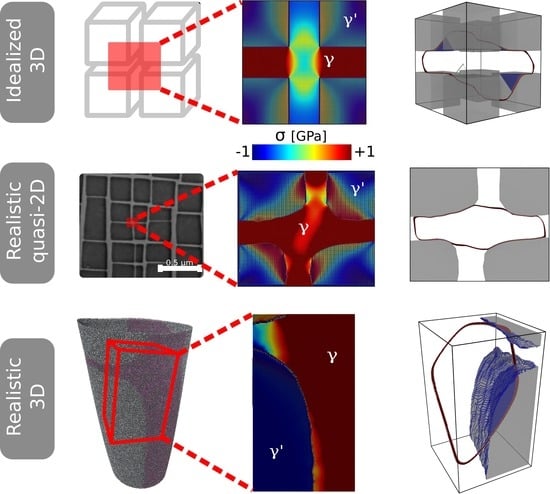

Idealized vs. Realistic Microstructures: An Atomistic Simulation Case Study on γ/γ′ Microstructures

Abstract

Share and Cite

Prakash, A.; Bitzek, E. Idealized vs. Realistic Microstructures: An Atomistic Simulation Case Study on γ/γ′ Microstructures. Materials 2017, 10, 88. https://doi.org/10.3390/ma10010088

Prakash A, Bitzek E. Idealized vs. Realistic Microstructures: An Atomistic Simulation Case Study on γ/γ′ Microstructures. Materials. 2017; 10(1):88. https://doi.org/10.3390/ma10010088

Chicago/Turabian StylePrakash, Aruna, and Erik Bitzek. 2017. "Idealized vs. Realistic Microstructures: An Atomistic Simulation Case Study on γ/γ′ Microstructures" Materials 10, no. 1: 88. https://doi.org/10.3390/ma10010088

APA StylePrakash, A., & Bitzek, E. (2017). Idealized vs. Realistic Microstructures: An Atomistic Simulation Case Study on γ/γ′ Microstructures. Materials, 10(1), 88. https://doi.org/10.3390/ma10010088