Mechanical Performance of Glass-Based Geopolymer Matrix Composites Reinforced with Cellulose Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Manufacturing of Geopolymer Samples

- Method 1: Molds were sealed in latex bags.

- Method 2: Molds were closed in an air-tightened jar with some water.

2.2. Manufacturing of Geopolymer Composite Samples

2.3. Mechanical Testing

2.4. Microstructural Investigation

3. Results and Discussion

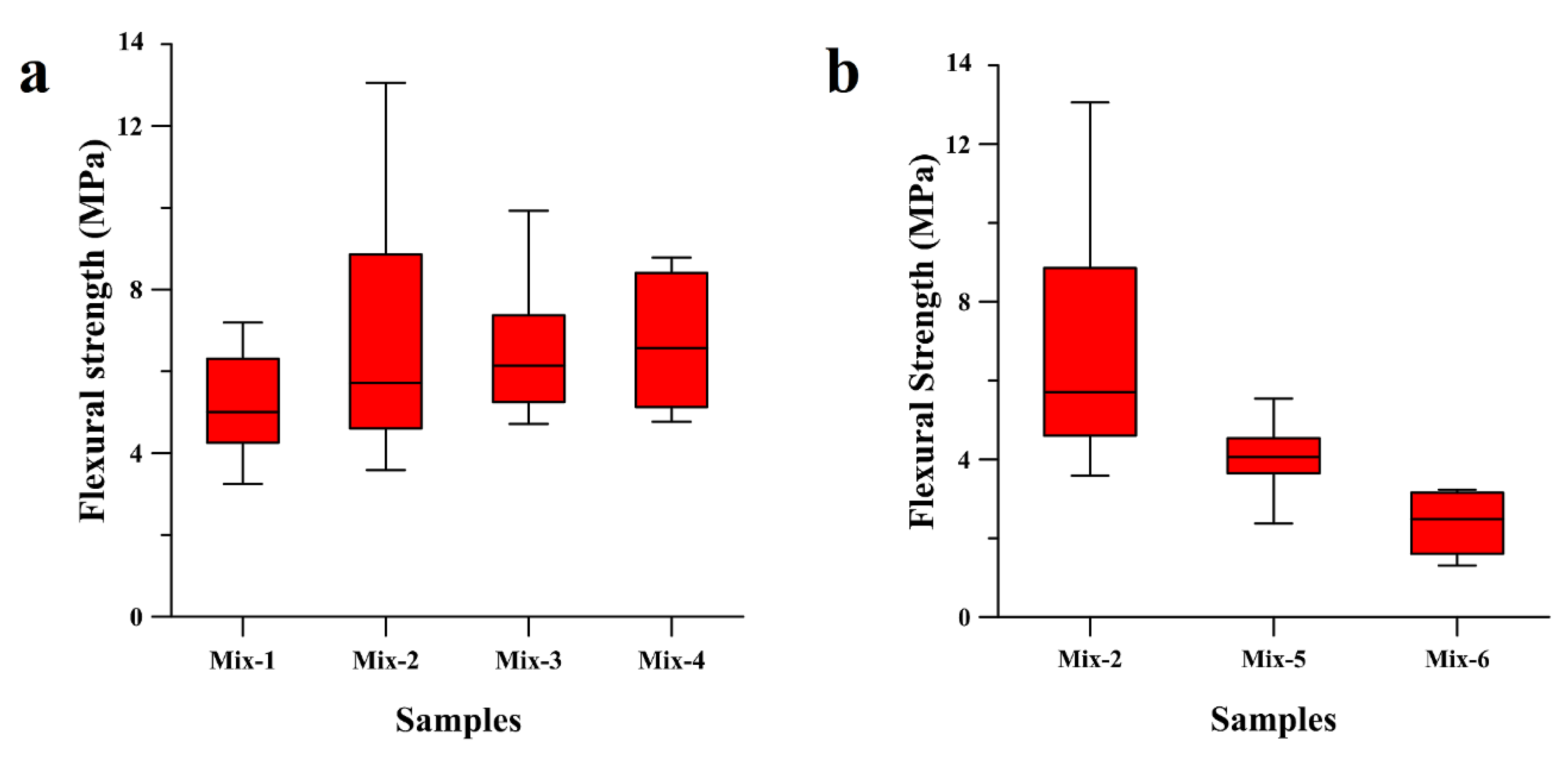

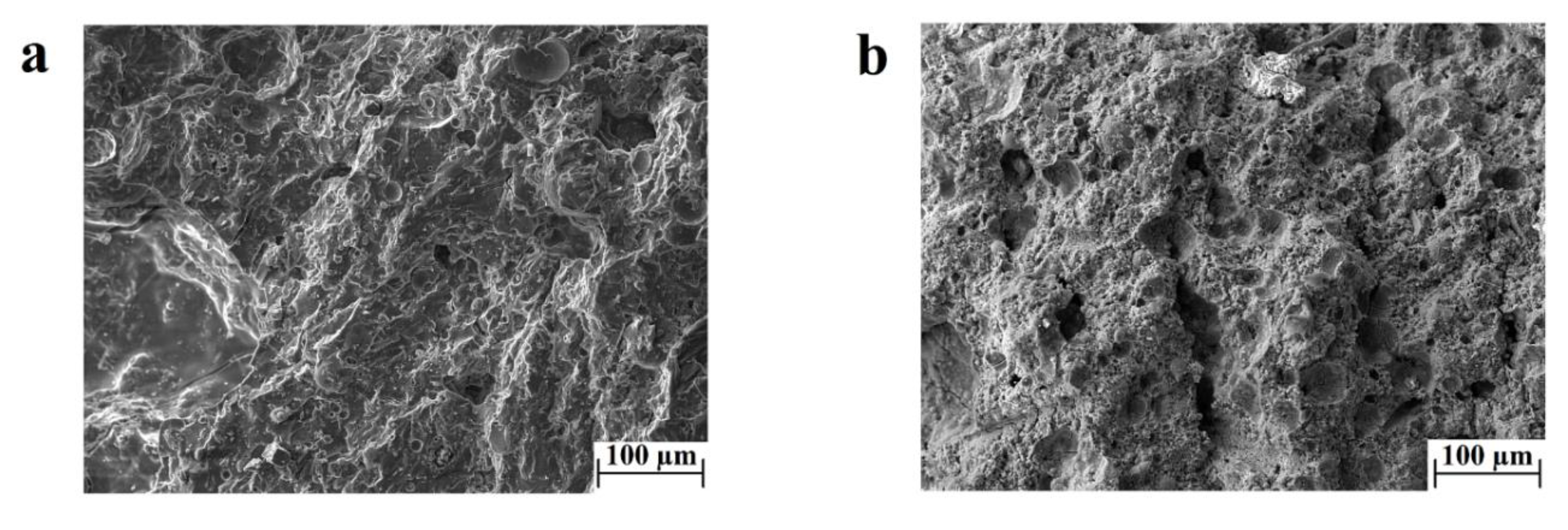

3.1. Geopolymer Characterization

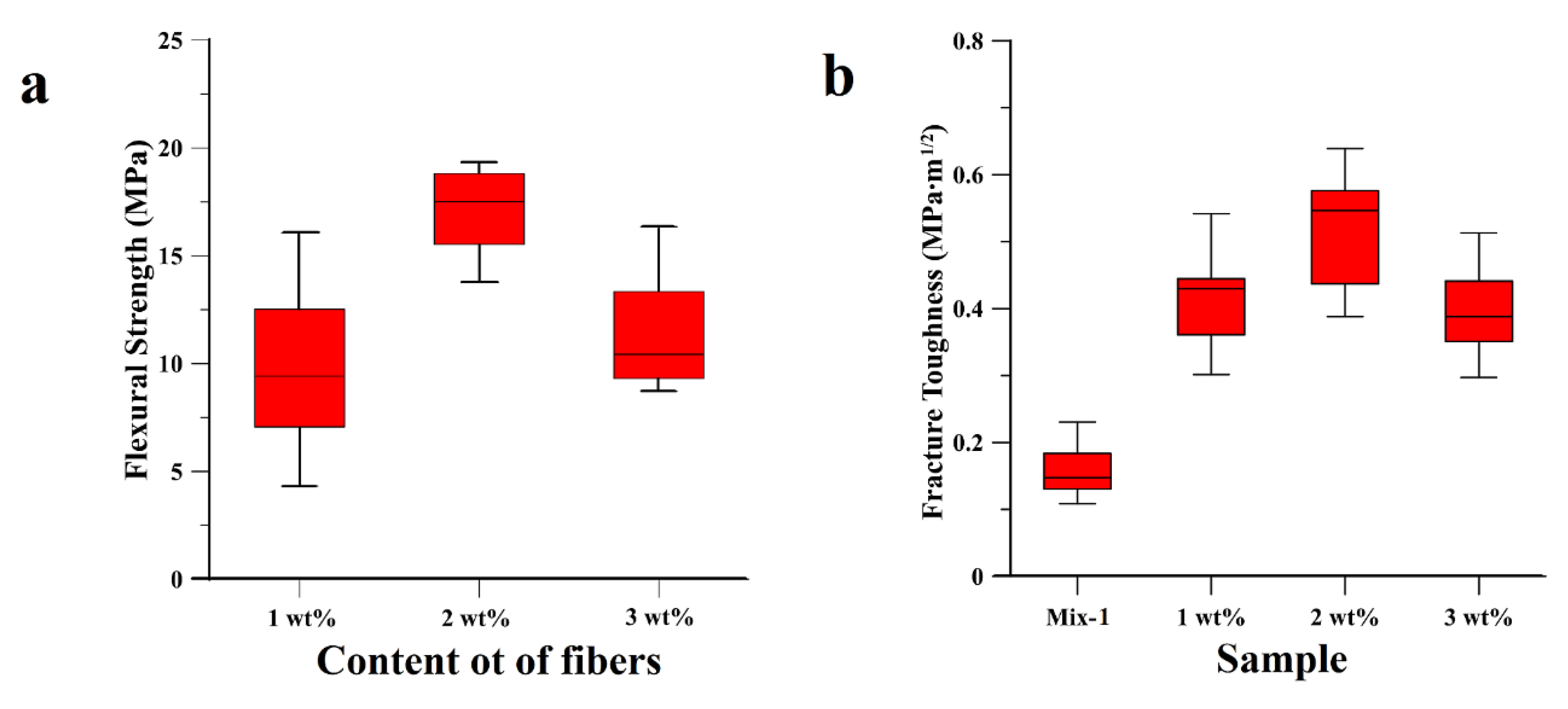

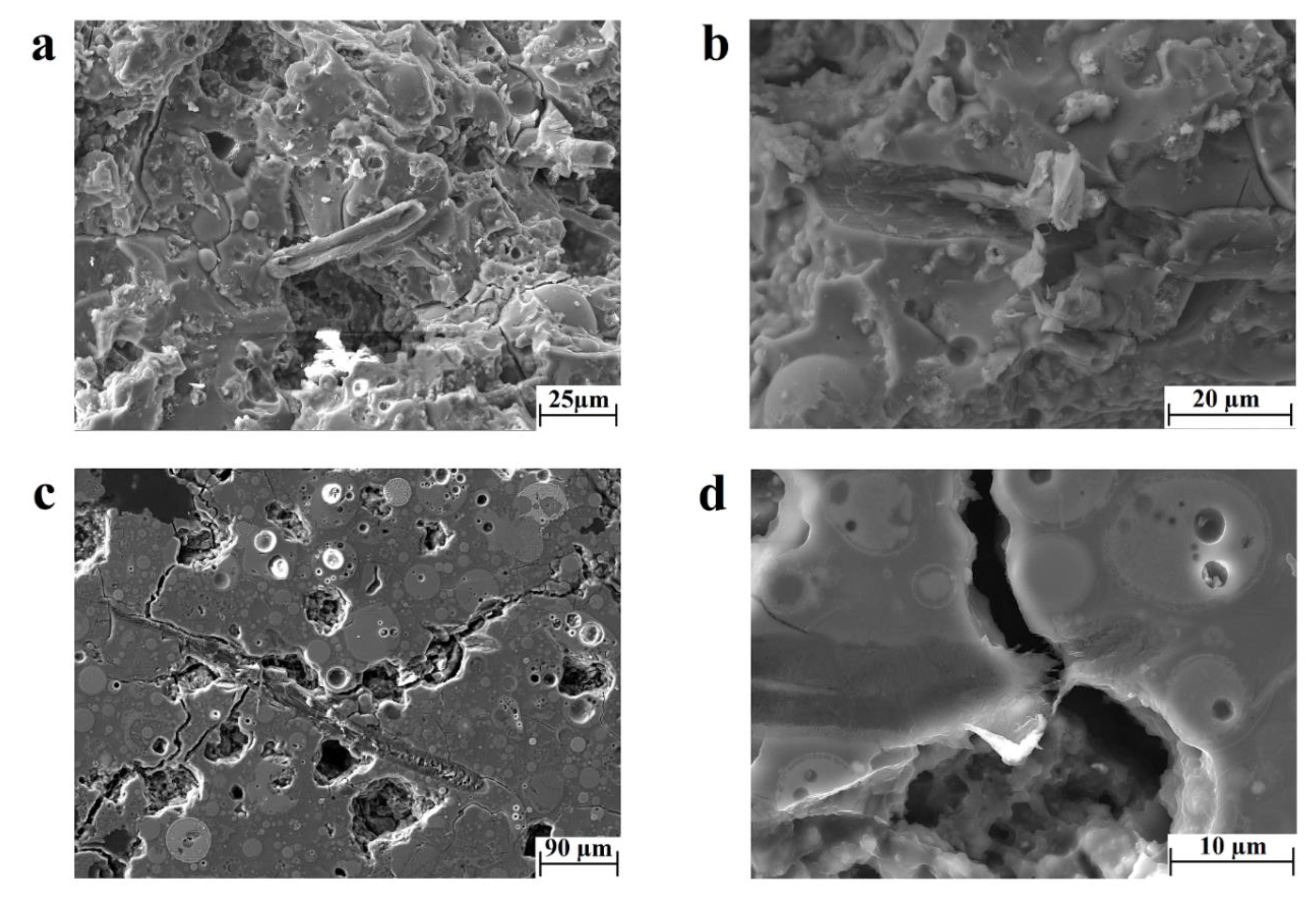

3.2. Geopolymer Composites

4. Conclusions

- Geopolymer samples incorporating fly ash and borosilicate wastes were processed using four different formulations (Mix-1, Mix-2, Mix-3, and