Modeling and Simulation of the Thermal Runaway Behavior of Cylindrical Li-Ion Cells—Computing of Critical Parameters

Abstract

:1. Introduction

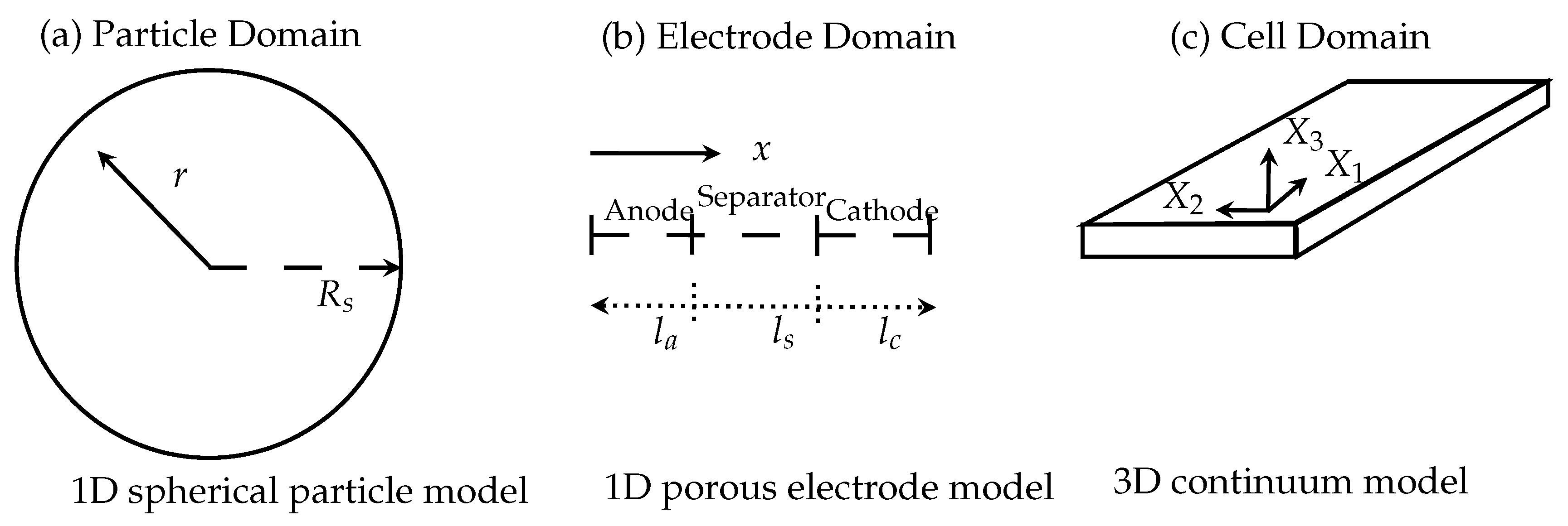

2. Modeling the Thermal Behavior of a Lithium-Ion Battery

- (1)

- In a certain (infinitesimal) time interval the cell is under constant charge, discharge or in relaxation.

- (2)

- The cell geometry resp. volume is constant, i.e., elastic processes and gas generation inside the cell are not considered.

- (3)

- Without loss of generality (W.l.o.g.) the emissivity , heat transfer coefficient h, the density , heat capacity and thermal conductivity are assumed to be constant in space and time.

2.1. The Energy Conservation

2.2. Identifying Heat Sources From Exothermic Reaction Kinetics Inside the Lithium-Ion Batteries

- (1)

- SEI decomposition reaction: At , in an exothermic reaction, the solid-electrolyte interface (SEI) decomposes.

- (2)

- Negative solvent reaction: At an exothermic reaction between the intercalated Li-ions and the electrolyte starts (NE).

- (3)

- Positive solvent reaction: For an exothermic reaction between the positive material and the electrolyte takes place under the evolution of oxygen inside the cell (PE).

- (4)

- Electrolyte decomposition: In a final exothermic reaction the electrolyte decomposes at (ELE).

2.3. Simplification of Combustion Model: The Constant Fuel Model

2.4. The Electrochemical Heat Source of a LIB and the Electrochemical Model

3. Simulations

3.1. Model Comparison

- (1)

- : In this case the LIB is unable to dissipate any generated heat to the environment. Therefore, a thermal runaway will always occur after a sufficiently large time.

- (2)

- h positive and a thermal runaway occurs after a sufficiently large time: In this case, more heat is generated inside the LIB, as can be dissipated to the environment.

