Development of SiC/PVB Composite Powders for Selective Laser Sintering Additive Manufacturing of SiC

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

4. Conclusions

- (1)

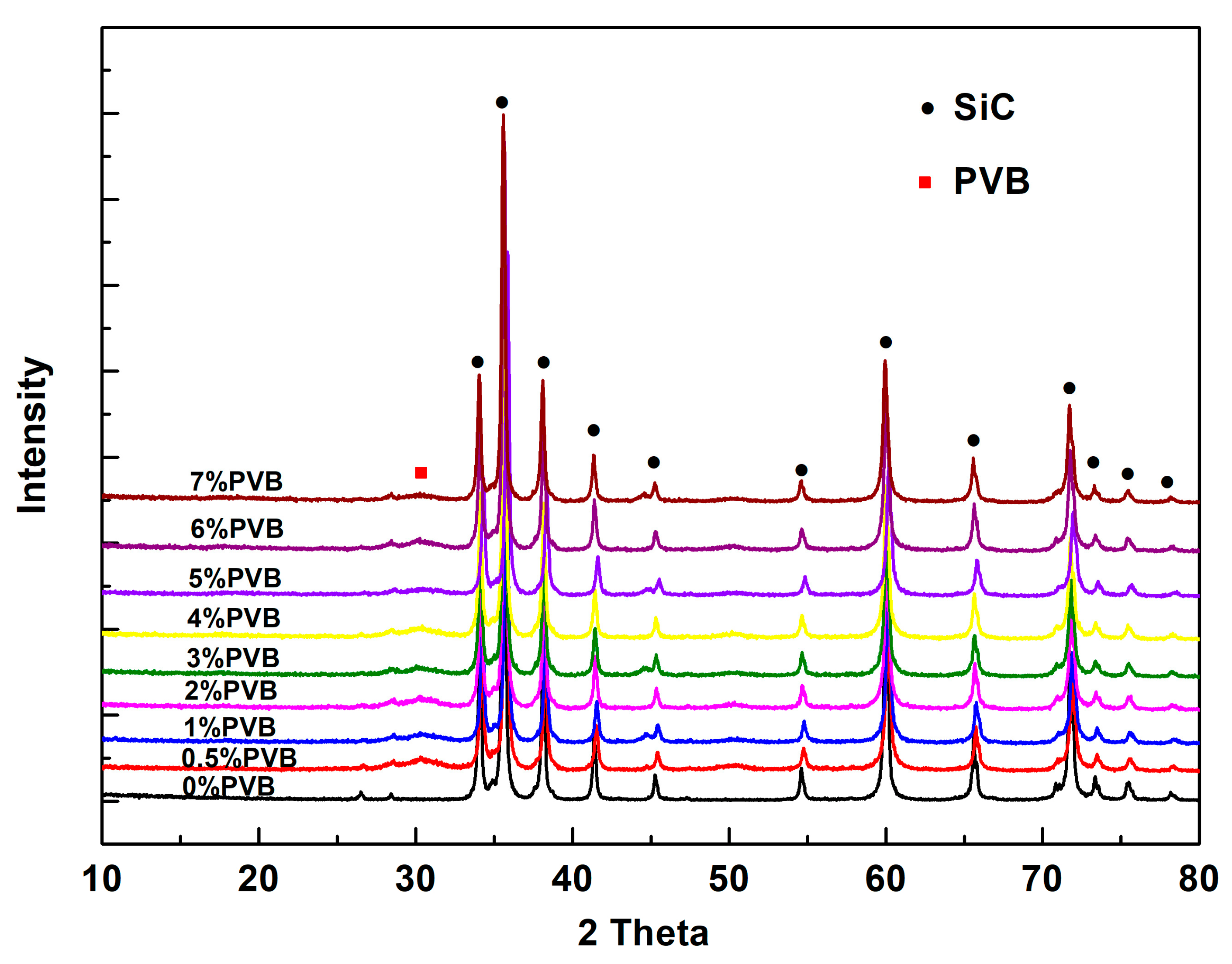

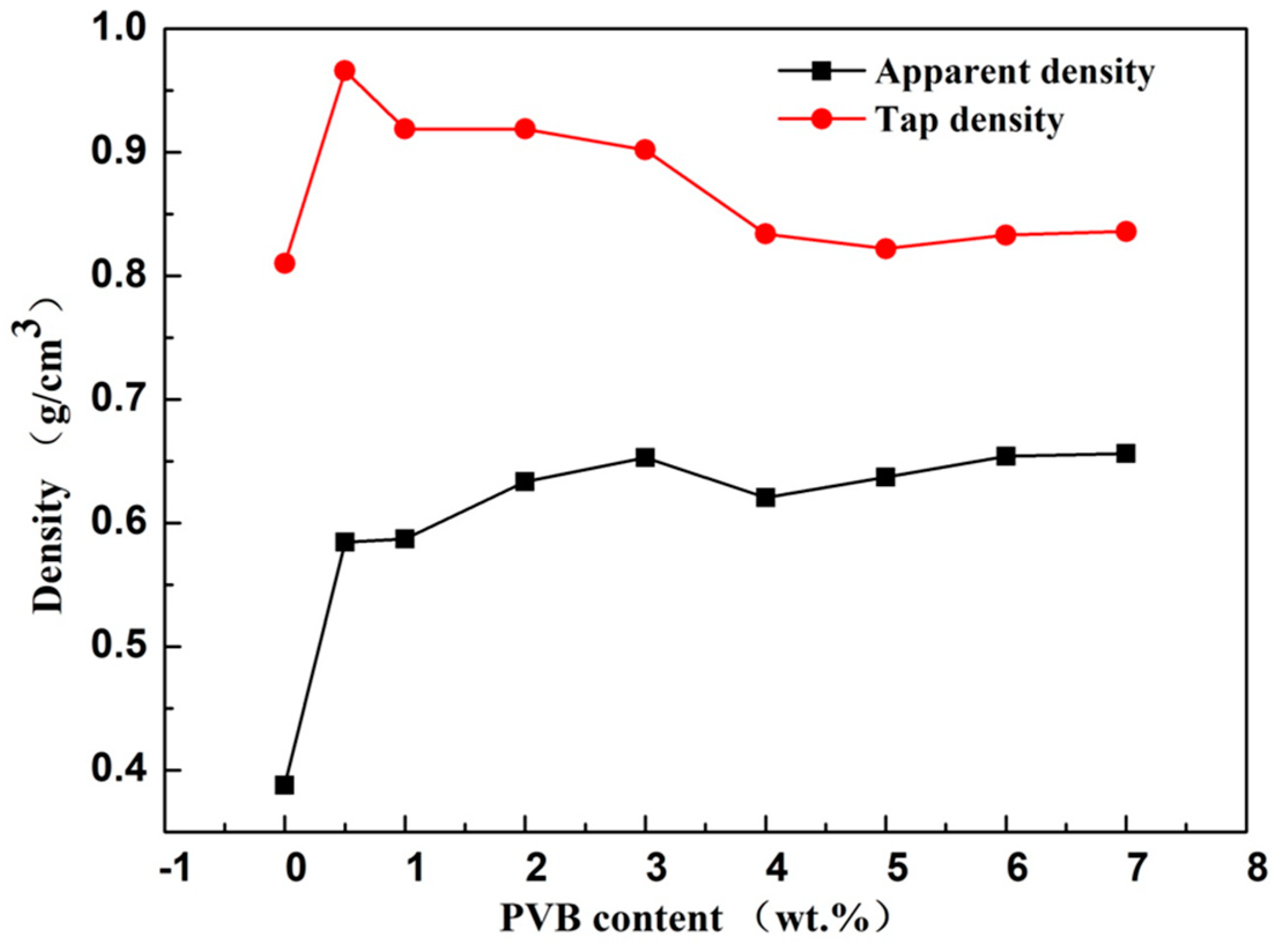

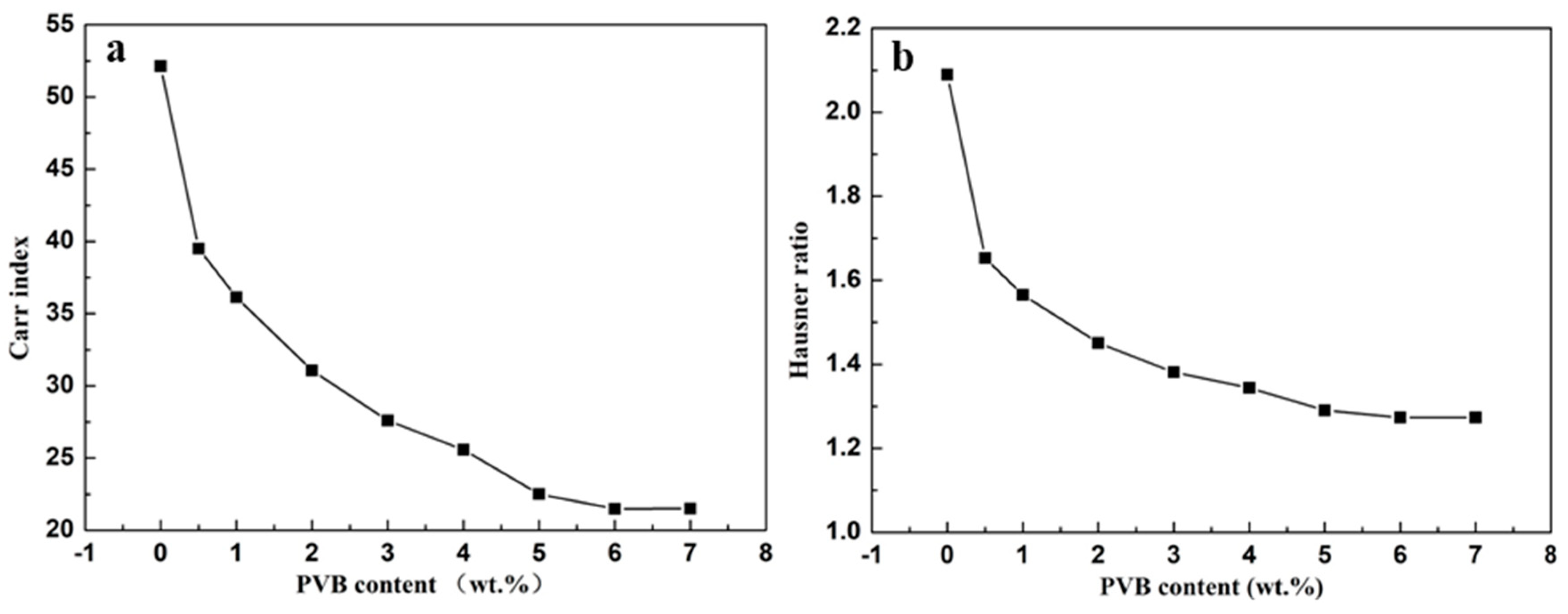

- The addition content of PVB has an optimal value (~3 wt. %). The modified SiC/PVB granules under the optimal addition of PVB exhibit good flowability and spreading performance.

- (2)

- The resultant composite powder shows good laser absorptivity when the wavelength is below 500 nm, suggesting that SLS additive manufacturing of the composite powder may be applicable using 3D printers of the corresponding wavelength (e.g., below 500 nm).

- (3)

- Results show that the addition of the polymer binder improves the size distribution characteristic and flowability of the granulated particles within a certain range. However, when the PVB content increases to a higher value (e.g., more than 7 wt. %), greater addition of PVB will not have much influence on the apparent density, tap density, Carr index or Hausner ratio.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Matović, B.; Bučevac, D.; Urbanović, V.; Stanković, N.; Daneu, N.; Volkov-Husović, T.; Babic, B. Monolithic nanocrystalline SiC ceramics. J. Eur. Ceram. Soc. 2016, 36, 3005–3010. [Google Scholar] [CrossRef]

- Iwami, M. Silicon carbide: Fundamentals. Nucl. Instrum. Methods Phys. Res. A 2001, 466, 406–411. [Google Scholar] [CrossRef]

- Wing, B.L.; Halloran, J.W. Relaxation of residual microstress in reaction bonded silicon carbide. Ceram. Int. 2018, 44, 11745–11750. [Google Scholar] [CrossRef]