Mix-4), two alkali solution molarities (10–13 M, Mix-5), and curing times (1–3 h, Mix-6) in order to evaluate the influence of these chemical/physical parameters on geopolymerization.

- The rate of influence was assessed in terms of flexural strength. The results of the bending test revealed that the higher flexural strength (13 MPa) was associated with the Mix-2 sample, which was activated with a 13 M NaOH solution and cured for 1 day.

- The fracture toughness of the geopolymer was enhanced by up to 4 times when geopolymer matrix samples including 2 wt% of cellulose fiber were processed.

- A mercerization and a surface modification of the cellulose fibers were also observed, and EDS analysis suggested a possible chemical interaction between the organic and inorganic polymeric chains.

- The dynamics of failure of the geopolymer matrix composite includes crack bridging, fiber pull-out, and fiber-tearing mechanisms.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Provis, J.L.; Bernal, S.A. Alkali Activated Materials: State of the Art Report. Taylor Fr. 2014, 13, 125–144. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.J. Geopolymers: Structures, Processing, Properties and Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2009; ISBN 9781845694494. [Google Scholar]

- Duxson, P.; Fernandez-Jimenez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; Van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Živica, V.; Palou, M.T.; Križma, M. Geopolymer Cements and Their Properties: A Review. Build. Res. J. 2015, 61. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.G.; Vijay, R.B. Fracture properties of geopolymer paste and concrete. Mag. Concr. Res. 2011, 63, 763–777. [Google Scholar] [CrossRef]

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Hooton, R.D. Bridging the gap between research and standards. Cem. Concr. Res. 2008, 38, 247–258. [Google Scholar] [CrossRef]

- Palomo, A.; Krivenko, P.; Garcia-Lodeiro, I.; Kavalerova, E.; Maltseva, O.; Fernandez-Jimenez, A. A review on alkaline activation: New analytical perspectives. Mater. Constr. 2014, 64, 1–23. [Google Scholar] [CrossRef]

- Toniolo, N.; Taveri, G.; Hurle, K.; Roether, J.A.A.; Ercole, P.; Dlouhý, I.; Boccaccini, A.R.R. Fly-ash-based geopolymers: How the addition of recycled glass or red mud waste influences the structural and mechanical properties. J. Ceram. Sci. Technol. 2017, 8, 411–419. [Google Scholar] [CrossRef]

