Indoor Thermal Environment of Temporary Mobile Energy Shelter Houses (MeSHs) in South Korea

Abstract

:1. Introduction

2. Methodlogy

2.1. Description of Mobile Energy Shelter House (MeSH)

2.2. Field Measurements

| Cold | Cool | Slightly Cool | Neutral | Slightly Warm | Warm | Hot |

|---|---|---|---|---|---|---|

| −3 | −2 | −1 | 0 | +1 | +2 | +3 |

| Activity | Clothing | |||

|---|---|---|---|---|

| Sit or Stand and Rest 1.2 | Summer season | Winter season | ||

| Underwear | 0.04 | Underwear | 0.04 | |

| Top wear | 0.14 | Top wear | 0.20 | |

| T-shirt (short) | 0.19 | T-shirt (Tick) | 0.34 | |

| Trousers (thin) | 0.15 | Pants (Tick) | 0.24 | |

| Socks | 0.03 | Socks | 0.03 | |

| - | - | Outwear (Thin) | 0.36 | |

| metabolic activity (met) (69.6 W/m2) | 0.55 clothing (clo) (0.085 m2·K/W) | 1.21 clo (0.186 m2·K/W) | ||

3. Results and Discussion

3.1. Indoor and Outdoor Temperature and Humidity

3.2. Indoor Thermal Comfort through Predicted Mean Vote (PMV) Analysis

| Parameter | Summer Season | Winter Season |

|---|---|---|

| Average temperature | 24.81 °C | 18.99 °C |

| Average humidity | 62.55% | 24.51% |

| Average Mean Radiant Temperature (MRT) | 24.15 °C | 18.09 °C |

| Average velocity | 0.093 m/s | 0.032 m/s |

| PMV | −1.21 to +1.07 | −0.85 to −0.08 |

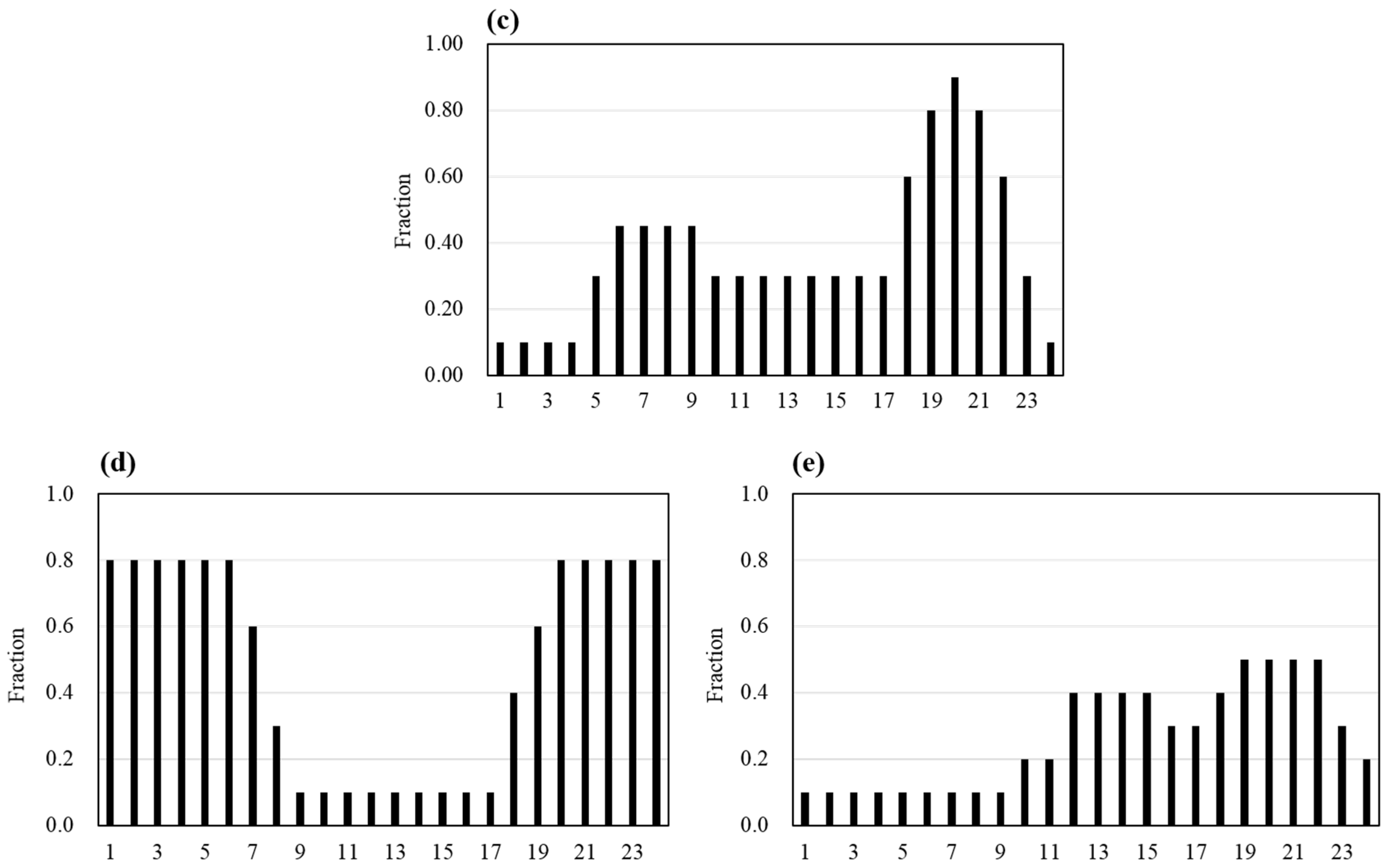

3.3. Predicted Energy Demand

4. Conclusions

Acknowledgements

Author Contributions

Conflicts of Interest

Appendix

| Parameters | Input values | |

|---|---|---|

| Location | Daejeon, Republic of Korea (36° N, 127° E) | |

| Number of floors | 1 floor | |

| Net floor area | 23.93 m2 | |

| Set temperature | Heating temperature | 24 |

| Heating set-back temperature | 12 | |

| Cooling temperature | 20 | |

| Cooling set-back temperature | 28 | |

| Internal heat gains | Equipment | 8.2 W/m2 |

| Lights | 5.8 W/m2 | |

| Occupancy | 0.03 Person/m2 | |

| U-values of envelopes | Exterior wall | 0.31 W/m2·K |

| Roof | 0.18 W/m2·K | |

| Floor | 0.23 W/m2·K | |

| Window | 1.50 W/m2·K | |

| Air flow | Ventilation rate | 0.51 L/(s·m2) (flow per exterior surface area) |

| Infiltration rate | 0.30 L/(s·m2) (flow per exterior surface area) | |

References

- Johnson, C. Impacts of prefabricated temporary housing after disasters: 1999 earthquake on Turkey. Habitat Int. 2007, 31, 36–52. [Google Scholar] [CrossRef]

