, W.; Wu, Z.; Wang, D.; Fang, H.; Chen, C.; Luo, Y.; Zhang, Q.; et al. High-efficiency ammonia-fuelled hybrid power generation system. Energy Convers. Manag. 2025, 325, 119358. [Google Scholar]

- Maghrabie, H.M.; Olabi, A.G.; Rezk, A.; Radwan, A.; Alami, A.H.; Abdelkareem, M.A. Energy storage for water desalination systems based on renewable energy resources. Energies 2023, 16, 3178. [Google Scholar] [CrossRef]

- Venturini, P. Green Hydrogen Production via Floating PV Systems. 2025. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5089572 (accessed on 9 January 2025).

- Díaz-González, F.; Sumper, A.; Gomis-Bellmunt, O.; Villafafila-Robles, R. A review of energy storage technologies for electric power applications. Renew. Sustain. Energy Rev. 2016, 50, 1215–1239. [Google Scholar] [CrossRef]

- Luthander, R.; Widén, J.; Nilsson, D.; Palm, J.; Paatero, J. Review of energy storage technologies for buildings. Appl. Energy 2015, 142, 195–221. [Google Scholar]

- Blaabjerg, F.; Teodorescu, R.; Liserre, M.; Timbus, A.V. Overview of control and grid synchronization for distributed power generation systems. IEEE Trans. Ind. Electron. 2006, 53, 1398–1409. [Google Scholar]

- Aluko, A.; Knight, A. A Review on Vanadium Redox Flow Battery Storage Systems for Large-Scale Power Systems Application. IEEE Access 2023, 11, 13773–13793. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. Electricity Storage and Renewables: Costs and Markets to 2030; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2017. [Google Scholar]

- Reserve, H.P. Hornsdale Power Reserve. 2018. Available online: https://hornsdalepowerreserve.com.au/ (accessed on 5 January 2025).

- Aurecon Australasia Pty Ltd. Hornsdale Power Reserve Expansion Project ARENA Knowledge Sharing: HPRX Market Report Neoen. 2023. Available online: https://arena.gov.au/assets/2024/02/Neoen-Hornsdale-Power-Reserve-Upgrade-HPRX-Market-Report.pdf (accessed on 14 December 2024).

- Mexis, I.; Todeschini, G. Battery Energy Storage Systems in the United Kingdom: A Review of Current State-of-the-Art and Future Applications. Energies 2020, 13, 3616. [Google Scholar] [CrossRef]

- Ratnayake, A. Notrees Wind Storage Project Description Special Thanks for Support from DOE. 2011; pp. 1–11. Available online: https://www.sandia.gov/ess-ssl/docs/pr_conferences/2011/3_Ratnayake_Notrees.pdf (accessed on 1 January 2025).

- Anastasovski, A. Is renewable energy storage sustainable? A review. Green Technol. Sustain. 2025, 3, 100176. [Google Scholar] [CrossRef]

- Wang, Y.; Ke, J.; Hao, Y.; Miao, Y.; Yin, Y.; Xing, X. Research on Capacity Optimization Configuration of Integrated Energy System in Smart Park Considering Carbon Flow and Demand Response. In International Conference of Electrical, Electronic and Networked Energy Systems; Springer Nature Singapore: Singapore, 2024; pp. 122–130. [Google Scholar]

- Renewables, I.E. 2021—Analysis. Feb. 2021. Available online: https://www.iea.org/reports/renewables-2021 (accessed on 14 December 2021).

