On the Mechanical Properties and Uncertainties of Jute Yarns

Abstract

:1. Introduction

2. Jute and Related Studies

3. Tensile Test of Jute Yarns

4. Energy Absorption Characteristics

5. Uncertainty Quantification

5.1. Statistical Approach

5.2. A Possibilistic Approach

6. Concluding Remarks

- (1)

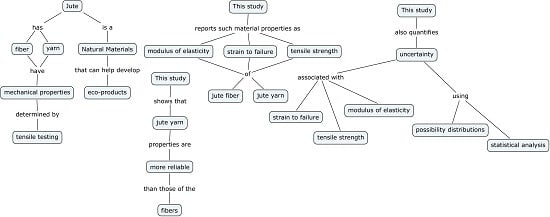

- This study clearly identified the tensile strength, modulus of elasticity, and strain to failure of jute yarns. This study also quantified the uncertainty associated with these properties, using both statistical analyses and possibility distributions. From a comparison of the results obtained here with those of the jute fibers, the results of jute fibers exhibited very high values and uncertainties. Therefore, we recommend users to employ the results for jute yarn properties for making design decisions, while developing a jute-based product.

- (2)

- To understand the failure mechanisms of both jute yarns and jute fibers, we considered the issue of energy absorption. Instability in the differences in energy absorption from one instance to another was observed for both jute yarns and fibers. Although the jute fiber exhibited a somewhat different instability pattern compared to the jute yarn, in both cases, high instability in energy absorption was observed before failure. This implies that after a certain amount of true strain, neither the fiber nor the yarn can withstand instability in energy absorption differences. At this point, failure occurs. Other natural materials may exhibit similar behavior. This remains an open issue for future research.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Umeda, Y.; Nishiyama, T.; Yamasaki, Y.; Kishita, Y.; Fukushige, S. Proposal of sustainable society scenario simulator. CIRP J. Manuf. Sci. Technol. 2009, 1, 272–278. [Google Scholar] [CrossRef]

- Ullah, A.M.M.S. A Fuzzy Monte Carlo Simulation technique for sustainable society scenario (3S) simulator. In Sustainability through Innovation in Product Life Cycle Design; Springer: Singapore, 2017. [Google Scholar]

- Allwood, J.M.; Cullen, J.M.; Milford, R.L. Options for achieving a 50% cut in industrial carbon emissions by 2050. Environ. Sci. Technol. 2010, 44, 1888–1894. [Google Scholar] [CrossRef] [PubMed]

- Milford, R.L.; Pauliuk, S.; Allwood, J.M.; Müller, D.B. The roles of energy and material efficiency in meeting steel industry CO2 targets. Environ. Sci. Technol. 2013, 47, 3455–3462. [Google Scholar] [CrossRef] [PubMed]

- Allwood, J.M.; Ashby, M.F.; Gutowski, T.G.; Worrell, E. Material efficiency: A white paper. Res. Conserv. Recycl. 2011, 55, 362–381. [Google Scholar] [CrossRef]

- Ullah, A.M.M.S.; Hashimoto, H.; Kubo, A.; Tamaki, J. Sustainability analysis of rapid prototyping: Material/resource and process perspectives. Int. J. Sustain. Manuf. 2013, 3, 20–36. [Google Scholar] [CrossRef]

- Ullah, A.M.M.S.; Fuji, A.; Kubo, A.; Tamaki, J. Analyzing the sustainability of bimetallic components. Int. J. Autom. Technol. 2014, 8, 745–753. [Google Scholar]

- Alves, C.; Ferrão, P.M.C.; Silva, A.J.; Reis, L.G.; Freitas, M.; Rodrigues, L.B.; Alves, D.E. Ecodesign of automotive components making use of natural jute fiber composites. J. Clean. Prod. 2010, 18, 313–327. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Pereira, T.V.C.; Gomes, O.D.F.M.; de Andrade Silva, F.; Toledo Filho, R.D. The effect of fiber morphology on the tensile strength of natural fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar] [CrossRef]

- Shahinur, S.; Ullah, A.M.M.S. Quantifying the uncertainty associated with the material properties of a natural fiber. Proced. CIRP 2017, 61, 541–546. [Google Scholar] [CrossRef]

- International Jute Study Group. Available online: http://www.jute.org/statistics_01.htm (accessed on 21 April 2017).