- Chan, R.C.K.; Yao, Y.M.; Zhao, S.X.B. Self-help housing for temporary population in Guangzhou, China. Habitat Int. 2003, 27, 16–35. [Google Scholar] [CrossRef]

- Fantozzi, F.; Galbiati, P.; Leccese, F.; Salvadori, G.; Rocca, M. Thermal analysis of the building envelope of lightweight temporary housing. J. Phys. Conf. Ser. 2014, 547, 491–502. [Google Scholar] [CrossRef]

- El-Anwar, O.; El-Rayes, K.; Elnashai, A. An automated system for optimizing post disaster housing allocation. Autom. Constr. 2009, 18, 983–993. [Google Scholar] [CrossRef]

- Felix, D.; Branco, J.M.; Feio, A. Temporary housing after disasters: A state of the art survey. Habitat Int. 2013, 40, 136–141. [Google Scholar] [CrossRef] [Green Version]

- National Disaster Information Center. Disaster yearbook, 2002–2012. Available online: http://www.safekorea.go.kr/ (accessed on 30 September 2015).

- Arslan, H. Re-design, re-use and recycle of temporary houses. Build. Environ. 2007, 42, 400–406. [Google Scholar] [CrossRef]

- United Nations Disaster Relief Organization. Shelter after Disaster: Guidelines for Assistance; United Nations: New York, NY, USA, 1982. [Google Scholar]

- Barakat, S. Housing Reconstruction after Conflict and Disaster; Overseas Development Institute: London, UK, 2003. [Google Scholar]

- Caia, G.; Ventimiglia, F.; Maass, A. Container vs. dacha: The psychological effects of temporary housing characteristics on earthquake survivors. J. Environ. Psychol. 2010, 30, 60–66. [Google Scholar] [CrossRef]

- Nigg, J.M.; Barnshaw, J.; Torres, M.R. Hurricane Katrina and the flooding of New Orleans: Emergent issues in sheltering and temporary housing. Ann. Am. Acad. Pol Soc. Sci. 2006, 604, 113–128. [Google Scholar] [CrossRef]

- Johnson, C.; Lizarralde, G.; Davidson, C.H. A system view of temporary housing projects in post-disaster reconstruction. Constr. Manag. Econ. 2006, 24, 367–378. [Google Scholar] [CrossRef]

- El-Anwar, O.; El-Rayes, K.; Elnashai, A. Optimizing large-scale temporary housing arrangements after natural disasters. J. Comput. Civil. Eng. 2009, 23, 110–118. [Google Scholar] [CrossRef]

- Arsalan, H.; Cosgun, N. The evaluation of temporary earthquake houses dismantling process in the context of building waste management. Available online: http://kocaeli2007.kocaeli.edu.tr/kocaeli2007/TAM_METIN_NUMARALI-SIRALI-PDF/678-678.pdf (accessed on 30 September 2015).

