Facile Fabrication of 100% Bio-based and Degradable Ternary Cellulose/PHBV/PLA Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

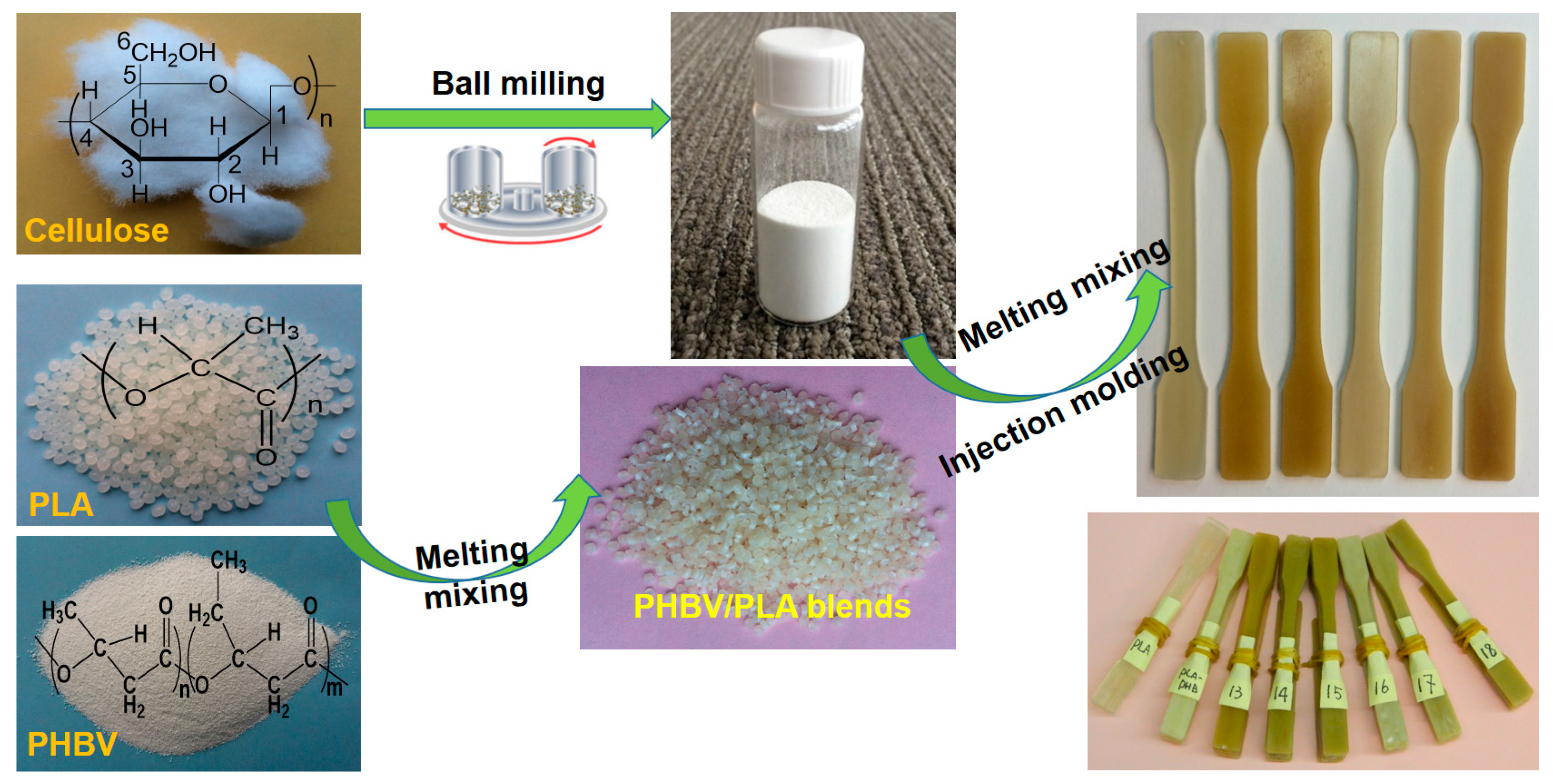

2.2. Fabrication of Composites

2.3. Characterization

2.4. Statistical Analysis

3. Results and Discussion

3.1. Ball Milling on the Cellulose Fibers

3.2. Mechanical Properties of the Composites

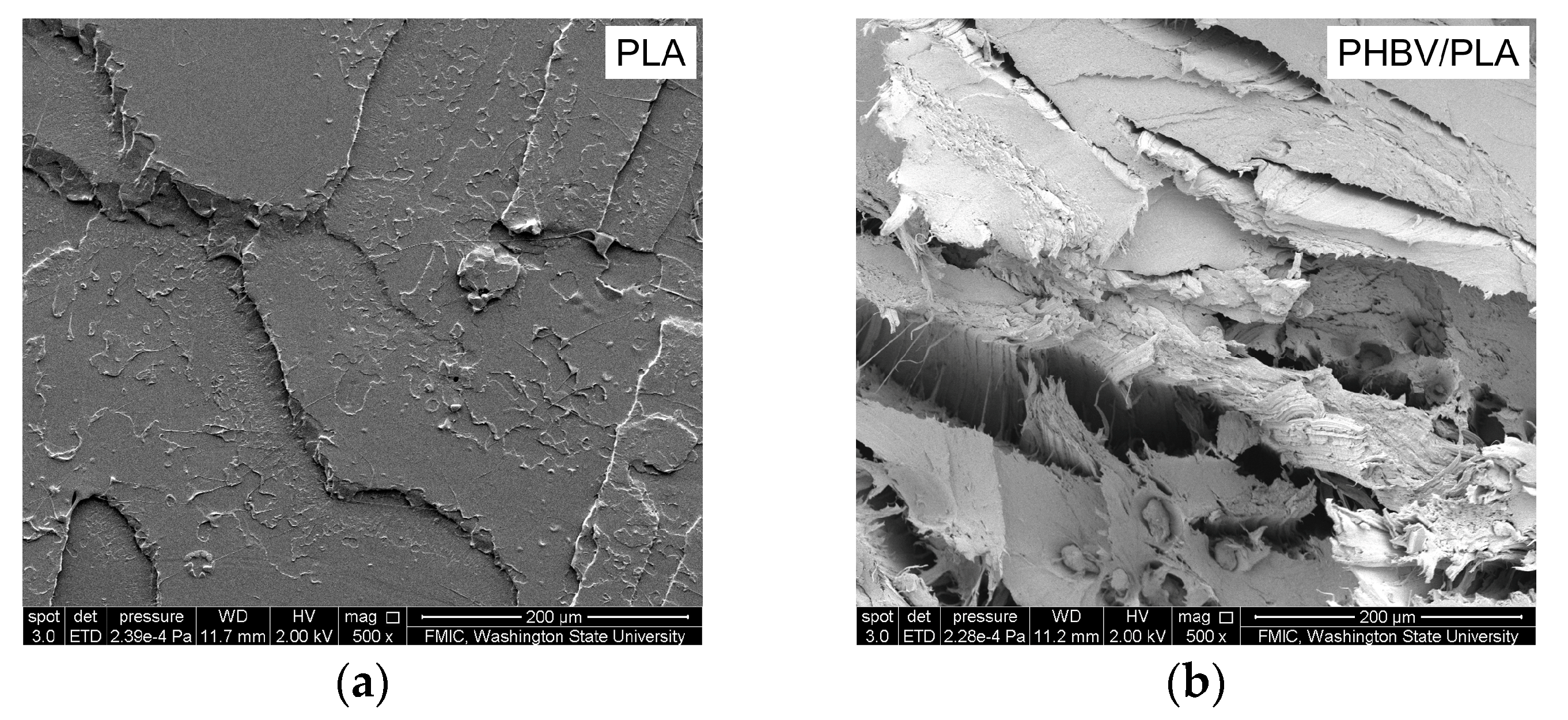

3.3. Tensile Fractured Surfaces

3.4. Statistical Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misratt, M. Perspective on polylactic acid (PLA) based sustainable materials for durable applications: Focus on toughness and heat resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Raquez, J.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Liu, M.; Pu, M.; Ma, H. Preparation, structure and thermal properties of polylactide/sepiolite nanocomposites with and without organic modifiers. Compos. Sci. Technol. 2012, 72, 1508–1514. [Google Scholar] [CrossRef]

- Papong, S.; Malakul, P.; Trungkavashirakun, R.; Wenunun, P.; Chom-in, T.; Nithitanakul, M.; Sarobol, E. Comparative assessment of the environmental profile of PLA and PET drinking water bottles from a life cycle perspective. J. Clean. Prod. 2014, 65, 539–550. [Google Scholar] [CrossRef]

- Qiang, T.; Yu, D.; Zhang, A.; Gao, H.; Li, Z.; Liu, Z.; Chen, W.; Han, Z. Life cycle assessment on polylactide-based wood plastic composites toughened with polyhydroxyalkanoates. J. Clean. Prod. 2014, 66, 139–145. [Google Scholar] [CrossRef]

