Investigation of γ-(2,3-Epoxypropoxy)propyltrimethoxy Silane Surface Modified Layered Double Hydroxides Improving UV Ageing Resistance of Asphalt

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Synthesis of KH560 Surface Modified Layered Double Hydroxides

2.3. Preparation of KH560-LDHs Modified Asphalt

2.4. UV Ageing Procedures

2.5. Characterization

2.6. Storage Stability Test

2.7. Dynamic Shear Rheometer Test

2.8. Thin-Layer Chromatography with Flame Ionization Detection Test

3. Results and Discussion

3.1. Characterization of KH560-LDHs

3.1.1. X-ray Photoelectron Spectroscopy

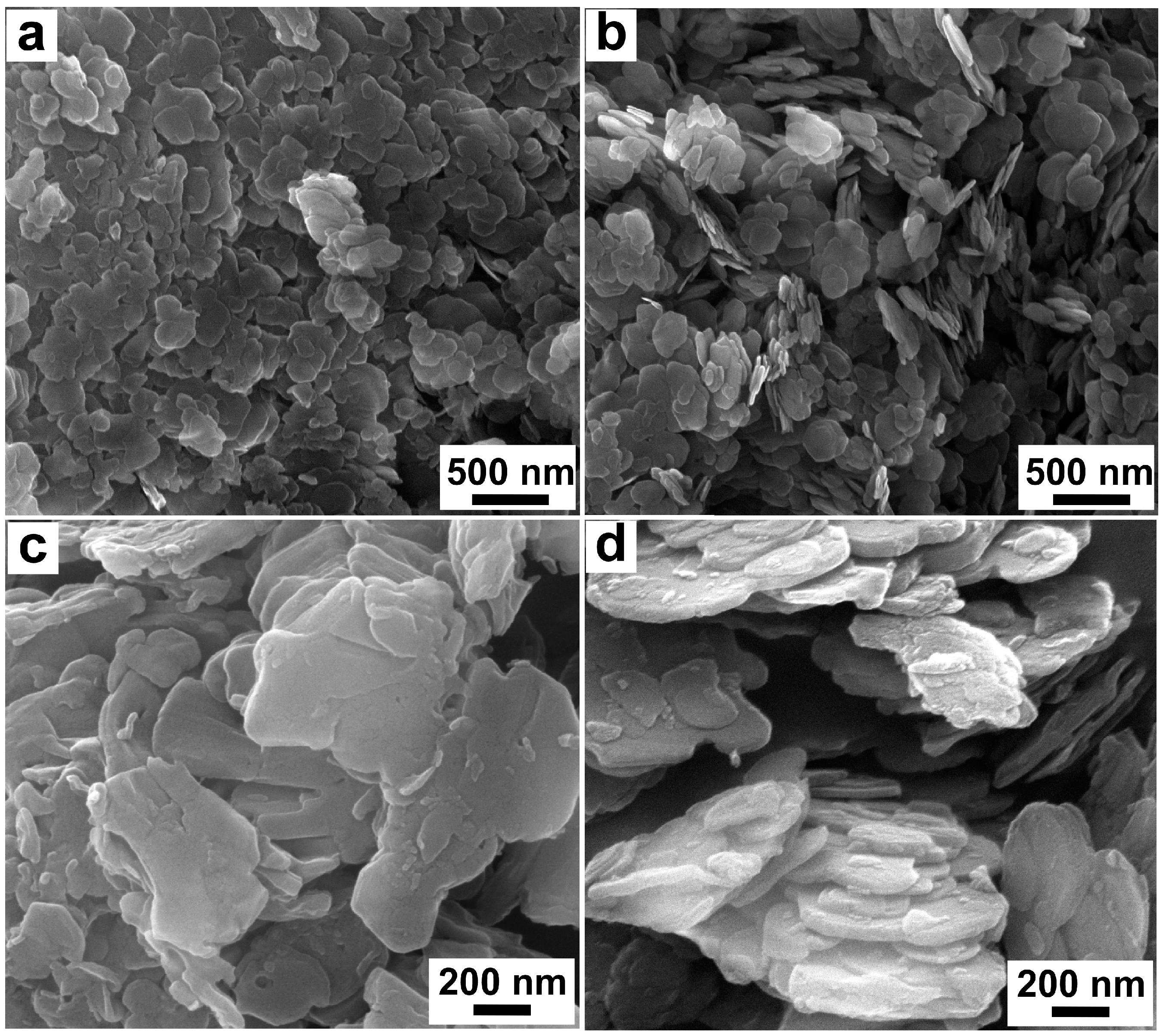

3.1.2. Scanning Electron Microscopy

3.2. Storage Stability of Modified Asphalt

3.3. Dynamic Viscoelastic Properties

3.3.1. Low Temperature Sweep

3.3.2. High Temperature Sweep

3.4. SARA Analysis

3.5. Atomic Force Microscopy Analysis

4. Conclusions

- According to XPS, KH560 has been successfully grafted onto the surface of LDHs, which was conducive to improving the stability of LDHs in the hydrophobic asphalt matrix. The SEM results showed that the agglomeration between LDHs particles was significantly weakened after KH560 surface modification, indicating that the dispersibility of LDHs in asphalt could be promoted by KH560 surface modification.

