Effects of Ball Milling Processes on the Microstructure and Rheological Properties of Microcrystalline Cellulose as a Sustainable Polymer Additive

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Grinding Method

2.3. Particle Size Distribution Analysis (PSD)

2.4. Scanning Electron Microscopy Analysis (SEM)

2.5. X-ray Diffraction Analysis (XRD)

2.6. Fourier Transform Infrared Spectroscopy Analysis (FTIR-ATR)

2.7. Differential Scanning Calorimetry Analysis (DSC)

2.8. Preparation of Polymer Composite Suspensions

2.9. Rheological Measurements

3. Results and Discussion

3.1. Particle Size Distribution

3.2. Surface Morphology

3.3. X-ray Diffraction

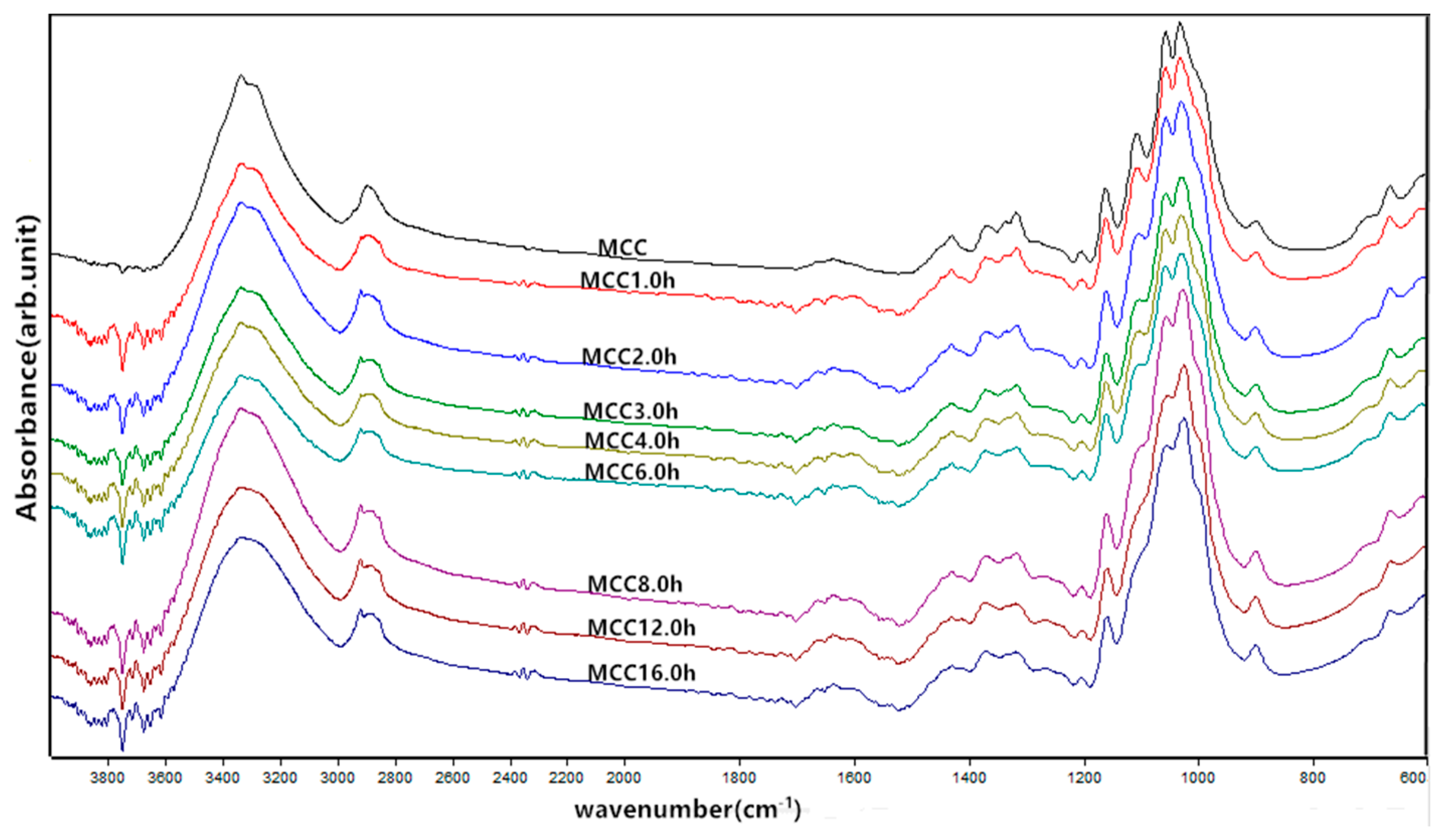

3.4. Fourier Transform Infrared Spectroscopy (FTIR)

3.5. Thermal Properties

3.6. Rheological Characterization

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, M.C.; Wu, Q.; Song, K.; Lee, S.; Qing, Y.; Wu, Y. Cellulose Nanoparticles: Structure-Morphology-Rheology Relationships. ACS Sustain. Chem. Eng. 2015, 3, 821–832. [Google Scholar] [CrossRef]

- Nsor-Atindana, J.; Chen, M.; Goff, H.D.; Zhong, F.; Sharif, H.R.; Li, Y. Functionality and nutritional aspects of microcrystalline cellulose in food. Carbohydr. Polym. 2017, 172, 159–174. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Reus-Medina, M.D.L.L.; Yang, D. Preparation, characterization, and tabletting properties of a new cellulose-based pharmaceutical aid. Int. J. Pharm. 2002, 235, 129–140. [Google Scholar] [CrossRef]

- Thoorens, G.; Krier, F.; Leclercq, B.; Carlin, B.; Evrard, B. Microcrystalline cellulose, a direct compression binder in a quality by design environment—A review. Int. J. Pharm. 2014, 473, 64–72. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Long, Z.; Wang, J.; Wu, M.; Wang, F.; Wang, B.; Lv, W. Preparation and properties of microcrystalline cellulose/hydroxypropyl starch composite films. Cellulose 2017, 24, 4449–4459. