Recent Progress in Magnetron Sputtering Technology Used on Fabrics

Abstract

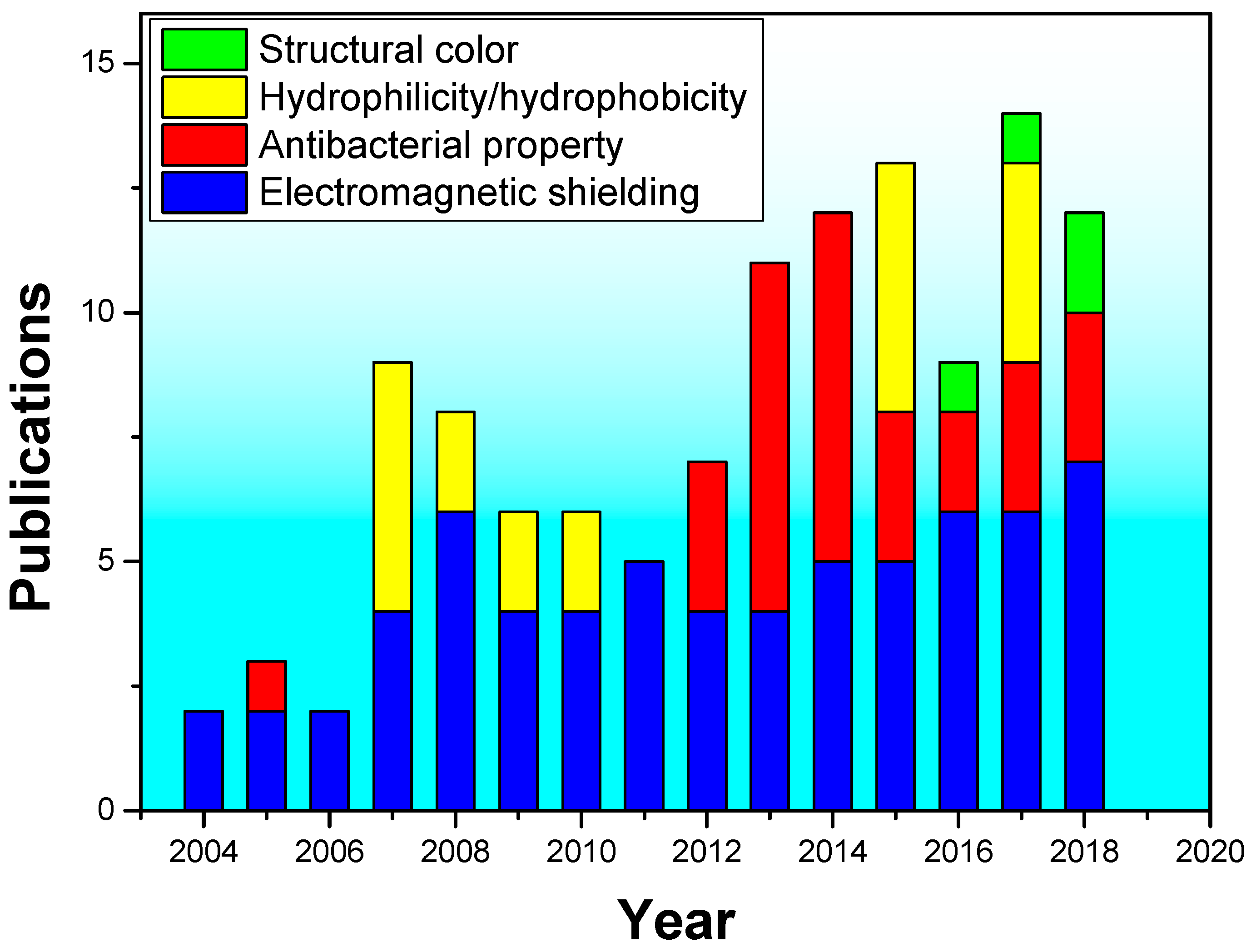

:1. Introduction

2. Application of Fabrics Coated with Magnetron Sputtering Nano Film

2.1. Nano Metal Film

2.1.1. Nano Cu Film

2.1.2. Nano Ag Film

2.1.3. Nano Ti Film

2.1.4. Nano Al film

2.1.5. Other Nano Metal Films

2.2. Nano Metal Oxide Films

2.2.1. Nano TiO2 Film

2.2.2. Nano ZnO Film

2.2.3. ITO (Indium Tin Oxide) and AZO (Aluminum Doped Zinc Oxide) Films

2.2.4. Other Nano Metal Oxides Films

2.3. Polymer Nano Film

2.4. Multi-layer Coated Nano Film

2.5. Effect of Plasma Pre-Treatment on Sputtering Coat

3. Conclusions and Outlooks

Author Contributions

Funding

Conflicts of Interest

References

- Asad, M.; Saba, N.; Asiri, A.M. Preparation and characterization of nanocomposite films from oil palm pulp nanocellulose/poly (vinyl alcohol) by casting Method. Carbohyd. Polym. 2018, 191, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Grant, D.S.; Siegele, R.; Bazaka, K. Formation of nanocrystalline and amorphous carbon by high fluence swift heavy ion irradiation of a plasma polymerized polyterpenol thin film precursor. J. Appl. Polym. Sci. 2018, 135, 29. [Google Scholar] [CrossRef]

- Comini, E. Metal oxide nano-crystals for gas sensing. Anal. Chim. Acta 2006, 568, 28–40. [Google Scholar] [CrossRef] [PubMed]

- Alagarasi, A.; Rajalakshmi, P.U.; Shanthi, K. Ordered mesoporous nanocrystalline titania: A promising new class of photocatalyic materials. Catal. Today 2018, 309, 202–211. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Weng, X.; Ahmed, S.R.; Neethirajan, S. A nanocomposite-based biosensor for bovine haptoglobin on a 3D paper-based analytical device. Sens. Actuator B Chem. 2018, 265, 242–248. [Google Scholar] [CrossRef]

- Lomov, S.V.; Wicks, S.; Gorbatrkh, L. Compressibility of nanofibre-grafted alumina fabric andyarns: Aligned carbon nanotube forests. Compos. Sci. Technol. 2014, 90, 57–66. [Google Scholar] [CrossRef]