- Lu, H.; Madbouly, S.A.; Schrader, J.A.; Srinivasan, G.; McCabe, K.G.; Grewell, D.; Kessler, M.R.; Graves, W.R. Biodegradation behavior of poly(lactic acid) (PLA)/distiller’s dried grains with solubles (DDGS) composites. ACS Sustain. Chem. Eng. 2014, 2, 2699–2706. [Google Scholar] [CrossRef]

- Yoon, J.T.; Lee, S.C.; Jeong, Y.G. Effects of grafted chain length on mechanical and electrical properties of nanocomposites containing polylactide-grafted carbon nanotubes. Compos. Sci. Technol. 2010, 70, 776–782. [Google Scholar] [CrossRef]

- Bax, B.; Mussig, J. Impact and tensile properties of PLA/Cordenka and PLA/flax composites. Compos. Sci. Technol. 2008, 68, 1601–1607. [Google Scholar] [CrossRef]

- Yusoff, R.B.; Takagi, H.; Nakagaito, A.N. Tensile and flexural properties of polylactic acid-based hybrid green composites reinforced by kenaf, bamboo and coir fibers. Ind. Crops Prod. 2016, 94, 562–573. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.M.; Chiralt, A.; Torre, L. Production and characterization of PLA_PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crops Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- Ten, E.; Turtle, J.; Bahr, D.; Jiang, L.; Wolcott, M. Thermal and mechanical properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/cellulose nanowhiskers composites. Polymer 2010, 51, 2652–2660. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; López, D.; Kenny, J.M.; Peponi, L. Development of flexible materials based on plasticized electrospun PLA-PHB blends: Structural, thermal, mechanical and disintegration properties. Eur. Polym. J. 2015, 73, 433–446. [Google Scholar] [CrossRef]

- Ho, M.P.; Lau, K. Enhancement of impact resistance of biodegradable polymer using bamboo charcoal particles. Mater. Lett. 2014, 136, 122–125. [Google Scholar] [CrossRef]

- Zhang, K.; Misra, M.; Mohanty, A.K. Toughened sustainable green composites from poly(3-hydroxybutyrate-co-3-hydroxyvalerate) based ternary blends and miscanthus biofiber. ACS Sustain. Chem. Eng. 2014, 2, 2345–2354. [Google Scholar] [CrossRef]

- Khalil, H.A.; Bhat, A.H.; Yusra, A.I. Green composites from sustainable cellulose nanofibrils: A review. Carbohydr. Polym. 2012, 87, 963–979. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.; Aitomäki, Y.; Berglund, L.A.; Oksman, K.; Bismarck, A. On the use of nanocellulose as reinforcement in polymer matrix composites. Compos. Sci. Technol. 2014, 105, 15–27. [Google Scholar] [CrossRef]

- Berglund, L.A.; Peijs, T. Cellulose biocomposites—From bulk moldings to nanostructured systems. MRS Bull. 2010, 35, 201–207. [Google Scholar] [CrossRef]

- Ojijo, V.; Ray, S.S. Processing strategies in bionanocomposites. Prog. Polym. Sci. 2013, 38, 1543–1589. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable composites based on lignocellulosic fibers—An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Septevani, A.A.; Evans, D.A.C.; Annamalai, P.K.; Martin, D.J. The use of cellulose nanocrystals to enhance the thermal insulation properties and sustainability of rigid polyurethane foam. Ind. Crops Prod. 2017, 107, 114–121. [Google Scholar] [CrossRef]

- Johari, A.P.; Mohanty, S.; Kurmvanshi, S.K.; Nayak, S.K. Influence of different treated cellulose fibers on the mechanical and thermal properties of poly(lactic acid). ACS Sustain. Chem. Eng. 2016, 4, 1619–1629. [Google Scholar] [CrossRef]

- Xu, H.; Xie, L.; Chen, Y.H.; Huang, H.D.; Xu, J.Z.; Zhong, G.J.; Hsiao, B.S.; Li, Z.M. Strong shear flow-driven simultaneous formation of classic Shish-Kebab, hybrid Shish-Kebab, and transcrystallinity in poly(lactic acid)/natural fiber biocomposites. ACS Sustain. Chem. Eng. 2013, 1, 1619–1629. [Google Scholar] [CrossRef]

- Wei, L.; Stark, N.M.; McDonald, A.G. Interfacial improvements in biocomposites based on poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) bioplastics reinforced and grafted with [small alpha]-cellulose fibers. Green Chem. 2015, 17, 4800–4814. [Google Scholar] [CrossRef]