- Fernández Jiménez, A.; Palomo, A. Factors affecting early compressive strength of alkali activated fly ash (OPC-free) concrete. Mater. Constr. 2007, 57, 7–22. [Google Scholar]

- Fernández-Jiménez, A.; Palomo, A. Composition and microstructure of alkali activated fly ash binder: Effect of the activator. Cem. Concr. Res. 2005, 35, 1984–1992. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Fly ash-based geopolymers: The relationship between composition, pore structure and efflorescence. Cem. Concr. Res. 2014, 64, 30–41. [Google Scholar] [CrossRef]

- Provis, J.L.; Yong, C.Z.; Duxson, P.; van Deventer, J.S.J. Correlating mechanical and thermal properties of sodium silicate-fly ash geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2009, 336, 57–63. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A. Characterisation of fly ashes. Potential reactivity as alkaline cements. Fuel 2003, 82, 2259–2265. [Google Scholar] [CrossRef]

- Toniolo, N.; Boccaccini, A.R. Fly ash-based geopolymers containing added silicate waste. A review. Ceram. Int. 2017, 43, 14545–14551. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A.; Criado, M. Microstructure development of alkali-activated fly ash cement: A descriptive model. Cem. Concr. Res. 2005, 35, 1204–1209. [Google Scholar] [CrossRef]

- Martin, A.; Pastor, J.Y.; Palomo, A.; Fernández Jiménez, A. Mechanical behaviour at high temperature of alkali-activated aluminosilicates (geopolymers). Constr. Build. Mater. 2015, 93, 1188–1196. [Google Scholar] [CrossRef] [Green Version]

- Pacheco-Torgal, F.; Abdollahnejad, Z.; Camões, A.F.; Jamshidi, M.; Ding, Y. Durability of alkali-activated binders: A clear advantage over Portland cement or an unproven issue? Constr. Build. Mater. 2012, 30, 400–405. [Google Scholar] [CrossRef] [Green Version]

- Davidovits, J. The Pyramids; Dorset Press: New York, NY, USA, 1990; ISBN 290293307X. [Google Scholar]

- Davidovits, J. Properties of Geopolymer Cements. In Proceedings of the First International Conference on Alkaline Cements and Concretes, Kiev, Ukraine, 11–14 October 1994; pp. 131–149. [Google Scholar]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Mallicoat, S.W.; Kriven, W.M.; Van Deventer, J.S.J. Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Surf. A Physicochem. Eng. Asp. 2005, 269, 47–58. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer: Chemistry & Applications; Institut Géopolymère: Saint-Quentin, France, 2008; ISBN 9782951482098. [Google Scholar]

- Klinowski, J. Nuclear magnetic resonance studies of zeolites. Prog. Nucl. Magn. Reson. Spectrosc. 1984, 16, 237–309. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass in the geopolymer preparation. Mechanical and microstructural characterisation. J. Clean. Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F.; Blanco-Varela, M. Preparación de cementos alcalinos a partir de residuos vítreos. Solubilidad de residuos vítreos en medios fuertemente básicos. In XII Congreso Nacional de Materiales and XII Iberomat: Conference Proceedings; Instituto Universitario de Materiales: Alicante, Spain, 2012. [Google Scholar]

- Torres-Carrasco, M.; Rodríguez-Puertas, C.; Del Mar Alonso, M.; Puertas, F. Alkali activated slag cements using waste glass as alternative activators. Rheological behaviour. Boletín de la Sociedad Española de Cerámica y Vidrio 2015, 54, 45–57. [Google Scholar] [CrossRef]

- Puertas, F.; Torres-Carrasco, M. Use of glass waste as an activator in the preparation of alkali-activated slag. Mechanical strength and paste characterisation. Cem. Concr. Res. 2014, 57, 95–104. [Google Scholar] [CrossRef]

- Chinnam, R.K.; Francis, A.A.; Will, J.; Bernardo, E.; Boccaccini, A.R. Review. Functional glasses and glass-ceramics derived from iron rich waste and combination of industrial residues. J. Non-Cryst. Solids 2013, 365, 63–74. [Google Scholar] [CrossRef]

- Taveri, G.; Tousek, J.; Bernardo, E.; Toniolo, N.; Boccaccini, A.R.R.; Dlouhy, I. Proving the role of boron in the structure of fly-ash/borosilicate glass based geopolymers. Mater. Lett. 2017, 200, 105–108. [Google Scholar] [CrossRef]

