Manufacture of Sustainable Clay Bricks Using Waste from Secondary Aluminum Recycling as Raw Material

Abstract

:1. Introduction

2. Materials and Methods

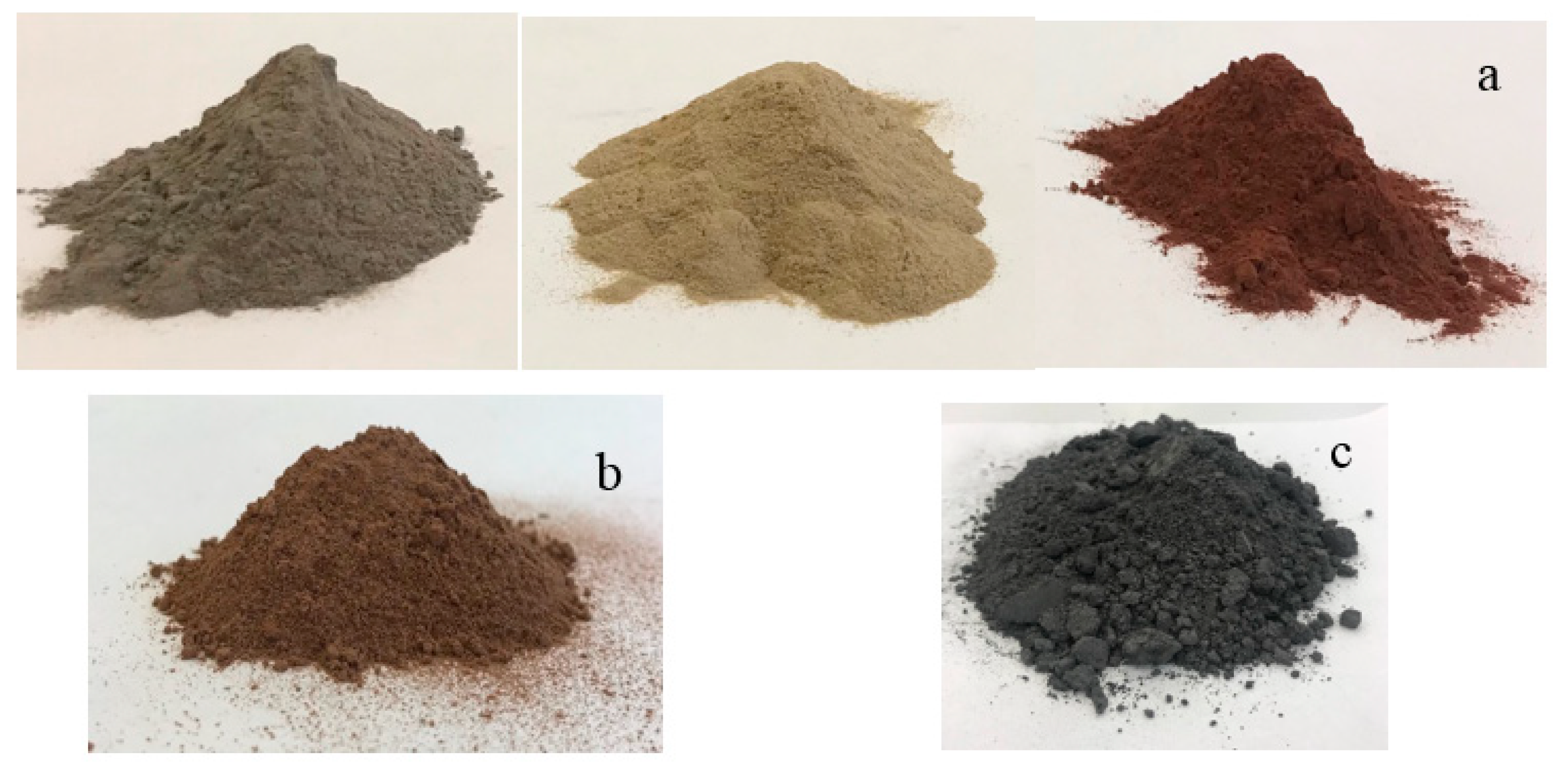

2.1. Materials

2.2. Processing Method

2.3. Techniques of Characterization of Raw Materials

2.4. Characterization of Fired Samples

3. Results and Discussion

3.1. Characterization of Raw Materials

3.2. Characterization of the Sustainable Fired Bricks

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Martelon, E.; Jarrige, J.; Ribeiro, M.J.; Ferreira, J.M.; Labrincha, J.A. New clay-based ceramic formulations containing different solid wastes. Ind. Ceram. 2000, 20, 71–76. [Google Scholar]