- Yu, H.; Qin, Z.; Yan, C.; Yao, J. Green nanocomposites based on functionalized cellulose nanocrystals: A study on the relationship between interfacial interaction and property enhancement. ACS Sustain. Chem. Eng. 2014, 2, 875–886. [Google Scholar] [CrossRef]

- Laadila, M.A.; Hegde, K.; Rouissi, T.; Brar, S.K.; Galvez, R.; Sorelli, L.; Cheikh, R.B.; Paiva, M.; Abokitse, K. Green synthesis of novel biocomposites from treated cellulosic fibers and recycled bio-plastic polylactic acid. J. Clean. Prod. 2017, 164, 575–586. [Google Scholar] [CrossRef]

- Haafiz, M.K.M.; Hassan, A.; Zakaria, Z.; Inuwa, I.M.; Islam, M.S.; Jawaid, M. Properties of polylactic acid composites reinforced with oil palm biomass microcrystalline cellulose. Carbohydr. Polym. 2013, 98, 139–145. [Google Scholar] [CrossRef] [PubMed]

- Malmir, S.; Montero, B.; Rico, M.; Barral, L.; Bouza, R. Morphology, thermal and barrier properties of biodegradable films of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) containing cellulose nanocrystals. Compos. Part A 2017, 93, 41–48. [Google Scholar] [CrossRef]

- Dasan, Y.K.; Bhat, A.H.; Faiz, A. Development and material properties of poly(lactic acid)/poly (3-hydroxybutyrate-co-3-hydroxyvalerate)-based nanocrystalline cellulose nanocomposites. J. Appl. Polym. Sci. 2016, 134. [Google Scholar] [CrossRef]

- Kiziltas, A.; Nazari, B.; Kiziltas, E.E.; Gardner, D.J.; Han, Y.; Rushing, T.S. Method to reinforce polylactic acid with cellulose nanofibers via a polyhydroxybutyrate carrier system. Carbohydr. Polym. 2016, 140, 393–399. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Yang, X.; Li, C.; Liang, M.; Lu, C.H.; Deng, Y. Mechanochemical activation of cellulose and its thermoplastic polyvinyl alcohol ecocomposites with enhanced physicochemical properties. Carbohydr. Polym. 2011, 83, 257–263. [Google Scholar] [CrossRef]

- Zhang, W.; Liang, M.; Lu, C.H. Morphological and structural development of hardwood cellulose during mechanochemical pretreatment in solid state through pan-milling. Cellulose 2007, 14, 447–456. [Google Scholar] [CrossRef]

- Lee, H.; Mani, S. Mechanical pretreatment of cellulose pulp to produce cellulose nanofibrils using a dry grinding method. Ind. Crops Prod. 2017, 104, 179–187. [Google Scholar] [CrossRef]

- Qiang, T.; Wang, J.; Wolcott, M.P. Facile preparation of cellulose/polylactide composite materials with tunable mechanical properties. Polym. Plast. Technol. Eng. 2017. [Google Scholar] [CrossRef]

- Avolio, R.; Bonadies, I.; Capitani, D.; Errico, M.E.; Gentile, G.; Avella, M. A multitechnique approach to assess the effect of ball milling on cellulose. Carbohydr. Polym. 2012, 87, 265–273. [Google Scholar] [CrossRef]

- Gao, H.H.; Qiang, T. Fracture surface morphology and impact strength of cellulose/PLA composites. Materials 2017, 10, 624. [Google Scholar] [CrossRef] [PubMed]

- Shimura, R.; Nishioka, A.; Kano, I.; Koda, T.; Nishio, T. Novel method for producing amorphous cellulose only by milling. Carbohydr. Polym. 2014, 102, 645–648. [Google Scholar] [CrossRef] [PubMed]

- Graupner, N.; Müssig, J. A comparison of the mechanical characteristics of kenaf and lyocell fibre reinforced poly(lactic acid) (PLA) and poly(3-hydroxybutyrate) (PHB) composites. Compos. Part A 2011, 42, 2010–2019. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Maier, G.; Zipper, P.; Stubicar, M.; Schurz, J. Amorphization of different cellulose samples by ball milling. Cell. Chem. Technol. 2005, 39, 167–177. [Google Scholar]

- Wang, Z.; McDonald, A.G.; Westerhof, R.J.; Kersten, S.R.; Cuba-Torres, C.M.; Ha, S.; Pecha, B.; Garcia-Perez, M. Effect of cellulose crystallinity on the formation of a liquid intermediate and on product distribution during pyrolysis. J. Anal. Appl. Pyrol. 2013, 100, 56–66. [Google Scholar] [CrossRef]