- The ΔS of KH560-LMA was much less than that of LMA, and the superiority of KH560-LMA became more prominent as the content of LDHs increased. The addition of KH560-LDHs could improve the high-temperature rutting resistance of asphalt.

- After UV ageing, the G’’ of asphalt significantly reduced, and correspondingly, the G’’ and G*/sin δ rapidly increased. The reduction of G’’ of the asphalt and the increase of G’ and G*/sin δ were inhibited after adding LDHs particles. Moreover, KH560-LDHs showed more effectiveness in hindering the rheological performance deterioration of asphalt in comparison to LDHs.

- The UV ageing of asphalt resulted in the significant reduction of aromatic content and the increase of asphaltene, which was unfavorable to the colloidal stability of asphalt and shortened the service life of asphalt pavement. Compared with LDHs, KH560-LDHs could better alleviate the variation of chemical compositions, implying that KH560-LDHs were superior to LDHs in improving the UV ageing resistance of asphalt.

- The amount and dimension of “bee-like” structures of asphalt noticeably decreased after UV ageing, which was due to the increasing polarity of asphalt. The change of “bee-like” structures of asphalt was mitigated noticeably with the introduction of KH560-LDHs, which further indicated that KH560 surface organic modification contributed significantly in improving the UV ageing resistance of LDHs modified asphalt.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Polacco, G.; Stastna, J.; Biondi, D.; Zanzotto, L. Relation between polymer architecture and nonlinear viscoelastic behavior of modified asphalts. Curr. Opin. Colloid Interface 2006, 11, 230–245. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Peng, C.; Jiang, G.; Lu, C.; Xu, F.; Yu, J.; Dai, J. Effect of 4,4′-stilbenedicarboxylic acid-intercalated layered double hydroxides on UV aging resistance of bitumen. RSC Adv. 2015, 5, 95504–95511. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, C.; Kuang, D. Physical, Rheological, and Aging Properties of Bitumen Containing Organic Expanded Vermiculite and Nano-Zinc Oxide. J. Mater. Civ. Eng. 2016, 28, 04015203. [Google Scholar] [CrossRef]

- Xiao, F.; Newton, D.; Putman, B.; Punith, V.S.; Amirkhanian, S.N. A long-term ultraviolet aging procedure on foamed WMA mixtures. Mater. Struct. 2013, 46, 1987–2001. [Google Scholar] [CrossRef]

- Mouillet, V.; Farcas, F.; Besson, S. Ageing by UV radiation of an elastomer modified bitumen. Fuel 2008, 87, 2408–2419. [Google Scholar] [CrossRef]

- Zargar, M.; Ahmadinia, E.; Asli, H.; Karim, M.R. Investigation of the possibility of using waste cooking oil as a rejuvenating agent for aged bitumen. J. Hazard. Mater. 2012, 233–234, 254–258. [Google Scholar] [CrossRef] [PubMed]

- Feng, Z.; Wang, S.; Bian, H.; Guo, Q.; Li, X. FTIR and rheology analysis of aging on different ultraviolet absorber modified bitumens. Constr. Build. Mater. 2016, 115, 48–53. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, A.N.; Amirkhanian, S.N. Influence of carbon nanoparticles on the rheological characteristics of short-term aged asphalt binders. J. Mater. Civ. Eng. 2011, 23, 423–431. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, D. Effect of Different Inorganic Nanoparticles on physical and ultraviolet aging properties of bitumen. J. Mater. Civ. Eng. 2015, 27, 04015049. [Google Scholar] [CrossRef]

- Shi, W.; Lin, Y.; Zhang, S.; Tian, R.; Liang, R.; Wei, M.; Evans, D.G.; Duan, X. Study on UV-shielding mechanism of layered double hydroxide materials. Phys. Chem. Chem. Phys. 2013, 15, 18217–18222. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wu, S.; Liu, G.; Li, L. Effect of ultraviolet aging on rheology and chemistry of LDH-Modified bitumen. Materials 2015, 8, 5238–5249. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, G. Recent Advances in the Preparation of Layered Double Hydroxides. Recent Pat. Nanotechnol. 2012, 6, 169–173. [Google Scholar] [CrossRef] [PubMed]

- Pang, L.; Liu, K.; Wu, S.; Lei, M.; Chen, Z. Effect of LDHs on the aging resistance of crumb rubber modified asphalt. Constr. Build. Mater. 2014, 67, 239–243. [Google Scholar] [CrossRef]