- Lu, Y. Electroless copper plating on 3-mercaptopropyltriethoxysilane modified PET fabric challenged by ultrasonic washing. Appl. Surf. Sci. 2009, 255, 8430–8434. [Google Scholar] [CrossRef]

- Choi, K.K.; Lee, J.Y.; Lee, W.B. Chemical vapor deposition carbon film as a capping layer in 4H-SiC based mosfets. J. Nanosci. Nanotechnol. 2018, 18, 5868–5875. [Google Scholar] [CrossRef] [PubMed]

- Pan, C.; Shen, L.; Shang, S. Preparation of superhydrophobic and UV blocking cotton fabric via solgel method and self-assembly. Appl. Surf. Sci. 2012, 259, 110–117. [Google Scholar] [CrossRef]

- Ellmer, K. Magnetron sputtering of transparent conductive zinc oxide: Relation between the sputtering parameters and the electronic properties. J. Phys. D Appl. Phys. 2000, 33, 17–32. [Google Scholar] [CrossRef]

- Vaideki, K.; Jayakumar, S.; Rajendran, R. Investigation on the effect of RF air plasma and neemleaf extract treatment on the surface modification and antimicrobial activity of cotton fabric. Appl. Surf. Sci. 2008, 254, 2472–2478. [Google Scholar] [CrossRef]

- Xue, C.H.; Wang, R.L.; Zhang, J. Growth of ZnO nanorod forests and characterization of ZnO coated nylonfibers. Mater. Lett. 2010, 64, 327–330. [Google Scholar] [CrossRef]

- Liu, J.Y.; Cheng, K.B.; Hwang, J.F. Study on the electrical and surface properties of polyester, polypropylene, and polyamide 6 using pen-type RF plasma treatment. J. Ind. Text. 2011, 41, 123–141. [Google Scholar] [CrossRef]

- Hegemann, D.; Amberg, M.; Ritter, A. Recent developments in Ag metallised textiles using plasma sputtering. Mater. Technol. 2009, 24, 41–45. [Google Scholar] [CrossRef]

- Kelly, P.J.; Arnell, R.D. Magnetron Sputtering: A Review of recent developments and applications. Vacuum 2000, 56, 159–172. [Google Scholar] [CrossRef]

- Yuan, X.; Wei, Q.; Chen, D. Electrical and optical properties of polyester fabric coated with Ag/TiO2 composite films by magnetron sputtering. Text. Res. J. 2016, 86, 887–894. [Google Scholar] [CrossRef]