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. A novel approach of developing micro crystalline cellulose reinforced cementitious composites with enhanced microstructure and mechanical performance. Cem. Concr. Comp. 2017, 78, 146–161. [Google Scholar] [CrossRef]

- Miri, N.E.; Abdelouahdi, K.; Barakat, A.; Zahouily, M.; Fihri, A.; Solhy, A.; Achaby, M.E. Bio-nanocomposite films reinforced with cellulose nanocrystals: Rheology of film-forming solutions, transparency, water vapor barrier and tensile properties of films. Carbohydr. Polym. 2015, 129, 156–167. [Google Scholar] [CrossRef] [PubMed]

- Ching, Y.C.; Ali, M.E.; Abdullah, L.C.; Choo, K.W.; Kuan, Y.C.; Julaihi, S.J.; Chuah, C.H.; Liou, N.S. Rheological properties of cellulose nanocrystal-embedded polymer composites: A review. Cellulose 2016, 23, 1011–1030. [Google Scholar] [CrossRef]

- Galus, S.; Kadzinska, J. Food applications of emulsion-based edible films and coatings. Trends Food Sci. Technol. 2015, 45, 273–283. [Google Scholar] [CrossRef]

- Hu, Z.; Ballinger, S.; Pelton, R.; Cranston, E.D. Surfactant-enhanced cellulose nanocrystal Pickering emulsions. J. Colloid Interface Sci. 2015, 439, 139–148. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; He, H.; Li, M.C.; Song, K.; Cheng, H.N.; Wu, Q. Morphological influence of cellulose nanoparticles (CNs) from cottonseed hulls on rheological properties of polyvinyl alcohol/CN suspensions. Carbohydr. Polym. 2016, 153, 445–454. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Li, Q.; Shi, Z.; Ye, J. Interactions between wheat starch and cellulose derivatives in short-term retrogradation: Rheology and FTIR study. Food Res. Int. 2017, 100, 858–863. [Google Scholar] [CrossRef] [PubMed]

