Comparative Analysis of Mechanical Properties and Metal-Ceramic Bond Strength of Co-Cr Dental Alloy Fabricated by Different Manufacturing Processes

Abstract

:1. Introduction

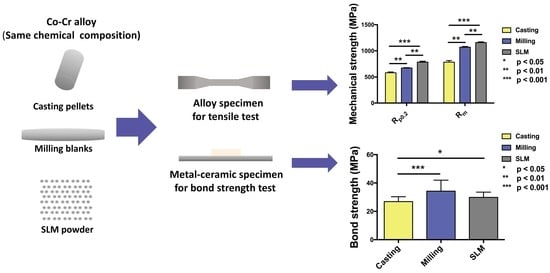

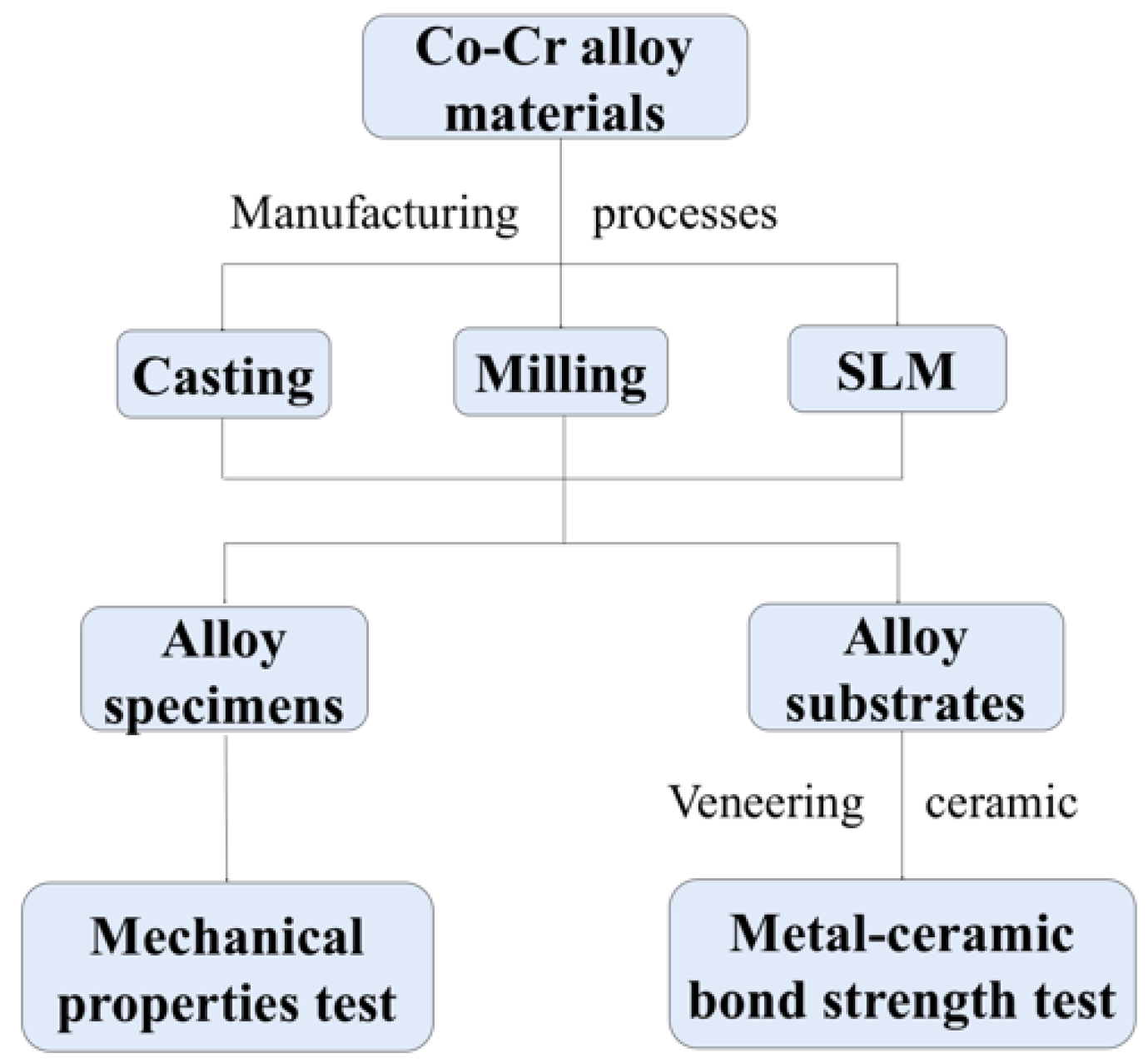

2. Materials and Methods

2.1. Specimen Preparation and Characterization of the Surface

2.1.1. Specimens Preparation for Mechanical Properties Test

2.1.2. Specimens Preparation for Metal-Ceramic Bond Strength Test

2.1.3. Surface Characterization

2.1.4. Application of the Veneering Ceramic

2.2. Mechanical Properties Test and Microstructure Analysis

2.3. Bond Strength Test and Microstructure Analysis

2.4. Statistical Analysis

3. Results

3.1. Surface Characteristics of the Metal Substrate

3.2. Mechanical Properties and Microstructure of Co-Cr Alloy Specimens

3.3. Bond Strength Test and Microstructure of Metal-Ceramic Specimens

4. Discussion

5. Conclusions

- The Co-Cr alloy specimens manufactured by the SLM technique have enhanced mechanical properties and comparable metal-ceramic bond strength compared with the specimens prepared by the casting and milling techniques;

- The microstructure of the Co-Cr alloy depends on the manufacturing techniques. Compared with casting and milling, the SLM specimens have relatively homogeneously distributed fine grains and more dispersed second-phase particles;

- According to the ISO 22674: 2016 and ISO 9693-1: 2012, the SLM technique can be used for fabricating dental bridges and crowns. SLM might be superior to the traditional manufacturing techniques for fixed dental restorations.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ANOVA | One-way analysis of variance |

| BSE | Backscattered electrons |

| CAD-CAM | Computer-aided design and computer-aided manufacturing |

| Co-Cr | Cobalt-chromium |

| CTE | Coefficient of thermal expansion |

| EDX | Energy dispersive X-Ray spectroscopy |

| PFM | Porcelain-fused-to-metal |

| Ra | Arithmetic average of the roughness profile |