- Chen, Y.; Hsu, C.; He, J. Antibacterial silver coating on poly(ethylene tterephthalate) fabric by using high power impulse magnetron sputtering. Surf. Coat. Technol. 2013, 232, 868–875. [Google Scholar] [CrossRef]

- Baghriche, O.; Kiwi, J.; Pulgarin, C. Antibacterial Ag-ZrN surfaces promoted by subnanometric Zr N-clusters deposited by reactive pulsed magnetron sputtering. J. Photochem. Photobiol. A Chem. 2012, 229, 39–45. [Google Scholar] [CrossRef]

- Shahidi, S.; Ghoranneviss, M. Plasma sputtering for fabrication of antibacterial and ultraviolet protective fabric. Cloth. Text. Res. J. 2015, 34, 37–47. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, L.; Min, G. Surface functionalization of nanostructured LaB6-coated poly trilobal fabric by magnetron sputtering. Appl. Surf. Sci. 2016, 384, 413–418. [Google Scholar] [CrossRef]

- Depla, D.; Segers, S.; Leroy, W. Smart textiles: An explorative study of the use of magnetron sputter deposition. Text. Res. J. 2011, 81, 1808–1817. [Google Scholar] [CrossRef]

- Yip, J.; Jiang, S.; Wong, C. Characterization of metallic textiles deposited by magnetron sputtering and traditional metallic treatments. Surf. Coat. Technol. 2009, 204, 380–385. [Google Scholar] [CrossRef]

- Sanjines, R.; Ruales, C.; Castro, C. Antimicrobial Cu-functionalized surfaces prepared by bipolar asymmetric DC-pulsed magnetron sputtering (DCP). J. Photochem. Photobiol. A Chem. 2011, 220, 70–76. [Google Scholar]

- Hegemann, D.; Hossain, M.M.; Balazs, D.J. Nanostructured plasma coatings to obtain multifunctional textile surfaces. Prog. Org. Coat. 2007, 58, 237–240. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, H. Silver plating on hollow glass microsphere and coating finishing of PET/cotton fabric. J. Ind. Text. 2013, 42, 283–296. [Google Scholar] [CrossRef]

- Lai, K.; Sun, R.J.; Chen, M.Y. Electromagnetic shielding effectiveness of fabrics with metallized polyester filaments. Text. Res. J. 2007, 77, 242–246. [Google Scholar] [CrossRef]

- Weickmann, H.; Tiller, J.C.; Thomann, R. Metallized organoclays as new intermediates for aqueous nanohybrid dispersions, nanohybrid catalysts and antimicrobial polymer hybrid nanocomposites. Macromol. Mater. Eng. 2005, 290, 875–883. [Google Scholar] [CrossRef]

- Putnina, A.; Kukle, S. Textile Surface Modification of Materials by Sputtering Technology. Ph.D. Thesis, Riga Technical University, Riga, Latvia, 2010. [Google Scholar]

- Shcherbakova, N.N.; Pereshivailov, V.K.; Perevoznikova, Y.V. Intermediate process control of the fabrication of a conducting layer on the surface of nanofibrous materials. Glass Ceram. 2018, 74, 329–331. [Google Scholar] [CrossRef]

- Chodun, R.; Wicher, B.; Okrasa, S. Multi-sided metallization of textile fibers by using magnetron system with grounded cathode. Mater. Sci. 2017, 35, 639–646. [Google Scholar]

- Yu, X.; Shen, Z. Metal copper films coated on microparticle substrates using an ultrasonic-assisted magnetron sputtering system. Powder Technol. 2008, 187, 239–243. [Google Scholar] [CrossRef]

- Thornton, J.A. Magnetron sputtering: basic physics and application to cylindrical magnetrons. J. Vac. Sci. Technol. 1977, 15, 171–177. [Google Scholar] [CrossRef]

- Boroujeni, A.Y.; Alhaik, M.; Emami, A. Hybrid ZnO nanorod grafted carbon fiber reinforced polymer composites; Randomly versus radially aligned long ZnO nanorods growth. J. Nanosci. Nanotechnol. 2018, 18, 4182–4188. [Google Scholar] [CrossRef] [PubMed]

- Jia, Z.N.; Hao, C.Z.; Yang, Y.L. Tribological performance of hybrid PTFE/serpentine composites reinforced with nanoparticles. Tribol. Mater. Surf. Interface 2014, 8, 139–145. [Google Scholar] [CrossRef]