- Delogu, F.; Gorrasi, G.; Sorrentino, A. Fabrication of polymer nanocomposites via ball milling: Present status and future perspectives. Prog. Mater. Sci. 2017, 86, 75–126. [Google Scholar] [CrossRef]

- Silva, G.G.D.; Couturier, M.; Berrin, J.G.; Buléon, A.; Rouau, X. Effects of grinding processes on enzymatic degradation of wheat straw. Bioresource Technol. 2012, 103, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Ulbrich, M.; Flöter, E. Impact of high pressure homogenization modification of a cellulose based fiber product on water binding properties. Food Hydrocoll. 2014, 41, 281–289. [Google Scholar] [CrossRef]

- Gao, C.; Xiao, W.; Ji, G.; Zhang, Y.; Cao, Y.; Han, L. Regularity and mechanism of wheat straw properties change in ball milling process at cellular scale. Bioresour. Technol. 2017, 241, 214–219. [Google Scholar] [CrossRef] [PubMed]

- Avolio, R.; Bonadies, I.; Capitani, D.; Errico, M.E.; Gentile, G.; Avella, M. A multitechnique approach to assess the effect of ball milling on cellulose. Carbohydr. Polym. 2012, 87, 265–273. [Google Scholar] [CrossRef]

- Wang, N.; Ding, E.; Cheng, R. Thermal degradation behaviors of spherical cellulose nanocrystals with sulfate groups. Polymer 2007, 48, 3486–3493. [Google Scholar] [CrossRef]

- Cheng, M.; Qin, Z.; Chen, Y.; Hu, S.; Ren, Z.; Zhu, M. Efficient Extraction of Cellulose Nanocrystals through Hydrochloric Acid Hydrolysis Catalyzed by Inorganic Chlorides under Hydrothermal Conditions. ACS Sustain. Chem. Eng. 2017, 5, 4656–4664. [Google Scholar] [CrossRef]

- Karinkanta, P.; Illikainen, M.; Niinimäki, J. Effect of different impact events in fine grinding mills on the development of the physical properties of dried Norway spruce (Picea abies) wood in pulverization. Powder Technol. 2014, 253, 352–359. [Google Scholar] [CrossRef]

- Guzzo, P.L.; Tino, A.A.A.; Santos, J.B. The onset of particle agglomeration during the dry ultrafine grinding of limestone in a planetary ball mill. Powder Technol. 2015, 284, 122–129. [Google Scholar] [CrossRef]

- Knieke, C.; Romeis, S.; Peukert, W. Influence of process parameters on breakage kinetics and grinding limit at the nanoscale. AIChE J. 2011, 57, 1751–1758. [Google Scholar] [CrossRef]

- Liao, Z.; Huang, Z.; Hu, H.; Zhang, Y.; Tan, Y. Microscopic structure and properties changes of cassava stillage residue pretreated by mechanical activation. Bioresour. Technol. 2011, 102, 7953–7958. [Google Scholar] [CrossRef] [PubMed]

- Lamaming, J.; Hashim, R.; Sulaiman, O.; Leh, C.P.; Sugimoto, T.; Nordin, N.A. Cellulose nanocrystals isolated from oil palm trunk. Carbohydr. Polym. 2015, 127, 202–208. [Google Scholar] [CrossRef] [PubMed]

- Kalita, R.D.; Nath, Y.; Ochubiojo, M.E.; Buragohain, A.K. Extraction and characterization of microcrystalline cellulose from fodder grass; Setaria glauca (L) P. Beauv, and its potential as a drug delivery vehicle for isoniazid, a first line antituberculosis drug. Colloid. Surface B Biointerfaces 2013, 108, 85–89. [Google Scholar] [CrossRef] [PubMed]