- (3)

- h positive and no thermal runaway occurs after a sufficiently large time: In this case the generated heat can be dissipated completely to the environment.

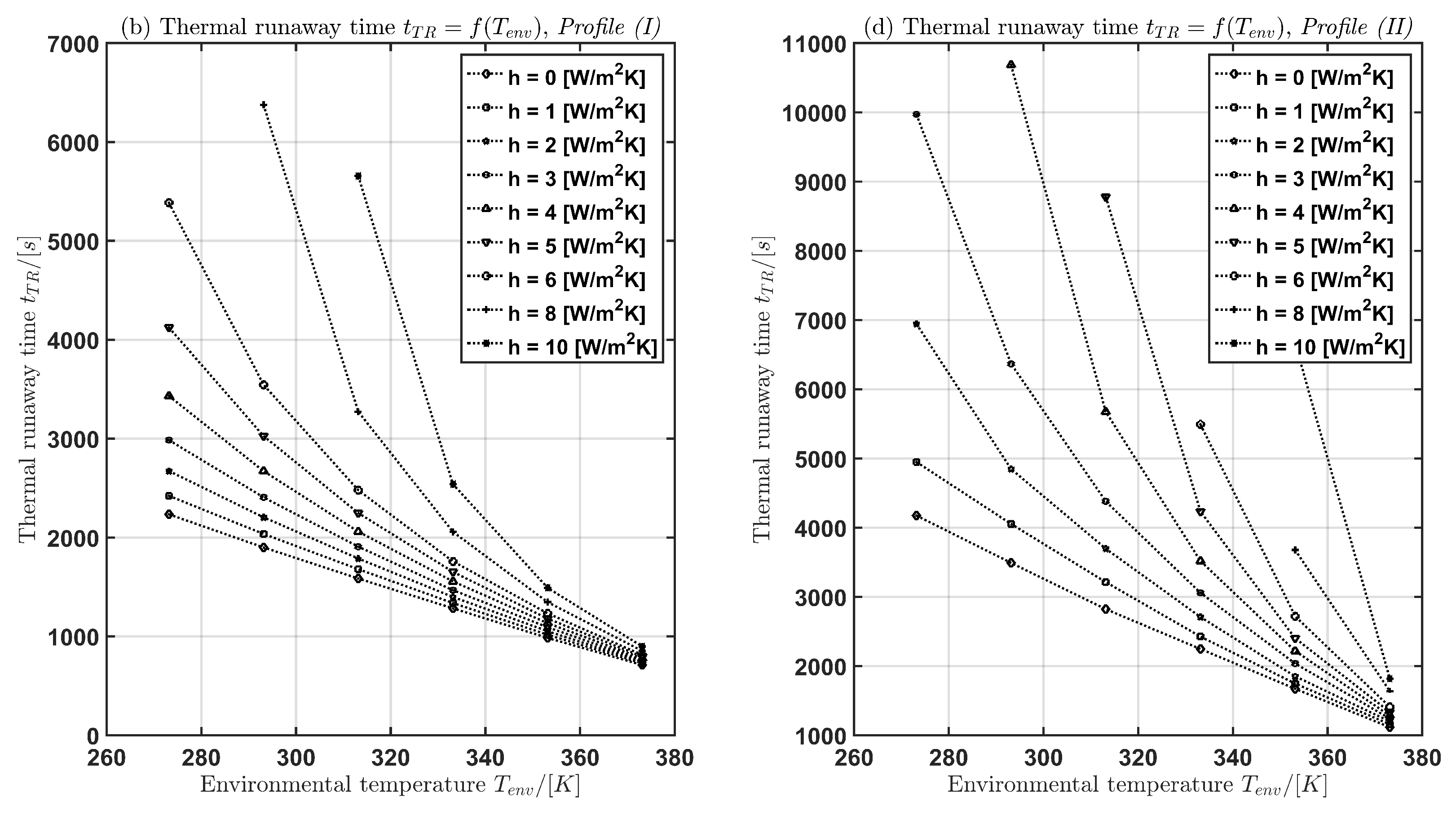

3.2. Computing the Thermal Runaway Time

3.3. Critical parameter intervals

- (a) If the environmental temperature is constant and fixed and the convective heat transfer coefficient h is allowed to vary, then with:

- -

- -

- (b) If the convective heat transfer coefficient h is constant and fixed and the environmental temperature is allowed to vary, then with:

- -

- -

4. Conclusions and Outlook

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix: Simulation Parameters

| Initial values | |||

|---|---|---|---|

| Li-concentration neg. solid phase | Li-concentration pos. solid phase | ||

| Initial temperature | Li-concentration liquid phase | ||

| Li-diffusivity | |||

| Neg. solid phase | Pos. solid phase | ||

| Volume frcation | |||

| Neg. solid phase | Pos. solid phase | ||

| Neg. liquid phase | Pos. liquid phase | ||

| Maximal concentration | |||

| Neg. solid phase | Pos. solid phase | ||

| Thermal conductivity | |||

| Neg. electrode | Pos. electrode | ||

| Neg. current collector | Pos. current collector | ||

| Density | |||

| Neg. electrode | Pos. electrode | ||

| Neg. current collector | Pos. current collector | ||

| Particle radius | |||

| Neg. particle | Pos. particle | ||

| Reaction rate coefficient | |||

| Neg. electrode | Pos. electrode | ||

| Neg. electrode | Pos. electrode | ||

| Neg. current collector | Pos. current collector | ||

| Separator | |||

| Density | Thermal conductivity | ||

| Heat capacity | |||

| Battery geometry | |||

| Radius | Height | ||

| Mandrel radius | |||

| Cell thickness | Thickness battery canister | ||

| Thickness neg. current collector | Thickness pos. current collector | ||

| Length pos./neg. electrode | Length separator | ||

| Reaction Heat | Frequency | Activation Energy | Volume Content | |

|---|---|---|---|---|

| factor | ||||

| SEI reaction | ||||

| Neg. solvent reaction | ||||

| Pos. solvent reaction | ||||

| Electrolyte decomp. |

References

- Doyle, M.; Fuller, T.F.; Newman, J. Modeling Galvanostatic Charge and Discharge of the Lithium/Polymer/ Insertion Cell. J. Electrochem. Soc. 1993, 140, 1526–1533. [Google Scholar] [CrossRef]

- Fuller, T.F.; Doyle, M.; Newman, J. Simulation and Optimization of the Dual Lithium Ion Insertion Cell. J. Electrochem. Soc. 1994, 141, 1–10. [Google Scholar] [CrossRef]

- Doyle, M.; Newman, J. Comparison of the Modeling Predictions with Experimental Data from Plastic Lithium Ion Cells. J. Electrochem. Soc. 1996, 143, 1890–1903. [Google Scholar] [CrossRef]

- Newman, J.; Tiedemann, W. Porous-Electrode Theory with Battery Applications. AIChE J. 1975, 21, 25–41. [Google Scholar] [CrossRef]

- Newman, J.; Tiedemann, W. Temperature Rise in a Battery Module with Constant Heat Generation. J. Electrochem. Soc. 1995, 142, 1054–1057. [Google Scholar] [CrossRef]

- Pals, C.R.; Newman, J. Thermal modeling of Lithium/Polymer Battery, I. Discharge Behavior of a Single Cell. J. Electrochem. Soc. 1995, 142, 3274–3281. [Google Scholar] [CrossRef]

- Pals, C.R.; Newman, J. Thermal modeling of Lithium/Polymer Battery, II. Temperature Profiles in a Cell Stack. J. Electrochem. Soc. 1995, 142, 3282–3288. [Google Scholar] [CrossRef]

- Al Hallaj, S.; Maleki, H.; Hong, J.S.; Selman, J.R. Thermal modeling and design considerations of lithium-ion batteries. J. Power Sour. 1999, 83, 1–8. [Google Scholar] [CrossRef]

- Chen, S.C.; Wan, C.C.; Wang, Y.Y. Thermal analysis of lithium-ion batteries. J. Power Sources 2005, 140, 111–124. [Google Scholar] [CrossRef]

- Inui, Y.; Kobayashi, Y.; Watanabe, Y.; Watase, Y.; Kitamura, Y. Simulation of temperature distribution in cylindrical and prismatic lithium ion secondary batteries. Energy Convers. Manag. 2007, 48, 2103–2109. [Google Scholar] [CrossRef]

- Zhu, C.; Li, X.; Song, L.; Xiang, L. Development of the theoretically based thermal model for lithium ion battery pack. J. Power Sources 2013, 223, 155–164. [Google Scholar] [CrossRef]

- Hu, J.; Tao, L.; Jing, L. Temperature Field Analysis and Thermal Dissipation Structure Optimization of Lithium-ion Battery Pack in PEVs. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 62–71. [Google Scholar]