- Ahmed, K.S.; Vijayarangan, S.; Naidu, A.C.B. Elastic properties, notched strength and fracture criterion in untreated woven jute-glass fabric reinforced polyester hybrid composites. Mater. Des. 2007, 28, 2287–2294. [Google Scholar] [CrossRef]

- Rawal, A.; Sayeed, M.M.A. Tailoring the structure and properties of jute blended nonwoven geotextiles via alkali treatment of jute fibers. Mater. Des. 2014, 53, 701–705. [Google Scholar] [CrossRef]

- Aggarwal, P.K.; Raghu, N.; Karmarkar, A.; Chuahan, S. Jute-polypropylene composites using m-TMI-grafted-polypropylene as a coupling agent. Mater. Des. 2013, 43, 112–117. [Google Scholar] [CrossRef]

- Hu, R.-H.; Sun, M.-Y.; Lim, J.-K. Moisture absorption, tensile strength and microstructure evolution of short jute fiber/polylactide composite in hygrothermal environment. Mater. Des. 2010, 31, 3167–3173. [Google Scholar] [CrossRef]

- Zhou, X.; Ghaffar, S.H.; Dong, W.; Oladiran, O.; Fan, M. Fracture and impact properties of short discrete jute fibre-reinforced cementitious composites. Mater. Des. 2013, 49, 35–47. [Google Scholar] [CrossRef]

- Abdellaoui, H.; Bensalah, H.; Echaabi, J.; Bouhfid, R.; Qaiss, A. Fabrication, characterization and modelling of laminated composites based on woven jute fibres reinforced epoxy resin. Mater. Des. 2015, 68, 104–113. [Google Scholar] [CrossRef]

- Vijaya Ramnath, B.; Manickavasagam, V.M.; Elanchezhian, C.; Vinodh Krishna, C.; Karthik, S.; Saravanan, K. Determination of mechanical properties of intra-layer abaca-jute-glass fiber reinforced composite. Mater. Des. 2014, 60, 643–652. [Google Scholar] [CrossRef]

- Sabeel Ahmed, K.; Khalid, S.S.; Mallinatha, V.; Amith Kumar, S.J. Dry sliding wear behavior of SiC/Al2O3 filled jute/epoxy composites. Mater. Des. 2012, 36, 306–315. [Google Scholar] [CrossRef]

- Santulli, C.; Sarasini, F.; Tirillò, J.; Valente, T.; Valente, M.; Caruso, A.P.; Infantino, M.; Nisini, E.; Minak, G. Mechanical behaviour of jute cloth/wool felts hybrid laminates. Mater. Des. 2013, 50, 309–321. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.P.S.A.; Bakar, A.A.; Khanam, P.N. Chemical resistance, void content and tensile properties of oil palm/jute fibre reinforced polymer hybrid composites. Mater. Des. 2011, 32, 1014–1019. [Google Scholar] [CrossRef]

- Li, Y.; Xie, L.; Ma, H. Permeability and mechanical properties of plant fiber reinforced hybrid composites. Mater. Des. 2015, 86, 313–320. [Google Scholar] [CrossRef]

- Matějka, V.; Fu, Z.; Kukutschová, J.; Qi, S.; Jiang, S.; Zhang, X.; Yun, R.; Vaculík, M.; Heliová, M.; Lu, Y. Jute fibers and powderized hazelnut shells as natural fillers in non-asbestos organic non-metallic friction composites. Mater. Des. 2013, 51, 847–853. [Google Scholar] [CrossRef]

- Prachayawarakorn, J.; Chaiwatyothin, S.; Mueangta, S.; Hanchana, A. Effect of jute and kapok fibers on properties of thermoplastic cassava starch composites. Mater. Des. 2013, 47, 309–315. [Google Scholar] [CrossRef]

- Shanmugam, D.; Thiruchitrambalam, M. Static and dynamic mechanical properties of alkali treated unidirectional continuous Palmyra Palm Leaf Stalk Fiber/jute fiber reinforced hybrid polyester composites. Mater. Des. 2013, 50, 533–542. [Google Scholar] [CrossRef]