- Liu, G.; van de Ven, M.; Wu, S.; Molenaar, A. Study on the intrinsic viscosity of bitumen containing organo montmorillonite nanoclay. J. Test. Eval. 2012, 40, 833–837. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, H.; Wang, X.; Yu, J. Microstructures and thermal aging mechanism of expanded vermiculite modified bitumen. Constr. Build. Mater. 2013, 47, 919–926. [Google Scholar] [CrossRef]

- Liu, X.; Wu, S.; Liu, G.; Li, L. Optical and UV-aging properties of LDH-modified bitumen. Materials 2015, 8, 4022–4033. [Google Scholar] [CrossRef]

- Xu, S.; Yu, J.; Zhang, C.; Sun, Y. Effect of ultraviolet aging on rheological properties of organic intercalated layered double hydroxides modified asphalt. Constr. Build. Mater. 2015, 75, 421–428. [Google Scholar] [CrossRef]

- Wang, Q.; O’Hare, D. Recent advances in the synthesis and application of layered double hydroxide (LDH) nanosheets. Chem. Rev. 2012, 112, 4124–4155. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Yu, J.; Wu, W.; Xue, L.; Sun, Y. Synthesis and characterization of layered double hydroxides intercalated by UV absorbents and their application in improving UV aging resistance of bitumen. Appl. Clay Sci. 2015, 114, 112–119. [Google Scholar] [CrossRef]

- Yao, Q.; Zhou, Y.; Sun, Y.; Ye, X. Synthesis of TiO2 hybrid molecular imprinted polymer for ethofumesate linked by silane coupling agent. J. Inorg. Organomet. Polym. 2008, 18, 477–484. [Google Scholar] [CrossRef]

- Sheng, K.; Yan, B.; Qiao, X.F.; Guo, L. Rare earth (Eu/Tb)/phthalic acid functionalized inorganic Si–O/organic polymeric hybrids: Chemically bonded fabrication and photophysical property. J. Photochem. Photobiol. A 2010, 210, 36–43. [Google Scholar] [CrossRef]

- Sun, Y.; Zhou, Y.; Wang, Z.; Ye, X. Fabrication of nanocomposites by collagen template synthesis of layered double hydroxides assisted by an acrylic silane coupling agent. Appl. Surf. Sci. 2009, 255, 4497–4502. [Google Scholar] [CrossRef]

- Carroll, C. Costochondral autograft as a salvage procedure after failed trapeziectomy in trapeziometacarpal osteoarthritis. Year Book Hand Upper Limb Surg. 2008, 2008, 194–195. [Google Scholar] [CrossRef]

- Xu, W.; Wang, S.; Li, A.; Wang, X. Synthesis of aminopropyltriethoxysilane grafted/tripolyphosphate intercalated ZnAl LDHs and their performance in the flame retardancy and smoke suppression of polyurethane elastomer. RSC Adv. 2016, 6, 48189–48198. [Google Scholar] [CrossRef]

- Majoni, S. Thermal and flammability study of polystyrene composites containing magnesium–aluminum layered double hydroxide (MgAl–C16 LDH), and an organophosphate. J. Therm. Anal. Calorim. 2015, 120, 1435–1443. [Google Scholar] [CrossRef]

- Liu, S.; Yan, H.; Fang, Z.; Guo, Z.; Wang, H. Effect of graphene nanosheets and layered double hydroxides on the flame retardancy and thermal degradation of epoxy resin. RSC Adv. 2014, 4, 18652–18659. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, J.; Feng, K.; Xue, L.; Xie, D. Synthesis and characterization of triethoxyvinylsilane surface modified layered double hydroxides and application in improving UV aging resistance of bitumen. Appl. Clay Sci. 2016, 120, 1–8. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, J.; Xu, S.; Xue, L.; Cao, Z. Influence of UV aging on the rheological properties of bitumen modified with surface organic layered double hydroxides. Constr. Build. Mater. 2016, 123, 574–580. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, Y.; Du, J.; Yang, H.; Hao, J. Properties of a-C:H:Si thin films deposited by middle-frequency magnetron sputtering. Appl. Surf. Sci. 2016, 379, 516–522. [Google Scholar] [CrossRef]

- Seftel, E.M.; Mertens, M.; Cool, P. The influence of the Ti4+ location on the formation of self-assembled nanocomposite systems based on TiO2 and Mg/Al-LDHs with photocatalytic properties. Appl. Catal. B Environ. 2013, 134–135, 274–285. [Google Scholar] [CrossRef]

- Feng, Z.; Rao, W.; Chen, C.; Tian, B.; Li, X.; Li, P.; Guo, Q. Performance evaluation of bitumen modified with pyrolysis carbon black made from waste tyres. Constr. Build. Mater. 2016, 111, 495–501. [Google Scholar] [CrossRef]

