Spray-Drying of Electrode Materials for Lithium- and Sodium-Ion Batteries

Abstract

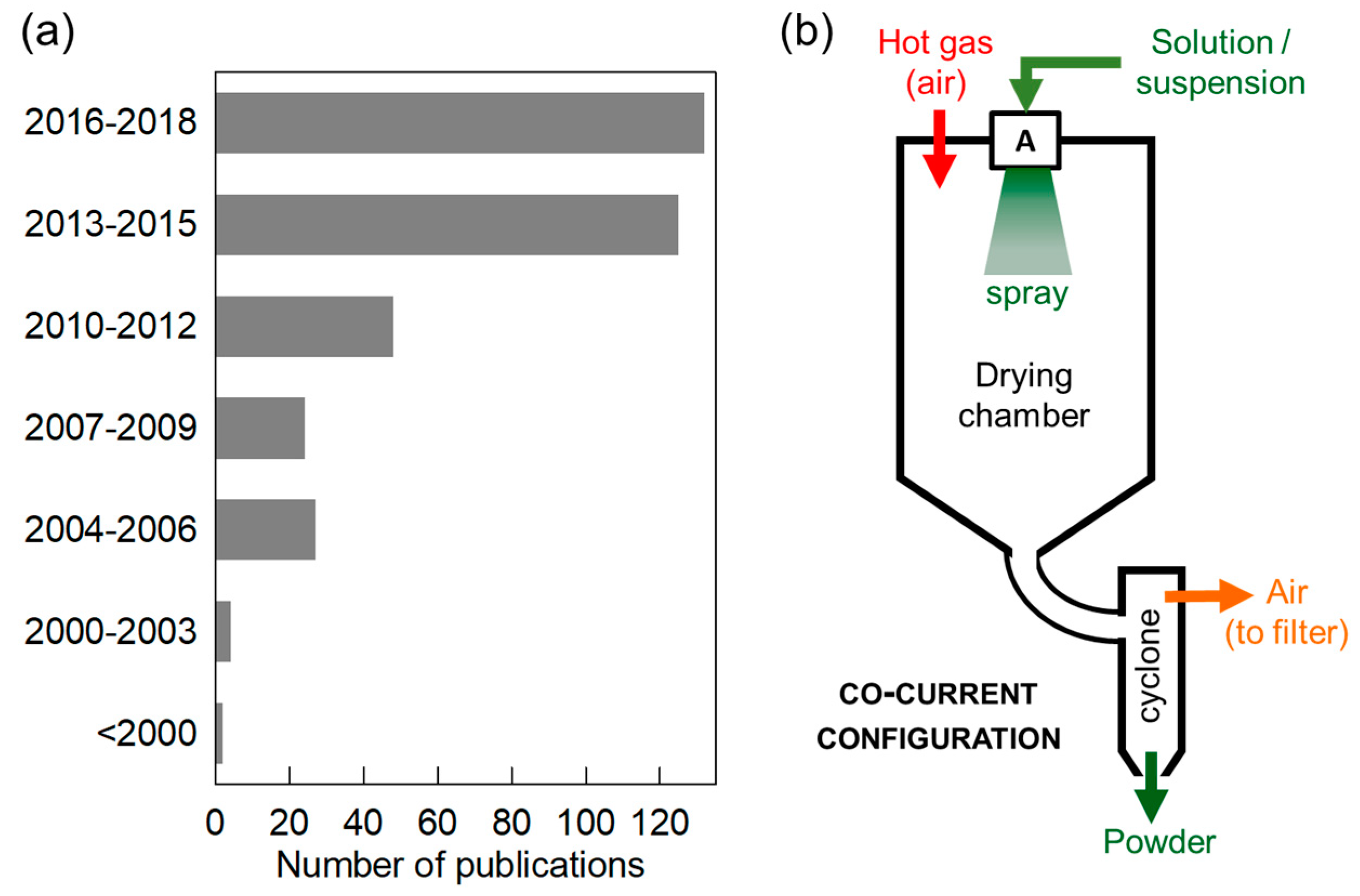

1. Introduction

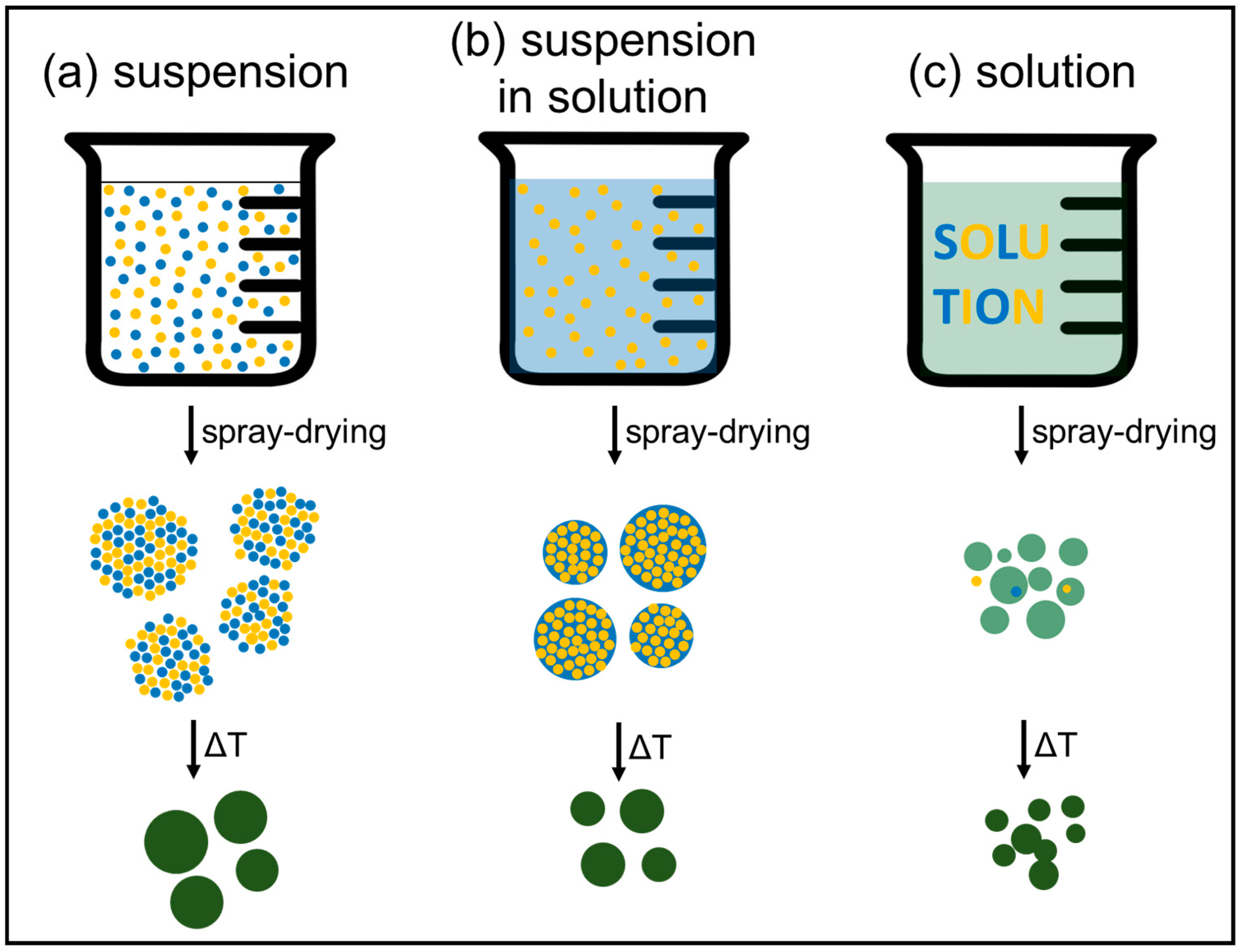

2. Experimental Parameters in Spray-drying

3. Formulation of Solutions/Suspensions: Inorganic Components

3.1. Solvent/Liquid Phase

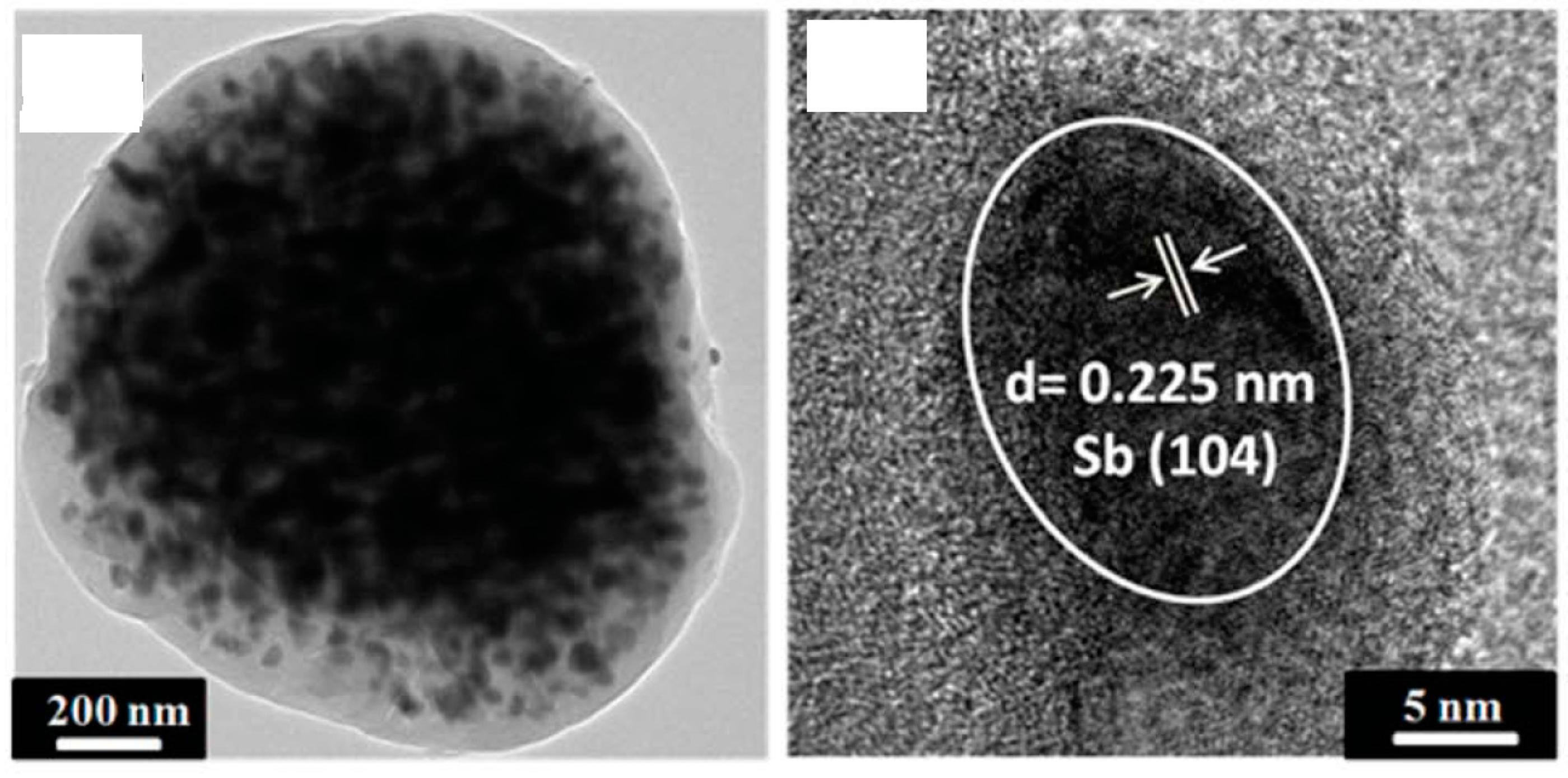

3.2. Solutions

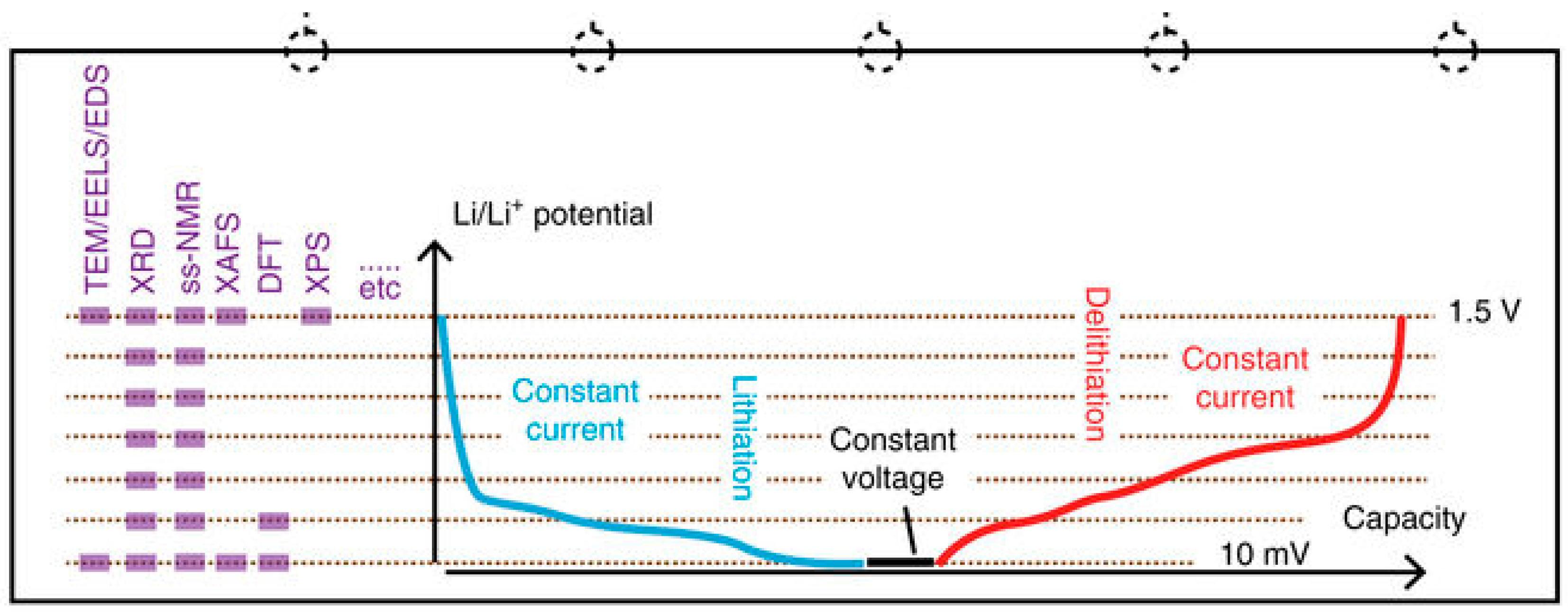

3.3. Suspensions

4. Formulation of Solutions/Suspensions: Organic/Carbon Components

5. Post-Processing of the Spray-Dried Precursors

5.1. Heat Treatment

5.2. More Complex Post-Processing

6. Microstructure

7. Electrochemical Properties

8. Concluding Remarks

