1. Introduction

In the last years, several polycrystalline disordered materials, such as Yb:LuYAG [

1,

2,

3] or Nd:YSAG [

4], were fabricated and characterized. These gain materials show a broader emission bandwidth respect to other pure hosts, like YAG [

5], Sc

2O

3 and Y

2O

3; moreover, their emission peaks can be tuned toward longer wavelengths [

6]. As a matter of fact, these laser materials are suitable for developing tunable laser systems for use in remote sensing systems as well as to generate short pulses below 100 fs [

7,

8]. At the same time, starting from undoped matrices with high thermal conductivity, they can preserve good thermal properties, making them suitable for high-average power lasers.

Concerning the Y

3Sc

xAl

(5−x)O

12 matrix (crystals [

9,

10] or ceramics), it is obtained by a partial substitution of Al

3+ ions with Sc

3+ ions in the Y

3Al

5O

12 matrix. Sc

3+ ion, owing a larger atomic radius respect to Al

3+ distorts the crystal structure with a consequent increase of the lattice constant [

6].

The modification in the crystal field results in a larger splitting of the sublevels of the upper (

2F

5/2) and of the lower (

2F

7/2) manifolds of Yb

3+ [

11], whereas the overall separation between the manifold barycenters (due to the spin-orbit splitting) remains constant [

11], as it is with good approximation host-independent [

12,

13]. All the host-induced structural effects described above determine a red shift of the main Yb

3+ emission peaks.

The presence of Sc3+ ions, in addition, produces an inhomogeneous broadening of the emission bandwidth. However, the balance between Sc3+ and Al3+ should be chosen carefully as it influences the lifetime of the laser transition and, as a consequence, the laser threshold.

The first Y

3Sc

xAl

(5−x)O

12 ceramic doped with Nd

3+ was fabricated by Sato et al. in 2003 [

14] . In 2004, Saikawa et al. [

11] demonstrated the laser action of 15 at.% Yb

3+-doped Y

3ScAl

4O

12 ceramic obtained by a reactive sintering process. In particular, in Continuous Wave (CW) the laser delivered a maximum output power of 600 mW with a slope efficiency η

s = 72% at a lasing wavelength of λ

L = 1032 nm and pumping wavelength of λ

P = 970 nm. Pulses of 280 fs at λ

L = 1035.8 nm were obtained by a passively mode-locked cavity based on 5 at.% Yb:Y

3(Sc

0.5Al

0.5)

5O

12. Moreover, it was demonstrated a tuning range of 52 nm while the slope efficiency was η

s = 72% [

7]. In a recent paper, Ma and co-workers [

15] have tested a Yb:Y

3ScAl

4O

12 ceramic obtaining mode-locked laser pulses with a duration of 96 fs at 1052 nm, and a repetition rate of 102 MHz; they have obtained a maximum average output power that was 51 mW.

This paper is devoted to exploring the overall potentiality of a laser prototype based on a 10 at.% Yb:Y

3Sc

1.5Al

3.5O

12 ceramic. The sample has been fabricated by solid-state reaction combined with vacuum sintering and its microstructure has been characterized through Field Emission Scanning Electron Microscopy (FESEM) and X-ray Diffraction (XRD). We present a spectroscopic characterization of the ceramic, in particular, the absorption and the emission cross section spectra and the upper laser level lifetime. Laser tests were carried out in Quasi-Continuous Wave (QCW) and in CW operation modes at room temperature. The implementation of a tunable cavity has allowed measuring a tuning curve as wide as 81.5 nm, which is comparable with data obtained with Yb

3+ in fluoride hosts [

16,

17,

18]. To the best of our knowledge, this is the broadest tuning range reported in literature for this material.

