Scaling Effects on Materials Tribology: From Macro to Micro Scale

Abstract

:1. Introduction

2. What Is Microtribology?

2.1. Magnitude of Forces

2.2. Scale/Size of Contact

2.3. Role of Adhesive Forces

2.4. Role of Roughness–Single vs. Multi-Asperity vs. Continuum

2.5. Third Bodies

2.6. Friction Behaviour at the Microscale

3. Application of Microtribology

4. Techniques in Micro-/Nanotribology

4.1. Atomic Force Microscopy

4.2. MEMS Tribometers

4.3. Microtribometers

4.3.1. Custom-Built Microtribometers

4.3.2. Low Load Tribometers

4.3.3. Commercially Available Microtribological Instrumentations

4.4. Nanoindentation Instruments

4.5. In Situ Tribometry

5. Materials in Microtribology

5.1. Biomaterials

5.1.1. Technology Relevance

5.1.2. Friction and Wear Behavior

5.1.3. Understanding of the Tribology through 3rd Bodies

5.2. Silicon Based Materials

5.2.1. Technology Relevance

5.2.2. Friction and Wear Behavior

5.2.3. Understanding of the Tribology through 3rd Bodies

5.2.4. Solutions/Improvements

5.3. Diamond-Like Carbon Coatings

5.3.1. Technology Relevance

5.3.2. Friction and Wear Behavior

5.3.3. Understanding of the Tribology through 3rd Bodies

5.3.4. Solutions/Improvements

5.4. MoS2 Based Coatings

5.4.1. Technology Relevance

5.4.2. Friction and Wear Behavior

5.4.3. Understanding of the Tribology through 3rd Bodies

5.5. Gold Coatings

5.5.1. Technology Relevance

5.5.2. Friction and Wear Behavior

5.6. Microtribology of Polymers

5.6.1. Industrial Relevance

5.6.2. Friction and Wear

5.6.3. Understanding of the Tribology through 3rd Bodies

5.7. Other Lubricants for MEMS

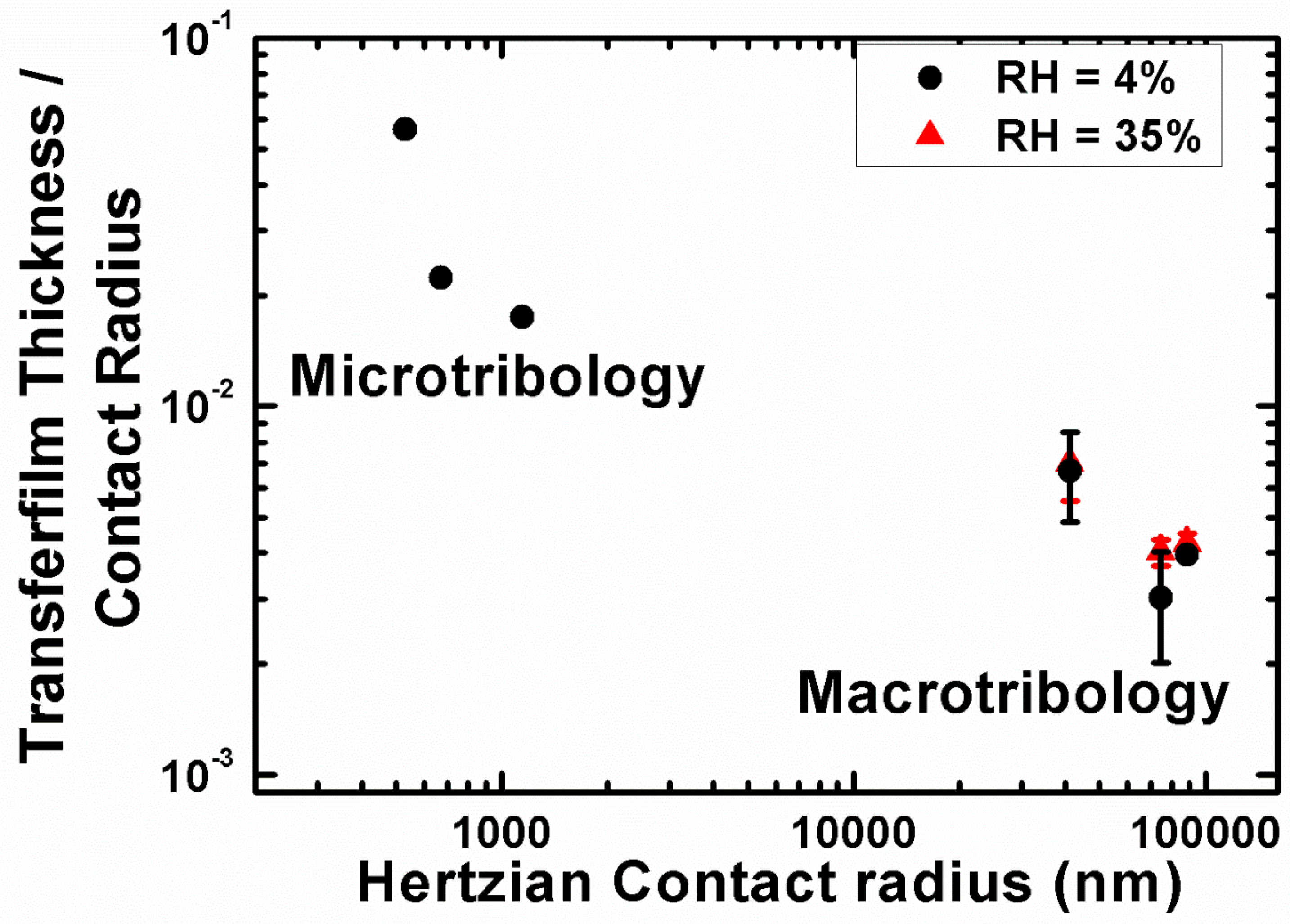

6. Comparison between Micro- and Macrotribology

7. Conclusions and Future Outlook

Acknowledgments

Conflicts of Interest

References

- Bhushan, B. (Ed.) Hndbook of Micro/Nano Tribology, 2nd ed.; CRC: Columbus, OH, USA, 1999. [Google Scholar]

- Bhushan, B. Micro/nanotribology and its applications to magnetic storage devices and MEMS. Tribol. Int. 1995, 28, 85. [Google Scholar] [CrossRef]

- Majumder, S.; McGruer, N.E.; Zavracky, P.M.; Adams, G.G.; Morrison, R.H.; Krim, J. Tribology Issues and Opportunities in MEMS; Bhushan, B., Ed.; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1998. [Google Scholar]

- Nosonovsky, M.; Bhushan, B. Scale effect in dry friction during multiple-asperity contact. Trans. ASME J. Tribol. 2005, 127, 37. [Google Scholar] [CrossRef]

- Williams, J.A.; Le, H.R. Tribology and MEMS. J. Phys. D Appl. Phys. 2006, 39, R201. [Google Scholar] [CrossRef]

- Kaneko, R. Microtribology. Tribol. Int. 1995, 28, 33–37. [Google Scholar] [CrossRef]

- Hu, Y.Z.; Ma, T.B. Comprehensive Nanoscience and Technology; David, L.A., Gregory, D.S., Gary, P.W., Eds.; Academic Press: Amsterdam, The Netherlands, 2011; pp. 383–418. [Google Scholar]

- Huber, G.; Mantz, H.; Spolenak, R.; Mecke, K.; Jacobs, K.; Gorb, S.N.; Arzt, E. Evidence for capillarity contributions to gecko adhesion from single spatula nanomechanical measurements. Proc. Natl. Acad. Sci. USA 2005, 102, 16293–16296. [Google Scholar] [CrossRef] [PubMed]

- Wahl, K. Micro- and Nanoscale Phenomena in Tribology; In Micro- and Nanoscale Phenomena in Tribology, CRC Press: Boca Raton, FL, USA, 2011; pp. 5–22. [Google Scholar]