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A

| Tinlet (°C) | Toutlet (°C) | Other Parameters | Spray-Drying Instrument | |

|---|---|---|---|---|

| SPRAY-DRYING OF SOLUTIONS | ||||

| A. Spray-drying of aqueous solution of nitrates and/or acetates | ||||

| Duvigneaud et al. [145] | 190 | 150 | - | Buchi mini spray-dryer 190 |

| He et al. [146] and He et al. [148] | 200 | - | 400 mL/h Bifluid nozzle 0.2 MPa | SD-2500 (Shanghai Triowin Lab Technology Company) |

| Kim et al. [152] | - | - | - | - |

| Kim et al. [187] | - | - | - | SD-1000, Tokyo Rikakikai Co. Ltd, Tokyo, Japan |

| Konstantinov et al. [153] | 190–200 | 90–100 | - | Yamato GA32 |

| Li et al. [154] | - | - | - | Yamato GB32 pulvis mini-spray |

| Li et al. [156] and Li et al. [157] | - | - | - | Buchi mini spray-dryer B-290 |

| Li et al. [160] | 300 | 100 | Bifluid nozzle 0.4 MPa | - |

| Liu et al. [166] | 350 | 150 | 10 L/h Bifluid nozzle 0.4 MPa | - |

| Wang et al. [263] | - | - | - | - |

| Wang et al. [172] | 200 | - | 2.5 mol/L total cation concentration | - |

| Wang et al. [173] | 210 | 110 | - | - |

| Wu et al. [175] | 220 | 110 | Air pressure 0.2 MPa | - |

| Yue et al. [179,180] | 220 | 110 | - | - |

| Zhang et al. [183] and Zhang et al. [186] and Zhao et al. [264] | - | - | - | Pulvis mini-spray GB22, Yamato, Japan |

| B. Spray-drying of aqueous solution of salts dissolved in aqueous citric acid | ||||

| Li et al. [158] | 180 | 65–70 | - | - |

| Sun et al. [171] | 2 mol/L concentration | Pulvis mini-spray GB22, Yamato, Japan | ||

| Watanabe et al. [174] | - | - | 2 mol/L concentration | Buchi B-290 |

| Zhang et al. [184,185] | - | - | - | Pulvis mini-spray GB22, Yamato, Japan |

| C. Spray-drying of aqueous solution of citrates | ||||

| Li et al. [155] | - | - | - | Yamato GB32 pulvis mini-spray |

| Qiao et al. [169] | - | - | - | L217, Lai Heng |

| Yuan et al. [178] | - | - | - | L217, Lai Heng |

| D. Spray-drying of aqueous solution (others) | ||||

| Li et al. [159] | 200 | - | Pumping 1.2 g/s Jet-air speed 6 kg/h 4 wt % solution | Spray-dryer Minor Niro A/S, Söborg, Denmark |

