The Energy and Environmental Performance of Ground-Mounted Photovoltaic Systems—A Timely Update

Abstract

:1. Introduction

2. Methodology

2.1. Life Cycle Assessment

2.2. Net Energy Analysis

2.3. Data Sources and Scope

3. System Descriptions

3.1. Photovoltaic System Process Stages

3.2. Production Sites and Electricity Mixes

4. Results and Discussion

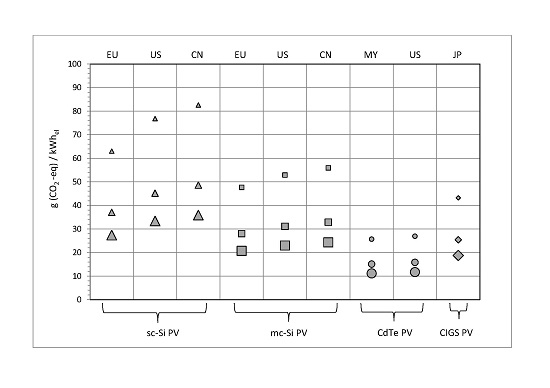

4.1. Fixed-Tilt Ground-Mounted Photovoltaic Systems

4.2. A Comparison to 1-Axis Tracking Installations

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Intergovernmental Panel on Climate Change (IPCC). Climate Change 2014: Mitigation of Climate Change; Cambridge University Press: New York, NY, USA, 2014. [Google Scholar]

- World Population Prospects: The 2015 Revision, Key Findings and Advance Tables; Working Paper No. ESA/P/WP.241; United Nations Department of Economic and Social Affairs, Population Division: New York, NY, USA, 2015.

- Snapshot of Global Photovoltaic Markets; Report IEA PVPS T1-29:2016; International Energy Agency (IEA): Paris, France, 2015.

- Global Market Outlook for Solar Power 2015–2019; Solar Power Europe, European Photovoltaic Industry Association: Brussels, Belgium, 2015.

- First Solar. Taking Energy Forward, Providing Comprehensive Solar Solutions to Diversify Your Energy Portfolio, 2016. Available online: http://www.firstsolar.com/ (accessed on 10 May 2016).

- Alsema, E. Energy requirements of thin-film solar cell modules—A review. Renew. Sustain. Energy Rev. 1998, 2, 387–415. [Google Scholar] [CrossRef]

- Alsema, E. Energy pay-back time and CO2 emissions of PV systems. Prog. Photovolt. 2000, 8, 17–25. [Google Scholar] [CrossRef]

- Alsema, E.; Nieuwlaar, E. Energy viability of photovoltaic systems. Energy Policy 2000, 28, 999–1010. [Google Scholar] [CrossRef]

- Fthenakis, V.M. Life cycle impact analysis of cadmium in CdTe PV production. Renew. Sustain. Energy Rev. 2004, 8, 303–334. [Google Scholar] [CrossRef]

- De Wild-Sholten, M.; Alsema, E. Towards cleaner solar PV: Environmental and health impacts of crystalline silicon photovoltaics. Refocus 2004, 5, 46–49. [Google Scholar] [CrossRef]

- Fthenakis, V.M.; Kim, H.C.; Alsema, E. Emissions from photovoltaic life cycles. Environ. Sci. Technol. 2008, 42, 2168–2174. [Google Scholar] [CrossRef] [PubMed]

- Fthenakis, V.M.; Held, M.; Kim, H.C.; Raugei, M.; Krones, J. Update of energy payback times and environmental impacts of photovoltaics. In Proceedings of the 24th European Photovoltaic Solar Energy Conference and Exhibition, Hamburg, Germany, 21–25 September 2009.

- Raugei, M.; Fullana-i-Palmer, P.; Fthenakis, V.M. The energy return on energy investment (EROI) of photovoltaics: Methodology and comparisons with fossil fuel life cycles. Energy Policy 2012, 45, 576–582. [Google Scholar] [CrossRef]

- Dale, M.; Benson, S.M. The energy balance of the photovoltaic (PV) industry—Is the PV industry a net energy provider? Environ. Sci. Technol. 2013, 47, 3482–3489. [Google Scholar] [CrossRef] [PubMed]

- Consoli, F.; Allen, D.; Boustead, I.; De Oude, N.; Fava, J.; Franklin, R.; Jensen, A.A.; Parrish, R.; Perriman, R.; Postlethwaite, D.; et al. Guidelines for Life-Cycle Assessment: A “Code of Practice”; Society of Environmental Toxicology and Chemistry: Sesimbra, Portugal, 1993. [Google Scholar]

- Environmental Management—Life Cycle Assessment—Principles and Framework; ISO 14040:2006; International Standardization Organization: Geneva, Switzerland, 2010.

- Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO 14044:2006; International Standardization Organization: Geneva, Switzerland, 2010.