| Rm | Ultimate tensile strength |

| Rp0.2 | 0.2 % yield strength |

| SEM | Scanning electron microscopy |

| SLM | Selective laser melting |

References

- Xin, X.Z.; Chen, J.; Xiang, N.; Gong, Y.; Wei, B. Surface characteristics and corrosion properties of selective laser melted Co-Cr dental alloy after porcelain firing. Dent. Mater. 2014, 30, 263–270. [Google Scholar] [CrossRef] [PubMed]

- Migliario, M.; Mergoni, G.; Vescovi, P.; De Martino, I.; Alessio, M.; Benzi, L.; Renò, F.; Fusco, V. Osteonecrosis of the jaw (ONJ) in osteoporosis patients: Report of delayed diagnosis of a multisite case and commentary about risks coming from a restricted ONJ definition. Dent. J. 2017, 5, 13. [Google Scholar] [CrossRef] [PubMed]

- Roberts, H.W.; Berzins, D.W.; Moore, B.K.; Charlton, D.G. Metal-ceramic alloys in dentistry: A review. J. Prosthodont. 2009, 18, 188–194. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.Y.; Kim, J.H.; Kim, H.Y.; Kim, W.C. Comparison and evaluation of marginal and internal gaps in cobalt–chromium alloy copings fabricated using subtractive and additive manufacturing. J. Prosthodont. Res. 2018, 62, 56–64. [Google Scholar] [CrossRef] [PubMed]

- Antanasova, M.; Kocjan, A.; Kovač, J.; Žužek, B.; Jevnikar, P. Influence of thermo-mechanical cycling on porcelain bonding to cobalt–chromium and titanium dental alloys fabricated by casting, milling, and selective laser melting. J. Prosthodont. Res. 2017, 62, 184–194. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Chen, C.; Liao, J.; Liu, L.; Ye, X.; Lin, S.; Ye, J. Bond strengths of porcelain to cobalt-chromium alloys made by casting, milling, and selective laser melting. J. Prosthet. Dent. 2017, 118, 69–75. [Google Scholar] [CrossRef] [PubMed]

- Sánchez Egea, A.J.; Martynenko, V.; Martínez Krahmer, D.; López de Lacalle, L.N.; Benítez, A.; Genovese, G. On the cutting performance of segmented diamond blades when dry-cutting concrete. Materials 2018, 11, 264. [Google Scholar] [CrossRef] [PubMed]