- Biswas, M.M.; Azim, M.; Saha, T.K.; Zobayer, U.; Urmi, M. Towards Implementation of Smart Grid: An Updated Review on Electrical Energy Storage Systems. Smart Grid Renew. Energy 2013, 4, 122–132. [Google Scholar] [CrossRef]

- Singh, P.; Kumar, R. Supply Chain Challenges and Environmental Impacts in the Lithium-Ion Battery Industry. Renew. Sustain. Energy Rev. 2023, 152, 111856. [Google Scholar]

- Chen, W.; Gao, X.; Zhao, Y. Updated Cost Analysis and CAPEX Estimates for Next-Generation Lithium-Ion Battery Systems. Energy Convers. Manag. 2023, 265, 115525. [Google Scholar]

- Papouis, C.; Kylili, A.; Fokaides, P.A. Adapting to energy storage needs: Gaps and challenges arising from the European directive for the electricity internal market. Clean. Technol. Environ. Policy 2023, 25, 2353–2366. [Google Scholar] [CrossRef]

- Jit, M. MCDA from a health economics perspective: Opportunities and pitfalls of extending economic evaluation to incorporate broader outcomes. Cost Eff. Resour. Alloc. 2018, 16, 45. [Google Scholar] [CrossRef]

- Mao, L.; Tang, A.; Wang, Q.; Yu, P.; Zeng, Z.; Liu, S. The Impact of Energy Storage Setup on Integrated Energy Systems. In Proceedings of the 2024 8th International Conference on Electrical, Mechanical and Computer Engineering (ICEMCE), Xi’an, China, 25–27 October 2024; pp. 163–169. [Google Scholar] [CrossRef]

- Adebiyi, A.A.; Moloi, K. Renewable energy source utilization progress in South Africa: A review. Energies 2024, 17, 3487. [Google Scholar] [CrossRef]

| Storage Type | Efficiency (%) | Energy Density (Wh/kg) | Power Density (kW/m3) | CAPEX (USD/kWh) | Cycle Life |

|---|---|---|---|---|---|

| PHES [26,27,28] | 70–85 | 0.5–3 | 0.5–3 | 500–2000 | 50+ |

| CAES [39,40] | 45–70 | 2–6 | 2–6 | 800–1500 | 20+ years |

| FESS [45,46] | 85–95 | 20–80 | 20–80 | 1000+ | 1,000,000+ (2 Ref) |

| Gravity Storage [27,47] | 75–90 | N/A | N/A | High | 50+ years (2 Ref) |

| LAES [28,43] | 50–70 | N/A | N/A | 600–1200 | 30+ years (2 Ref) |

| Storage Type | Efficiency (%) | Energy Density (Wh/kg) | Power Density (kW/m3) | CAPEX (USD/kWh) | Cycle Life |

| Lithium-Ion [52,53] | 85–95 | 250–700 | 100–200 | 300–600 | 4000–10,000 |

| Sodium-Ion [64,65] | 80–90 | 120–200 | 80–150 | 200–400 | 3000–6000 |

| Lead–Acid [69,70] | 75–85 | 30–50 | 50–80 | 100–200 | 500–2000 |

| Flow Battery [75,76] | 60–80 | 20–50 | 30–100 | 400–800 | 20,000+ |

| Metal–Air [78,79] | 50–70 | 800–1300 | N/A | High | Limited Rechargeability |

| Technology | Efficiency (%) | Energy Density (Wh/kg) | Cycle Life | Key Advantages | Key Challenges |

|---|---|---|---|---|---|

| Lithium-Ion [52,53] | 85–95 | 250–700 | 100–200 | 300–600 | 4000–10,000 |

| Sodium-Ion [64,65] | 80–90 | 120–200 | 80–150 | 200–400 | 3000–6000 |

| RFBs [84,88,89] | 70–85 | 25–50 | 15–20 years | Scalable, long duration | High initial cost, low energy density |

| Hydrogen Storage [91,92] | 40–60 | 33,300 | 10+ years | High energy density, versatile use | Storage losses, infrastructure costs |

| Ammonia [93] | 50–70 | 5.17 kWh/L | 10+ years | Carbon-free fuel | Toxicity, production complexity |

| Methanol [94] | 45–65 | 4.4 kWh/L | 10+ years | Compatible with fuel cells | CO2 emissions in production |

| Technology | Efficiency (%) | Energy Density (kWh/m3) | Key Applications | Advantages | Challenges |