- Davidson, C.; Lizarralde, G.; Johnson, C. Myths and Realities of Prefabrication for Post-Disaster Reconstruction. In Proceedings of the 4th International i-Rec Conference, Christchurch, New Zealand, 30–2 May 2008.

- Kronenburg, R.H. Mobile and flexible architecture: solutions for shelter and rebuilding in post-flood disaster situations. Available online: http://rice.iuav.it/351/1/KRONENBURG.pdf (accessed on 30 September 2015).

- Park, Y.J. A research of actual conditions of temporal residence in stricken districts. Resid. Environ. Inst. Korea 2004, 2, 36–50. [Google Scholar]

- Moon, J.I.; Song, Y.H.; Wang, W.C.; Lim, S.H. A study field examinations and interviews for Yeonpyeongdo temporary housing. J. Korean Hous. Assoc. 2012, 23, 21–28. [Google Scholar] [CrossRef]

- Shin, H.Y.; Kim, J.G.; Kim, J.H. A study on mobile energy shelter house for emergency welfare. Archit. Inst. Korea 2012, 33, 357–358. [Google Scholar]

- Hidayat, B.; Egbu, C. A literature review of the role of project management in post-disaster. In Proceedings of the 26th Annual ARCOM Conference: Association of Researchers in Construction Management, Leeds, UK, 6–8 September 2010; pp. 1269–1278.

- Shin, H.Y.; Kim, J.G.; Kim, J.H.; Jeong, H.G.; Jang, C.Y.; Hong, W.H. Indoor thermal environment performance of mobile energy shelter house for emergency welfare. Soc. Air-conditioning Refrig. Eng. Korea 2014, 14, 355–358. [Google Scholar]

- Minimum Dwelling Standard; under Residential Code Section 5; Ministry of Land, Infrastructure and Transport: Se-jong city, South Korea, 2011.

- Arslan, H.; Cosgun, N. Reuse and recycle potentials of the temporary houses after occupancy: example of Duzce, Turkey. Build. Environ. 2008, 43, 702–709. [Google Scholar] [CrossRef]

- Ergonomics of the Thermal Environment; ISO7730; International Organization for Standardization: Geneva, Switzerland, 2005.

- Song, Y.H.; Wang, W.C.; Lim, S.H. A study of temporary housing design with unit modular method. Archit Inst. Korea 2013, 3, 155–162. [Google Scholar]

- ASHRAE Handbook: Fundamentals; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2013.

- Johnson, C. What’s the Big Deal about Temporary Housing? Planning Considerations for Temporary Accommodation after Disasters: Example of the 1999 Turkish Earthquake. In Proceedings of the 2002 TIEMS Disaster Management Conference, Waterloo, ON, Canada, 15–17 May 2002.

- Cornaro, C.; Sapori, D.; Bucci, F.; Pierro, M.; Giammanco, C. Thermal performance analysis of an emergency shelter using dynamic building simulation. Energy Build. 2015, 88, 122–134. [Google Scholar] [CrossRef]

- Comité Européen de Normalisation (CEN). Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings-Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics; EN15251; CEN: Brussels, Belgium, 2007. [Google Scholar]

- Heo, Y.; Choudhary, R.; Augenbroe, G.A. Calibration of building energy models for retrofit analysis under uncertainty. Energy Build. 2012, 47, 550–560. [Google Scholar] [CrossRef]

- Ahn, B.L.; Park, J.W.; Yoo, S.H.; Kim, J.H.; Jeong, H.J.; Leigh, S.B.; Jang, C.Y. Synergetic effect between lighting efficiency enhancement and building energy reduction using alternative thermal operating system of indoor LED lighting. Energies 2015, 8, 8736–8748. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-G.; Lee, J.; Ahn, B.-L.; Shin, H.; Yoo, S.; Jang, C.-Y.; Song, D.; Kim, J. Indoor Thermal Environment of Temporary Mobile Energy Shelter Houses (MeSHs) in South Korea. Energies 2015, 8, 11139-11152. https://doi.org/10.3390/en81011139

Kim J-G, Lee J, Ahn B-L, Shin H, Yoo S, Jang C-Y, Song D, Kim J. Indoor Thermal Environment of Temporary Mobile Energy Shelter Houses (MeSHs) in South Korea. Energies. 2015; 8(10):11139-11152. https://doi.org/10.3390/en81011139

Chicago/Turabian StyleKim, Jeong-Gook, Junghun Lee, Byung-Lip Ahn, Hwayeon Shin, Seunghwan Yoo, Cheol-Yong Jang, Doosam Song, and Jonghun Kim. 2015. "Indoor Thermal Environment of Temporary Mobile Energy Shelter Houses (MeSHs) in South Korea" Energies 8, no. 10: 11139-11152. https://doi.org/10.3390/en81011139