- Kaźmierczak-Bałata, A.; Mazur, J. Effect of carbon nanoparticle reinforcement on mechanical and thermal properties of silicon carbide ceramics. Ceram. Int. 2018, 44, 10273–10280. [Google Scholar] [CrossRef]

- Lara, A.; Ortiz, A.L.; Muñoz, A.; Domínguez-Rodríguez, A. Densification of additive-freepolycrystalline-SiC by spark-plasma sintering. Ceram. Int. 2012, 38, 45–53. [Google Scholar] [CrossRef]

- Leua, M.C.; Pattnaika, S.; Hilmas, G.E. Investigation of laser sintering for freeform fabrication of zirconium diboride parts. Virtual Phys. Prototyp. 2012, 7, 25–36. [Google Scholar] [CrossRef]

- Chen, A.N.; Wu, J.M.; Liu, K.; Chen, J.Y.; Xiao, H.; Chen, P.; Li, C.H.; Shi, Y.S. High-performance ceramic parts with complex shape prepared by selective laser sintering: A review. Adv. Appl. Ceram. 2017, 4, 1–18. [Google Scholar] [CrossRef]

- Shao, H.; He, Y.; Fu, J.; He, D.; Yang, X.; Xie, J.; Yao, C.; Ye, J.; Xu, S.; Gou, Z. 3D printing magnesium-doped wollastonite/b-TCP bioceramics scaffolds with high strength and adjustable degradation. J. Eur. Ceram. Soc. 2016, 36, 1495–1503. [Google Scholar] [CrossRef]

- Ben, Y.; Zhang, L.; Wei, S.; Zhou, T.Y.; Li, Z.; Yang, H.; Wang, Y.; Selim, F.A.; Wong, C.P.; Chen, H. PVB modified spherical granules of b-TCP by spray drying for 3D ceramic printing. J. Alloys Compd. 2017, 721, 312–319. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Boury, S.; Neirinck, B.; Kruth, J.P.; Vleugels, J. Preparation and indirect selective laser sintering of alumina/PA microspheres. Ceram. Int. 2012, 38, 1241–1247. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Zhang, Z.Y.; Kruth, J.P.; Vleugels, J. Additive manufacturing of zirconia parts by indirect selective laser sintering. J. Eur. Ceram. Soc. 2014, 34, 81–89. [Google Scholar] [CrossRef]

- Chang, S.; Li, L.; Lu, L.; Fuh, J.Y.H. Selective laser sintering of porous silica enabled by carbon additive. Materials 2017, 10, 1313. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.H.; Lin, S.F.; Hou, Y.H.; Wang, D.W.; Zhou, P.; Han, P.L.; Li, Y.L.; Yan, M. Layered surface structure of gas-atomized high Nb-containing TiAl powder and its impact on laser energy absorption for selective laser melting. Appl. Surf. Sci. 2018, 441, 210–217. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Kruth, J.P.; Vleugels, J. Additive manufacturing of alumina parts by indirect selective laser sintering and post processing. J. Mater. Process. Technol. 2013, 213, 1484–1494. [Google Scholar] [CrossRef]

- Yu, Y.Q.; Guo, Y.L.; Jiang, T.; Li, J.; Jiang, K.Y.; Zhang, H. Study on the ingredient proportions and after-Treatment of laser sintering walnut shell composites. Materials 2017, 10, 1381. [Google Scholar] [CrossRef] [PubMed]

- Tian, X.; Li, D.; Heinrich, J.G. Rapid prototyping of porcelain products by layerwise slurry deposition (LSD) and direct laser sintering. Rapid Prototyp. J. 2012, 18, 362–373. [Google Scholar] [CrossRef]

- Klocke, F.; Derichs, C.; Ader, C.; Demmer, A. Investigations on laser sintering of ceramic slurries. Prod. Eng. 2007, 1, 279–284. [Google Scholar] [CrossRef]

- Wu, Y.; Du, J.; Choy, K.L.; Hench, L.L. Laser densification of powder beds generated using aerosol assisted spray deposition. J. Eur. Ceram. Soc. 2007, 27, 4727–4735. [Google Scholar] [CrossRef]