- Côrtes Pires, E.F.; Campinho de Azevedo, C.M.; Pimenta, A.R.; da Silva, F.J.; Darwish, F.A.I. Fracture Properties of Geopolymer Concrete Based on Metakaolin, Fly Ash and Rice Rusk Ash. Mater. Res. 2017, 20, 630–636. [Google Scholar] [CrossRef] [Green Version]

- Dias, D.P.; Thaumaturgo, C. Fracture toughness of geopolymeric concretes reinforced with basalt fibers. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Oderji, S.Y.; Chen, B.; Taseer, S.; Jaffar, A. Effects of relative humidity on the properties of fly ash-based geopolymers. Constr. Build. Mater. 2017, 153, 268–273. [Google Scholar] [CrossRef]

- García-Mejía, T.A.; de Lourdes Chávez-García, M. Compressive Strength of Metakaolin-Based Geopolymers: Influence of KOH Concentration, Temperature, Time and Relative Humidity. Mater. Sci. Appl. 2016, 7, 772–791. [Google Scholar] [CrossRef]

- Criado, M.; Fernández Jiménez, A.; Sobrados, I.; Palomo, A.; Sanz, J. Effect of relative humidity on the reaction products of alkali activated fly ash. J. Eur. Ceram. Soc. 2012, 32, 2799–2807. [Google Scholar] [CrossRef]

- Yan, S.; He, P.; Jia, D.; Yang, Z.; Duan, X.; Wang, S.; Zhou, Y. Effect of fiber content on the microstructure and mechanical properties of carbon fiber felt reinforced geopolymer composites. Ceram. Int. 2016, 42, 7837–7843. [Google Scholar] [CrossRef]

- Assaaedi, H.; Alomayri, T.; Shaikh, A.; Low, I. Characterisation of mechanical and thermal properties in flax fabric reinforced geopolymer composites. J. Adv. Cermics 2015, 4, 272–281. [Google Scholar] [CrossRef] [Green Version]

- Shaikh, F.U.A. Deflection hardening behaviour of short fibre reinforced fly ash based geopolymer composites. Mater. Des. 2013, 50, 674–682. [Google Scholar] [CrossRef]

- Yuan, J.; He, P.; Jia, D.; Yan, S.; Cai, D.; Xu, L.; Yang, Z.; Duan, X.; Wang, S.; Zhou, Y. SiC fiber reinforced geopolymer composites, part 1: Short SiC fiber. Ceram. Int. 2016, 42, 5345–5352. [Google Scholar] [CrossRef]

- Sá Ribeiro, R.A.; Sá Ribeiro, M.G.; Kriven, W.M. Review of particle- and fiber-reinforced metakaolin-based geopolymer composites. J. Ceram. Sci. Technol. 2017, 8, 307–321. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Characterisation of cotton fibre-reinforced geopolymer composites. Compos. Part B Eng. 2013, 50, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Alomayri, T.; Low, I.M. Synthesis and characterization of mechanical properties in cotton fiber-reinforced geopolymer composites. J. Asian Ceram. Soc. 2013, 1, 30–34. [Google Scholar] [CrossRef] [Green Version]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Thermal and mechanical properties of cotton fabric-reinforced geopolymer composites. J. Mater. Sci. 2013, 48, 6746–6752. [Google Scholar] [CrossRef]

- Dlouhý, I.; Boccaccini, A.R. Reliability of the chevron notch technique for fracture toughness determination in glass composites reinforced by continuous fibres. Scr. Mater. 2001, 44, 531–537. [Google Scholar] [CrossRef]

- Abubakar, M.; Mat Yajid, M.A.; Ahmad, N. Comparison of Weibull and normal probability distribution of flexural strength of dense and porous fired clay. J. Teknol. 2016, 78, 73–78. [Google Scholar] [CrossRef]

- Sahin, Z.; Ergun, G.; Author, C. The Assessment of Some Physical and Mechanical Properties of PMMA Added Different Forms of Nano-ZrO 2. J. Dent. Oral. Heal. 2017, 3, 64–74. [Google Scholar]