- Vijaya Ramnath, B.; Junaid Kokan, S.; Niranjan Raja, R.; Sathyanarayanan, R.; Elanchezhian, C.; Rajendra Prasad, A.; Manickavasagam, V.M. Evaluation of mechanical properties of abaca-jute-glass fibre reinforced epoxy composite. Mater. Des. 2013, 51, 357–366. [Google Scholar] [CrossRef]

- Katogi, H.; Takemura, K.; Akiyama, M. Residual tensile property of plain woven jute fiber/poly(lactic acid) green composites during thermal cycling. Materials 2016. [Google Scholar] [CrossRef]

- Hossain, S.I.; Hasan, M.; Hasan, M.N.; Hassan, A. Effect of chemical treatment on physical, mechanical and thermal properties of ladies finger natural fiber. Adv. Mater. Sci. Eng. 2013, 8. [Google Scholar] [CrossRef]

- de Andrade Silva, F.; Chawla, N.; de Toledo Filho, R.D. Tensile behavior of high performance natural (sisal) fibers. Compos. Sci. Technol. 2008, 68, 3438–3443. [Google Scholar] [CrossRef]

- D’Almeida, J.R.M.; Aquino, R.C.M.P.; Monteiro, S.N. Tensile mechanical properties, morphological aspects and chemical characterization of piassava (Attalea funifera) fibers. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1473–1479. [Google Scholar] [CrossRef]

- Nechwatal, A.; Mieck, K.-P.; Reußmann, T. Developments in the characterization of natural fibre properties and in the use of natural fibres for composites. Compos. Sci. Technol. 2003, 63, 1273–1279. [Google Scholar] [CrossRef]

- Tomczak, F.; Sydenstricker, T.H.D.; Satyanarayana, K.G. Studies on lignocellulosic fibers of Brazil. Part II: Morphology and properties of Brazilian coconut fibers. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1710–1721. [Google Scholar] [CrossRef]

- Defoirdt, N.; Biswas, S.; Vriese, L.D.; Tran, L.Q.N.; Acker, J.V.; Ahsan, Q.; Gorbatikh, L.; Vuure, A.V.; Verpoest, I. Assessment of the tensile properties of coir, bamboo and jute fibre. Compos. Part A Appl. Sci. Manuf. 2010, 41, 588–595. [Google Scholar] [CrossRef]

- Biswas, S.; Ahsan, Q.; Cenna, A.; Hasan, M.; Hassan, A. Physical and mechanical properties of jute, bamboo and coir natural fiber. Fibers Polym. 2013, 14, 1762–1767. [Google Scholar] [CrossRef]

- Biswas, S.; Ahsan, Q.; Verpoest, I.; Hasan, M. Effect of span length on the tensile properties of natural fibers. Adv. Mater. Res. 2011. [Google Scholar] [CrossRef]

- Shahinur, S.; Hasan, M.; Ahsan, Q.; Saha, D.K.; Islam, M.S. Characterization on the properties of jute fiber at different portions. Int. J. Polym. Sci. 2015. [Google Scholar] [CrossRef]

- Jafrin, S.; Shahinur, S.; Khayer, M.M.A.; Dilruba, A.F.; Assaduzzaman, M.; Dhali, S.K. Effect of weak acid and weak alkali on jute fibre and fabrics in physical properties. Indian J. Nat. Fibers 2014, 1, 83–90. [Google Scholar]

- Hossain, M.R.; Islam, M.A.; Van Vuure, A.; Verpoest, I. Quantitative analysis of hollow lumen in jute. Procedia Eng. 2014, 90, 52–57. [Google Scholar] [CrossRef]

- Kantz, H.; Schreiber, T. Nonlinear Time Series Analysis; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Hillier, F.S.; Lieberman, G.J. Introduction to Operations Research; McGraw Hill: New York, NY, USA, 2005. [Google Scholar]

- Montgomery, D.C. Introduction to Statistical Quality Control; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Tables for Probability Distributions. Available online: http://www.itl.nist.gov/div898/handbook/eda/section3/eda367.htm (accessed on 15 April 2017).