| Oh et al. [167] | - | - | - | - |

| SPRAY-DRYING OF SUSPENSIONS | ||||

| E. Spray-drying of an aqueous suspension to mix reactants | ||||

| Hou et al. [149] | - | - | - | - |

| Lin et al. [164] | 200 | - | - | - |

| Liu et al. [165] | - | - | - | - |

| Wang et al. [189] | - | - | - | - |

| Yue et al. [181] | - | - | - | - |

| F. Spray-drying of an ethanol suspension to mix reactants | ||||

| Hu et al. [150] | - | - | - | - |

| Lin et al. [161] | - | - | - | Niro 2108, Copenhagen |

| Lin et al. [162] | 150 | - | - | Niro 2108, Copenhagen |

| G. Mixing of AMO2 active material with conductive carbon or conductive carbon precursor | ||||

| Cheng et al. [144] | 200 | - | Bifluid nozzle 0.2 MPa | SD-2500 |

| Xia et al. [176] | - | - | - | SD-1500 laboratory scale spray-dryer (Tridwin Tech. Co. Shanghai, China) |

| Yang et al. [177] | 220 | - | 1.5 L/h Atomization pressure 0.5 MPa | - |

| Yue et al. [182] | - | - | - | - |

| H. Shaping of AMO2 as spheres | ||||

| Chen et al. [143] | 220 | 90 | Compressed air pressure 0.2 MPa | - |

| Element | Precursor |

|---|---|

| Al | Nitrate [145,250,337] |

| B | H3BO3 [20], LiBO2.8H2O[21,22] |

| Ce | Nitrate [98] |

| Co | Acetate [146,148,151,152,153,154,155,156,157,160,171,172,173,174,175,177,178,179,180,186,187,200,201,215], nitrate [92,99,100,101,102,138,139,145,166,213,355], Co3O4 [7,161,162,163,189], Co(OH)2 [159,167], (Co,Ni,Mn)OHx [149,165,188], (Co,Ni,Mn)Ox [150] |

| Cr | Acetate [146,203], chloride [103], sulfate [203], Cr2O3 [202,203] |

| Cu | Acetate [140,346], nitrate [104,105,106,366] |

| F | NaF [87,88,89,91,92,93,94], HF [84], NH4F [72], trifluoroacetic acid CF3COOH [85,86] |

| Ge | GeO2 dissolved in ammonia solution [111], GeO2 from hydrolysis of GeCl4 [112] |

| Fe | Fe [87,88,89] |

| Fe2+ | Oxalate [271,273,274,275,279,280,317,323,337,349,350,351,352,359], sulfate [135,281,296,304,310], acetate [86,305], chloride [310], (Fe,Mn)3(PO4)2.xH2O [312,313,314,319] |

| Fe3+ | Nitrate [21,22,110,136,158,212,268,269,270,285,286,300,301,302,303,310,347,354,361,363,366], phosphate [272,277,278,283,284,287,288,290,291,292,293,294,299,306,307,308,311], citrate [107,108,295,360,362], Fe2O3 [109,190,276], |

| La | Nitrate [113,357] |

| Li | Carbonate [7,20,84,149,153,155,161,162,163,164,167,188,189,190,202,203,216,217,218,220,221,227,228,230,231,232,237,243,247,248,251,258,259,260,261,271,273,277,283,286,294,295,299,300,301,302,303,308,317,323,325,329,333,334,362], hydroxide [150,159,165,168,169,172,177,178,184,185,192,193,199,210,222,223,224,225,226,229,233,235,239,240,241,249,253,254,255,256,257,262,272,278,279,281,284,285,287,288,290,291,292,293,296,304,306,311,312,313,314,319,327,331,332,335,336,337,349,351,358,359,360,363], acetate [72,85,86,146,148,160,171,173,174,175,179,180,183,191,194,195,196,197,198,200,201,204,205,208,209,211,212,215,250,274,275,305,307,357], nitrate [145,151,152,154,156,157,158,166,186,187,244,324,364], oxalate [350,352], LiBO2.8H2O [21,22], LiH2PO4 [276,280,310,328,365] |