- Liu, Y.; Leng, J.; Wu, Q. Investigation on the properties of nano copper matrix composite via vacuum arc melting method. Mater. Res. Express 2017, 4, 10. [Google Scholar] [CrossRef]

- Ehiasarian, A.; Pulgarin, C.; Kiwi, J. Inactivation of bacteria under visible light and in the dark by Cu films. Advantages of Cu-HIPIMS-sputtered films. Environ. Sci. Pollut. Res. 2012, 19, 3791. [Google Scholar] [CrossRef] [PubMed]

- Scholz, J.; Nocke, G.; Hollstein, F. Investigations on fabrics coated with precious metals using the magnetron sputter technique with regard to their anti-microbial properties. Surf. Coat. Technol. 2005, 192, 252–256. [Google Scholar] [CrossRef]

- Russell, A.D. Biocide use and antibiotic resistance: The relevance of laboratory findings to clinical and environmental situations. Lancet Infect. Dis. 2003, 3, 794–803. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, Y.; Kim, J.W. Transparent and flexible film for shielding electromagnetic interference. Mater. Des. 2016, 89, 703–707. [Google Scholar] [CrossRef]

- Wang, L.; Wei, Q.; Meng, L. Morphology and properties of nanoscale copper films deposited on polyester substrates. Int. J. Cloth. Sci. Technol. 2014, 26, 367–376. [Google Scholar]

- Jiang, S.; Xu, J.; Chen, Z. Enhanced electro-conductivity and multi-shielding performance with copper, stainless steel and titanium coating onto PVA impregnated cotton fabric. J. Mater. Sci. Mater. Electron. 2018, 29, 5624–5633. [Google Scholar] [CrossRef]

- Miao, D.; Jiang, S.; Liu, J. Fabrication of copper and titanium coated textiles for sunlight management. J. Mater. Sci. Mater. Electron. 2017, 28, 9852–9858. [Google Scholar] [CrossRef]

- Amirsoleimani, M.; Khalilzadeh, M.A.; Sadeghifar, F. Surface modification of nanosatrch using nano silver: a potential antibacterial for food package coating. J. Food Sci. Technol. Mysore 2018, 55, 899. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Suganuma, K.; Iwashige, T. High-temperature reliability of sintered microporous Ag on electroplated Ag, Au, and sputtered Ag metallization substrates. J. Mater. Sci. Mater. Electron. 2018, 29, 1785–1797. [Google Scholar] [CrossRef]

- Chu, Z.; Zhao, T.; Li, L. Characterization of antimicrobial poly (lactic acid)/nano-composite films with silver and zinc oxide nanoparticles. Materials 2017, 10, 659. [Google Scholar] [CrossRef] [PubMed]

- Montazer, M.; Komeily, N.Z. Conductive nylon fabric through in situ synthesis of nano-silver: Preparation and characterization. Mater. Sci. Eng. C Mater. Biol. Appl. 2015, 56, 341–347. [Google Scholar] [CrossRef] [PubMed]

- Perumalraj, R.; Narayanan, K.S. Nano silver conductive composite material for electromagnetic compatibility. J. Reinf. Plast. Compos. 2014, 33, 1000–1016. [Google Scholar] [CrossRef]

- Charton, C.; Fahland, M. Electrical properties of Ag films on polyethylene terephthalate deposited by magnetron sputtering. Thin Solid Films 2004, 449, 100–104. [Google Scholar] [CrossRef]

- Du, W.Q.; Yu, F.; Qi, H.J. Sputter-deposited nano-metal films in a short period for electromagnetic shielding textiles. Adv. Mater. Res. 2011, 150, 1383–1386. [Google Scholar] [CrossRef]

- Rtimi, S.; Pascu, M.; Sanjines, R. ZrNO–Ag co-sputtered surfaces leading to E. coli, inactivation under actinic light: Evidence for the oligodynamic effect. Appl. Catal. B Environ. 2013, 138, 113–121. [Google Scholar] [CrossRef]

- Huang, X.M.; Wang, Q.W.; Li, Y.L. Effects of Ar gas pressure on characterization of nano-structured silver films deposited on the surface of polyester fabric. Appl. Mech. Mater. 2012, 189, 105–109. [Google Scholar] [CrossRef]

- Jiang, S.X.; Qin, W.F.; Guo, R.H. Surface functionalization of nanostructured silver-coated polyester fabric by magnetron sputtering. Surf. Coat. Technol. 2010, 204, 3662–3667. [Google Scholar] [CrossRef]