- Ferreira, J.M.F.; Torres, P.M.C.; Silva, M.S.; Labrincha, J.A. Recycling of granite sludges in brick-type and floor tile-type ceramic formulations. J. Eur. Ceram. Soc. 2004, 24, 3177–3185. [Google Scholar]

- Knirsch, M.; Penschke, A.; Krebs, S.; Russ, W.; Mörtel, H.; Mayer, W.A.; Mayer-Pittroff, R. Application of brewery wastes in the production of bricks. Tile Brick Int. 1998, 14, 93–101. [Google Scholar]

- Ferreira, J.M.F.; Alves, H.M.; Mendonça, A.M. Inertization of galvanic sludges by its incorporation in ceramic products. Bol. Soc. Esp. Ceram. Vidr. 1999, 38, 127–131. [Google Scholar] [CrossRef]

- Ribeiro, M.J.; Tulyaganov, D.U.; Ferreira, J.M.; Labrincha, J.A. Recycling of Al-rich industrial sludge in refractory ceramic pressed bodies. Ceram. Int. 2002, 28, 319–326. [Google Scholar] [CrossRef]

- Couto, D.M.S.; Silva, R.F.; Castro, F.; Labrincha, J.A. Attempts of incorporation of metal plating sludges in ceramic products. Ind. Ceram. 2001, 21, 163–168. [Google Scholar]

- Pérez, J.A.; Terradas, R.; Manent, M.R.; Sejas, M.; Martinez, S. Inertization of industrial wastes in ceramic materials. Ind. Ceram. 1996, 16, 7–10. [Google Scholar]

- Asociación Española de Fabricantes de Ladrillos y Tejas de Arcilla Cocida. Available online: https://www.hispalyt.es/contenido (accessed on 1 September 2018).

- Totten, E.; MacKenzie, D.S. Handbook of Aluminum: Physical Metallurgy and Processes; Marcel Dekker Inc.: New York, NY, USA, 2003; Volume 1. [Google Scholar]

- Tayibi, H. Tratamiento de los Polvos Procedentes de la Metalurgia Secundaria del Aluminio. Ph.D. Thesis, Universidad Complutense de Madrid, Madrid, Spain, 2004. [Google Scholar]

- Harben, P.W.; Kužvart, M. Industrial Minerals: A Global Geology; Industrial Minerals Information Limited: London, UK, 1997; p. 462. [Google Scholar]

- Tsakiridis, P.E. Aluminium salt slag characterization and utilization. A. review. J. Hazard. Mater. 2012, 217–218, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Gil, A. Gestión de las Escorias Salinas de la Segunda Fusión del Aluminio Dpto. In de Química Aplicada; Universidad Pública de Navarra: Pamplona, Spain, 2006. [Google Scholar]

- Befesa. Available online: htpps://www.befesa.com (accessed on 1 September 2017).

- López-Gómez, F.A.; López-Delgado, A. Procedimiento de Estabilización/Compactación de Polvos de Aluminio. ES2197797B1, 1 January 2004. [Google Scholar]

- Kammer, C. Aluminium Handbook: Fundamentals and Materials; Aluminium-Verlag Marketing & Kommunikation GmbH: Düsseldorf, Germany, 1999; Volume 1. [Google Scholar]

- Oreja Arratibel, J. Filler de Aluminio para la Elaboración de Ladrillos Cerámicos; Universidad de Navarra: Pamplona, Spain, 2011. [Google Scholar]

- Huang, X.-L.; El Badawy, A.; Arambewela, M.; Ford, R.; Barlaz, M.; Tolaymat, T. Characterization of salt cake from secondary aluminum production. J. Hazard. Mater. 2014, 273, 192–199. [Google Scholar] [CrossRef] [PubMed]

- Kumar Mandal, A.; Ranjan Verma, H.; Sinha, O.P. Utilization of aluminum plant’s waste for production of insulation bricks. J. Clean. Prod. 2017, 162, 949–957. [Google Scholar] [CrossRef]

- Gil, A.; Korili, S.A. Management and valorization of aluminum saline slags: Current status and future trends. Chem. Eng. J. 2016, 289, 74–84. [Google Scholar] [CrossRef]