- Bora, C.K.; Flater, E.E.; Street, M.D.; Redmond, J.M.; Starr, M.J.; Carpick, R.W.; Plesha, M.E. Multiscale roughness and modeling of MEMS interfaces. Tribol. Lett. 2005, 19, 37. [Google Scholar] [CrossRef]

- Bushby, A.J.; Jennett, N.M. Determining the area function of spherical indenters for nanoindentation. In Fundamentals of Nanoindentation and Nanotribology II; Materials Research Society: Warrendale, PA, USA, 2001. [Google Scholar]

- McGuiggan, P.M.; Zhang, J.; Hsu, S.M. Comparison of friction measurements using the atomic force microscope and the surface forces apparatus: The issue of scale. Tribol. Lett. 2001, 10, 217. [Google Scholar] [CrossRef]

- Yoon, E.; Singh, R.A.; Oh, H.; Kong, H. The effect of contact area on nano/micro-scale friction. Wear 2005, 259, 1424. [Google Scholar] [CrossRef]

- Achanta, S.; Liskiewicz, T.; Drees, D.; Celis, J.P. Friction mechanisms at the micro-scale. Tribol. Int. 2009, 42, 1792. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Y.; Bao, H.; Xiong, B.; Bao, M. Friction and wear properties in MEMS. Sens. Actuators A Phys. 2002, 97–98, 486. [Google Scholar] [CrossRef]

- Autumn, K.; Liang, Y.A.; Hsieh, S.T.; Zesch, W.; Chan, W.P.; Kenny, T.W.; Fearing, R.; Full, R.J. Adhesive force of a single gecko foot-hair. Nature 2000, 405, 681. [Google Scholar] [PubMed]

- Szlufarska, I.; Chandross, M.; Carpick, R.W. Recent advances in single-asperity nanotribology. J. Phys. D Appl. Phys. 2008, 41, 123001. [Google Scholar] [CrossRef]

- Johnson, K.L.; Kendall, K.; Roberts, A.D. Surface energy and the contact of elastic solids. Proc. R. Soc. Lond. A Math. Phys. Sci. 1971, 324, 301. [Google Scholar] [CrossRef]

- Derjaguin, B.V.; Muller, V.M.; Toporov, Y.P. Effect of contact deformations on the adhesion of particles. J. Colloid Interface Sci. 1975, 53, 314. [Google Scholar] [CrossRef]

- Ando, Y.; Ishikawa, Y.; Kitahara, T. Friction characteristics and adhesion force under low normal load. J. Tribol. 1995, 117, 569. [Google Scholar] [CrossRef]

- Stoyanov, P.; Goldbaum, D.; Lince, J.R.; Zhang, X.; Chromik, R. Microtribological performance of Au/MoS2 and Ti/MoS2 coatings with varying contact pressure. Tribol. Lett. 2010, 40, 199. [Google Scholar] [CrossRef]

- Stoyanov, P.; Chromik, R.R.; Gupta, S.; Lince, J.R. Micro-scale sliding contacts on Au and Au-MoS2 coatings. Surf. Coat. Technol. 2010, 205, 1449. [Google Scholar] [CrossRef]

- Barriga, J.; Fernández-Diaz, B.; Juarros, A.; Ahmed, S.I.U.; Arana, J.L. Microtribological analysis of gold and copper contacts. Tribol. Int. 2007, 40, 1526. [Google Scholar] [CrossRef]

- Blau, P.J. Friction Science and Technology: From Concepts to Applications, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Stoyanov, P.; Strauss, H.; Chromik, R.R. Scaling effects between micro- and macrotribology of Ti-MoS2 coatings. Wear 2012, 274–275, 149. [Google Scholar] [CrossRef]

- Scharf, T.W.; Prasad, S.V. Solid lubricants: A review. J. Mater. Sci. 2013, 48, 511. [Google Scholar] [CrossRef]

- Homola, A.M.; Israelachvili, J.N.; McGuiggan, P.M.; Gee, M.L. Fundamental experimental studies in tribology: The transition from “interfacial” friction of undamaged molecularly smooth surfaces to “normal” friction with wear. Wear 1990, 136, 65. [Google Scholar] [CrossRef]

- Hammerberg, J.E.; Holian, B.L.; Röder, J.; Bishop, A.R.; Zhou, S.J. Nonlinear dynamics and the problem of slip at material interfaces. Phys. Nonlinear Phenom. 1998, 123, 330. [Google Scholar] [CrossRef]

- Rigney, D.A. Transfer, mixing and associated chemical and mechanical processes during the sliding of ductile materials. Wear 2000, 245, 1–9. [Google Scholar] [CrossRef]

- Fu, X.; Falk, M.L.; Rigney, D.A. Sliding behavior of metallic glass: Part II. Computer simulations. Wear 2001, 250, 420. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Kim, H.J.; Rigney, D.A. Velocity and strain-rate profiles in materials subjected to unlubricated sliding. Phys. Rev. Lett. 2005, 95, 106001. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J.; Emge, A.; Winter, R.E.; Keightley, P.T.; Kim, W.K.; Falk, M.L.; Rigney, D.A. Nanostructures generated by explosively driven friction: Experiments and molecular dynamics simulations. Acta Mater. 2009, 57, 5270–5282. [Google Scholar] [CrossRef]

- Pastewka, L.; Moser, S.; Gumbsch, P.; Moseler, M. Anisotropic mechanical amorphization drives wear in diamond. Nat. Mater. 2011, 10, 34. [Google Scholar] [CrossRef] [PubMed]

- Godet, M. The third-body approach: A mechanical view of wear. Wear 1984, 100, 437. [Google Scholar] [CrossRef]

- Battaile, C.C.; Boyce, B.L.; Weinberger, C.R.; Prasad, S.V.; Michael, J.R.; Clark, B.G. The hardness and strength of metal tribofilms: An apparent contradiction between nanoindentation and pillar compression. Acta Mater. 2012, 60, 1712–1720. [Google Scholar] [CrossRef]

- Prasad, S.V.; Battaile, C.C.; Kotula, P.G. Friction transitions in nanocrystalline nickel. Scr. Mater. 2011, 64, 729. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batchelor, A.W. Engineering Tribology, 3rd ed.; Butterworth-Heinemann: Burlington, UK, 2006; pp. 553–572. [Google Scholar]

- Sasada, T.; Norose, S.; Mishina, H. Proceedings of the International Conference on Wear of Materials, Dearborn, MI, USA, 16–18 April 1979; Ludema, K.C., Glaeser, W.A., Rhee, S.K., Eds.; American Society of Mechanical Engineers: Dearborn, MI, USA, 1979; pp. 72–80.

- Sasada, T.; Norose, S.; Mishina, H. The Behavior of adhered fragments interposed between sliding surfaces and the formation process of wear particles. J. Lubr. Technol. 1981, 103, 195. [Google Scholar] [CrossRef]

- Wahl, K.J.; Dunn, D.N.; Singer, I.L. Wear behavior of Pb-Mo-S solid lubricating coatings. Wear 1999, 230, 175. [Google Scholar] [CrossRef]

- Wahl, K.J.; Seitzman, L.E.; Bolster, R.N.; Singer, I.L. Low-friction, high-endurance, ion-beam-deposited Pb-Mo-S coatings. Surf. Coat. Technol. 1995, 73, 152. [Google Scholar] [CrossRef]

- Dvorak, S.D.; Wahl, K.J.; Singer, I.L. In situ analysis of third body contributions to sliding friction of a Pb-Mo-S coating in dry and humid air. Tribol. Lett. 2007, 28, 263. [Google Scholar] [CrossRef]

- Scharf, T.W.; Kotula, P.G.; Prasad, S.V. Friction and wear mechanisms in MoS2/Sb2O3/Au nanocomposite coatings. Acta Mater. 2010, 58, 4100. [Google Scholar] [CrossRef]