- Strub, J.R.; Rekow, E.D.; Witkowski, S. Computer-aided design and fabrication of dental restorations. J. Am. Dent. Assoc. 2006, 137, 1289–1296. [Google Scholar] [CrossRef] [PubMed]

- Demir, A.G.; Previtali, B. Additive manufacturing of cardiovascular CoCr stents by selective laser melting. Mater. Des. 2017, 119, 338–350. [Google Scholar] [CrossRef]

- Lu, Y.; Ren, L.; Wu, S.; Yang, C.; Lin, W.; Xiao, S.; Yang, Y.; Yang, K.; Lin, J. CoCrWCu alloy with antibacterial activity fabricated by selective laser melting: Densification, mechanical properties and microstructural analysis. Powder Technol. 2018, 325, 289–300. [Google Scholar] [CrossRef]

- Lu, Y.; Ren, L.; Xu, X.; Yang, Y.; Wu, S.; Luo, J.; Yang, M.; Liu, L.; Zhuang, D.; Yang, K. Effect of Cu on microstructure, mechanical properties, corrosion resistance and cytotoxicity of CoCrW alloy fabricated by selective laser melting. J. Mech. Behav. Biomed. Mater. 2018, 81, 130–141. [Google Scholar] [CrossRef] [PubMed]

- Hedberg, Y.S.; Qian, B.; Shen, Z.; Virtanen, S.; Odnevall Wallinder, I. In vitro biocompatibility of CoCrMo dental alloys fabricated by selective laser melting. Dent. Mater. 2014, 30, 525–534. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Zhao, C.; Ren, L.; Guo, S.; Gan, Y.; Yang, C.; Wu, S.; Lin, J.; Huang, T.; Yang, K. Preliminary assessment of metal-porcelain bonding strength of CoCrW alloy after 3 wt. % Cu addition. Mater. Sci. Eng. C 2016, 63, 37–45. [Google Scholar] [CrossRef] [PubMed]

- Martínez, S.; Lamikiz, A.; Ukar, E.; Calleja, A.; Arrizubieta, J.A.; de Lacalle, L.N.L. Analysis of the regimes in the scanner-based laser hardening process. Opt. Lasers Eng. 2017, 90, 72–80. [Google Scholar] [CrossRef]

- Badrossamay, M.; Childs, T.H.C. Further studies in selective laser melting of stainless and tool steel powders. Int. J. Mach. Tools Manuf. 2007, 47, 779–784. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Byeong-Don, J.O.O.; Jeong-Hwan, J.; Jae-Ho, L.E.E.; Young-Myung, S.O.N.; Young-Hoon, M. Selective laser melting of Fe-Ni-Cr layer on AISI H13 tool steel. Trans. Nonferrous Met. Soc. China 2009, 19, 921–924. [Google Scholar]

- Wysocki, B.; Idaszek, J.; Zdunek, J.; Rożniatowski, K.; Pisarek, M.; Yamamoto, A.; Święszkowski, W. The influence of selective laser melting (SLM) process parameters on in-vitro cell response. Int. J. Mol. Sci. 2018, 19, 1619. [Google Scholar] [CrossRef] [PubMed]

- Yadroitsev, I.; Bertrand, P.; Smurov, I. Parametric analysis of the selective laser melting process. Appl. Surf. Sci. 2007, 253, 8064–8069. [Google Scholar] [CrossRef]

- Kim, B.; Zhang, Y.; Pines, M.; Thompson, V.P. Fracture of porcelain-veneered structures in fatigue. J. Dent. Res. 2007, 86, 142–146. [Google Scholar] [CrossRef] [PubMed]

- Xin, X.; Xiang, N.; Chen, J.; Xu, D.; Wei, B. Corrosion characteristics of a selective laser melted Co–Cr dental alloy under physiological conditions. J. Mater. Sci. 2012, 47, 4813–4820. [Google Scholar] [CrossRef]

- Zeng, L.; Xiang, N.; Wei, B. A comparison of corrosion resistance of cobalt-chromium-molybdenum metal ceramic alloy fabricated with selective laser melting and traditional processing. J. Prosthet. Dent. 2014, 112, 1217–1224. [Google Scholar] [CrossRef] [PubMed]

- ISO 9693-1:2012 Dentistry—Compatibility Testing—Part 1: Metal-Ceramic Systems; International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 22674:2016 Dentistry—Metallic Materials for Fixed and Removable Restorations and Appliances; International Organization for Standardization: Geneva, Switzerland, 2016.