- Yu, X.; Zaumanis, M.; dos Santos, S.; Poulikakos, L.D. Rheological, microscopic, and chemical characterization of the rejuvenating effect on asphalt binders. Fuel 2014, 135, 162–171. [Google Scholar] [CrossRef]

- Eberhardsteiner, L.; Füssl, J.; Hofko, B.; Handle, F.; Hospodka, M.; Blab, R.; Grothe, H. Influence of asphaltene content on mechanical bitumen behavior: Experimental investigation and micromechanical modeling. Mater. Struct. 2014, 48, 3099–3112. [Google Scholar] [CrossRef]

- Xu, M.; Yi, J.; Feng, D.; Huang, Y.; Wang, D. Analysis of Adhesive Characteristics of Asphalt Based on Atomic Force Microscopy and Molecular Dynamics Simulation. ACS Appl. Mater. Interfaces 2016, 8, 12393–12403. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Wang, H.; Yu, J. Effect of aging on morphology of organo-montmorillonite modified bitumen by atomic force microscopy. J. Microsc. 2011, 242, 37–45. [Google Scholar] [CrossRef] [PubMed]

- Dehouche, N.; Kaci, M.; Mouillet, V. The effects of mixing rate on morphology and physical properties of bitumen/organo-modified montmorillonite nanocomposites. Constr. Build. Mater. 2016, 114, 76–86. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Effect of ageing on bitumen chemistry and rheology. Constr. Build. Mater. 2002, 16, 15–22. [Google Scholar] [CrossRef]

| Items | Measured Values | |

|---|---|---|

| Chemical constituents | Asphaltenes (%) | 9.7 |

| Saturates (%) | 13.3 | |

| Resins (%) | 31.3 | |

| Aromatics (%) | 45.7 | |

| Physical properties | Penetration (25 °C, 0.1 mm) | 73 |

| Ductility (15 °C/10 °C, cm) | >150/16.5 | |

| Softening point (°C) | 48.8 | |

| Viscosity (135 °C, Pa·s) | 0.49 |

| Asphalt Samples | Before UV Ageing (°C) | After UV Ageing (°C) | Increase of Tp (°C) |

|---|---|---|---|

| VA | 5.3 | 14.8 | 9.5 |

| LMA | 8.3 | 12.5 | 4.2 |

| KH560-LMA | 9.8 | 10.9 | 1.1 |

| Asphalt Samples | VA | LMA | KH560-LMA |

|---|---|---|---|

| TG*/sin δ (1 kPa at 10 rad/s) | 69.5 °C | 71.5 °C | 72.9 °C |

| Performance grade | PG 64 | PG 70 | PG 70 |

| Asphalt Samples | Fresh | Aged | GI (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sa. (%) | Ar. (%) | Re. (%) | As. (%) | CI | Sa. (%) | Ar. (%) | Re. (%) | As. (%) | CI | ||

| VA | 12.86 | 45.92 | 31.48 | 9.74 | 3.425 | 11.93 | 33.59 | 32.33 | 22.15 | 1.934 | 43.5 |

| LMA | 12.97 | 45.85 | 31.57 | 9.61 | 3.429 | 12.14 | 39.38 | 32.54 | 15.94 | 2.561 | 25.3 |

| KH560-LMA | 12.88 | 45.35 | 32.11 | 9.66 | 3.436 | 12.01 | 41.54 | 33.85 | 12.6 | 3.063 | 10.9 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Yu, J.; Xue, L.; Sun, Y. Investigation of γ-(2,3-Epoxypropoxy)propyltrimethoxy Silane Surface Modified Layered Double Hydroxides Improving UV Ageing Resistance of Asphalt. Materials 2017, 10, 78. https://doi.org/10.3390/ma10010078

Zhang C, Yu J, Xue L, Sun Y. Investigation of γ-(2,3-Epoxypropoxy)propyltrimethoxy Silane Surface Modified Layered Double Hydroxides Improving UV Ageing Resistance of Asphalt. Materials. 2017; 10(1):78. https://doi.org/10.3390/ma10010078

Chicago/Turabian StyleZhang, Canlin, Jianying Yu, Lihui Xue, and Yubin Sun. 2017. "Investigation of γ-(2,3-Epoxypropoxy)propyltrimethoxy Silane Surface Modified Layered Double Hydroxides Improving UV Ageing Resistance of Asphalt" Materials 10, no. 1: 78. https://doi.org/10.3390/ma10010078

APA StyleZhang, C., Yu, J., Xue, L., & Sun, Y. (2017). Investigation of γ-(2,3-Epoxypropoxy)propyltrimethoxy Silane Surface Modified Layered Double Hydroxides Improving UV Ageing Resistance of Asphalt. Materials, 10(1), 78. https://doi.org/10.3390/ma10010078