- Miqueleiz, L.; Ramirez, F.; Oti, J.E.; Seco, A.; Kinuthia, J.M.; Oreja, I.; Urmeneta, P. Alumina filler waste as clay replacement material for unfired brick production. Eng. Geol. 2013, 163, 68–74. [Google Scholar] [CrossRef]

- American Society for Testing and Materials (ASTM). Test Method for Drying and Firing Shrinkage of Ceramic Whiteware Clays; ASTM C326; ASTM: West Conshohocken, PA, USA, 1997. [Google Scholar]

- The Spanish Association for Standardization. Methods of Test for Masonry Units—Part 13: Determination of Net and Gross Dry Density of Masonry Units (Except for Natural Stone); UNE-EN 772-13; UNE: Madrid, Spain, 2001. [Google Scholar]

- The Spanish Association for Standardization. Methods of Test for Masonry Units—Part 21: Determination of Water Absorption of Clay and Calcium Silicate Masonry Units by Cold Water Absorption; UNE-EN 772-21; UNE: Madrid, Spain, 2011. [Google Scholar]

- The Spanish Association for Standardization. Methods of Test for Masonry Units—Part 11: Determination of Water Absorption of Aggregate Concrete, Manufactured Stone and Natural Stone Masonry Units Due to Capillary Action and the Initial Rate of Water Absorption of Clay Masonry Units; UNE-EN 772-11; UNE: Madrid, Spain, 2001. [Google Scholar]

- The Spanish Association for Standardization. Methods of Test for Masonry Units—Part 1: Determination of Compressive Strength; UNE EN 772-1; UNE: Madrid, Spain, 2001. [Google Scholar]

- Barrett, E.O.; Youner, L.G.; Halenda, P.P. The determination of pore volume and area distributions in porous substances II. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Method 13–11 toxicity characteristics leaching procedure (TCLP). Fed. Regist. 1992, 51, 11798–11877. [Google Scholar]

- Eliche-Quesada, D.; Leite-Costa, J. Use of bottom ash from olive pomace combustion in the production of eco-friendly fired clay bricks. Waste Manag. 2016, 48, 323–333. [Google Scholar] [CrossRef] [PubMed]

- RL-88. General Specification for Reception of the Ceramic in the Construction Works; Ministry of relations with the courts and secretary of the government of Spain. Decree of July 27th, approving the general specification for the reception of ceramic bricks in the construction works. Off. State Bull. 1988, 185, 23921–23924. [Google Scholar]

- American Sociaty for Testing and Material (ASTM). Standards Tests Method for Sampling and Testing Bricks and Structural Clay Tile; ASTM C67-03; ASTM: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierrotti, R.A.; Rouquerol, J.; Siemienieswka, T. Reporting physisorption data for gas/solid systems. Pure Appl. Chem. 1985, 57, 603–609. [Google Scholar] [CrossRef]

- García-Ten, J.; Orts, M.J.; Saburit, A.; Silva, G. Thermal conductivity of traditional ceramics. Part I: Influence of bulk density and firing temperature. Ceram. Int. 2010, 36, 1951–1959. [Google Scholar] [CrossRef]

- Presidency of the Govemment of Spain. Royal Decree 2429/1979, of July 6th, approving the basic construction standard NBE-CT-79, on thermal conditions in buildings. Off. State Bull. 1979, 253, 24524–24550. [Google Scholar]

| Brick Series | Clay (wt %) | FDA (wt %) |

|---|---|---|

| 100C | 100 | - |

| 95C-5FDA | 95 | 5 |

| 90C-10FDA | 90 | 10 |

| 85C-15FDA | 85 | 15 |

| 80C-20FDA | 80 | 20 |

| 75C-25FDA | 75 | 25 |

| Oxide Content (%) | Clay | AFD |

|---|---|---|

| SiO2 | 54.4 | 0.38 |

| Al2O3 | 12.36 | 21.56 |

| Fe2O3 | 4.58 | 0.64 |

| CaO | 8.76 | 1.31 |

| MgO | 2.46 | 2.37 |

| MnO | 0.03 | 0.05 |

| Na2O | - | 21.69 |

| K2O | 3.37 | 5.88 |

| TiO2 | 0.60 | 0.37 |

| P2O5 | 0.11 | 0.03 |

| SO3 | 0.68 | - |

| ZnO | 0.026 | - |

| SrO | 0.027 | - |

| ZrO2 | 0.033 | - |

| Cl | - | 24.42 |

| LOI | 12.51 | 21.82 |

| Sample | Linear Shrinkage (%) | Mass Loss on Ignition (%) | Suction Water (kg/m2·min) |