- Wu, L.; Zhu, H.; Gai, X.; Wang, Y. Evaluation of the mechanical properties and porcelain bond strength of cobalt-chromium dental alloy fabricated by selective laser melting. J. Prosthet. Dent. 2014, 111, 51–55. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Li, N.; Yan, J.; Zeng, Q. Comparative analysis of the microstructures and mechanical properties of Co-Cr dental alloys fabricated by different methods. J. Prosthet. Dent. 2018. [Google Scholar] [CrossRef] [PubMed]

- Fischer, J. Ceramic bonding to a dental gold–titanium alloy. Biomaterials 2002, 23, 1303–1311. [Google Scholar] [CrossRef]

- Johnson, T.; van Noort, R.; Stokes, C.W. Surface analysis of porcelain fused to metal systems. Dent. Mater. 2006, 22, 330–337. [Google Scholar] [CrossRef] [PubMed]

- Li, K.C.; Tran, L.Y.; Prior, D.J.; Waddell, J.N.; Swain, M.V. Porcelain bonding to novel Co–Cr alloys: Influence of interfacial reactions on phase stability, plasticity and adhesion. Dent. Mater. 2016, 32, 1504–1512. [Google Scholar] [CrossRef] [PubMed]

- De Melo, R.M.; Travassos, A.C.; Neisser, M.P. Shear bond strengths of a ceramic system to alternative metal alloys. J. Prosthet. Dent. 2005, 93, 64–69. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Lin, M.; Lee, T.; Yang, H.; Chen, F.; Wu, S.; Hsu, C. Effect of chemical composition of Ni-Cr dental casting alloys on the bonding characterization between porcelain and metal. J. Oral Rehabil. 2005, 32, 206–212. [Google Scholar] [CrossRef] [PubMed]

- Nikellis, I.; Levi, A.; Zinelis, S. Effect of soldering on the metal-ceramic bond strength of an Ni-Cr base alloy. J. Prosthet. Dent. 2005, 94, 435–439. [Google Scholar] [CrossRef] [PubMed]

- Saji, V.S.; Choe, H.-C. Electrochemical behavior of Co-Cr and Ni-Cr dental cast alloys. Trans. Nonferrous Met. Soc. China 2009, 19, 785–790. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Löber, L.; Wang, Z.; Chaubey, A.K.; Kühn, U.; Eckert, J. Microstructure and mechanical properties of Al–12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Kim, H.R.; Jang, S.H.; Kim, Y.K.; Son, J.S.; Min, B.K.; Kim, K.H.; Kwon, T.Y. Microstructures and mechanical properties of Co-Cr dental alloys fabricated by three CAD/CAM-based processing techniques. Materials 2016, 9. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Feng, Q.; Li, N.; Xu, S. Evaluation of metal-ceramic bond characteristics of three dental Co-Cr alloys prepared with different fabrication techniques. J. Prosthet. Dent. 2016, 116, 916–923. [Google Scholar] [CrossRef] [PubMed]

- Örtorp, A.; Jönsson, D.; Mouhsen, A.; Vult Von Steyern, P. The fit of cobalt-chromium three-unit fixed dental prostheses fabricated with four different techniques: A comparative in vitro study. Dent. Mater. 2011, 27, 356–363. [Google Scholar] [CrossRef] [PubMed]

- Serra-Prat, J.; Cano-Batalla, J.; Cabratosa-Termes, J.; Figueras-Àlvarez, O. Adhesion of dental porcelain to cast, milled, and laser-sintered cobalt-chromium alloys: Shear bond strength and sensitivity to thermocycling. J. Prosthet. Dent. 2014, 112, 600–605. [Google Scholar] [CrossRef] [PubMed]

- Akova, T.; Ucar, Y.; Tukay, A.; Balkaya, M.C.; Brantley, W.A. Comparison of the bond strength of laser-sintered and cast base metal dental alloys to porcelain. Dent. Mater. 2008, 24, 1400–1404. [Google Scholar] [CrossRef] [PubMed]

- Tabernero, I.; Lamikiz, A.; Martinez, S.; Ukar, E.; De Lacalle, L.N.L. Modelling of energy attenuation due to powder flow-laser beam interaction during laser cladding process. J. Mater. Process. Technol. 2012, 212, 516–522. [Google Scholar] [CrossRef]

