A Dislocation-Scale Characterization of the Evolution of Deformation Microstructures around Nanoindentation Imprints in a TiAl Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Characterization of the Microstructure around the Regions of Interest

3.2. Microstructure Evolution of ROI2

4. Discussion

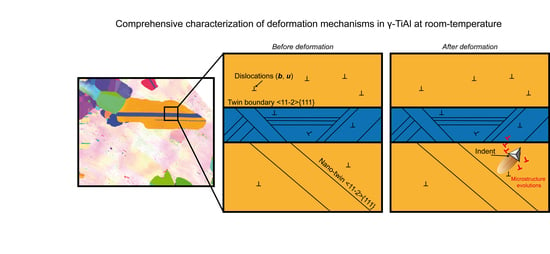

- At RT, twinning was observed to be the main deformation mechanism, in agreement with literature [2,7,8]. However, this runs contrary to Zambaldi et al., who prefer to suggest that ordinary dislocation glide is the main deformation mechanism at RT (without totally excluding twinning) from observations by atomic force microscopy around high-load (3000 µN) imprints [18].

- Deformation was observed to be localized near the indent.

- Under the indent, the NT was formed.

- The stress concentration at the tip of the NT nucleated ordinary dislocation loops gliding in the planes. The dislocation loops formed an ellipsoid surrounding the NT, thus producing lines after projection on the observation plane.

- The elliptical area or B1 grew by adding successive dislocation loops at its extremity.

- B1 extended until it met an obstacle, such as the TB (for B2 for example).

- At the location where B2 intercepts the TB, a stress concentration appeared. It resulted in a local distortion of the boundary. Therefore, the TB seems to be a strong obstacle to the propagation of the deformation, and at higher load it may cause microcracking at its vicinity, as observed in References [18,25,26].

5. Conclusions

- At RT, twinning was observed to be the main deformation mechanism.

- Twinning was accommodated by ordinary dislocation mechanism, leading to the canalization of the deformation.

- TB could play the role of obstacle to the propagation of deformation to neighbor grains, leading to a stress concentration at the vicinity of the boundary. Therefore, the true twin seems to be one of the weak links explaining the poor ductility of γ-TiAl at RT.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kim, Y.; Dimiduk, D. Progress in the understanding of gamma titanium aluminides. JOM 1991, 43, 40–47. [Google Scholar] [CrossRef]

- Appel, F.; Wagner, R. Microstructure and deformation of two-phase gamma-titanium aluminides. Mater. Sci. Eng. R Rep. 1998, 22, 187–268. [Google Scholar] [CrossRef]

- Loria, E. Quo vadis gamma titanium aluminide. Intermetallics 2001, 9, 997–1001. [Google Scholar] [CrossRef]

- Schuster, J.; Palm, M. Reassessment of the binary aluminum-titanium phase diagram. J. Phase Equilib. Diff. 2006, 27, 255–277. [Google Scholar] [CrossRef]

- Zambaldi, C. Micromechanical Modeling Gamma-TiAl Based Alloys; RWTH Aachen University: Aachen, Germany, 2010; ISBN 978-3-8322-9717-6. [Google Scholar]

- Appel, F.; Paul, D.; Oehring, M. Gamma Titanium Aluminide Alloys: Science and Technology; Wiley-VCH Verlaf GmbJ: Weinheim, Germany, 2011; ISBN 9783527315253. [Google Scholar]

- Beran, P.; Heczko, M.; Kruml, T.; Panzner, T.; Van Petegem, S. Complex investigation of deformation twinning in γ-TiAl by TEM and neutron diffraction. J. Mech. Phys. Sol. 2016, 95, 647–662. [Google Scholar] [CrossRef]

- Kauffmann, F.; Bidlingmaier, T.; Dehm, G.; Wanner, A.; Clemens, H. On the origin of acoustic emission during room temperature compressive deformation of a gamma-TiAl based alloy. Intermetallics 2000, 8, 823–830. [Google Scholar] [CrossRef]

- Zambaldi, C.; Zaefferer, C.; Wright, S. Characterization of order domains in γ-TiAl by orientation microscopy based on electron backscatter diffraction. J. Appl. Crystallogr. 2009, 42, 1092–1101. [Google Scholar] [CrossRef]

- Dey, S.; Hazotte, A.; Bouzy, E. Multiscale gamma variant selection in a quaternary near-gamma Ti-Al alloy. Philos. Mag. 2006, 86, 3089–3112. [Google Scholar] [CrossRef]

- Dey, S.; Morawiec, A.; Bouzy, E.; Hazotte, A.; Fundenberger, J.-J. Determination of gamma/gamma interface relationships in a (alpha2 + gamma) TiAl base alloy using TEM Kikuchi patterns obtained by nanoprobe scanning. Mater. Lett. 2003, 60, 646–650. [Google Scholar] [CrossRef]

- Marketz, M.; Fischer, F.; Clemens, H. Deformation mechanisms in TiAl intermetallics—Experiments and modeling. Int. J. Plast. 2003, 19, 281–321. [Google Scholar] [CrossRef]