- Zadeh, L.A. Fuzzy sets as a basis for a theory of possibility. Fuzzy Sets Syst. 1999, 100, 9–34. [Google Scholar] [CrossRef]

- Dubois, D.; Foulloy, L.; Mauris, G.; Prade, H. Probability-possibility transformations, triangular fuzzy sets, and probabilistic inequalities. Reliab. Comput. 2004, 10, 273–297. [Google Scholar] [CrossRef]

- Ullah, A.M.M.S.; Shamsuzzaman, M. Fuzzy Monte Carlo Simulation using point-cloud-based probability—Possibility transformation. Simulation 2013, 89, 860–875. [Google Scholar] [CrossRef]

- Masson, M.H.; Denœux, T. Inferring a possibility distribution from empirical data. Fuzzy Sets Syst. 2006, 157, 319–340. [Google Scholar] [CrossRef]

- Mauris, G.; Lasserre, V.; Foulloy, L. A fuzzy approach for the expression of uncertainty in measurement. Meas. J. Int. Meas. Confed. 2001, 29, 165–177. [Google Scholar] [CrossRef]

| Specimen No. | Tensile Strength (MPa) | Modulus of Elasticity (GPa) | Strain to Failure (%) |

|---|---|---|---|

| 1 | 42.65 | 0.68 | 6.27 |

| 2 | 38.24 | 0.67 | 5.71 |

| 3 | 48.04 | 0.68 | 7.11 |

| 4 | 44.44 | 0.68 | 6.51 |

| 5 | 44.22 | 0.64 | 6.88 |

| 6 | 46.43 | 0.72 | 6.41 |

| 7 | 45.70 | 0.71 | 6.40 |

| 8 | 37.39 | 0.65 | 5.78 |

| 9 | 39.20 | 0.73 | 5.37 |

| 10 | 33.87 | 0.67 | 5.03 |

| 11 | 42.13 | 0.62 | 6.74 |

| 12 | 44.94 | 0.61 | 7.37 |

| 13 | 41.00 | 0.72 | 5.70 |

| 14 | 37.46 | 0.64 | 5.82 |

| 15 | 39.48 | 0.73 | 5.38 |

| Parameters | Properties (x) | |||

|---|---|---|---|---|

| TS (MPa) | E (GPa) | s (%) | ||

| Minimum | 33.87 | 0.61 | 5.03 | |

| Maximum | 48.04 | 0.73 | 7.37 | |

| Average () | 41.68 | 0.68 | 6.17 | |

| Standard Deviation (sd) | 4.01 | 0.04 | 0.69 | |

| Confidence Interval 95% | Expected Value (μ) | [37.76, 45.60] | [0.64, 0.72] | [5.53, 6.87] |

| Standard Deviation () | [2.94, 6.32] | [0.03, 0.06] | [0.51, 1.09] | |

| Alpha | TS (MPa) | E (GPa) | s (%) |

|---|---|---|---|

| 0 | [37.2, 46.4] | [0.615, 0.73] | [3.355, 7.105] |

| 0.5 | [39.1, 44.4] | [0.6425, 0.7] | [5.585, 6.7475] |

| 1 | [37.2, 42.4] | 0.67 | [5.815, 6.39] |

| Expected values (centroid method) | 41.75 | 0.67 | 5.67 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullah, A.S.; Shahinur, S.; Haniu, H. On the Mechanical Properties and Uncertainties of Jute Yarns. Materials 2017, 10, 450. https://doi.org/10.3390/ma10050450

Ullah AS, Shahinur S, Haniu H. On the Mechanical Properties and Uncertainties of Jute Yarns. Materials. 2017; 10(5):450. https://doi.org/10.3390/ma10050450

Chicago/Turabian StyleUllah, AMM Sharif, Sweety Shahinur, and Hiroyuki Haniu. 2017. "On the Mechanical Properties and Uncertainties of Jute Yarns" Materials 10, no. 5: 450. https://doi.org/10.3390/ma10050450

APA StyleUllah, A. S., Shahinur, S., & Haniu, H. (2017). On the Mechanical Properties and Uncertainties of Jute Yarns. Materials, 10(5), 450. https://doi.org/10.3390/ma10050450