| Mg | Acetate [308] |

| Mn | Acetate [90,91,114,140,146,148,151,152,154,155,156,157,168,169,171,172,173,174,177,178,179,180,183,186,187,191,192,193,194,195,196,197,198,200,201,204,205,206,207,208,209,211,212,213,214,215,262,263,264,357,365], nitrate [158,166,199,310,311,364], carbonate [20,161,162,163,189,192], chloride [310], sulfate [310], MnC2O4.2H2O [317,323], MnO2 [7,190,202,203], Mn3O4 [164], (Co,Ni,Mn)OHx [149,165,188], (Co,Ni,Mn)Ox [150], (Ni,Mn) oxalate [210], (Fe,Mn)3(PO4)2.xH2O [312,313,314,319] |

| Mo | (NH4)6Mo7O24⋅4H2O [115,141,367], MoS2 [353] |

| Na | NaOH [87,88,89,97], acetate [263,265,343], Na2CO3 [339,340,344,346,351], NaHCO3 [342], NaNO3 [264,347], NaF [87,88,89,90,91,92,93,94], NaH2PO4 [91,345], sodium carboxymethylcellulose [333] |

| Ni | Acetate [22,85,117,146,148,151,152,154,155,156,157,168,169,171,172,174,175,177,178,179,180,183,184,185,186,187,204,205,207,208,209,211,212,215,263,264,357,358,375], nitrate [138,139,141,145,158,166,206,213,214,367], carbonate [164], Ni(OH)2 [167], NiO [7,161,162,163,189], (Co,Ni,Mn)OHx [149,165,188], (Co,Ni,Mn)Ox [150], (Ni,Mn) oxalate [210] |

| Nb | Nb2O5 [142,190], (NH4)NbO(C2O4)2·H2O [131], ethoxide [251] |

| P | NH4H2PO4 [87,88,89,90,93,94,268,269,270,271,273,274,275,279,285,286,295,301,302,305,317,323,324,325,327,329,332,333,334,335,337,339,340,342,343,344,346,359,360,362], NaH2PO4 [91,345], LiH2PO4 [276,280,310,328,365], H3PO4 [92,93,281,296,300,303,304,312,313,314,319,331,336,363,364], FePO4(.xH2O) [272,278,283,284,287,288,290,291,292,293,299,306,307,308,351], 1-hydroxyethane 1,1-diphosphonic acid HEDP (CH3C(OH)(H2PO3)2) [347,348], P [36], (Fe,Mn)3(PO4)2.xH2O [312,313,314,319] |

| Ru | Acetate [212] |

| S | Thiourea [114], sulfur [37,38,39], MoS2 [353] |

| Sb | SbCl3 [40] |

| Se | Se [83], H2SeO3 by dissolving SeO2 in water [354], H2Se gas for post-treatment of spray-dried precursor [367] |

| Si | Si [42,43,44,45,46,47,50,51,53,54,55,56,57,58,59,60,62,63,64,65,66,67,69,71,73,74,75,76,77,78,79,80,81,366], SiO2 [48,49,120,121,349], SiO [52,118,119], tetraethyl ethoxysilane TEOS [350,352], Si/poly(acrylonitrile-divinylbenzene) hybrid microspheres [68], Si/poly(styrene-acrylonitrile) hybrid microspheres [70] |

| Sn2+ | Oxalate [122,124,355], chloride [169] |

| Sn4+ | Chloride [82,123,348] |

| Ti | TiO2 [84,133,142,216,217,218,221,223,224,225,226,228,230,231,232,233,237,244,247,308,323,339,340], TiO2 from basic hydrolysis of TiOSO4·H2SO4·8H2O [126], TiOSO4·H2SO4·H2O [131], Ti peroxo-carbonate solution [127], acidic solution of [NH4]2[Ti(C2O4)3] [184,185], titania nanosheets [129,130], TiO(OH)2(·xH2O) [220,358], Ti tetraisopropoxide (C3H7O)4Ti [128,132,212,227,235,243,248,251], Ti tetrabutoxide (C4H9O)4Ti [211,222,229,238,239,240,241,249,250,265] |

| V | NH4VO3 [94,254,257,324,327,329,331,332,333,335,336,337,342,343,345,346,352,359,361,363,365], V2O5 [93,253,255,256,258,259,260,261,325,328,334,344,360,362,364], |

| Zn | Sulfate [135], nitrate [136] |

| Zr | ZrO2 [161], Zr(NO3)4.5H2O [357] |

| Compound Type, Formulas and References | Discharge Capacity after 50 Cycles | |