- Descartes, S.; Berthier, Y. Rheology and flows of solid third bodies: Background and application to an MoS1.6 coating. Wear 2002, 252, 546. [Google Scholar] [CrossRef]

- Shockley, J.M.; Descartes, S.; Irissou, E.; Legoux, J.G.; Chromik, R.R. Third body behavior during dry sliding of cold-sprayed Al-Al2O3 composites: In situ tribometry and microanalysis. Tribol. Lett. 2014, 54, 191. [Google Scholar] [CrossRef]

- Stoyanov, P.; Linsler, D.; Schlarb, T.; Scherge, M.; Schwaiger, R. Dependence of tribofilm characteristics on the running-in behavior of aluminum–silicon alloys. J. Mater. Sci. 2015, 50, 5524. [Google Scholar] [CrossRef]

- Mo, Y.; Turner, K.T.; Szlufarska, I. Friction laws at the nanoscale. Nature 2009, 457, 1116. [Google Scholar] [CrossRef] [PubMed]

- Johnson, K.L.; Greenwood, J.A. An adhesion map for the contact of elastic spheres. J. Colloid Interface Sci. 1997, 192, 326. [Google Scholar] [CrossRef] [PubMed]

- Holmberg, K. Coatings Tribology: Properties, Mechanisms, Techniques and Applications in Surface Engineering, 2nd ed.; Tribology and Interface Engineering Series; Elsevier Science: Amsterdam, The Netherlands; Boston, MA, USA; London, UK, 2009. [Google Scholar]

- Van Kessel, P.F.; Hornbeck, L.J.; Meier, R.E.; Douglass, M.R. A MEMS-based projection display. Proc. IEEE 1998, 86, 1687. [Google Scholar] [CrossRef]

- Goldsmith, C.L.; Zhimin, Y.; Eshelman, S.; Denniston, D. Performance of low-loss RF MEMS capacitive switches. Microw. Guided Wave Lett. 1998, 8, 269. [Google Scholar] [CrossRef]

- Romig, A.D.; Dugger, M.T.; McWhorter, P.J. Materials issues in microelectromechanical devices: Science, engineering, manufacturability and reliability. Acta Mater. 2003, 51, 5837. [Google Scholar] [CrossRef]

- Tanner, D.M. MEMS reliability: Where are we now? Microelectron. Reliab. 2009, 49, 937–940. [Google Scholar] [CrossRef]

- Van Spengen, W.M. MEMS reliability from a failure mechanisms perspective. Microelectron. Reliabil. 2003, 43, 1049. [Google Scholar] [CrossRef]

- Komvopoulos, K. Surface engineering and microtribology for microelectromechanical systems. Wear 1996, 200, 305. [Google Scholar] [CrossRef]

- Butt, H.-J. Measuring electrostatic, van der Waals, and hydration forces in electrolyte solutions with an atomic force microscope. Biophys. J. 1991, 60, 1438. [Google Scholar] [CrossRef]

- Butt, H.; Cappella, B.; Kappl, M. Force measurements with the atomic force microscope: Technique, interpretation and applications. Surf. Sci. Rep. 2005, 59, 1–152. [Google Scholar] [CrossRef]

- Gosvami, N.N.; Egberts, P.; Bennewitz, R. Molecular Order and Disorder in the Frictional Response of Alkanethiol Self-Assembled Monolayers. J. Phys. Chem. A 2011, 115, 6942. [Google Scholar] [CrossRef] [PubMed]

- Labuda, A.; Hausen, F.; Gosvami, N.N.; Grütter, P.H.; Lennox, R.B.; Bennewitz, R. Switching atomic friction by electrochemical oxidation. Langmuir 2011, 27, 2561. [Google Scholar] [CrossRef] [PubMed]

- Ducker, W.A.; Senden, T.J.; Pashley, R.M. Direct measurement of colloidal forces using an atomic force microscope. Nature 1991, 353, 239. [Google Scholar] [CrossRef]

- Dvorak, S.D.; Woodland, D.D.; Unertl, W.N. Nanotribometer: A new instrument for nano-scale to micron-scale friction and wear measurements. Tribol. Lett. 1998, 4, 199. [Google Scholar] [CrossRef]

- Lim, M.G.; Chang, J.C.; Schultz, D.P.; Howe, R.T.; White, R.M. Micro Electro Mechanical Systems. In Proceedings of the IEEE Micro Electro Mechanical Systems, An Investigation of Micro Structures, Sensors, Actuators, Machines and Robots, Nara, Japan, 30 December 1990–2 January 1991; pp. 82–88. [Google Scholar]

- Mehregany, M.; Senturia, S.D.; Lang, J.H. Friction and Wear in Microfabricated Harmonic Side-Drive Motors. In Proceedings of the IEEE Solid-State Sensor and Actuator Workshop, Hilton Head Island, SC, USA, 4–7 June 1990; pp. 17–22. [Google Scholar]

- Miller, S.L.; Sniegowski, J.J.; LaVigne, G.; McWhorter, P.J. Friction in Surface-Micromachined Microengines; Vijay, K.V., Paul, J.M., Eds.; SPIE: Bellingham, WA, USA, 1996; pp. 197–204. [Google Scholar]

- De Boer, M.P.; Redmond, J.M.; Michalske. A Hinged-Pad Test Structure for Sliding Friction Measurement in Micromachining; Craig, R.F., Yuli, V., Eds.; SPIE: Bellingham, WA, USA, 1998; pp. 241–250. [Google Scholar]

- De Boer, M.P.; Mayer, T.M. Tribology of MEMS. MRS Bull. 2001, 26, 302. [Google Scholar] [CrossRef]

- Srinivasan, U.; Houston, M.R.; Howe, R.T.; Maboudian, R. Alkyltrichlorosilane-based self-assembled monolayer films for stiction reduction in silicon micromachines. J. Microelectromech. Syst. 1998, 7, 252. [Google Scholar] [CrossRef]

- De Boer, M.P.; Luck, D.L.; Ashurst, W.R.; Maboudian, R.; Corwin, A.D.; Walraven, J.A.; Redmond, J.M. High-performance surface-micromachined inchworm actuator. J. Microelectromech. Syst. 2004, 13, 63. [Google Scholar] [CrossRef]

- Patton, S.T.; Cowan, W.D.; Eapen, K.C.; Zabinski, J.S. Effect of surface chemistry on the tribological performance of a MEMS electrostatic lateral output motor. Tribol. Lett. 2001, 9, 199–209. [Google Scholar] [CrossRef]

- Senft, D.C.; Dugger, M.T.; Kevin, H.C.; Patrick, J.F. Friction and Wear in Surface-Micromachined Tribological Test Devices; SPIE: Bellingham, WA, USA, 1997; Volume 3224, pp. 31–38. [Google Scholar]

- Van Spengen, W.; Frenken, J. The leiden MEMS tribometer: Real time dynamic friction loop measurements with an On-Chip tribometer. Tribol. Lett. 2007, 28, 149. [Google Scholar] [CrossRef]

- Corwin, A.D.; Street, M.D.; Carpick, R.W.; Ashurst, W.R.; de Boer, M.P. Pre-Sliding Tangential Deflections Can Govern the Friction of MEMS Devices. In Proceedings of the ASME 2004 23rd International Conference on Offshore Mechanics and Arctic Engineering, Vancouver, BC, Canada, 20–25 June 2004; p. 113. [Google Scholar]

- Corwin, A.D.; de Boer, M.P. Effect of adhesion on dynamic and static friction in surface micromachining. Appl. Phys. Lett. 2004, 84, 2451. [Google Scholar] [CrossRef]

- Starr, M.J.; Reedy, E.D.; Corwin, A.D.; Carpick, R.W.; Flater, E.E. Proceedings of the 2005 International Conference on MEMS, NANO and Smart Systems, Banff, AB, Canada, 24–27 July 2005; pp. 421–422.