- Wang, C.Y.; Gu, W.B.; Liaw, B.Y. Micro-Macroscopic Coupled Modeling of Batteries and Fuel Cells. I. Model Development. J. Electrochem. Soc. 1998, 145, 3407–3417. [Google Scholar] [CrossRef]

- Gu, W.B.; Wang, C.Y.; Liaw, B.Y. Micro-Macroscopic Coupled Modeling of Batteries and Fuel Cells. II.Application to Nickel Cadmium and Nickel-Metal Hybride Cells. J. Electrochem. Soc. 1998, 145, 3418–3427. [Google Scholar] [CrossRef]

- Howes, F.A.; Whitaker, S. The Spatial Averaging Theorem Revisited. Chem. Eng. Sci. 1985, 40, 1387–1392. [Google Scholar] [CrossRef]

- Latz, A.; Zausch, J.; Iliev, O. Modeling of Species and Charge Transport in Li-Ion Batteries Based on Non-equilibrium Thermodynamics; Dimov, I., Dimova, S., Kolkovska, N., Eds.; NMA 2010, LNCS 6046; Springer: Berlin, Germany, 2011; pp. 329–337. [Google Scholar]

- Richardson, G.; Denault, G.; Please, C.P. Multiscale modeling and analysis of lithium-ion battery charge and discharge. J. Eng. Math. 2012, 72, 41–72. [Google Scholar] [CrossRef]

- Landstorfer, M.; Jacob, T. Mathematical modeling of intercalation batteries at the cell level and beyond. Chem. Soc. Rev. 2013, 42, 3234–3252. [Google Scholar] [CrossRef] [PubMed]

- Gu, W.B.; Wang, C.Y. Thermal-Electrochemical Modeling of Battery Systems. J. Electrochem. Soc. 2000, 147, 2910–2922. [Google Scholar] [CrossRef]

- Wang, C.Y.; Srinivasan, V. Computational battery dynamics (CBD)-electrochemical/thermal coupled modeling and multi-scale modeling. J. Power Sources 2002, 110, 364–376. [Google Scholar] [CrossRef]

- Kumaresan, K.; Sikha, G.; White, R.E. Thermal Model for Lion-Ion Cell. J. Electrochem. Soc. 2008, 155, A164–A171. [Google Scholar] [CrossRef]

- Cai, L.; White, R.E. Mathematical modeling of lithium ion battery with thermal effects in COMSOL Inc. Multiphysics (MP) software. J. Power Sources 2011, 196, 5985–5989. [Google Scholar] [CrossRef]

- Kim, G.H.; Smith, K.; Lee, K.J.; Santhanagopalan, A.P. Multi-Domain Modeling of Lithium-Ion Batteries Encompassing Multi-Phyiscs in Varied Length Scales. J. Electrochem. Soc. 2011, 158, A955–A969. [Google Scholar] [CrossRef]

- Guo, M.; Kim, G.H.; White, R.E. A three-dimensional multi-physics model for a Li-ion battery. J. Power Sources 2013, 240, 80–94. [Google Scholar] [CrossRef]

- Lee, K.J.; Smith, K.; Pesaran, A.; Kim, G.H. Three dimensional thermal-, electrical, and electrochemical-coupled model for cylindrical wound large format lithium-ion batteries. J. Power Sources 2013, 241, 20–32. [Google Scholar] [CrossRef]

- Abraham, D.P.; Roth, E.P.; Kostecki, R.; McCarthy, K.; MacLaren, S.; Doughty, D.H. Diagnostic examination of thermally abused high-power lithium-ion cells. J. Power Sources 2006, 161, 648–657. [Google Scholar]

- Hatchard, T.D.; MacNeil, D.D.; Basu, A.; Dahn, J.R. Thermal Model of Cylindrical and Prismatic Lithium-Ion Cells. J. Electrochem. Soc. 2001, 148, A755–A761. [Google Scholar] [CrossRef]

- Spotnitz, R.; Franklin, J. Abuse behavior of high-power, lithium-ion cells. J. Power Sources 2003, 113, 81–100. [Google Scholar] [CrossRef]

- Spotnitz, R.M.; Weaver, J.; Yeduvaka, G.; Doughty, D.H.; Roth, E.P. Simulation of abuse tolerance of lithium-ion battery packs. J. Power Sources 2007, 163, 1080–1086. [Google Scholar] [CrossRef]