- Fthenakis, V.; Frischknecht, R.; Raugei, M.; Kim, H.C.; Alsema, E.; Held, M.; De Wild-Scholten, M. Methodology Guidelines on Life Cycle Assessment of Photovoltaic Electricity; Report IEA-PVPS T12-03:2011; International Energy Agency (IEA): Paris, France, 2016. [Google Scholar]

- Frischknecht, R.; Wyss, F.; Büsser Knöpfel, S.; Lützkendorf, T.; Balouktsi, M. Cumulative energy demand in LCA: The energy harvested approach. Int. J. Life Cycle Assess. 2015, 20, 957–969. [Google Scholar] [CrossRef]

- Leach, G. Net energy-is it any use? Energy Policy 1975, 3, 332–344. [Google Scholar] [CrossRef]

- Chambers, R.S.; Herendeen, R.A.; Joyce, J.J.; Penner, P.S. Gasohol: Does it or doesn’t produce positive net energy? Science 1979, 206, 789–795. [Google Scholar] [CrossRef] [PubMed]

- Herendeen, R. Net energy considerations. In Economic Analysis of Solar Thermal Energy Systems; West, R., Kreith, F., Eds.; MIT Press: Cambridge, MA, USA, 1988; pp. 255–273. [Google Scholar]

- Cleveland, C.J.; Costanza, R.; Hall, C.A.S.; Kaufmann, R. Energy and the U.S. economy: A biophysical perspective. Science 1984, 225, 890–897. [Google Scholar] [CrossRef] [PubMed]

- Cleveland, C.J. Energy quality and energy surplus in the extraction of fossil fuels in the U.S. Ecol. Indic. 1992, 6, 139–162. [Google Scholar] [CrossRef]

- Herendeen, R. Net Energy Analysis: Concepts and Methods. In Encyclopedia of Energy; Elsevier: Amsterdam, The Netherlands, 2004; pp. 283–289. [Google Scholar]

- Carbajales-Dale, M.; Barnhart, C.; Brandt, A.R.; Benson, S. A better currency for investing in a sustainable future. Nat. Clim. Chang. 2014, 4, 524–527. [Google Scholar] [CrossRef]

- Raugei, M.; Frischknecht, R.; Olson, C.; Sinha, P.; Heath, G. Methodological Guidelines on Net Energy Analysis of Photovoltaic Electricity; Report IEA-PVPS T12-071:2016; International Energy Agency (IEA): Paris, France, 2016. [Google Scholar]

- Hall, C.A.S.; Balogh, S.; Murphy, D.J.R. What is the minimum EROI that a sustainable society must have? Energies 2009, 2, 25–47. [Google Scholar] [CrossRef]

- Lambert, J.C.; Hall, C.A.S.; Balogh, S.; Gupta, A.; Arnold, M. Energy, EROI and quality of life. Energy Policy 2014, 64, 153–167. [Google Scholar] [CrossRef]

- Raugei, M.; Leccisi, E. A comprehensive assessment of the energy performance of the full range of electricity generation technologies deployed in the United Kingdom. Energy Policy 2016, 90, 46–59. [Google Scholar] [CrossRef]

- Ecoinvent Database, 2016. Available online: http://www.ecoinvent.org/ (accessed on 10 May 2016).

- Frischknecht, R.; Itten, R.; Sinha, P.; de Wild-Scholten, M.; Zhang, J.; Fthenakis, V.; Kim, H.C.; Raugei, M.; Stucki, M. Life Cycle Inventories and Life Cycle Assessment of Photovoltaic Systems; Report IEA-PVPS T12-04:2015; International Energy Agency (IEA): Paris, France, 2015. [Google Scholar]

- De Wild-Scholten, M. Life Cycle Assessment of Photovoltaics Status 2011, Part 1 Data Collection; SmartGreenScans: Groet, The Netherlands, 2014. [Google Scholar]

- Sander, K.; Schilling, S.; Reinschmidt, J.; Wambach, K.; Schlenker, S.; Müller, A.; Springer, J.; Fouquet, D.; Jelitte, A.; Stryi-Hipp, G.C. Study on the Development of a Take Back and Recovery System for Photovoltaic Products; Institut für Ökologie und Politik GmbH: Wuppertal, Germany, 2007. [Google Scholar]

- Corcelli, F.; Ripa, M.; Leccisi, E.; Cigolotti, V.; Fiandra, V.; Graditi, G.; Sannino, L.; Tammaro, M.; Ulgiati, S. Sustainable urban electricity supply chain—Indicators of material recovery and energy savings from crystalline silicon photovoltaic panels end-of-life. Ecol. Indic. 2016. [Google Scholar] [CrossRef]

- Carbajales-Dale, M.; Raugei, M.; Barnhart, C.J.; Fthenakis, V.M. Energy return on investment (EROI) of solar PV: An attempt at reconciliation. Proc. IEEE 2015, 103, 995–999. [Google Scholar] [CrossRef]

- Nikolakakis, T.; Fthenakis, V.M. The optimum mix of electricity from wind- and solar-sources in conventional power systems: Evaluating the case for New York State. Energy Policy 2011, 39, 6972–6980. [Google Scholar] [CrossRef]

- Pre Consultants 2014. SimaPro 8 LCA Software. Available online: https://www.pre-sustainability.com/simapro (accessed on 10 May 2016).