- Carpick, R.W.; Street, M.D.; Ashurst, W.R.; Corwin, A.D. Friction of Different Monolayer Lubricants in MEMs Interfaces; Sandia Report, SAND2005-7954: Albuquerque, NM, USA, 2006. [Google Scholar]

- Flater, E.E.; Corwin, A.D.; de Boer, M.P.; Carpick, R.W. In situ wear studies of surface micromachined interfaces subject to controlled loading. Wear 2006, 260, 580. [Google Scholar] [CrossRef]

- Nainaparampil, J.J.; Eapen, K.C.; Sanders, J.H.; Voevodin, A.A. Ionic-liquid lubrication of sliding MEMS contacts: Comparison of AFM liquid cell and device-level tests. J. Microelectromech. Syst. 2007, 16, 836. [Google Scholar] [CrossRef]

- Eapen, K.C.; Patton, S.T.; Smallwood, S.A.; Phillips, B.S.; Zabinski, J.S. MEMS lubricants based on bound and mobile phases of hydrocarbon compounds: Film deposition and performance evaluation. J. Microelectromech. Syst. 2005, 14, 954. [Google Scholar] [CrossRef]

- Smallwood, S.A.; Eapen, K.C.; Patton, S.T.; Zabinski, J.S. Performance results of MEMS coated with a conformal DLC. Wear 2006, 260, 1179. [Google Scholar] [CrossRef]

- Eapen, K.C.; Smallwood, S.A.; Zabinski, J.S. Lubrication of MEMS under vacuum. Surf. Coat. Technol. 2006, 201, 2960. [Google Scholar] [CrossRef]

- Patton, S.T.; Cowan, W.D.; Zabinski, J.S. Proceedings of the 37th Annual 1999 IEEE International Reliability Physics Symposium Proceedings, San Diego, CA, USA, 23–25 March 1999; pp. 179–188.

- Prasad, R.; MacDonald, N.; Taylor, D. Proceedigns of the 8th International Conference on Solid-State Sensors and Actuators and Eurosensors IX, Stockholm, Sweden, 25–29 June 1995; Volume 2, pp. 52–55.

- Jie, W.; Shao, W.; Jianmin, M. A MEMS device for studying the friction behavior of micromachined sidewall surfaces. J. Microelectromech. Syst. 2008, 17, 921. [Google Scholar] [CrossRef]

- Tas, N.R.; Gui, C.; Elwenspoek, M. Proceedigns of the Thirteenth Annual International Conference on Micro Electro Mechanical Systems (MEMS 2000), Miyazaki, Japan, 23–27 January 2000; pp. 193–198.

- Tas, N.R.; Gui, C.; Elwenspoek, M. Static friction in elastic adhesion contacts in MEMS. J. Adhes. Sci. Technol. 2003, 17, 547. [Google Scholar] [CrossRef]

- Ashurst, W.R.; Yau, C.; Carraro, C.; Maboudian, R.; Dugger, M.T. Dichlorodimethylsilane as an anti-stiction monolayer for MEMS: A comparison to the octadecyltrichlorosilane self-assembled monolayer. J. Microelectromech. Syst. 2001, 10, 41. [Google Scholar] [CrossRef]

- Ashurst, W.R.; Wijesundara, M.B.J.; Carraro, C.; Maboudian, R. Tribological impact of SiC encapsulation of released polycrystalline silicon microstructures. Tribol. Lett. 2004, 17, 195. [Google Scholar] [CrossRef]

- Alsem, D.H.; Stach, E.A.; Dugger, M.T.; Enachescu, M.; Ritchie, R.O. An electron microscopy study of wear in polysilicon microelectromechanical systems in ambient air. Thin Solid Films 2007, 515, 3259. [Google Scholar] [CrossRef]

- Gabriel, K.J.; Behi, F.; Mahadevan, R.; Mehregany, M. In situ friction and wear measurements in integrated polysilicon mechanisms. Sens. Actuators A Phys. 1990, 21, 184. [Google Scholar] [CrossRef]

- Srinivasan, U.; Foster, J.D.; Habib, U.; Howe, R.T.; Maboudian, R.; Senft, D.C.; Dugger, M.T. Lubrication of Polysilicon Micromechanisms with Self-Assembled Monolayers; Sandia National Labs: Albuquerque, MN, USA, 1998. [Google Scholar]

- Gee, M.G.; Gee, A.D. A cost effective test system for micro-tribology experiments. Wear 2007, 263, 1484. [Google Scholar] [CrossRef]

- Gee, M.G.; Nunn, J.W.; Muniz-Piniella, A.; Orkney, L.P. Micro-tribology experiments on engineering coatings. Wear 2011, 271, 2673. [Google Scholar] [CrossRef]

- Pignie, C.; Gee, M.G.; Nunn, J.W.; Jones, H.; Gant, A.J. Simulation of abrasion to WC/Co hardmetals using a micro-tribology test system. Wear 2013, 302, 1050. [Google Scholar] [CrossRef]

- Liu, Y.; Timmers, H. Micro-scratching of polyethylene terephthalate: Mechanisms of wear debris generation. Eur. Polym. J. 2013, 49, 1984. [Google Scholar] [CrossRef]

- Kosinskiy, M.; Ahmed, S.I.; Liu, Y.; Schaefer, J.A. A compact reciprocating vacuum microtribometer. Tribol. Int. 2012, 56, 81. [Google Scholar] [CrossRef]

- Nevshupa, R.A.; Scherge, M.; Ahmed, S.I.U. Transitional microfriction behavior of silicon induced by spontaneous water adsorption. Surf. Sci. 2002, 517, 17. [Google Scholar] [CrossRef]

- Ando, Y. Lowering friction coefficient under low loads by minimizing effects of adhesion force and viscous resistance. Wear 2003, 254, 965. [Google Scholar] [CrossRef]

- Gellman, A.; Ko, J. The current status of tribological surface science. Tribol. Lett. 2001, 10, 39. [Google Scholar] [CrossRef]

- McDonald, T.G.; Peebles, D.E.; Pope, L.E.; Peebles, H.C. Device to measure friction coefficients and contact resistance inside a scanning Auger microscope. Rev. Sci. Instrum. 1987, 58, 593. [Google Scholar] [CrossRef]

- Tao, Z.; Bhushan, B. Bonding, degradation, and environmental effects on novel perfluoropolyether lubricants. Wear 2005, 259, 1352. [Google Scholar] [CrossRef]

- Le, H.R.; Williams, J.A.; Luo, J.K. Characterisation of tribological behaviour of silicon and ceramic coatings under repeated sliding at micro-scale. Int. J. Surf. Sci. Eng. 2008, 2, 1. [Google Scholar] [CrossRef]

- Marchetto, D.; Benzig, R.; Korres, S.; Dienwiebel, M. Design and testing of ultrahigh vacuum microtribometer. Tribol. Mater. Surf. Int. 2012, 6, 95. [Google Scholar] [CrossRef]

- Scherge, M.; Li, X.; Schaefer, J.A. The effect of water on friction of MEMS. Tribol. Lett. 1999, 6, 215. [Google Scholar] [CrossRef]

- Stoyanov, P.; Romero, P.A.; Järvi, T.T.; Pastewka, L.; Scherge, M.; Stemmer, P.; Fischer, A.; Dienwiebel, M.; Moseler, M. Experimental and numerical atomistic investigation of the third body formation process in dry tungsten/tungsten-carbide tribo couples. Tribol. Lett. 2013, 50, 67. [Google Scholar] [CrossRef]

- Liu, H.; Bhushan, B. Adhesion and friction studies of microelectromechanical systems/nanoelectromechanical systems materials using a novel microtriboapparatus. AVS 2003, 21, 1528–1538. [Google Scholar] [CrossRef]

- Rennie, A.C.; Dickrell, P.L.; Sawyer, W.G. Friction coefficient of soft contact lenses: Measurements and modeling. Tribol. Lett. 2005, 18, 499. [Google Scholar] [CrossRef]