2. Ceramic Fabrication Technique

Commercial powders of Y2O3 (99.99%, Yuelong, Shanghai, China), Sc2O3 (99.99%, Jingyun, Shanghai, China), α-Al2O3 (99.99%, Fenghe, Shanghai, China), and Yb2O3 (99.99%, Zhongkai, Shandong, China) were used as staring materials to fabricate 10 at.% Yb:Y3Sc1.5Al3.5O12 (i.e., Yb0.3Y2.7Sc1.5Al3.5O12) ceramics. MgO powder (99.998%, Alfa Aesar, Tianjin, China) and tetraethoxysilane (TEOS, >99.999%, Alfa Aesar, Tianjin, China) were used as sintering aids. The powders were mixed in ethanol and ball-milled with high-purity corundum balls for 12 h. After the ball milling, the slurry was dried at 70 °C for 2 h in an oven and then sieved through 200-mesh screen.

The powder mixtures were calcined at 600 °C for 4 h to remove the organic components. The calcined powders were uniaxially pressed into 18 mm diameter pellets at low pressure (46 MPa) and then the green bodies obtained were isostatically pressed at 250 MPa at room temperature. The pellets were sintered at 1820 °C for 30 h in a tungsten mesh-heated vacuum furnace and then annealed in air at 1450 °C for 20 h to remove the oxygen vacancies. Finally, the ceramics were mirror-polished on both surfaces and reduced to 2.0 mm of thickness for optical measurements. The polished specimens were thermally etched at 1450 °C for 3 h to expose the grain boundaries for the microstructural analysis.

Figure 1a shows the FESEM micrograph of the thermally etched surface of a 10 at.% Yb:Y

3Sc

1.5Al

3.5O

12 transparent ceramics sintered at 1820 °C for 30 h. The grain composing the sample have an average size of 44 μm, determined by the linear intercept method (more than 200 grains were counted); the grain boundaries are very clean; at the grain boundaries and in the inner grains the presence of pores is quite negligible.

Figure 1b shows the XRD pattern of the Yb:YSAG sample. The ceramics crystal structure shows the expected cubic garnet phase with a lattice parameter of 1.2225 nm, which is about 2% larger than that of the lattice constant reported for 10 at.% Yb

3+ doped YAG that is 1.200058 nm [

19].

3. Spectroscopic and Optical Characterization

The spectroscopic characterization was aimed mainly to determine the absorption and the emission cross section spectra of the Yb3+ in the sample, and to determine the upper laser level lifetime.

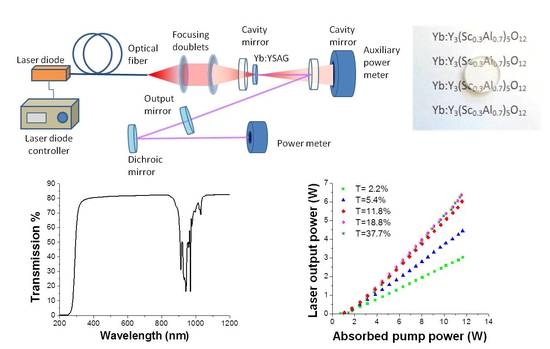

The transmission spectrum of the ceramic sample was measured with a Perkin Elmer Lambda 1050 spectrophotometer, with a spectral resolution of 1 nm (

Figure 2a).

The transmission spectrum, see

Figure 2a, clearly shows the absorption bands due to the Yb

3+ 2F

5/2–

2F

7/2 transition in the range 900–1020 nm. No other absorption features can be seen between 300 and 900 nm.

Regarding the theoretical transmission, to our knowledge no refractive index data are available in literature for this specific composition; Allik et al. [

10] reported a value of the refractive index of 1.873 at 632.8 nm for Nd-doped Y

3Sc

2Al

3O

12, from which a theoretical transmission value of 82.39% (due to the Fresnel reflections) can be calculated. This is very similar to the measured value of 81.65% obtained at the same wavelength. The scattering coefficient at 632.8 nm is then about 0.05 cm

−1.

Figure 2b reports the microscopic optical image (in transmission) of the sample, showing the distribution of the residual pores that appear as dark spots in the image. The optical uniformity of the sample is quite good, and the residual pores are mainly distributed near to the edge of the sample. Their presence does not influence significantly the transmission of the sample (see

Figure 2a).