|---|---|---|

| Borates | ||

| LiFeBO3 vs. Li [21] | 127 mAh/g | after 30 cycles at 10 mA/g + 20 cycles at 20 mA/g |

| LiFe0.94Ni0.06BO3 vs. Li [22] | 132 mAh/g | after 35 cycles at 10 mA/g + 15 cycles at 20 mA/g |

| Elements | ||

| C vs. Li [25] | 355 mAh/g | after 50 cycles at 0.1 A/g |

| C vs. Li [27] | 460 mAh/g | after 50 cycles at 0.37 A/g (1 C) |

| C vs. Li [31] | 245 mAh/g | after 50 cycles at 0.1 A/g |

| C vs. Li [33] | 460 mAh/g | after 50 cycles at 0.05 A/g |

| C (with 4 wt % Ni) vs. Li [35] | 640 mAh/g | after 50 cycles at 0.5 A/g |

| P/C vs. Na [36] | 2200 mAh/g | after 50 cycles at 0.1 A/g |

| S/C vs. Li [37] | 980 mAh/g | after 50 cycles at 0.2 C |

| C/S vs. Li [38] | 980 mAh/g | after 50 cycles at 0.1 C |

| S/C vs. Li [39] | 840 mAh/g | after 50 cycles at 0.1 C |

| Sb/C vs. Na [40] | 630 mAh/g | after 50 cycles at 0.2 A/g (0.33 C) |

| Si/C vs. Li [41] | 1150 mAh/g | after 50 cycles at 0.45 A/g |

| Si/C vs. Li [42] | 2200 mAh/g | after 50 cycles at 0.3 A/g |

| Si/C vs. Li [43] | 1150 mAh/g | after 50 cycles at 0.1 A/g |

| Si/C vs. Li [44] | 500 mAh/g | after 50 cycles at 0.1 A/g |

| Si/C vs. Li [46] | 900 mAh/g | after 50 cycles at 0.2 A/g |

| Si/C vs. Li [47] | 2450 mAh/g | after 50 cycles at 0.3 A/g |

| Si/C vs. Li [48] | 1100 mAh/g | after 50 cycles at 0.3 A/g |

| Si/C vs. Li [49] | 2200 mAh/g | after 50 cycles at 1 A/g |

| Si/C vs. Li [50] | 420 mAh/g | after 50 cycles at 0.05 A/g |

| Si/C vs. Li [52] | 600 mAh/g | after 50 cycles at 0.1 A/g |

| Si/C vs. Li [54] | 1250 mAh/g | after 50 cycles at 1 A/g |

| Si/C vs. Li [55] | 2100 mAh/g | after 50 cycles at 0.5 C |

| Si/C vs. Li [56] | 570 mAh/g | after 50 cycles at 0.1 C |

| Si/C vs. Li [58] | 650 mAh/g | after 50 cycles at 0.1 A/g |

| Si/C vs. Li [60] | 1160 mAh/g | after 50 cycles at 0.1 A/g |

| Si/C vs. Li [61] | 580 mAh/g | after 50 cycles at 0.1 A/g |

| Si/C vs. Li [63] | 1800 mAh/g | after 50 cycles at 0.2 A/g |

| Si/C vs. Li [64] | 560 mAh/g | after 50 cycles at 0.05 A/g |

| Si/C vs. Li [65] | 500 mAh/g | after 50 cycles at 0.1 A/g |

| Si/C vs. Li [66] | 500 mAh/g | after 50 cycles at 0.1 A/g |

| Si/C vs. Li [67] | 950 mAh/g | after 50 cycles at 0.1 A/g |

| Si/C vs. Li [68] | 500 mAh/g | after 50 cycles at 0.1 A/g |

| Si/C vs. Li [69] | 2100 mAh/g | after 50 cycles at 0.5 A/g |

| Si/C vs. Li [70] | 450 mAh/g | after 50 cycles at 0.1 A/g |

| Si/C vs. Li [71] | 500 mAh/g | after 50 cycles at 5 C |

| Si/C vs. Li [73] | 820 mAh/g | after 50 cycles at 0.1 A/g |

| Si/C vs. Li [74] | 1400 mAh/g | after 50 cycles at 0.05 C |

| Si/C vs. Li [75] | 500 mAh/g | after 50 cycles at 0.05 A/g |

| Si/C vs. Li [76] | 1200 mAh/g | after 50 cycles at 0.3 A/g |