- Kian, L.K.; Jawaid, M.; Ariffin, H.; Alothman, O.Y. Isolation and characterization of microcrystalline cellulose from roselle fibers. Int. J. Biol. Macromol. 2017, 103, 931–940. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, M.A.; Salleh, W.N.W.; Jaafar, J.; Ismail, A.F.; Mutalib, M.A.; Mohamad, A.B.; Zain, M.F.M.; Awang, N.A.; Hir, Z.A.M. Physicochemical characterization of cellulose nanocrystal and nanoporous self-assembled CNC membrane derived from Ceibapentandra. Carbohydr. Polym. 2017, 157, 1892–1902. [Google Scholar] [CrossRef] [PubMed]

- Lu, Q.; Cai, Z.; Lin, F.; Tang, L.; Wang, S.; Huang, B. Extraction of Cellulose Nanocrystals with a High Yield of 88% by Simultaneous Mechanochemical Activation and Phosphotungstic Acid Hydrolysis. ACS Sustain. Chem. Eng. 2016, 4, 2165–2172. [Google Scholar] [CrossRef]

- Haafiz, M.K.M.; Hassan, A.; Zakaria, Z.; Inuwa, I.M. Isolation and characterization of cellulose nanowhiskers from oil palm biomass microcrystalline cellulose. Carbohydr. Polym. 2014, 103, 119–125. [Google Scholar] [CrossRef] [PubMed]

- Wanrosli, W.D.; Rohaizu, R.; Ghazali, A. Synthesis and characterization of cellulose phosphate from oil palm empty fruit bunches microcrystalline cellulose. Carbohydr. Polym. 2011, 84, 262–267. [Google Scholar] [CrossRef]

- Trache, D.; Donnot, A.; Khimeche, K.; Benelmi, R.; Brosse, N. Physico-chemical properties and thermal stability of microcrystalline cellulose isolated from Alfa fibres. Carbohydr. Polym. 2014, 104, 223–230. [Google Scholar] [CrossRef] [PubMed]

- Kavanagh, G.M.; Ross-murphy, S.B. Rheological Characterisation of Polymer Gels. Prog. Polym. Sci. 1998, 23, 533–562. [Google Scholar] [CrossRef]

- Cui, S.; Li, M.; Zhang, S.; Liu, J.; Sun, Q.; Xiong, L. Physicochemical properties of maize and sweet potato starches in the presence of cellulose nanocrystals. Food Hydrocoll. 2018, 77, 220–227. [Google Scholar] [CrossRef]

- Khanna, S.; Tester, R.F. Influence of purified konjac glucomannan on the gelatinization and retrogradation properties of maize and potato starches. Food Hydrocoll. 2006, 20, 567–576. [Google Scholar] [CrossRef]

- Yang, S.; Tang, Y.; Wang, J.; Kong, F.; Zhang, J. Surface Treatment of Cellulosic Paper with Starch-Based Composites Reinforced with Nanocrystalline Cellulose. Ind. Eng. Chem. Res. 2014, 53, 13980–13988. [Google Scholar] [CrossRef]

- Movchan, T.G.; Ur’ev, N.B.; Khamova, T.V.; Tarasyuk, E.V.; Potapov, A.N.; Shilova, O.A.; Klimenko, N.S.; Shevchenko, V.V. Kinetics of Structuring in the Sol–Gel Systems Based on Tetraethoxysilane with Organic Additives: I. Sols. Glass Phys. Chem. 2005, 31, 219–228. [Google Scholar] [CrossRef]

- Saarikoski, E.; Rissanen, M.; Seppälä, J. Effect of rheological properties of dissolved cellulose/microfibrillated cellulose blend suspensions on film forming. Carbohydr. Polym. 2015, 119, 62–70. [Google Scholar] [CrossRef] [PubMed]