The cations sites density of the Y

3Sc

1.5Al

3.5O

12, calculated from the lattice constant value of 1.2225 nm (determined by X-ray diffraction measurements), is 1.314 × 10

22 ions/cm

3. From the transmission spectrum of

Figure 2a it was then possible to calculate the absorption cross section spectrum, shown in

Figure 3a.

The absorption cross section of Yb

3+ features a broad peak at about 943 nm, whereas the zero-phonon line peak is located at 969.7 nm. By comparing it with the absorption cross section spectrum of Yb:YAG (also shown in

Figure 3a), it appears that both the main absorption peak (peaked at 939.4 nm in YAG) and the zero line peak (at 968.93 nm in YAG) are slightly shifted toward longer wavelengths. Moreover, at about 1030 nm (one of the main lasing wavelengths) the ground level absorption cross section of Yb

3+ in YSAG is lower than in YAG.

The emission cross section spectrum

σem(

λ) (

Figure 3b) was calculated from the absorption cross section spectrum

σab(

λ) by means of the reciprocity (McCumber) formula [

20]:

where

EZL is the energy of the zero-phonon line transition,

h is the Planck’s constant,

c is the speed of light,

kB is the Boltzmann constant,

T is the temperature,

Zl and

Zu are the partition functions of the lower and upper level, respectively. For the evaluation of

Zl/

Zu we used the values of the energy levels for Yb in YSAG and YAG reported by Saikawa et al. [

11]. Even though these values are valid for the host composition Y

3Sc

2Al

3O

12, the resulting value of

Zl/

Zu at room temperature for Y

3Sc

2Al

3O

12 (0.8835) is very close to that of YAG (0.8817). We assumed then that in Equation (1) the same value can be used as a good approximation for the value of

Zl/

Zu in Y

3Sc

1.5Al

3.5O

12.

These measurements confirm the trend already observed by Saikawa et al. [

11]: the main emission cross section peak in Yb:Y

3Sc

1.5Al

3.5O

12, located at about 1031 nm, has a lower peak value (about 1.2 × 10

−21 cm

2) than the corresponding peak in Yb:YAG (about 1.8 × 10

−21 cm

2 at 1030 nm), but it is significantly broader than in YAG (13 nm vs. 8.5 nm FWHM). Furthermore, the emission spectrum of Yb:Y

3Sc

1.5Al

3.5O

12 shows a relatively high tail extending up to 1075 nm and above, whereas in the same spectral region the emission cross section of Yb:YAG decreases quite rapidly. It must be noticed that for a crystal with composition Yb:Y

3Sc

2Al

3O

12 Dong et al. [

9] have reported a peak emission cross section of about 1.9 × 10

−20 cm

2 at 1030.7 nm (that is larger than both our value and that reported by Saikawa et al. [

11]) and a slightly larger peak bandwidth (∼13.3 nm FWHM).

The lifetime of the upper level was measured by means of the so-called pinhole method to compensate for radiation trapping effects [

21,

22,

23] and using a pulsed ns Ti:Sapphire laser as excitation source. We obtained a lifetime value of 966 ± 6 μsec. This is comparable with the value commonly accepted for Yb:YAG (∼950 μsec, [

23]), but shorter than the value (∼1.1 msec) reported for both the ceramics with composition Yb:Y

3ScAl

4O

12 (Saikawa et al. [

11]) and for the crystal with composition Yb:Y

3Sc

2Al

3O

12 (Dong et al. [

9]). The shortening of the lifetime could be related to some non-radiative decay processes affecting the upper laser level of Yb

3+, due to defects in the crystal lattice. On the other hand, it must be noticed that in Ref. [

11] the upper level lifetime was not measured directly, but determined as a fitting parameter to match the emission spectrum obtained from the reciprocity formula and from the Füchtbauer–Ladenburg method applied to the fluorescence spectrum. Ref. [

9], instead, actually reports the measured fluorescence lifetime, which could be affected by radiation trapping effects, resulting in a larger value than the actual upper level lifetime.