- Miao, D.; Li, A.; Jiang, S. Fabrication of Ag and AZO/Ag/AZO ceramic films on cotton fabrics for solar control. Ceram. Int. 2015, 41, 6312–6317. [Google Scholar] [CrossRef]

- Talebi, S.; Chaibakhsh, N.; Moradi-Shoeili, Z. Application of nanoscale ZnS/TiO2 composite for optimized photocatalytic decolorization of a textile dye. J. Appl. Res. Technol. 2017, 15, 378–385. [Google Scholar] [CrossRef]

- Veerachamy, S.; Hameed, P.; Sen, D. Studies on mechanical, biocompatibility and antibacterial activity of plasma sprayed nano/micron ceramic bilayered coatings on Ti-6Al-4V alloy for biomedical application. J. Nanosci. Nanotechnol. 2018, 18, 4515–4523. [Google Scholar] [CrossRef] [PubMed]

- Pan, F.; Gao, S.; Chen, C. Recent progress in resistive random access memories: Materials, switching mechanisms, and performance. Mater. Sci. Eng. R Rep. 2014, 83, 1–59. [Google Scholar] [CrossRef]

- Esen, M.; Ilhan, I.; Karaaslan, M. Electromagnetic absorbance properties of a textile material coated using filtered arc-physical vapor deposition method. J. Ind. Text. 2015, 45, 298–309. [Google Scholar] [CrossRef]

- Yao, C.W.; Sebastian, D.; Lian, I. Corrosion resistance and durability of superhydrophobic copper surface in corrosive NaCl aqueous solution. Coatings 2018, 8, 70. [Google Scholar] [CrossRef]

- Habisch, S.; Böhme, M.; Peter, S. The effect of interlayer materials on the joint properties of diffusion-bonded aluminium and magnesium. Metals 2018, 8, 138. [Google Scholar] [CrossRef]

- Xiao, H.; Guo, X.F.; Wang, X.S. Tensile properties affected by magnetron sputtering of nylon yam and its surface morphology observation. Text. Res. J. 2010, 5, 14. [Google Scholar]

- Liu, Z.M.; Du, H.; Shi, N.L.; Wen, L.S. Influence of conductivity size effect on the microwave absorption properties of aluminium films. Acta Metall. Sin. 2008, 44, 1099–1104. [Google Scholar]

- Bandorf, R.; Waschke, S.; Carreri, F.C. Direct metallization of PMMA with aluminum films using HIPIMS. Surf. Coat. Technol. 2016, 290, 77–81. [Google Scholar] [CrossRef]

- Shahidi, S.; Ghoranneviss, M.; Moazzenchi, B. Aluminum coatings on cotton fabrics with low temperature plasma of argon and oxygen. Surf. Coat. Technol. 2007, 201, 5646–5650. [Google Scholar] [CrossRef]

- Yuen, C.W.M.; Jiang, S.Q.; Kan, C.W. Influence of surface treatment on the electroless nickel plating of textile fabric. Appl. Surf. Sci. 2007, 253, 5250–5257. [Google Scholar] [CrossRef]

- Shahidi, S.; Ghoranneviss, M. Investigation on dye ability and antibacterial activity of nanolayer platinum coated polyester fabric using DC magnetron sputtering. Prog. Org. Coat. 2011, 70, 300–303. [Google Scholar] [CrossRef]

- Dhineshbabu, N.R.; Bercy, E.W. Multifunctional property of graphene oxide nanostructures on silica-coated cotton fabrics. J. Nanosci. Nanotechnol. 2018, 18, 4923. [Google Scholar] [CrossRef] [PubMed]

- Nam, Y.W.; Kumar, S.; Akhil, V. Multi-functional aramid/epoxy composite for stealth space hypervelocity impact shielding system. Compos. Struct. 2018, 193, 113–120. [Google Scholar] [CrossRef]

- Wilson, R.L.; Simion, C.E.; Blackman, C.S. The effect of film thickness on the gas sensing properties of ultra-thin TiO₂ films deposited byatomic layer deposition. Sensors 2018, 18, 735. [Google Scholar] [CrossRef] [PubMed]

- Alexandra, P.P.; Thomas, M.; Sandra, T. Highly sensitive SnO2 sensor via reactive laser-induced transfer. Sci. Rep. 2016, 6, 25144. [Google Scholar]