- Dunn, A.; Zaveri, T.; Keselowsky, B.; Sawyer, W. Macroscopic friction coefficient measurements on living endothelial cells. Tribol. Lett. 2007, 27, 233. [Google Scholar] [CrossRef]

- Dickrell, P.L. Frictional anisotropy of oriented carbon nanotube surfaces. Tribol. Lett. 2005, 18, 59. [Google Scholar] [CrossRef]

- Bonnevie, E.; Baro, V.; Wang, L.; Burris, D.L. In situ studies of cartilage microtribology: Roles of speed and contact area. Tribol. Lett. 2011, 41, 83. [Google Scholar] [CrossRef] [PubMed]

- Gitis, N.; Vinogradov, N.; Hermann, I.; Kuiry, S. Comprehensive mechanical and tribological characterization of Ultra-Thin-Films. Mater. Res. Soci. Symp. Proc. 2007, 1049, 3. [Google Scholar] [CrossRef]

- Ding, Q.; Wang, L.; Hu, L.; Hu, T.; Wang, Y. The pairing-dependent effects of laser surface texturing on micro tribological behavior of amorphous carbon film. Wear 2012, 274–275, 43. [Google Scholar] [CrossRef]

- CSM-Instruments, in SA Rue de la Gare 4 Galileo Center CH-2034 Peseux, Switzerland. Available online: http://www.csm-instruments.com/index1.html (accessed on 18 May 2017).

- Sahoo, R.; Biswas, S. Microtribology and friction-induced material transfer in layered MoS2 nanoparticles sprayed on a steel surface. Tribol. Lett. 2010, 37, 313. [Google Scholar] [CrossRef]

- Henry, P.; Pac, M.J.; Rousselot, C.; Tuilier, M.H. Wear mechanisms of titanium and aluminium nitride coatings: A microtribological approach. Surf. Coat. Technol. 2013, 223, 79. [Google Scholar] [CrossRef]

- Zhao, H.; Mu, C.; Ye, F. Microtribological mechanisms of tungsten and aluminum nitride films. J. Mater. Eng. Perform. 2016, 25, 1446. [Google Scholar] [CrossRef]

- Zheng, J.; Li, Y.; Shi, M.Y.; Zhang, Y.F.; Qian, L.M.; Zhou, Z.R. Microtribological behaviour of human tooth enamel and artificial hydroxyapatite. Tribol. Int. 2013, 63, 177. [Google Scholar] [CrossRef]

- Zheng, J.; Weng, L.Q.; Shi, M.Y.; Zhou, J.; Hua, L.C.; Qian, L.M.; Zhou, Z.R. Effect of water content on the nanomechanical properties and microtribological behaviour of human tooth enamel. Wear 2013, 301, 316. [Google Scholar] [CrossRef]

- Marchetto, D.; Held, C.; Hausen, F.; Wählisch, F.; Dienwiebel, M.; Bennewitz, R. Friction and Wear on single-layer epitaxial graphene in multi-asperity contacts. Tribol. Lett. 2012, 48, 77. [Google Scholar] [CrossRef]

- Scherge, M.; Gorb, S. Biological Micro- and Nanotribology; Springer: Berlin, Germany, 2001. [Google Scholar]

- Roba, M.; Duncan, E.G.; Hill, G.A.; Spencer, N.D.; Tosatti, S.G.P. Friction measurements on contact lenses in their operating environment. Tribol. Lett. 2011, 44, 387. [Google Scholar] [CrossRef]

- Scherge, M.; Sarembe, S. A Kiesow, M Petzold, Dental tribology at the microscale. Wear 2013, 297, 1040. [Google Scholar] [CrossRef]

- Marchetto, D.; Feser, T.; Dienwiebel, M. Microscale study of frictional properties of graphene in ultra high vacuum. Friction 2015, 3, 161. [Google Scholar] [CrossRef]

- Stoyanov, P.; Schneider, J.; Rinke, M.; Ulrich, S.; Nold, E.; Dienwiebel, M.; Stüber, M. Microstructure, mechanical properties and friction behavior of magnetron-sputtered V-C coatings. Surf. Coat. Technol. 2017, 321, 366–377. [Google Scholar] [CrossRef]

- Tomastik, C.; Pauschitz, A.; Roy, M. Microtribological behavior of W-S-C films deposited by different sputtering procedures. J. Tribol. 2012, 135, 011001. [Google Scholar] [CrossRef]

- Cooper, R. Ubi 1 User Manual; Hysitron Incorporated Minneapolis: Minneapolis, MN, USA, 2007. [Google Scholar]

- Schiffmann, K.I. Microtribological/mechanical testing in 0, 1 and 2 dimensions: A comparative study on different materials. Wear 2008, 265, 1826. [Google Scholar] [CrossRef]

- Schiffmann, K.I.; Hieke, A. Analysis of microwear experiments on thin DLC coatings: Friction, wear and plastic deformation. Wear 2003, 254, 565. [Google Scholar] [CrossRef]

- Stoyanov, P.; Fishman, Z.; Lince, J.R.; Chromik, R.R. Micro-tribological performance of MoS2 lubricants with varying Au content. Surf. Coat. Technol. 2008, 203, 761. [Google Scholar] [CrossRef]

- Stoyanov, P.; Gupta, S.; Lince, J.R.; Chromik, R.R. Micro-tribological performance of Au-MoS2 nanocomposite and Au/MoS2 bilayer coatings. Tribol. Int. 2012, 52, 144–152. [Google Scholar] [CrossRef]

- Singer, I.L.; Bolster, R.N.; Wegand, J.; Fayeulle, S.; Stupp, B.C. Hertzian stress contribution to low friction behavior of thin MoS2 coatings. Appl. Phys. Lett. 1990, 57, 995. [Google Scholar] [CrossRef]

- Singer, I.L. Fundamentals of Friction: Macroscopic and Microscopic Processes; Singer, I.L., Pollock, A.H.M., Eds.; Springer Science + Buisness Media: Aadordrecht, The Netherlands, 1992; pp. 237–261. [Google Scholar]

- Stoyanov, P.; Chromik, R.R. Microtribology of Solid Lubricant Coatings for MEMS. Appl. Note. Available online: www.hysitron.com.

- Kuster, R.L.A.; Schiffmann, K.I. Nano-scratch testing on thin diamond-like carbon coatings for microactuators: Friction, wear and elastic-plastic deformation. Z. Metallkunde/Mater. Res. Adv. Tech. 2004, 95, 306. [Google Scholar] [CrossRef]

- Chromik, R.R.; Strauss, H.W.; Scharf, T.W. materials phenomena revealed by in situ tribometry. JOM 2012, 64, 35. [Google Scholar] [CrossRef]

- Gohar, R.; Cameron, A. The mapping of elastohydrodynamic contacts. ASLE Trans. 1967, 10, 215. [Google Scholar] [CrossRef]

- Foord, C.A.; Hammann, W.C.; Cameron, A. Evaluation of lubricants using optical elastohydrodynamics. ASLE Trans. 1968, 11, 31. [Google Scholar] [CrossRef]

- Sliney, H.E. Dynamics of solid lubrication as observed by optical microscopy. ASLE Trans. 1978, 21, 109. [Google Scholar] [CrossRef]

- Alazemi, A.A.; Sadeghi, F.; Stacke, L. Adhesion and friction force measurements using an optical Micro-Apparatus. Tribol. Lett. 2016, 64, 49. [Google Scholar] [CrossRef]

- Chromik, R.R.; Winfrey, A.L.; Luning, J.; Nemanich, R.J.; Wahl, K.J. Run-in behavior of nanocrystalline diamond coatings studied by in situ tribometry. Wear 2008, 265, 477. [Google Scholar] [CrossRef]