- Kim, G.H.; Pesaran, A.; Spotnitz, R. A three-dimensional thermal abuse model for lithium-ion cells. J. Power Sources 2007, 170, 476–489. [Google Scholar] [CrossRef]

- Peng, P.; Sun, Y.; Jiang, F. Thermal analyses of LiCoO2 lithium-ion battery during oven tests. Heat Mass Transf. 2014, 50, 1405–1416. [Google Scholar] [CrossRef]

- Peng, P.; Sun, Y.; Jiang, F. Numerical simulations and thermal behavior analysis for oven thermal abusing of LiCoOO2 lithium-ion battery. CIESC J. 2014, 65, 647–657. [Google Scholar]

- Lopez, C.F.; Jeervarajan, J.A.; Mukherjee, P.P. Characterizarion of Lithium-Ion Battery Thermal Abuse Behavior Using Experimental and Computational Analysis. J. Electrochem. Soc. 2015, 162, A2163–A2173. [Google Scholar] [CrossRef]

- Chen, M.; Sun, Q.; Wu, K.; Liu, B.; Peng, P.; Wang, Q. A Thermal Runaway Simulation on a Lithium Titanate Battery and Battery Module. Energies 2015, 8, 490–500. [Google Scholar] [CrossRef]

- Tanaka, N. Modeling and Simulation of Thermo-Electrochemistry of Thermal Runaway in Lithium-Ion Batteries. Ph.D. Thesis, University of Stuttgart, Stuttgart, Germany, 2015. [Google Scholar]

- Bebernes, J.; Eberly, D. Mathematical Problems from Combustion Theory; Applied Mathematical Sciences Volume 83, Springer: Berlin, Germany, 1989. [Google Scholar]

- Volpert, V. Elliptic Partial Differential Equations, Volume 2: Reactions-Diffusion Equations; Birkhäuser: Basel, Switzerland, 2014. [Google Scholar]

- Frank-Kamentstskij, D.A. Diffusion And Heat Transfer in Chemical Kinetics; Plenum Press: New York, NY, USA, 1969. [Google Scholar]

- Guo, G.; Long, B.; Cheng, B.; Zhou, S.; Cao, B. Three-dimensional thermal finite element modeling of lithium-ion battery in thermal abuse application. J. Power Sources 2010, 195, 2393–2398. [Google Scholar]

- Chiu, K.-Ch.; Lin, C.-H.; Yeh, S.-F.; Lin, Y.-H.; Chen, K.-C. An electrochemical modeling of lithium-ion battery nail penetration. J. Power Sources 2014, 251, 254–263. [Google Scholar] [CrossRef]

- Wang, Q.; Ping, P.; Sun, J. Catastrophe analysis of cylindrical lithium ion battery. Nonlinear Dyn. 2010, 61, 763–772. [Google Scholar] [CrossRef]

- Wang, Q.; Ping, P.; Zhao, X.; Chu, G.; Sun, J.; Chen, C. Thermal runaway caused fire and explosion of lithium ion battery. J. Power Sources 2012, 208, 210–224. [Google Scholar] [CrossRef]

- Lisbona, D.; Snee, T. A review of hazards associated with lithium and lithium-ion batteries. Process Saf. Environ. Protect. 2011, 89, 434–442. [Google Scholar] [CrossRef]

- Veluchamy, A.; Doh, C.-H.; Kim, D.-H.; Lee, J.-H.; Shin, H.-M.; Jin, B.-S.; Kim, H.-S.; Moon, S.-I. Thermal analysis of LixCoO2 cathode material of lithium ion battery. J. Power Sources 2009, 189, 855–858. [Google Scholar] [CrossRef]

- Dahn, J.R.; Fuller, E.W.; Obrovac, M.; Von Sacken, U. Thermal stability of LixCoO2,LixNiO2 and λ-MnO2 and consequences for the safety of Li-ion cells. Solid State Ion. 1994, 69, 265–270. [Google Scholar] [CrossRef]

- Melcher, A.; Ziebert, C.; Lei, B.; Zhao, W.; Rohde, M.; Seifert, H.J. Modellierung und Simulation des thermischen Runaways in zylindrischen Li-Ionen Batterien. In Workshop ASIM/GI-Fachgruppen “Simulation technischer Systeme inklusive der Grundlagen und Methoden in Modellbildung und Simulation”; Tikhomiriv, D., Mammen, H.-T., Pawletta, T., Eds.; ARGESIM Report 51, ASIM Mittelung AM 158, ISBN 978-3-901608-48-3, Hochschule Hamm-Lippstadt, 10./11.03.2016; ARGESIM Verlag: Vienna, Austria.