|---|---|---|---|

| 100C | −2.878 ± 0.654 | 12.890 ± 0.049 | 2.127 ± 0.217 |

| 95C-5FDA | −3.092 ± 0.673 | 13.818 ± 0.548 | 2.437 ± 0.068 |

| 90C-10FDA | −2.720 ± 0.134 | 13.894 ± 0.326 | 2.592 ± 0.114 |

| 85C-15FDA | −2.800 ± 0.175 | 15.388 ± 1.098 | 2.623 ± 0.159 |

| 80C-20FDA | −2.827 ± 0.140 | 16.105 ± 0.985 | 2.782 ± 0.262 |

| 75C-25FDA | −1.379 ± 0.397 | 20.216 ± 0.918 | 2.876 ± 0.152 |

| Sample | BET Surface Area (m2/g) | t-Plot Micropore Area (cm3/g) | BJH Cumulative Volume of Pores (between 1.7 and 300 nm) (cm3/g) | BJH Average Pore Diameter (nm) |

|---|---|---|---|---|

| 100C | 1.4134 | 0.1302 | 0.008012 | 24.6500 |

| 95C-5FDA | 1.5759 | 0.2408 | 0.007365 | 21.8648 |

| 90C-10FDA | 1.7654 | 0.2002 | 0.008023 | 19.0877 |

| 85C-15FDA | 1.8653 | 0.1975 | 0.006574 | 14.6692 |

| 80C-20FDA | 1.8797 | 0.2799 | 0.007348 | 17.5119 |

| 75C-25FDA | 2.1905 | 0.2249 | 0.008291 | 15.6814 |

| Component (ppb) | 100C | 95C-5AFD | 90C-10AFD | 85C-15AFD | 80C-20AFD | 75C-25AFD | USEPA Regulated TCLP Limits (ppb) |

|---|---|---|---|---|---|---|---|

| V | 0.990 | 3.062 | 1.146 | 1.194 | 1.870 | 0.829 | N/A |

| Cr | 0.021 | 0.251 | 0.371 | 0.188 | 0.393 | 0.493 | 5000 |

| Co | 0.714 | 0.242 | 0.153 | 0.673 | 0.469 | 0.030 | N/A |

| Ni | 0.151 | 0.463 | 0.110 | 0.128 | 0.083 | 0.047 | 250 |

| Cu | 0.310 | 2.338 | 9.291 | 12.210 | 14.185 | 24.698 | 5000 |

| Zn | 0.321 | 1.088 | 0.724 | 0.783 | 0.304 | 1.323 | 300 |

| As | 0.024 | 0.042 | 0.004 | 0.007 | 0.017 | 0.003 | 5000 |

| Cd | 0.026 | 0.016 | 0.155 | 0.177 | 0.247 | 0.351 | 1000 |

| Ba | 0.295 | 0.489 | 0.498 | 0.562 | 0.565 | 0.591 | 100 |

| Hg | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 200 |

| Pb | 0.000 | 0.020 | 0.076 | 0.000 | 0.000 | 0.013 | 5000 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonet-Martínez, E.; Pérez-Villarejo, L.; Eliche-Quesada, D.; Castro, E. Manufacture of Sustainable Clay Bricks Using Waste from Secondary Aluminum Recycling as Raw Material. Materials 2018, 11, 2439. https://doi.org/10.3390/ma11122439

Bonet-Martínez E, Pérez-Villarejo L, Eliche-Quesada D, Castro E. Manufacture of Sustainable Clay Bricks Using Waste from Secondary Aluminum Recycling as Raw Material. Materials. 2018; 11(12):2439. https://doi.org/10.3390/ma11122439

Chicago/Turabian StyleBonet-Martínez, Eduardo, Luis Pérez-Villarejo, Dolores Eliche-Quesada, and Eulogio Castro. 2018. "Manufacture of Sustainable Clay Bricks Using Waste from Secondary Aluminum Recycling as Raw Material" Materials 11, no. 12: 2439. https://doi.org/10.3390/ma11122439

APA StyleBonet-Martínez, E., Pérez-Villarejo, L., Eliche-Quesada, D., & Castro, E. (2018). Manufacture of Sustainable Clay Bricks Using Waste from Secondary Aluminum Recycling as Raw Material. Materials, 11(12), 2439. https://doi.org/10.3390/ma11122439