- Dvorak, S.D.; Wahl, K.J.; Singer, I.L. Friction behavior of boric acid and annealed boron carbide coatings studied by in situ raman tribometry. Tribol. Trans. 2002, 45, 354. [Google Scholar] [CrossRef]

- Scharf, T.W.; Singer, I.L. Quantification of the thickness of carbon transfer films using raman tribometry. Tribol. Lett. 2003, 14, 137. [Google Scholar] [CrossRef]

- Scharf, T.W.; Singer, I.L. Thickness of diamond-like carbon coatings quantified with Raman spectroscopy. Thin Solid Films 2003, 440, 138. [Google Scholar] [CrossRef]

- Berthier, Y. Wear—Materials, Mechanisms and Practice; Stachowiak, G.W.M., Ed.; John Wiley and Sons, Ltd.: West Sussex, UK, 2005; pp. 291–316. [Google Scholar]

- Wahl, K.J.; Chromik, R.R.; Lee, G.Y. Quantitative in situ measurement of transfer film thickness by a Newton’s rings method. Wear 2008, 264, 731. [Google Scholar] [CrossRef]

- Chromik, R.R.; Baker, C.C.; Voevodin, A.A.; Wahl, K.J. In situ tribometry of solid lubricant nanocomposite coatings. Wear 2007, 262, 1239. [Google Scholar] [CrossRef]

- Singer, I.L.; Dvorak, S.D.; Wahl, K.J.; Scharf, T.W. Role of third bodies in friction and wear of protective coatings. J. Vac. Sci. Technol. A Vac. Surf. Films 2003, 21, S232. [Google Scholar] [CrossRef]

- Scharf, T.W.; Singer, I.L. Role of third bodies in friction behavior of diamond-like nanocomposite coatings studied by in situ tribometry. Tribol. Trans. 2002, 45, 363. [Google Scholar] [CrossRef]

- Shockley, J.M.; Strauss, H.W.; Chromik, R.R.; Brodusch, N.; Gauvin, R.; Irissou, E.; Legoux, J.-G. In situ tribometry of cold-sprayed Al-Al2O3 composite coatings. Surf. Coat. Technol. 2013, 215, 350. [Google Scholar] [CrossRef]

- Hertz, H. Über die berührung fester elastischer Körper. J. Angew. Math. 1881, 92, 156. [Google Scholar]

- Strauss, H.W.; Chromik, R.R.; Hassani, S. In situ tribology of nanocomposite Ti-Si-C-H coatings prepared by PE-CVD. Wear 2011, 272, 16. [Google Scholar] [CrossRef]

- Sawyer, W.G.; Wahl, K.J. Accessing inaccessible interfaces: In situ approaches to materials tribology. MRS Bull. 2008, 33, 1145. [Google Scholar] [CrossRef]

- Korres, S.; Dienwiebel, M. Design and construction of a novel tribometer with online topography and wear measurement. AIP 2010, 81, 063904. [Google Scholar] [CrossRef] [PubMed]

- Stoyanov, P.; Stemmer, P.; Järvi, T.; Merz, R.; Romero, P.; Scherge, M.; Kopnarski, M.; Moseler, M.; Fischer, A.; Dienwiebel, M. Friction and wear mechanisms of tungsten-carbon systems: A comparison of dry and lubricated conditions. ACS Appl. Mater. Interfaces 2013, 5, 6123–6135. [Google Scholar] [CrossRef] [PubMed]

- Stoyanov, P.; Shockley, J.M.; Dienwiebel, M.; Chromik, R.R. Combining in situ and online approaches to monitor interfacial processes in lubricated sliding contacts. MRS Commun. 2016, 6, 301. [Google Scholar] [CrossRef]

- Krick, B.; Vail, J.; Persson, B.J.; Sawyer, W.G. Optical in situ micro tribometer for analysis of real contact area for contact mechanics, adhesion, and sliding experiments. Tribol. Lett. 2012, 45, 185. [Google Scholar] [CrossRef]

- Krick, B.A.; Vail, J.R.; Persson, B.N.J.; Sawyer, W.G. Reply to the “Discussion of the paper by krick et al.: Optical in situ micro tribometer for analysis of real contact area for contact mechanics, adhesion, and sliding experiments”. Tribol. Lett. 2012, 46, 207. [Google Scholar] [CrossRef]

- Persson, B.N.J. Theory of rubber friction and contact mechanics. J. Chem. Phys. 2001, 115, 3840. [Google Scholar] [CrossRef]

- Erickson, G.M.; Krick, B.A.; Hamilton, M.; Bourne, G.R.; Norell, M.A.; Lilleodden, E.; Sawyer, W.G. Complex dental structure and wear biomechanics in hadrosaurid dinosaurs. Science 2012, 338, 98. [Google Scholar] [CrossRef] [PubMed]

- Maderson, P.F.A. Keratinized epidermal derivatives as an aid to climbing in gekkonid lizards. Nature 1964, 203, 780. [Google Scholar] [CrossRef]

- Russell, A.P. A contribution to the functional analysis of the foot of the Tokay, Gekko gecko (Reptilia: Gekkonidae). J. Zool. 1975, 176, 437. [Google Scholar] [CrossRef]

- Dunn, A.; Cobb, J.; Kantzios, A.; Lee, S.; Sarntinoranont, M.; Tran-Son-Tay, R.; Sawyer, W.G. Friction coefficient measurement of hydrogel materials on living epithelial cells. Tribol. Lett. 2008, 30, 13. [Google Scholar] [CrossRef]

- Ku, I.S.Y.; Reddyhoff, T.; Holmes, A.S.; Spikes, H.A. Wear of silicon surfaces in MEMS. Wear 2011, 271, 1050. [Google Scholar] [CrossRef]

- Bhushan, B.; Venkatesan, S. Friction and wear studies of silicon in sliding contact with thin-film magnetic rigid disks. J. Mater. Res. 1993, 8, 1611. [Google Scholar] [CrossRef]

- Shen, S.; Meng, Y.; Zhang, W. Characteristics of the wear process of side-wall surfaces in bulk-fabricated si-mems devices in nitrogen gas environment. Tribol. Lett. 2012, 47, 455. [Google Scholar] [CrossRef]

- Ahmed, S.I.U.; Bregliozzi, G.; Haefke, H. Microtribology of silicon, oxide, and carbide surfaces. Tribotest 2006, 12, 175. [Google Scholar] [CrossRef]

- Bandorf, R.; Luthje, H.; Staedler, T. Influencing factors on microtribology of DLC films for MEMS and microactuators. Diam. Relat. Mater. 2004, 13, 1491. [Google Scholar] [CrossRef]

- Dugger, M.T.; Eaton, W.P.; Irwin, L.W.; Miller, S.L.; Miller, W.M.; Smith, N.F.; Tanner, D.M.; Walraven, J.A. The Effect of Humidity on the Reliability of a Surface Micromachined Microengine. In Proceedings of the 1999 37th Annual IEEE International Reliability Physics Symposium, San Diego, CA, USA, 23–25 March 1999; pp. 189–197. [Google Scholar]

- Alsem, D.H.; van der Hulst, R.; Stach, E.A.; Dugger, M.T.; De Hosson, J.T.M.; Ritchie, R.O. Wear mechanisms and friction parameters for sliding wear of micron-scale polysilicon sidewalls. Sens. Actuators A Phys. 2010, 163, 373. [Google Scholar] [CrossRef]

- Beerschwinger, U.; Mathieson, D.; Reuben, R.L.; Yang, S.J. A study of wear on MEMS contact morphologies. J. Micromech. Microeng. 1994, 4, 95. [Google Scholar] [CrossRef]

- Houston, M.R.; Howe, R.T.; Komvopoulos, K.; Maboudian, R. Diamond-like carbon films for silicon passivation in microelectromechanical devices. In Proceedings of the Sixth Annual ACM-SIAM Symposium on Discrete Algorithms, San Francisco, CA, USA, 22–24 January 1995; p. 391. [Google Scholar]