- Dixit, U.S.; Joshi, S.N.; Davim, J.P. Incorporation of material behavior in modeling of metal forming and machining processes: A review. Mater. Des. 2011, 32, 3655–3670. [Google Scholar] [CrossRef]

- Silva, C.M.A.; Rosa, P.A.R.; Martins, P.A.F. Innovative testing machines and methodologies for the mechanical characterization of materials. Exp. Tech. 2016, 40, 569–581. [Google Scholar] [CrossRef]

- Krahmer, D.M.; Polvorosa, R.; de Lacalle, L.N.; Alonso-Pinillos, U.; Abate, G.; Riu, F. Alternatives for specimen manufacturing in tensile testing of steel plates. Exp. Tech. 2016, 40, 1555–1565. [Google Scholar] [CrossRef]

- Koutsoukis, T.; Zinelis, S.; Eliades, G.; Al-Wazzan, K.; Al Rifaiy, M.; Al Jabbari, Y.S. Selective laser melting technique of Co-Cr dental alloys: A review of structure and properties and comparative analysis with other available techniques. J. Prosthodont. 2015, 24, 303–312. [Google Scholar] [CrossRef] [PubMed]

- Beranoagirre, A.; Olvera, D.; de Lacalle, L.N. Milling of gamma titanium—Aluminum alloys. Int. J. Adv. Manuf. Technol. 2012, 62, 83–88. [Google Scholar] [CrossRef]

- Al Jabbari, Y.S.; Koutsoukis, T.; Barmpagadaki, X.; Zinelis, S. Metallurgical and interfacial characterization of PFM Co-Cr dental alloys fabricated via casting, milling or selective laser melting. Dent. Mater. 2014, 30, e79–e88. [Google Scholar] [CrossRef] [PubMed]

- Ayyıldız, S.; Soylu, E.H.; Ide, S.; Kılıç, S.; Sipahi, C.; Pişkin, B.; Gökçe, H.S. Annealing of Co-Cr dental alloy: Effects on nanostructure and Rockwell hardness. J. Adv. Prosthodont. 2013, 5, 471–478. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Wu, S.; Gan, Y.; Zhang, S.; Guo, S.; Lin, J.; Lin, J. Microstructure, mechanical property and metal release of As-SLM CoCrW alloy under different solution treatment conditions. J. Mech. Behav. Biomed. Mater. 2015, 55, 179–190. [Google Scholar] [CrossRef] [PubMed]

- Reyes, M.J.D.; Oshida, Y.; Andres, C.J.; Barco, T.; Hovijitra, S.; Brown, D. Titanium–porcelain system. Part III: Effects of surface modification on bond strengths. Biomed. Mater. Eng. 2001, 11, 117–136. [Google Scholar] [PubMed]

- Maressa, P.; Anodio, L.; Bernasconi, A.; Demir, A.G.; Previtali, B. Effect of surface texture on the adhesion performance of laser treated Ti6Al4V alloy. J. Adhes. 2015, 91, 518–537. [Google Scholar] [CrossRef]

- Henriques, B.; Faria, S.; Soares, D.; Silva, F.S. Hot pressing effect on the shear bond strength of dental porcelain to CoCrMoSi alloy substrates with different surface treatments. Mater. Sci. Eng. C 2013, 33, 557–563. [Google Scholar] [CrossRef] [PubMed]

- Fox, J.C.; Moylan, S.P.; Lane, B.M. Effect of process parameters on the surface roughness of overhanging structures in laser powder bed fusion additive manufacturing. Procedia CIRP 2016, 45, 131–134. [Google Scholar] [CrossRef]

- Bae, E.-J.; Kim, J.-H.; Kim, W.-C.; Kim, H.-Y. Bond and fracture strength of metal-ceramic restorations formed by selective laser sintering. J. Adv. Prosthodont. 2014, 6, 266. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vaithilingam, J.; Prina, E.; Goodridge, R.D.; Hague, R.J.M.; Edmondson, S.; Rose, F.R.A.J.; Christie, S.D.R. Surface chemistry of Ti6Al4V components fabricated using selective laser melting for biomedical applications. Mater. Sci. Eng. C 2016, 67, 294–303. [Google Scholar] [CrossRef] [PubMed]