4. Laser Results and Analysis

The laser behavior of the ceramic was tested by using the V-shape cavity reported in

Figure 4. The uncoated ceramic, of 1.85 mm length and doping concentration of 10 at.% Yb

3+, was welded by a sheet of indium on a copper heat-sink and cooled with water at 17 °C. The input and output facets of the sample were polished for optical measurements.

The ceramic was pumped by a fiber-coupled laser-diode which emits at 936 nm with a Gaussian pump intensity distribution in the region of the focal plane (i.e., waist radius around 95 µm at 1/e2, measured with a Charge-Coupled Device (CCD) camera). With this cavity we performed two sets of measurements. In the first, the ceramic was pumped in QCW regime, at 10 Hz of repetition rate with a duty factor of DF = 20%, in order to limit the thermal load into the ceramic. In the second set of measurements, the ceramic was pumped in CW regime. With both schemes the maximum incident pump power was 19.2 W.

Figure 5 reports the QCW laser output power as a function of the absorbed pump power, P

abs, measured by using different output coupler mirrors; their transmission ranged from

T = 2.2% to

T = 37.7%. The highest slope efficiency was achieved with

T = 18.8%, i.e., η

s = 67.8%, while the laser maximum output power of 6.3 W at λ

L ∼ 1031 nm was obtained with both the output coupler mirrors with

T = 18.8% and with

T = 37.7%. The longest wavelength in free running lasing, i.e., λ

L = 1051 nm, is measured with

T = 2.2% (which has also given the lowest laser threshold, i.e., P

th = 0.74 W).

Concerning the red shift of the emission wavelength, observed using an Output Coupler (OC) with a lower transmittance, this effect can be addressed to the quasi three-level system behavior of the Yb

3+. As a matter of fact, using OCs with higher transmission, the cavity losses increases, and in turn, the fraction of the excited population needed to reach the lasing threshold increases as well determining a shift of the peak of the effective gain spectrum toward shorter wavelengths (gain-tuning effect [

8]).

From the values of the slope efficiency obtained with output couplers with different transmission, it was possible to calculate the overall internal losses of the cavity by means of the Caird formula [

24]. We obtained a single pass loss of 1.7%, which is slightly higher than the estimated internal transmission losses of the sample (∼0.7%) and is probably also affected by the residual losses due to the Fresnel reflection at the interfaces.

Remarkable results are confirmed in CW pumping. Two different measurements were performed using mirrors with

T = 11.7% and

T = 18.8% as output couplers. Very similar results in terms of output power and slope efficiency were found with the two output couplers as reported in

Figure 6a. In particular, the laser delivered P

out = 5 W with both output couplers while the slope efficiency were η

s = 52.2% and η

s = 52.7%, respectively; the laser threshold and the emission wavelength remained instead unchanged. It must be noticed that in CW the pump absorption is slightly increased as a consequence of the emission wavelength red shift of the pump laser. From these data it appears that the thermal load determines only a modest decrease of the laser performance, in particular, the maximum output power decreases from 6 W (η

s = 65.1%) to 5 W (η

s = 52.7%) switching from QCW to CW at the same pump power values (

Figure 5b). These results demonstrate the high thermal quality of this material. Finally, we note that the laser threshold and the emission wavelength remained unchanged, i.e., P

th ∼ 1 W, λ

L ∼ 1031 nm.