- Krauss, A.R.; Auciello, O.; Gruen, D.M.; Jayatissa, A.; Sumant, A.; Tucek, J.; Mancini, D.C.; Moldovan, N.; Erdemir, A.; Ersoy, D.; et al. Ultrananocrystalline diamond thin films for MEMS and moving mechanical assembly devices. Diam. Relat. Mater. 2001, 10, 1952. [Google Scholar] [CrossRef]

- Suzuki, S.; Matsuura, T.; Uchizawa, M.; Yura, S.; Shibata, H.; Fujita, H. An Investigation of Micro Structures, Sensors, Actuators, Machines and Robots. In Proceedings of the IEEE Micro Electro Mechanical Systems (MEMS ’91), Nara, Japan, 30 December 1990–2 January 1991; pp. 143–147. [Google Scholar]

- Wang, X.D.; Hong, G.D.; Zhang, J.; Lin, B.L.; Gong, H.Q.; Wang, W.Y. Precise patterning of diamond films for MEMS application. J. Mater. Process. Technol. 2002, 127, 230. [Google Scholar] [CrossRef]

- Eapen, K.C.; Patton, S.T.; Smallwood, S.A.; Nainaparampil, J.J.; Zabinski, J.S. Aging of a fluorinated lubricant on bare and DLC-coated silicon-based MEMS. Surf. Coat. Technol. 2005, 197, 270. [Google Scholar] [CrossRef]

- Kvasnica, S.; Schalko, J.; Eisenmenger-Sittner, C.; Benardi, J.; Vorlaufer, G.; Pauschitz, A.; Roy, M. Nanotribological study of PECVD DLC and reactively sputtered Ti containing carbon films. Diam. Relat. Mater. 2006, 15, 1743. [Google Scholar] [CrossRef]

- Miki, H.; Takeno, T.; Takagi, T. Tribological properties of multilayer DLC/W-DLC films on Si. Thin Solid Films 2008, 516, 5414. [Google Scholar] [CrossRef]

- Zhang, T.H.; Huan, Y. Nanoindentation and nanoscratch behaviors of DLC coatings on different steel substrates. Compos. Sci. Technol. 2005, 65, 1409. [Google Scholar] [CrossRef]

- Xie, G.; Zheng, B.; Li, W.; Xue, W. Tribological behavior of diamond-like carbon film with different tribo-pairs: A size effect study. Appl. Surf. Sci. 2008, 254, 7022. [Google Scholar] [CrossRef]

- Grill, A. Review of the tribology of diamond-like carbon. Wear 1993, 168, 143. [Google Scholar] [CrossRef]

- Ferrari, A.C. Diamond-like carbon for magnetic storage disks. Surf. Coat. Technol. 2004, 180–181, 190. [Google Scholar] [CrossRef]

- Erdemir, A.; Donnet, C. Tribology of diamond-like carbon films: Recent progress and future prospects. J. Phys. D Appl. Phys. 2006, 39, R311. [Google Scholar] [CrossRef]

- Depositions performed by Surmet Corporation, 33 B Street, Burlington, MA 01803 Phone # 781-272-9185. Available online: http://www.surmet.com/.

- Donnet, C.; Erdmir, A. Tribology of Diamond-Like Carbon Films: Fundamentals and Applications; Springer: New York, NY, USA, 2008. [Google Scholar]

- Scharf, T.W.; Prasad, S.V.; Dugger, M.T.; Kotula, P.G.; Goeke, R.S.; Grubbs, R.K. Growth, structure, and tribological behavior of atomic layer-deposited tungsten disulphide solid lubricant coatings with applications to MEMS. Acta Mater. 2006, 54, 4731. [Google Scholar] [CrossRef]

- Scharf, T.W.; Prasad, S.V.; Dugger, M.T.; Mayer, T.M. Atomic Layer Deposition of Solid Lubricant Thin Films; American Society of Mechanical Engineers: New York, NY, USA; Washington, DC, USA, 2005; pp. 375–376. [Google Scholar]

- Wahl, K.J.; Dunn, D.N.; Singer, I.L. Effects of ion implantation on microstructure, endurance and wear behavior of IBAD MoS2. Wear 2000, 237, 1. [Google Scholar] [CrossRef]

- Lansdown, A.R. Molybdenum Disulphide Lubrication; Tribology Series; Dowson, D., Ed.; Elsevier Science B.V.: Amsteram, The Netherlands, 1999; Volume 35. [Google Scholar]

- Zabinski, J.S.; Donley, M.S.; Walck, S.D.; Schneider, T.R.; McDevitt, N.T. Effects of dopants on the chemistry and tribology of sputter-deposited mos2 films. Tribol. Trans. 1995, 38, 894. [Google Scholar] [CrossRef]

- Tagawa, M.; Yokota, K.; Ochi, K.; Akiyama, M.; Matsumoto, K.; Suzuki, M. Comparison of macro and microtribological property of molybdenum disulfide film exposed to leo space environment. Tribol. Lett. 2012, 45, 349. [Google Scholar] [CrossRef]

- Kim, H.; Lince, J. Direct visualization of sliding-induced tribofilm on Au/MoS2 nanocomposite coatings by c-AFM. Tribol. Lett. 2007, 26, 61. [Google Scholar] [CrossRef]

- Patton, S.T.; Zabinski, J.S. Fundamental studies of Au contacts in MEMS RF switches. Tribol. Lett. 2005, 18, 215. [Google Scholar] [CrossRef]

- Hyman, D.; Mehregany, M. Contact physics of gold microcontacts for MEMS switches. IEEE Trans. Compon. Packag. Technol. 1999, 22, 357. [Google Scholar] [CrossRef]

- Astrene, T.T. 20 Minutes with Dr. Michael T Dugger. Tribol. Lubr. Technol. 2005. [Google Scholar]

- Lince, J.R.; Kim, H.I.; Adams, P.M.; Dickrell, D.J.; Dugger, M.T. Nanostructural, electrical, and tribological properties of composite Au-MoS2 coatings. Thin Solid Films 2009, 517, 5516. [Google Scholar] [CrossRef]

- Lince, J.R. Tribology of co-sputtered nanocomposite Au/MoS2 solid lubricant films over a wide contact stress range. Tribol. Lett. 2004, 17, 419. [Google Scholar] [CrossRef]

- Tambe, N.S.; Bhushan, B. Micro/nanotribological characterization of PDMS and PMMA used for BioMEMS/NEMS applications. Ultramicroscopy 2005, 105, 238. [Google Scholar] [CrossRef]

- Bhushan, B. Handbook of Nanotechnology; Springer: Berlin, Germany, 2004. [Google Scholar]

- Shipway, P.H.; Ngao, N.K. Microscale abrasive wear of polymeric materials. Wear 2003, 255, 742. [Google Scholar] [CrossRef]

- Tsujii, Y.; Nomura, A.; Okayasu, K.; Gao, W.; Ohno, K.; Fukuda, T. AFM studies on microtribology of concentrated polymer brushes in solvents. J. Phys. 2009, 184, 012031. [Google Scholar] [CrossRef]

- Halperin, A.; Zhulina, E.B. Atomic Force Microscopy of Polymer Brushes: Colloidal versus Sharp Tips. Langmuir 2010, 26, 8933. [Google Scholar] [CrossRef] [PubMed]

- Drobek, T.; Spencer, N.D. Nanotribology of Surface-Grafted PEG Layers in an Aqueous Environment. Langmuir 2007, 24, 1484. [Google Scholar] [CrossRef] [PubMed]

- Ewers, B.W.; Batteas, J.D. Molecular Dynamics Simulations of Alkylsilane Monolayers on Silica Nanoasperities: Impact of Surface Curvature on Monolayer Structure and Pathways for Energy Dissipation in Tribological Contacts. J. Phys. Chem. C 2012, 116, 25165. [Google Scholar] [CrossRef]