- Roetzel, W.; Spang, B. VDI Heat Atlas, C3 Typical Values of Overall Heat Transfer Coefficients, Springer Materials; Springer-Verlag: Berlin, Germany, 2010. [Google Scholar]

- Gomadam, P.M.; White, R.E.; Weidner, J.W. Modeling Heat Conduction in Spiral Geometries. J. Electrochem. Soc. 2003, 150, A1339–A1345. [Google Scholar] [CrossRef]

- Chen, S.-C.; Wang, Y.-Y.; Wan, C.-C. Thermal Analysis of Spirally Wound Lithium Batteries. J. Electrochem. Soc. 2006, 153, A637–A648. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, B.; Huang, J. Simultaneous estimation of thermal parameter for large-format laminated lithium-ion batteries. J. Power Sources 2014, 259, 106–116. [Google Scholar] [CrossRef]

- Drake, S.J.; Wetz, D.A.; Ostanek, J.K.; Miller, S.P.; Heinzel, J.M.; Jain, A. Measurment of anisotropic thermophysical properties of cylindrical Li-ion cells. J. Power Sources 2014, 252, 298–304. [Google Scholar] [CrossRef]

- Semenoff, N.N. Zur Theorie des Verbrennungsprozesses. Z. Phys. Hadron. Nucl. 1928, 48, 571–582. [Google Scholar] [CrossRef]

| Parameter | Zhang [50] | Drake [51] | Simulation |

|---|---|---|---|

| Initial: | |||

| Optimized: | |||

| Initial: | |||

| Optimized: | |||

| Initial: | |||

| Optimized: | |||

| - | - |

| Zone | Abraham [26] | Peng [32] | Simulation |

|---|---|---|---|

| (I) | |||

| (II) | for | ||

| for | |||

| (III) | for | ||

| for | |||

| Chemistry |

| (a) : | 0 | 2 | 4 | 6 | 8 | 10 | (b) : | 0 | 2 | 4 | 6 | 8 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2234 | 2672 | 3431 | 5385 | - | - | 4173 | 6943 | - | - | - | - | ||

| 1899 | 2204 | 2671 | 3544 | 6376 | - | 3490 | 4847 | 10684 | - | - | - | ||

| 1585 | 1787 | 2059 | 2478 | 3272 | 5656 | 2821 | 3695 | 5673 | - | - | - | ||

| 1283 | 1398 | 1556 | 1758 | 2057 | 2539 | 2246 | 2708 | 3517 | 5491 | - | - | ||

| 984 | 1052 | 1133 | 1232 | 1346 | 1490 | 1671 | 1850 | 2217 | 2719 | 3677 | 6664 | ||

| 1116 | 1199 | 1282 | 1408 | 1636 | 1818 | 710 | 741 | 777 | 812 | 852 | 897 |

| Profile (I) | () | () | Profile (II) | () | () |

|---|---|---|---|---|---|

| Profile (I) | () | () | Profile (II) | () | () |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melcher, A.; Ziebert, C.; Rohde, M.; Seifert, H.J. Modeling and Simulation of the Thermal Runaway Behavior of Cylindrical Li-Ion Cells—Computing of Critical Parameters. Energies 2016, 9, 292. https://doi.org/10.3390/en9040292

Melcher A, Ziebert C, Rohde M, Seifert HJ. Modeling and Simulation of the Thermal Runaway Behavior of Cylindrical Li-Ion Cells—Computing of Critical Parameters. Energies. 2016; 9(4):292. https://doi.org/10.3390/en9040292

Chicago/Turabian StyleMelcher, Andreas, Carlos Ziebert, Magnus Rohde, and Hans Jürgen Seifert. 2016. "Modeling and Simulation of the Thermal Runaway Behavior of Cylindrical Li-Ion Cells—Computing of Critical Parameters" Energies 9, no. 4: 292. https://doi.org/10.3390/en9040292

APA StyleMelcher, A., Ziebert, C., Rohde, M., & Seifert, H. J. (2016). Modeling and Simulation of the Thermal Runaway Behavior of Cylindrical Li-Ion Cells—Computing of Critical Parameters. Energies, 9(4), 292. https://doi.org/10.3390/en9040292