- Xiang, N.; Xin, X.Z.; Chen, J.; Wei, B. Metal-ceramic bond strength of Co-Cr alloy fabricated by selective laser melting. J. Dent. 2012, 40, 453–457. [Google Scholar] [CrossRef] [PubMed]

| Materials | Brand Name | Material Type | Composition (wt %) | CTE (×10−6K−1) | Manufacturer |

|---|---|---|---|---|---|

| Co-Cr Alloy | Remanium Star | Metal ingots: casting | Co 60.5%, Cr 28%, W 9%, Si 1.5%, Other (Mn, N, Nb, Fe) < 1% | 14.1 | Dentaurum, Ispringen, Germany |

| Remanium Star MDI | Metal blank: milling | 14.1 | |||

| Remanium Star CL | Metal powder: SLM | 14.1 | |||

| Ceramic | Ceramotion Me | Dental ceramic | Glass (silica) based ceramic | 13.9–15.1 |

| Product Name | Pre-Heating Temp. (°C) | Drying Time (min) | Heating Rate (°C/min) | Final Temp. (°C) | Holding Time (min) | Vacuum |

|---|---|---|---|---|---|---|

| Paste opaque | 500 | 8 | 75 | 950 | 1 | + |

| 1st Dentin | 500 | 6 | 55 | 870 | 2 | + |

| 2nd Dentin | 500 | 6 | 55 | 870 | 1 | + |

| Glaze | 500 | 6 | 75 | 860 | 1 | - |

| Group | Ra (μm) |

|---|---|

| Casting | 1.27 ± 0.10 a |

| Milling | 1.33 ± 0.10 a |

| SLM | 1.51 ± 0.58 b |

| Group | Rp0.2 (MPa) | Rm (MPa) | Elongation (%) | Young’s Modulus (GPa) | Hardness (Hv 10) |

|---|---|---|---|---|---|

| Casting | 581 ± 16 a | 783 ± 32 a | 12 ± 2 ab | 188 ± 19 a | 303 ± 15 a |

| Milling | 672 ± 4 b | 1069 ± 10 b | 10 ± 1 a | 253 ± 14 b | 353 ± 6 b |

| SLM | 783 ± 15 c | 1158 ± 10 c | 13 ± 1 b | 195 ± 15 a | 399 ± 24 c |

| Group | Bond Strength (MPa) | Passing Rate (%) |

|---|---|---|

| Casting | 26.86 ± 3.48 a | 69% |

| Milling | 34.22 ± 7.77 b | 95% |

| SLM | 29.88 ± 3.62 b | 95% |

| Group | Frequency of the Failure Mode (n) | Area Fraction of Adhering Ceramic (%) | ||

|---|---|---|---|---|

| Adhesive | Cohesive | Mixed | ||

| Casting | 29 | 0 | 0 | 5.5 ± 3.1 a |

| Milling | 40 | 0 | 0 | 7.9 ± 3.4 b |

| SLM | 40 | 0 | 0 | 8.0 ± 3.2 b |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.; Sawada, T.; Schille, C.; Schweizer, E.; Scheideler, L.; Geis-Gerstorfer, J.; Rupp, F.; Spintzyk, S. Comparative Analysis of Mechanical Properties and Metal-Ceramic Bond Strength of Co-Cr Dental Alloy Fabricated by Different Manufacturing Processes. Materials 2018, 11, 1801. https://doi.org/10.3390/ma11101801

Han X, Sawada T, Schille C, Schweizer E, Scheideler L, Geis-Gerstorfer J, Rupp F, Spintzyk S. Comparative Analysis of Mechanical Properties and Metal-Ceramic Bond Strength of Co-Cr Dental Alloy Fabricated by Different Manufacturing Processes. Materials. 2018; 11(10):1801. https://doi.org/10.3390/ma11101801

Chicago/Turabian StyleHan, Xingting, Tomofumi Sawada, Christine Schille, Ernst Schweizer, Lutz Scheideler, Jürgen Geis-Gerstorfer, Frank Rupp, and Sebastian Spintzyk. 2018. "Comparative Analysis of Mechanical Properties and Metal-Ceramic Bond Strength of Co-Cr Dental Alloy Fabricated by Different Manufacturing Processes" Materials 11, no. 10: 1801. https://doi.org/10.3390/ma11101801

APA StyleHan, X., Sawada, T., Schille, C., Schweizer, E., Scheideler, L., Geis-Gerstorfer, J., Rupp, F., & Spintzyk, S. (2018). Comparative Analysis of Mechanical Properties and Metal-Ceramic Bond Strength of Co-Cr Dental Alloy Fabricated by Different Manufacturing Processes. Materials, 11(10), 1801. https://doi.org/10.3390/ma11101801