- Bielecki, R.; Crobu, M.; Spencer, N. Polymer-Brush Lubrication in Oil: Sliding Beyond the Stribeck Curve. Tribol. Lett. 2013, 49, 263. [Google Scholar] [CrossRef]

- Sakata, H.; Kobayashi, M.; Otsuka, H.; Takahara, A. Tribological Properties of Poly(Methyl Methacrylate) Brushes Prepared by Surface-Initiated Atom Transfer Radical Polymerization; Nature Publishing Group: Avenel, NJ, USA, 2005; Volume 37, p. 9. [Google Scholar]

- Müller, M.; Lee, S.; Spikes, H.; Spencer, N. The Influence of Molecular Architecture on the Macroscopic Lubrication Properties of the Brush-Like Co-polyelectrolyte Poly(l-lysine)-g-poly(ethylene glycol) (PLL-g-PEG) Adsorbed on Oxide Surfaces. Tribol. Lett. 2003, 15, 395. [Google Scholar] [CrossRef]

- Ohmae, N.; Mori, S.; Martin, J.M. Micro and Nanotribology; ASME Press: New York, NY, USA, 2005; p. 185. [Google Scholar]

- Maboudian, R.; Ashurst, W.R.; Carraro, C. Tribological Challenges in Micromechanical Systems. Tribol. Lett. 2002, 12, 95. [Google Scholar] [CrossRef]

- Kang, Z.; Liu, Q.; Liu, Y. Preparation and micro-tribological property of hydrophilic self-assembled monolayer on single crystal silicon surface. Wear 2013, 303, 297. [Google Scholar] [CrossRef]

- Patton, S.T.; Voevodin, A.A.; Vaia, R.A.; Pender, M.; Diamanti, S.J.; Phillips, B. Nanoparticle Liquids for Surface Modification and Lubrication of MEMS Switch Contacts. J. Microelectromech. Syst. 2008, 17, 741. [Google Scholar] [CrossRef]

- Asay, D.; Dugger, M.; Kim, S. In-situ Vapor-Phase Lubrication of MEMS. Tribol. Lett. 2008, 29, 67. [Google Scholar] [CrossRef]

- Asay, D.B.; Kim, S.H. Molar Volume and Adsorption Isotherm Dependence of Capillary Forces in Nanoasperity Contacts. Langmuir 2007, 23, 12174. [Google Scholar] [CrossRef] [PubMed]

- Voevodin, A.A.; Vaia, R.A.; Patton, S.T.; Diamanti, S.; Pender, M.; Yoonessi, M.; Brubaker, J.; Hu, J.-J.; Sanders, J.H.; Phillips, B.S.; MacCuspie, R.I. Nanoparticle-wetted surfaces for Relays and Energy Transmission Contacts. Small 2007, 3, 1957. [Google Scholar] [CrossRef] [PubMed]

- Erdemir, A.; Eryilmaz, O.L.; Fenske, G. Synthesis of diamondlike carbon films with superlow friction and wear properties. J. Vac. Sci. Technol. A 2000, 18, 1987–1992. [Google Scholar] [CrossRef]

- Jiang, J.; Arnell, R.D.; Tong, J. The effect of substrate properties on tribological behaviour of composite DLC coatings. Tribol. Int. 1997, 30, 613. [Google Scholar] [CrossRef]

- Merhej, R.; Fouvry, S. Contact size effect on fretting wear behaviour: Application to an AISI 52100/AISI 52100 interface. Lubr. Sci. 2009, 21, 83. [Google Scholar] [CrossRef]

| Friction Laws | Ff vs. Area | Ff vs. L | Notes |

|---|---|---|---|

| Macroscale Theories | |||

| Amontons‘ law | Independent of Amacro | Law first discovered by Leonardo da Vinci | |

| Bowden and Tabor | Law results from contact roughness | ||

| Single-Asperity Theories | |||

| Non-adhesive (based on Hertz model) | Linear dependence of Ff on Aasp is generally believed to be true for microscale contacts, but has been questioned for nanoscale contacts | ||

| Adhesive (for example, Maugis–Dugdale) | Sublinear | – | |

| Category of Failure | Types of Failure |

|---|---|

| Fracture | Overload Fracture Fatigue Fracture |

| Creep | Applied Stress Intrinsic Stress Thermal Stress |

| Stiction | Solid Bridging Capillarity force van der Waals force Electrostatic force Asperity deformation force Micromachine critical stiffness |

| Electromigration | – |

| Wear | Adhesive Abrasive Corrosive |

| Degradation of Dielectrics | Leakage Charging Breakdown |

| Delamination, Contamination, Pitting of Contacting Surfaces, and Electrostatic Discharge | – |

| Type | Capability | Activation | Interfaces |

|---|---|---|---|

| (First) MEMS tribometer -1990 [62] | -Measurement of friction using restoring force of a displaced spring | Electrostatic attraction | -polySi * on Si3N4 -polySi on polySi |

| The Nanotractor [68] | -bi-directional motion -100 µm displacement range -high forces/velocities -study of friction and wear | ‘Inchworm foot’ | -monolayer coatings |

| MEMS electrostatic lateral output motor [69] | -wear behavior information at many contact locations -varying environmental conditions | Voltage applied to curled cantilever provides lateral motion | -bound/mobile hydrocarbon-based lubricants -Ionic-liquid lubricants -OTS self-assembled monolayer(SAM) coatings -DLC |

| Sidewall tribometer [70] | -first microdevice to measure kinetic friction at realistic MEMS contacts/velocities -various environmental conditions | Two electro-static comb-drive actuators | -monolayer coatings -thin hard coatings |

| Leiden MEMS tribometer [71] | -variety of tip shapes to be used -large range of normal forces -studying complex nanotribological effects -friction loops output | -Applied voltage to normal/lateral comb drive | -silicon oxide surfaces |

| Solid Lubricant | Wear Volume (µm3) (L: 3.0/5.0 mN) | So (MPa) | Friction (μ) (L: 3.0/5.0 mN) | Friction/Load Relationship |

|---|---|---|---|---|

| MoS2 | 1.1/1.9 | 39 (±6) | 0.15/0.14 | F ∝ L0.78 |

| Au-MoS2 | 0.3/0.5 | 23.2 (±0.4) | 0.10/0.10 | F ∝ L0.79 |

| Ti-MoS2 | 0.1/0.2 | 15 (±3) | 0.11/0.10 | F ∝ L0.84 |

| - | Stage I: Solid Lubrication | Stage II: Micro-Plowing | Stage III: Plowing |

|---|---|---|---|

| Limiting Friction (α) | ~small | ~big | ~Lm |

| Friction behavior | Hertzian | non-Hertzian | non-Hertzian |

| General sliding behavior | solid lubricant | solid lubricant | not solid lubricant |

| VAM | interfacial sliding and/or interfilm shearing | interfacial sliding + micro-plowing | Interfacial sliding + plowing |

| Wear mechanism | adhesion | micro-plowing + adhesion | plowing |

| Tribofilm Formation ^ | Yes | Yes | No |

| Transfer Film Present | Yes | Yes | No |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoyanov, P.; Chromik, R.R. Scaling Effects on Materials Tribology: From Macro to Micro Scale. Materials 2017, 10, 550. https://doi.org/10.3390/ma10050550

Stoyanov P, Chromik RR. Scaling Effects on Materials Tribology: From Macro to Micro Scale. Materials. 2017; 10(5):550. https://doi.org/10.3390/ma10050550

Chicago/Turabian StyleStoyanov, Pantcho, and Richard R. Chromik. 2017. "Scaling Effects on Materials Tribology: From Macro to Micro Scale" Materials 10, no. 5: 550. https://doi.org/10.3390/ma10050550

APA StyleStoyanov, P., & Chromik, R. R. (2017). Scaling Effects on Materials Tribology: From Macro to Micro Scale. Materials, 10(5), 550. https://doi.org/10.3390/ma10050550