- Nicholson, C.; Murray, B.; Fletcher, R.A.; Brew, D.R.M.; MacKenzie, K.J.D.; Schmuker, M. Novel geopolymer materials containing borate structural units. In Geopolymer, Green Chemistry and Sustainable Development Solutions; Geopolymer Institute: Saint-Quentin, France, 2005. [Google Scholar]

- Xu, H.; van Deventer, J.S.J. Geopolymerisation of alumino-silicate minerals. Int. J. Miner. Process. 2000, 59, 247–266. [Google Scholar] [CrossRef]

- Weng, L.; Sagoe-Crentsil, K. Dissolution processes, hydrolysis and condensation reactions during geopolymer synthesis: Part I-Low Si/Al ratio systems. J. Mater. Sci. 2007, 42, 2997–3006. [Google Scholar] [CrossRef]

- Weng, L.; Sagoe-Crentsil, K. Dissolution processes, hydrolysis and condensation reactions during geopolymer synthesis: Part II-High Si/Al ratio systems. J. Mater. Sci. 2007, 42, 3007–3014. [Google Scholar] [CrossRef]

- Trochez, J.J.; De Gutiérrez, R.M.; Rivera, J.; Bernal, S.A. Synthesis of Geopolymer from Spent FCC: Effect of SiO2/Al2O3 and Na2O/SiO2 Molar Ratios. Mater. Constr. 2015, 65, 1–11. [Google Scholar] [CrossRef]

- Wang, Y. Cellulose Fiber Dissolution in Sodium Hydroxide Solution at Low Temperature: Dissolution Kinetics and Solubility Improvement. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2008. [Google Scholar]

- Tonoli, G.H.D.; Rodrigues Filho, U.P.; Savastano, H.; Bras, J.; Belgacem, M.N.; Rocco Lahr, F.A. Cellulose modified fibres in cement based composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 2046–2053. [Google Scholar] [CrossRef]

- Merrill, R.; Spencer, R. Sorption of Sodium Silicates and Silica Sols by Cellulose Fibers. Ind. Eng. Chem. 1950, 42, 744–747. [Google Scholar] [CrossRef]

| Sample | Powder Mixture (FA%–BSG%) | Molarity (M) | Curing Time (day) | SiO2/Al2O3 | α Coefficient |

|---|---|---|---|---|---|

| Mix-1 | 70–30 | 13 | 1 | 2.7 | 2.2 |

| Mix-2 | 55–45 | 13 | 1 | 3.3 | 2.5 |

| Mix-3 | 40–60 | 13 | 1 | 4.2 | 2.8 |

| Mix-4 | 30–70 | 13 | 1 | 5.0 | 3.0 |

| Mix-5 | 55–45 | 13 | 3 | 3.3 | 2.5 |

| Mix-6 | 55–45 | 10 | 1 | 3.3 | 2.5 |

| SiO2 | Al2O3 | B2O3 | Fe2O3 | CaO | K2O | Na2O | LOI 1 | Remainder | |

|---|---|---|---|---|---|---|---|---|---|

| Fly ash (wt%) | 46.3 | 26 | / | 13.9 | 3.5 | 3.9 | 0.2 | 0.7 | 5.5 |

| BSG (wt%) | 72 | 7 | 12 | / | 1 | 2 | 6 | / | / |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taveri, G.; Bernardo, E.; Dlouhy, I. Mechanical Performance of Glass-Based Geopolymer Matrix Composites Reinforced with Cellulose Fibers. Materials 2018, 11, 2395. https://doi.org/10.3390/ma11122395

Taveri G, Bernardo E, Dlouhy I. Mechanical Performance of Glass-Based Geopolymer Matrix Composites Reinforced with Cellulose Fibers. Materials. 2018; 11(12):2395. https://doi.org/10.3390/ma11122395

Chicago/Turabian StyleTaveri, Gianmarco, Enrico Bernardo, and Ivo Dlouhy. 2018. "Mechanical Performance of Glass-Based Geopolymer Matrix Composites Reinforced with Cellulose Fibers" Materials 11, no. 12: 2395. https://doi.org/10.3390/ma11122395

APA StyleTaveri, G., Bernardo, E., & Dlouhy, I. (2018). Mechanical Performance of Glass-Based Geopolymer Matrix Composites Reinforced with Cellulose Fibers. Materials, 11(12), 2395. https://doi.org/10.3390/ma11122395