- Zghal, S.; Coujou, A.; Couret, A. Transmission of the deformation through γ-γ interfaces in a polysynthetically twinned TiAl alloy. Philos. Mag. 2001, 81, 345–382. [Google Scholar] [CrossRef]

- Dey, S.; Hazotte, A.; Bouzy, E.; Naka, S. Development of Widmanstätten laths in a near-gamma TiAl alloy. Acta Mater. 2005, 53, 3783–3794. [Google Scholar] [CrossRef]

- Mansour, H.; Guyon, J.; Crimp, M.; Gey, N.; Beausir, B.; Maloufi, N. Accurate electron channeling contrast analysis of dislocations in fine grained bulk materials. Scr. Mater. 2014, 84, 11–14. [Google Scholar] [CrossRef]

- Kriaa, H.; Guitton, A.; Maloufi, N. Fundamental and experimental aspects of diffraction for characterizing dislocations by electron channeling contrast imaging in scanning electron microscope. Sci. Rep. 2017, 7, 9742. [Google Scholar] [CrossRef] [PubMed]

- Guyon, J.; Mansour, H.; Gey, N.; Crimp, M.; Chalal, S.; Maloufi, N. Sub-micron resolution selected area electron channeling patterns. Ultromicroscopy 2015, 149, 34–44. [Google Scholar] [CrossRef] [PubMed]

- Zambaldi, C.; Raabe, D. Plastic anisotropy of gamma-TiAl revealed by axisymmetric indentation. Acta Mater. 2010, 58, 3516–3530. [Google Scholar] [CrossRef]

- Kad, B.; Asaro, R.J. Apparent Hall-Petch effects in polycrystalline lamellar TiAl. Philos. Mag. A 2006, 75, 87–104. [Google Scholar] [CrossRef]

- Simki, B.; Ng, B.; Crimp, M.; Bieler, T. Crack opening due to deformation twin shear at grain boundaries in near-γ TiAl. Intermetallics 2007, 15, 55–60. [Google Scholar] [CrossRef]

- Ng, B.; Simki, B.; Crimp, M.; Bieler, T. The role of mechanical twinning on microcrack nucleation and crack propagation in a near-γ TiAl alloy. Intermetallics 2004, 12, 1317–1323. [Google Scholar] [CrossRef]

- Gehard, S.; Pyczak, F.; Göken, M. Microstructural and micromechanical characterisation of TiAl alloys using atomic force microscopy and nanoindentation. Mater. Sci. Eng. A 2009, 523, 235–241. [Google Scholar] [CrossRef]

- Hirth, J.P.; Lothe, J. Theory of Dislocations, 2nd ed.; Krieger Publishing Company: Malabar, FL, USA, 1982; p. 756. ISBN 0521864364. [Google Scholar]

- Gibson, M.; Forwood, C. Slip transfer of deformation twins in duplex γ-based Ti-Al alloys: Part III. Transfer across general large-angle γ-γ grain boundaries. Philos. Mag. A 2002, 82, 1381–1404. [Google Scholar] [CrossRef]

- Simki, B.; Crimp, M.; Bieler, T. A factor to predict microcrack nucleation at gamma-gamma grain boundary in TiAl. Scr. Mater. 2003, 49, 149–154. [Google Scholar] [CrossRef]

- Bieler, T.; Fallahi, A.; Ng, B.; Kumar, D.; Crimp, M.; Simki, B.; Zamiri, A.; Pourboghrat, F.; Mason, D. Fracture initiation/propagation parameters for duplex TiAl grain boundaries based on twinning, slip, crystal orientation and boundary misorientation. Intermetallics 2005, 13, 979–984. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guitton, A.; Kriaa, H.; Bouzy, E.; Guyon, J.; Maloufi, N. A Dislocation-Scale Characterization of the Evolution of Deformation Microstructures around Nanoindentation Imprints in a TiAl Alloy. Materials 2018, 11, 305. https://doi.org/10.3390/ma11020305

Guitton A, Kriaa H, Bouzy E, Guyon J, Maloufi N. A Dislocation-Scale Characterization of the Evolution of Deformation Microstructures around Nanoindentation Imprints in a TiAl Alloy. Materials. 2018; 11(2):305. https://doi.org/10.3390/ma11020305

Chicago/Turabian StyleGuitton, Antoine, Hana Kriaa, Emmanuel Bouzy, Julien Guyon, and Nabila Maloufi. 2018. "A Dislocation-Scale Characterization of the Evolution of Deformation Microstructures around Nanoindentation Imprints in a TiAl Alloy" Materials 11, no. 2: 305. https://doi.org/10.3390/ma11020305

APA StyleGuitton, A., Kriaa, H., Bouzy, E., Guyon, J., & Maloufi, N. (2018). A Dislocation-Scale Characterization of the Evolution of Deformation Microstructures around Nanoindentation Imprints in a TiAl Alloy. Materials, 11(2), 305. https://doi.org/10.3390/ma11020305