- Schwanninger, M.; Rodrigues, J.C.; Pereira, H.; Hinterstoisser, B. Effects of short-time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib. Spectrosc. 2004, 36, 23–40. [Google Scholar] [CrossRef]

- Ferrus, R.; Pages, P. Water retention value and degree of crystallinity by infrared absorption spectroscopy in caustic soda treated cotton. Cell. Chem. Technol. 1977, 11, 633–637. [Google Scholar]

- Lu, Q.; Lin, W.; Tang, L.; Wang, S.; Chen, X.; Huang, B. A mechanochemical approach to manufacturing bamboo cellulose nanocrystals. J. Mater. Sci. 2015, 50, 611–619. [Google Scholar] [CrossRef]

- Popescu, V.; Muresan, A.; Popescu, G.; Balan, M.; Dobromir, M. Ethyl chitosan synthesis and quantification of the effects acquired after grafting it on a cotton fabric, using ANOVA statistical analysis. Carbohydr. Polym. 2016, 138, 94–105. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Jiang, Z.; Deng, J.; Wang, G.; Zhang, D.; Zhao, Q.; Cai, L.; Shi, S.Q. Evaluation of the uniformity of density and mechanical properties of bamboo-bundle laminated veneer lumber (BLVL). BioResources 2014, 9, 554–565. [Google Scholar] [CrossRef]

- Lin, W.; Wu, Y.; Cheng, A.; Chao, S.; Hsu, H. Engineering properties and correlation analysis of fiber cementitious materials. Materials 2014, 7, 7423–7435. [Google Scholar] [CrossRef] [PubMed]

| Materials Code | Content of Cellulose/PHBV/PLA/wt % | Average Particle Size of Cellulose/μm |

|---|---|---|

| Sample A | 4.8/23.8/71.4 | 120.0 |

| Sample B | 13.0/21.8/65.3 | |

| Sample C | 20.0/20.0/60.0 | |

| Sample D | 4.8/23.8/71.4 | 39.7 |

| Sample E | 13.0/21.8/65.3 | |

| Sample F | 20.0/20.0/60.0 | |

| Sample G | 4.8/23.8/71.4 | 38.9 |

| Sample H | 13.0/21.8/65.3 | |

| Sample I | 20.0/20.0/60.0 |

| Factor | Mechanical Property | F | p-Value |

|---|---|---|---|

| Particle size | Tensile strength * | 20.15 | 0.000 |

| Tensile modulus * | 11.47 | 0.000 | |

| Elongation at break | 1.247 | 0.299 | |

| Fracture work | 0.9949 | 0.380 | |

| Filling content | Tensile strength * | 829.7 | 0.000 |

| Tensile modulus * | 378.6 | 0.000 | |

| Elongation at break * | 37.04 | 0.000 | |

| Fracture work * | 47.04 | 0.000 |

| Factor | Mechanical Property | Pearson Coefficients | Significance |

|---|---|---|---|

| Particle size | Tensile strength | 0.116 | 0.447 |

| Tensile modulus | 0.155 | 0.309 | |

| Elongation at break | −0.143 | 0.349 | |

| Fracture work | −0.111 | 0.468 | |

| Filling content | Tensile strength * | −0.962 | 0.000 |

| Tensile modulus * | 0.904 | 0.000 | |

| Elongation at break * | −0.784 | 0.000 | |

| Fracture work * | −0.815 | 0.000 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiang, T.; Wang, J.; Wolcott, M.P. Facile Fabrication of 100% Bio-based and Degradable Ternary Cellulose/PHBV/PLA Composites. Materials 2018, 11, 330. https://doi.org/10.3390/ma11020330

Qiang T, Wang J, Wolcott MP. Facile Fabrication of 100% Bio-based and Degradable Ternary Cellulose/PHBV/PLA Composites. Materials. 2018; 11(2):330. https://doi.org/10.3390/ma11020330

Chicago/Turabian StyleQiang, Tao, Jinwu Wang, and Michael P. Wolcott. 2018. "Facile Fabrication of 100% Bio-based and Degradable Ternary Cellulose/PHBV/PLA Composites" Materials 11, no. 2: 330. https://doi.org/10.3390/ma11020330

APA StyleQiang, T., Wang, J., & Wolcott, M. P. (2018). Facile Fabrication of 100% Bio-based and Degradable Ternary Cellulose/PHBV/PLA Composites. Materials, 11(2), 330. https://doi.org/10.3390/ma11020330