|---|---|---|---|---|---|

| SHS | 50–90 | 20–50 | Solar thermal plants, district heating | Low cost, simple operation | Low energy density, thermal losses |

| LHS | 70–95 | 100–200 | Building heating, industrial cooling | High energy density, stable temperatures | Low conductivity, long charging time |

| TCS | 60–80 | 300–500 | Industrial waste heat, hydrogen storage | No heat loss, long-term storage | High material cost, slow kinetics |

| Technology | Efficiency (%) | Energy Density (Wh/kg) | Power Density (kW/kg) | Key Applications | Challenges |

|---|---|---|---|---|---|

| EDLCs | 90–98 | 5 | ~10,000 | Fast charging, regenerative braking | Low energy density |

| Pseudocapacitors | 85–95 | 10–50 | ~5000 | Renewable energy buffering | Cycle degradation |

| SMES | 95–98 | ~1 | ~50,000 | Grid stabilization, power quality | High cost, cryogenic cooling |

| Dielectric Capacitors | 90–98 | ~1 | ~100,000 | Pulsed power, aerospace | Limited capacity |

| System | Mechanism | Advantages | Challenges | Applications | Economic Metrics | References |

|---|---|---|---|---|---|---|

| Battery–Supercapacitor | Combination of electrochemical (battery) and electrostatic (supercap) storage |

|

| Electric vehicles, microgrids | CAPEX: ~ USD 400–600/kWh OPEX: Low (~1–2% annual degradation cost) ROI: Favorable over 8–10 years LCOS: 8–12 cents/kWh | [128,129] |

| Battery–Thermal Storage | Integration of battery systems with thermal storage modules (e.g., PCM-based) |

|

| Renewable energy systems, grid peak shaving | CAPEX: ~ USD 350–500/kWh equivalent OPEX: Moderate (requires periodic thermal calibration) ROI: 7–9 years LCOS: 10–14 cents/kWh | [130,131] |

| Hydrogen-Based Systems | Combination of hydrogen fuel cells with batteries |

|

| Grid stabilization, industrial applications | CAPEX: ~ USD 800–1000/kWh equivalent OPEX: Higher due to hydrogen handling ROI: Longer payback (>10 years) LCOS: 12–16 cents/kWh | [132] |

| Hybrid Nanofluid Systems | Utilizes nanofluid-based thermal storage |

|

| Industrial cooling, process optimization | CAPEX: ~ USD 500/kWh equivalent (projected) OPEX: Low due to passive cooling ROI: 8–10 years LCOS: ~10 cents/kWh | [133] |

| Flywheel–Supercapacitor | Combination of kinetic (flywheel) and electrostatic storage |

|

| Grid frequency regulation | CAPEX: ~USD 700–900/kWh equivalent OPEX: Very low (high cycle life) ROI: ~8 years LCOS: 9–13 cents/kWh | [127,134] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Areola, R.I.; Adebiyi, A.A.; Moloi, K. Integrated Energy Storage Systems for Enhanced Grid Efficiency: A Comprehensive Review of Technologies and Applications. Energies 2025, 18, 1848. https://doi.org/10.3390/en18071848

Areola RI, Adebiyi AA, Moloi K. Integrated Energy Storage Systems for Enhanced Grid Efficiency: A Comprehensive Review of Technologies and Applications. Energies. 2025; 18(7):1848. https://doi.org/10.3390/en18071848

Chicago/Turabian StyleAreola, Raphael I., Abayomi A. Adebiyi, and Katleho Moloi. 2025. "Integrated Energy Storage Systems for Enhanced Grid Efficiency: A Comprehensive Review of Technologies and Applications" Energies 18, no. 7: 1848. https://doi.org/10.3390/en18071848

APA StyleAreola, R. I., Adebiyi, A. A., & Moloi, K. (2025). Integrated Energy Storage Systems for Enhanced Grid Efficiency: A Comprehensive Review of Technologies and Applications. Energies, 18(7), 1848. https://doi.org/10.3390/en18071848