- Ramesan, M.T.; Santhi, V. In situ synthesis, characterization, conductivity studies of polypyrrole/silver doped zinc oxide nanocomposites and their application for ammonia gas sensing. J. Mater. Sci. Mater. Electron. 2017, 28, 18804–18814. [Google Scholar] [CrossRef]

- Molina-Reyes, J. Design and electrochemical characterization of ion-sensitive capacitors with ALD Al2O3 as the sensitive dielectric. IEEE Sens. J. 2018, 18, 231–236. [Google Scholar] [CrossRef]

- Mothes, F.; Ifang, S.; Gallus, M. Bed flow photoreactor experiments to assess the photocatalytic nitrogen oxides abatement under simulated atmospheric conditions. Appl. Catal. B Environ. 2018, 231, 161–172. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, H.; Wei, Q. Structures and properties of the polyester nonwovens coated with titanium dioxide by reactive sputtering. J. Coat. Technol. Res. 2010, 7, 637–642. [Google Scholar] [CrossRef]

- Zgura, I.; Frunza, S.; Frunza, L. Titanium dioxide layer deposited at low temperature upon polyester fabrics. J. Optoelectron. Adv. Mater. 2015, 17, 1055–1063. [Google Scholar]

- Xu, Y.; Xu, W.; Huang, F. Preparation and photocatalytic activity of TiO2-deposited fabrics. Int. J. Photoenergy 2012, 2012, 1–5. [Google Scholar]

- Zhang, Y.M. Research on preparation and properties of textile materials deposited with nanostructured titanium oxide. Adv. Mater. Res. 2014, 998, 136–139. [Google Scholar] [CrossRef]

- Rtimi, S.; Sanjines, R.; Andrzejczuk, M. Innovative transparent non-scattering TiO2, bactericide thin films inducing increased E. coli cell wall fluidity. Surf. Coat. Technol. 2014, 254, 333–343. [Google Scholar] [CrossRef]

- Rtimi, S.; Baghriche, O.; Sanjines, R. TiON and TiON-Ag sputtered surfaces leading to bacterial inactivation under indoor actinic light. J. Photochem. Photobiol. A Chem. 2013, 256, 52–63. [Google Scholar] [CrossRef] [Green Version]

- Rtimi, S.; Baghriche, O.; Sanjines, R. Photocatalysis/catalysis by innovative TiN and TiN-Ag surfaces inactivate bacteria under visible light. Appl. Catal. B Environ. 2012, 123, 306–315. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Sheng, J.; Yin, X. Functional modification of breathable polyacrylonitrile/polyurethane/TiO2 nanofibrous membranes with robust ultraviolet resistant and waterproof performance. J. Colloid Interface Sci. 2017, 508, 508–516. [Google Scholar] [CrossRef] [PubMed]

- Miao, D.; Hu, H.; Li, A. Fabrication of porous and amorphous TiO2, thin films on flexible textile substrates. Ceram. Int. 2015, 41, 9177–9182. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, X.; Li, X. Surface modification of PMMA/O-MMT composite microfibers by TiO2 coating. Appl. Surf. Sci. 2011, 258, 98–102. [Google Scholar] [CrossRef]

- Chuang, K.T.; Abdullah, H.; Leu, S.J. Metal oxide composite thin films made by magnetron sputtering for bactericidal application. J. Photochem. Photobiol. A Chem. 2017, 337, 151–164. [Google Scholar] [CrossRef]

- Ni, L.W.S.; Kaneti, Y.V.; Yuliarto, B. Hybrid nanoarchitecturing of hierarchical zinc oxide wool-ball-like nanostructures with multi-walled carbon nanotubes for achieving sensitive and selective detection of sulfur dioxide. Sens. Actuator B Chem. 2018, 261, 241–251. [Google Scholar]

- Ahmed, M.A.M.; Mwankemwa, B.S.; Carleschi, E. Effect of Sm doping ZnO nanorods on structural optical and electrical properties of Schottky diodes prepared by chemical bath deposition. Mater. Sci. Semicond. Process 2018, 79, 53–60. [Google Scholar] [CrossRef]

- Deng, B.; Yan, X.; Wei, Q. AFM characterization of nonwoven material functionalized by ZnO sputter coating. Mater. Charact. 2007, 58, 854–858. [Google Scholar] [CrossRef]

- Mao, X.; Zou, J.; Li, H. Magnetron sputtering fabrication and photoelectric properties of WSe2 film solar cell device. Appl. Surf. Sci. 2018, 444, 126–132. [Google Scholar] [CrossRef]