Regarding the beam quality structure, in the near field the laser beam has about a Gaussian intensity distribution. The beam quality factor M

2 was measured by means of a CCD camera (model BC106, Thorlabs Inc., Newton, NJ, USA) and a beam analysis software, using the output coupler with transmittance 18.8% (that provided the highest output power both in QCW and in CW pumping conditions). The measurement was carried out at 3.3 W of output power (i.e., about half of the maximum output power) and it resulted in M

2x = 2.2, M

2y = 2.4 in QCW and M

2x = 2.5, M

2y = 2.8 in CW pumping conditions (here,

x and

y refer to the directions respectively parallel and perpendicular to the cavity folding plane, see

Figure 4). The far-field intensity distribution both in QCW and in CW pumping mode is shown in

Figure 7. The beam has then a multimode structure, because the pump beam in the sample (radius at 1/e

2 95 μm, see above) is larger than the cavity TEM

00 mode radius (about 48 μm) in the pumped volume. The asymmetry between the

x and the

y direction is due to the slight cavity astigmatism introduced by the tilted spherical mirror (i.e., the Folding Mirror FM, see

Figure 4). In any case, it must be noticed that no attempt was carried out to optimize the beam quality, but only the power extraction.

The tunability range of the ceramic was explored by inserting a ZnSe prism in Brewster configuration (apex angle 41.8°) between the FM and the OC. The emission wavelength was measured by a spectrometer with a focal length of 60 cm equipped with a multichannel detector. The spectral resolution was 0.4 nm. We have measured the output power at several wavelengths (see

Figure 8), obtaining a tuning range as wide as 81.5 nm (i.e., from λ

L = 991.5 nm to λ

L = 1073 nm). The curve shows two main peaks at λ

L = 1030 nm and λ

L = 1050 nm with an output power of 118 mW and 89 mW, respectively. The laser emission line width is about 2.5 nm across the whole tuning range. It is worth noting that the tuning limit at short wavelengths is also affected by the cutoff of the transmission curve of the End Mirror EM (see

Figure 4).

5. Conclusions

In this experiment, we have investigated the microstructural and spectroscopic properties as well as the laser performance of a 10 at.% Yb:YSAG ceramic fabricated by reactive vacuum sintering. Concerning the spectroscopic characterization, we have determined the absorption and emission cross sections and the lifetime of the upper state of the laser transition. The mixed composition has shown a significant broadening of the main peak of the emission spectrum near 1031 nm with respect to YAG (13 nm vs. 8.5 nm, FWHM). By comparing our results with previous literature on Yb:YSAG [

7,

9], it appears that the general trend is toward a broadening of the emission spectrum for increasing content of Sc

3+, as discussed above. The upper level lifetime resulted slightly longer than that reported for Yb:YAG, but shorter than those reported for the ceramics with composition Yb:Y

3ScAl

4O

12 (Saikawa et al. [

11]) and for the crystal with composition Yb:Y

3Sc

2Al

3O

12 (Dong et al. [

9]). The discrepancies in the upper level lifetime could be due to the use of different assessment methodologies, as pointed out above.

Good results are achieved in terms of laser performance such as output power, slope efficiency and laser threshold. A direct comparison can be made with the CW emission results reported by Saikawa et al. [

7,

11]. The authors obtained a maximum slope efficiency η

s of 72% (maximum output power ∼0.6 W) under pumping at 970 nm and a maximum η

s of 54% (max. output power ∼0.8 W) pumping at 940 nm, using a CW Ti:Sapphire laser as a pump source. The values of the slope efficiencies here reported (up to 67.7%) are comparable with the previous results, but the output power levels reached in our experiments are much higher than those previously reported in [

5,

7,

11]. It is important to emphasize that our experiments have been carried out using a high power diode laser as a pump source, which is less favorable in terms of beam quality with respect to the Ti:Sapphire laser used in [

7,

11], but much more relevant in view of practical applications. Finally, the observed tuning range (from λ

L = 991.5 nm to λ

L = 1073 nm) is much broader than previously reported (from about 1015 nm to 1065 nm) [

7].

The results reported here demonstrate a significant advancement in the quality of Yb:YSAG ceramics as a laser gain material. The improvement in the laser performance, indeed, is favored by the high optical and spectroscopic quality of the sample. Further investigations will address the comparison of the spectroscopic and laser performances of Yb:YSAG ceramics with different Sc/Al balance, in order to obtain additional improvements.