- Peressini, D.; Bravin, B.; Lapasin, R.; Rizzotti, C.; Sensidoni, A. Starch-methylcellulose based edible films: Rheological properties of film-forming dispersions. J. Food Eng. 2003, 59, 25–32. [Google Scholar] [CrossRef]

| Sample | Starch (g) | MCC (g) | Glycerol (g) | Xylitol (g) | Water (g) |

|---|---|---|---|---|---|

| Control (0%) | 3.50 | 0.00 | 0.75 | 0.75 | 95.00 |

| ST/MCC (3%) | 3.39 | 0.15 | 0.73 | 0.73 | 95.00 |

| ST/MCC (6%) | 3.30 | 0.30 | 0.70 | 0.70 | 95.00 |

| ST/MCC (9%) | 3.19 | 0.45 | 0.68 | 0.68 | 95.00 |

| ST/MCC (12%) | 3.08 | 0.60 | 0.66 | 0.66 | 95.00 |

| ST/MCC (15%) | 2.97 | 0.75 | 0.64 | 0.64 | 95.00 |

| Sample | D10 (μm) | D50 (μm) | D90 (μm) | CI (%) |

|---|---|---|---|---|

| Untreated | 8.39 ± 0.24 a | 23.43 ± 0.32 a | 54.50 ± 0.61 a | 56.29 ± 0.08 a |

| MCC1.0 h | 5.35 ± 0.02 b | 15.90 ± 0.10 b | 40.43 ± 0.78 c | 47.89 ± 0.06 b |

| MCC2.0 h | 4.36 ± 0.06 c | 13.63 ± 0.21 c | 40.40 ± 1.51 c | 41.12 ± 0.09 c |

| MCC3.0 h | 4.18 ± 0.01 d | 13.20 ± 0.17 d | 48.73 ± 6.55 b | 36.44 ± 0.09 d |

| MCC4.0 h | 4.24 ± 0.04 c,d | 13.20 ± 0.17 d | 40.80 ± 3.70 c | 34.81 ± 0.08 e |

| MCC6.0 h | 3.76 ± 0.08 e | 11.50 ± 0.20 e | 29.97 ± 0.72 d | 31.63 ± 0.01 f |

| MCC8.0 h | 3.51 ± 0.07 f | 10.53 ± 0.06 f | 27.77 ± 0.47 d,e | 29.75 ± 0.03 g |

| MCC12.0 h | 3.21 ± 0.03 g | 9.72 ± 0.03 g | 24.70 ± 0.35 e | 25.24 ± 0.07 h |

| MCC16.0 h | 3.17 ± 0.09 g | 9.43 ± 0.12 g | 24.17 ± 0.40 e | 25.17 ± 0.02 h |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Fu, Z.; Li, D.; Wu, M. Effects of Ball Milling Processes on the Microstructure and Rheological Properties of Microcrystalline Cellulose as a Sustainable Polymer Additive. Materials 2018, 11, 1057. https://doi.org/10.3390/ma11071057

Zheng Y, Fu Z, Li D, Wu M. Effects of Ball Milling Processes on the Microstructure and Rheological Properties of Microcrystalline Cellulose as a Sustainable Polymer Additive. Materials. 2018; 11(7):1057. https://doi.org/10.3390/ma11071057

Chicago/Turabian StyleZheng, Yu, Zongqiang Fu, Dong Li, and Min Wu. 2018. "Effects of Ball Milling Processes on the Microstructure and Rheological Properties of Microcrystalline Cellulose as a Sustainable Polymer Additive" Materials 11, no. 7: 1057. https://doi.org/10.3390/ma11071057

APA StyleZheng, Y., Fu, Z., Li, D., & Wu, M. (2018). Effects of Ball Milling Processes on the Microstructure and Rheological Properties of Microcrystalline Cellulose as a Sustainable Polymer Additive. Materials, 11(7), 1057. https://doi.org/10.3390/ma11071057