- CML-IA Characterisation Factors, 2016. Available online: http://www.universiteitleiden.nl/en/research/research-output/science/cml-ia-characterisation-factors (accessed on 10 May 2016).

- Photovoltaics Report; Fraunhofer Institute for Solar Energy Systems: Freiburg, Germany, 2016.

- Silicon, 2016. Available online: http://minerals.usgs.gov/minerals/pubs/commodity/silicon/mcs-2016-simet.pdf (accessed on 10 May 2016).

- Statistics Search, 2016. Available online: http://www.iea.org/statistics/statisticssearch/ (accessed on 10 May 2016).

- EIA U.S. Energy Information Administration. Today in Energy, 2016. Available online: http://www.eia.gov (accessed on 10 May 2016).

- Breakdown of Electricity Generation by Energy Source. The Shift Project Data Protal, 2014. Available online: http://www.tsp-data-portal.org/Breakdown-of-Electricity-Generation-by-Energy-Source#tspQvChart (accessed on 10 May 2016).

- Suruhanjaya Tenaga Energy Commission. Peninsular Malaysia Electricity Supply Industry Outolook 2014. Available online: http://www.st.gov.my/index.php/en/component/k2/item/606-peninsular-malaysia-electricity-supply-industry-outlook-2014.html (accessed on 10 May 2016).

- De Wild-Scholten, M. Energy payback time and carbon footprint of commercial photovoltaic systems. Sol. Energy Mater. Sol. Cells 2013, 119, 296–305. [Google Scholar] [CrossRef]

- Mason, J.; Fthenakis, V.M.; Hansen, T.; Kim, C. Energy pay-back and life cycle CO2 emissions of the BOS in an optimized 3.5 MW PV installation. Prog. Photovolt. Res. Appl. 2006, 14, 179–190. [Google Scholar] [CrossRef]

- Murphy, D.; Hall, C.A.S. Year in review—EROI or energy return on (energy) invested. Ann. N. Y. Acad. Sci. 2010, 1185, 102–118. [Google Scholar] [CrossRef] [PubMed]

- Sinha, P.; Schneider, M.; Dailey, S.; Jepson, C.; De Wild-Scholten, M. Eco-efficiency of CdTe photovoltaics with tracking systems. In Proceedings of the 39th IEEE Photovoltaic Specialists Conference (PVSC), Tampa, FL, USA, 16–21 June 2013.

| Irradiation and Grid Efficiency (η) | sc-Si PV | mc-Si PV | CdTe PV | CIGS PV |

|---|---|---|---|---|

| 1000 kWh/(m2·yr); η = 0.3 | 2.8 | 2.1 | 1.1 | 1.9 |

| 1700 kWh/(m2·yr); η = 0.3 | 1.6 | 1.2 | 0.6 | 1.1 |

| 2300 kWh/(m2·yr); η = 0.3 | 1.2 | 0.9 | 0.5 | 0.8 |

| Indicator | sc-Si PV | mc-Si PV | CdTe PV | CIGS PV |

|---|---|---|---|---|

| GWP | −14% | −11% | −1% | −6% |

| AP | −12% | −9% | −7% | −16% |

| ODP | −13% | −11% | −4% | −9% |

| EPBT | −13.2% | −10.5% | −2.3% | −7.8% |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leccisi, E.; Raugei, M.; Fthenakis, V. The Energy and Environmental Performance of Ground-Mounted Photovoltaic Systems—A Timely Update. Energies 2016, 9, 622. https://doi.org/10.3390/en9080622

Leccisi E, Raugei M, Fthenakis V. The Energy and Environmental Performance of Ground-Mounted Photovoltaic Systems—A Timely Update. Energies. 2016; 9(8):622. https://doi.org/10.3390/en9080622

Chicago/Turabian StyleLeccisi, Enrica, Marco Raugei, and Vasilis Fthenakis. 2016. "The Energy and Environmental Performance of Ground-Mounted Photovoltaic Systems—A Timely Update" Energies 9, no. 8: 622. https://doi.org/10.3390/en9080622

APA StyleLeccisi, E., Raugei, M., & Fthenakis, V. (2016). The Energy and Environmental Performance of Ground-Mounted Photovoltaic Systems—A Timely Update. Energies, 9(8), 622. https://doi.org/10.3390/en9080622