- Wang, K.L.; Xin, Y.Q.; Zhao, J.F. High transmittance in IR region of conductive ITO/AZO multilayers deposited by RF magnetron sputtering. Ceram. Int. 2018, 44, 6769–6774. [Google Scholar] [CrossRef]

- Beica, T.; Nistor, L.C.; Morosanu, C. Studies on multifunctional textile materials. Plasma deposition onto textile materials and onto reference plates. J. Optoelectron. Adv. Mater. 2008, 10, 2811–2817. [Google Scholar]

- Jiang, S.; Xu, J.; Miao, D. Water-repellency, ultraviolet protection and infrared emissivity properties of AZO film on polyester fabric. Ceram. Int. 2017, 43, 2424–2430. [Google Scholar] [CrossRef]

- Koc, U.; Karaca, G.Y.; Oksuz, A.U. RF sputtered electrochromic wool textile in different liquid media. J. Mater. Sci. Mater. Electron. 2017, 28, 8725–8732. [Google Scholar] [CrossRef]

- Schawaller, D.; Voss, M.; Bauch, V. Flexible, switchable electrochromic textiles. Macromol. Mater. Eng. 2014, 299, 330–335. [Google Scholar] [CrossRef]

- Subramanian, B.; Priya, K.A.; Rajan, S.T. Antimicrobial activity of sputtered nanocrystalline CuO impregnated fabrics. Mater. Lett. 2014, 128, 1–4. [Google Scholar] [CrossRef]

- Eren, E.; Karaca, G.Y.; Alver, C. Fast electrochromic response for RF-magnetron sputtered electrospun V2O5 mat. Eur. Polym. J. 2016, 84, 345–354. [Google Scholar] [CrossRef]

- Alawajji, R.A.; Kannarpady, G.K.; Biris, A.S. Fabrication of transparent superhydrophobic polytetrafluoroethylene coating. Appl. Surf. Sci. 2018, 444, 208–215. [Google Scholar] [CrossRef]

- Mahdavi, H.R.; Arzani, M.; Isanejad, M. Effect of hydrophobic and hydrophilic nanoparticles loaded in D2EHPA/M2EHPA—PTFE supported liquid membrane for simultaneous cationic dyes pertraction. J. Environ. Manag. 2018, 213, 288–296. [Google Scholar] [CrossRef] [PubMed]

- Huang, F.; Wei, Q.; Liu, Y. Surface functionalization of silk fabric by PTFE sputter coating. J. Mater. Sci. 2007, 42, 8025–8028. [Google Scholar] [CrossRef]

- Wi, D.Y.; Kim, I.W.; Kim, J. Water repellent cotton fabrics prepared by PTFE RF sputtering. Fiber Polym. 2009, 10, 98–101. [Google Scholar] [CrossRef]

- Huang, M.L.; Di, J.F.; Qi, H.J. Research of producing antiultraviolet PET fabric through magnetron sputtering. Cotton Text. Technol. 2008, 36, 7–9. [Google Scholar]

- Miao, D.; Jiang, S.; Shang, S. Infrared reflective properties of AZO/Ag/AZO trilayers prepared by RF magnetron sputtering. Ceram. Int. 2014, 40, 12847–12853. [Google Scholar] [CrossRef]

- Miao, D.; Zhao, H.; Peng, Q. Fabrication of high infrared reflective ceramic films on polyester fabrics by RF magnetron sputtering. Ceram. Int. 2015, 41, 1595–1601. [Google Scholar] [CrossRef]

- Yuan, X.; Xu, W.; Huang, F. Structural colors of fabric from Ag/TiO2 composite films prepared by magnetron sputtering deposition. Int. J. Cloth. Sci. Technol. 2017, 29, 427–435. [Google Scholar] [CrossRef]

- Koprowska, J.; Dobruchowska, E.; Reszka, K. Morphology and electromagnetic shielding effectiveness of PP nonwovens modified with metallic layers. Fiber Text. East. Eur. 2015, 5, 84–91. [Google Scholar] [CrossRef]

- Ziaja, J.; Koprowska, J.; Janukiewicz, J. Using plasma metallisation for manufacture of textile screens against electromagnetic fields. Fiber Text. East. Eur. 2008, 16, 64–66. [Google Scholar]

- Ziaja, J.; Ozimek, M.; Koprowska, J. Metallic and oxide Zn and Ti layers on unwoven fabric as shields for electromagnetic fields. In Proceedings of the 2009 EMC Europe Workshop Materials in EMC Applications, Athens, Greece, 11 June 2009; pp. 1–4. [Google Scholar]