- Gahler, A.; Heinrich, J.G. Direct laser sintering in the Al2O3-SiO2 dental ceramic components by layer-wise slurry deposition. J. Am. Ceram. Soc. 2006, 89, 3076–3080. [Google Scholar] [CrossRef]

- Drummer, D.; Rietzel, D.; Kühnlein, F. Development of a characterization approach for the sintering behavior of new thermoplastics for selective laser sintering. Phys. Procedia 2010, 5, 533–542. [Google Scholar] [CrossRef]

- Zhang, L.; Ben, Y.; Chen, H.; Tang, D.; Fu, X.; Sun, R.; Song, B.; Wong, C. Low temperature-sintering and microstructure of highly transparent yttria ceramics. J. Alloys Compd. 2016, 695, 2580–2586. [Google Scholar] [CrossRef]

- Zhang, L.; Ben, Y.; Wu, J.; Yang, H.; Wong, C.; Zhang, Q.; Chen, H. Alumina assisted grain refinement and physical performance enhancement of yttria transparent ceramics by two-step sintering. Mater. Sci. Eng. 2017, 684, 466–469. [Google Scholar] [CrossRef]

- Tubío, C.R.; Guitian, F.; Gil, A. Fabrication of ZnO periodic structures by 3D printing. J. Eur. Ceram. Soc. 2016, 36, 3409–3415. [Google Scholar] [CrossRef]

- Dhaliwal, A.K.; Hay, J.N. The characterization of polyvinyl butyral by thermal analysis. Thermochim. Acta 2002, 391, 245–255. [Google Scholar] [CrossRef]

- Charitidis, C.A.; Koumoulos, E.P.; Giorcelli, M.; Musso, S.; Jagadale, P.; Tagliaferro, A. Nanomechanical and tribological properties of carbon nanotube/polyvinyl butyral composites. Polym. Compos. 2013, 34, 1950–1960. [Google Scholar] [CrossRef]

- Kuo, C.C.; Liu, L.C.; Teng, W.F.; Chang, H.Y.; Chien, F.M.; Liao, S.J.; Kuo, W.F.; Chen, C.M. Preparation of starch/acrylonitrile-butadiene-styrene copolymers (ABS) biomass alloys and their feasible evaluation for 3D printing applications. Compos. B Eng. 2016, 86, 36–39. [Google Scholar] [CrossRef]

- Masuda, H.; Yoshida, H.; Iinoya, K. Statistical analysis of carr’s flowability index. J. Res. Assoc. Powder Technol. 2010, 12, 209–216. [Google Scholar] [CrossRef]

- Raghupathy, B.P.C.; Binner, J.G.P. Spray granulation of nanometric zirconia particles. J. Am. Ceram. Soc. 2010, 94, 42–48. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, P.; Qi, H.; Zhu, Z.; Qin, H.; Li, H.; Chu, C.; Yan, M. Development of SiC/PVB Composite Powders for Selective Laser Sintering Additive Manufacturing of SiC. Materials 2018, 11, 2012. https://doi.org/10.3390/ma11102012

Zhou P, Qi H, Zhu Z, Qin H, Li H, Chu C, Yan M. Development of SiC/PVB Composite Powders for Selective Laser Sintering Additive Manufacturing of SiC. Materials. 2018; 11(10):2012. https://doi.org/10.3390/ma11102012

Chicago/Turabian StyleZhou, Peng, Huilin Qi, Zhenye Zhu, Huang Qin, Hui Li, Chenglin Chu, and Ming Yan. 2018. "Development of SiC/PVB Composite Powders for Selective Laser Sintering Additive Manufacturing of SiC" Materials 11, no. 10: 2012. https://doi.org/10.3390/ma11102012

APA StyleZhou, P., Qi, H., Zhu, Z., Qin, H., Li, H., Chu, C., & Yan, M. (2018). Development of SiC/PVB Composite Powders for Selective Laser Sintering Additive Manufacturing of SiC. Materials, 11(10), 2012. https://doi.org/10.3390/ma11102012