- Rtimi, S.; Baghriche, O.; Pulgarin, C. Growth of TiO2/Cu films by hipims for accelerated bacterial loss of viability. Surf. Coat. Technol. 2013, 232, 804–813. [Google Scholar] [CrossRef]

- Rtimi, S.; Giannakis, S.; Pulgarin, C. Self-sterilizing sputtered films for applications in hospital facilities. Molecules 2017, 22, 7. [Google Scholar] [CrossRef] [PubMed]

- Rtimi, S.; Sanjines, R.; Bensimon, M. Accelerated Escherichia coli inactivation in the dark on uniform copper flexible surfaces. Biointerphases 2014, 9, 2. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.H.; Wu, G.W.; He, J.L. Antimicrobial brass coatings prepared on poly (ethylene terephthalate) textile by high power impulse magnetron sputtering. Mater. Sci. Eng. C Mater. Biol. Appl. 2015, 48, 41–47. [Google Scholar] [CrossRef] [PubMed]

- Saffari, M.R.; Miab, R.K. The antibacterial property of PLA textiles coated by nano-TiO2 through eco-friendly low temperature plasma. Int. J. Cloth. Sci. Technol. 2016, 28, 830–840. [Google Scholar] [CrossRef]

- Wei, Q.; Wang, H.; Deng, B. Surface and interface investigation of indium-tin-oxide (ITO) coated nonwoven fabrics. J. Adhes. Sci. Technol. 2010, 24, 135–147. [Google Scholar] [CrossRef]

| Serial Number | Target Materials | Functions | Characterizing Methods |

|---|---|---|---|

| 1 | Cu, Ag, Ti, Al, Ni, TiO2, ZnO, WO3, V2O5, Al2O3, ITO, AZO, etc. | Electromagnetic shielding, anti-static, conductive properties | Electromagnetic shielding efficiency, charge surface density, electrical conductivity, resistivity, square resistance |

| 2 | Cu, Ag, Ti, Al, Ni, Pt, TiO2, ZnO, MgO, ITO, AZO, PTFE, etc. | Anti-UV, anti-infrared properties | UPF (ultraviolet protection factor) value, infrared reflectivity |

| 3 | Cu, Ag, Zn, Ti, TiO2, Pt, ZnO, MgO, CuO, brass, etc. | Antibacterial property | Bacteriostatic rate |

| 4 | Ni, Al, TiO2, PTFE, TiN, SiO2, etc. | Hydrophobic and hydrophilic properties | Static contact angle, surface free energy |

| 5 | TiO2, ZnO, MgO, SnO2, Al2O3, Fe2O3, etc. | Adsorbed gas or gas sensitivity properties | Resistivity, electrical conductivity |

| 6 | Ti, Al, TiO2, WO3, SiO2, SnO2, TiN, etc. | Structural color effect | Reflectance, transmittance, refractive index |

| 7 | SiO2, Al2O3, LaB6, etc. | Heat resistant or warmness | Thermal stability, Thermal insulation coefficient, Thermal conductivity |

| 8 | Cu, Ag, Pt | Improved dyeing fastness | Light fastness, washing fastness |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, X.-Q.; Liu, J.-Y.; Niu, J.-R.; Liu, J.-Y.; Tian, J.-Y. Recent Progress in Magnetron Sputtering Technology Used on Fabrics. Materials 2018, 11, 1953. https://doi.org/10.3390/ma11101953

Tan X-Q, Liu J-Y, Niu J-R, Liu J-Y, Tian J-Y. Recent Progress in Magnetron Sputtering Technology Used on Fabrics. Materials. 2018; 11(10):1953. https://doi.org/10.3390/ma11101953

Chicago/Turabian StyleTan, Xue-Qiang, Jian-Yong Liu, Jia-Rong Niu, Jia-Yin Liu, and Jun-Ying Tian. 2018. "Recent Progress in Magnetron Sputtering Technology Used on Fabrics" Materials 11, no. 10: 1953. https://doi.org/10.3390/ma11101953

APA StyleTan, X. -Q., Liu, J. -Y., Niu, J. -R., Liu, J. -Y., & Tian, J. -Y. (2018). Recent Progress in Magnetron Sputtering Technology Used on Fabrics. Materials, 11(10), 1953. https://doi.org/10.3390/ma11101953