| Si/C vs. Li [77] | 1100 mAh/g | after 50 cycles at 0.2 A/g |

| Si/C vs. Li [78] | 780 mAh/g | after 50 cycles at 0.2 A/g |

| Si/C vs. Li [79] | 1700 mAh/g | after 50 cycles at 1 C |

| Si/C vs. Li [80] | 1550 mAh/g | after 50 cycles at 0.05 A/g |

| Si/C vs. Li [81] | 1860 mAh/g | after 50 cycles at 0.1 A/g |

| Sn/C vs. Li [82] | 670 mAh/g | after 50 cycles at 0.2 A/g |

| Sn/C vs. Na [82] | 400 mAh/g | after 50 cycles at 0.05 A/g |

| Se/C vs. Li [83] | 590 mAh/g | after 50 cycles at 0.1 C |

| Fluorides | ||

| Li3FeF6 vs. Li [86] | 85 mAh/g | after 50 cycles at 0.05 C |

| Fluorophosphates | ||

| Na2MnPO4F/C vs. Na [90] | 77 mAh/g | after 50 cycles at 6.2 mA/g |

| Na3V2(PO4)2F3/C vs. Li [93] | 100 mAh/g | after 50 cycles at 1 C |

| Na3V2O2(PO4)2F/C vs. Na [94] | 117 mAh/g | after 50 cycles at 0.5 C |

| Organic salts | ||

| Li2C8H4O4 vs. Li [95] | 150 mAh/g | after 50 cycles at 0.05 C |

| Na2C8H4O4/C vs. Li [96] | 210 mAh/g | after 50 cycles at 0.1 C |

| Oxides MxOy | ||

| CoO/C vs. Li [100] | 900 mAh/g | after 50 cycles at 1.4 A/g |

| Co3O4 vs. Li [100] | 830 mAh/g | after 50 cycles at 1.4 A/g |

| Co3O4 vs. Li [101] | 1020 mAh/g | after 50 cycles at 0.5 A/g |

| Co3O4 vs. Li [102] | 1050 mAh/g | after 50 cycles at 1.4 A/g |

| Cr2O3/C vs. Li [103] | 630 mAh/g | after 50 cycles at 0.1 A/g |

| CuO vs. Li [104] | 690 mAh/g | after 50 cycles at 1 A/g |

| CuO/C vs. Li [105] | 700 mAh/g | after 50 cycles at 2 A/g |

| CuO vs. Li [106] | 760 mAh/g | after 50 cycles at 1 A/g |

| Fe2O3 vs. Li [107] | 870 mAh/g | after 50 cycles at 0.4 A/g |

| Fe2O3/C vs. Li [108] | 880 mAh/g | after 50 cycles at 0.4 A/g |

| Fe2O3/C vs. Li [109] | 710 mAh/g | after 50 cycles at 0.8 A/g |

| Fe2O3 vs. Li [110] | 1020 mAh/g | after 50 cycles at 0.4 A/g |

| GeOx/C vs. Li [111] | 975 mAh/g | after 50 cycles at 0.5 A/g |

| GeO2/C vs. Li [112] | 1060 mAh/g | after 50 cycles at 0.2 C |

| MnO/C vs. Li [114] | 300 mAh/g | after 50 cycles at 0.5 A/g |

| MoO3/C vs. Li [115] | 1120 mAh/g | after 50 cycles at 0.5 A/g |

| NiO vs. Li [117] | 590 mAh/g | after 50 cycles at 0.1 C |

| SnO2/C vs. Li [122] | 600 mAh/g | after 50 cycles at 2 A/g |

| SnO2/C vs. Li [123] | 1200 mAh/g | after 50 cycles at 0.1 A/g |

| SnO2 vs. Li [124] | 715 mAh/g | after 50 cycles at 2 A/g |

| SnO2 vs. LiMn2O4 [124] | 365 mAh/g | after 50 cycles at 1 A/g |

| TiO2 vs. Li [126] | 75 mAh/g | after 50 cycles from 0.1 C to 10 C |

| TiO2/C vs. Li [127] | 150 mAh/g | after 50 cycles at 0.94 A/g |

| TiO2 vs. Li [130] | 80 mAh/g | after 50 cycles at 0.02A/g |

| TiO2 vs. Li [131] | 190 mAh/g | after 50 cycles at 0.5 C |

| TiO2/C vs. Na [133] | 140 mAh/g | after 50 cycles at 0.2 C |

| V2O5/C vs. Li [134] | 240 mAh/g | after 50 cycles at 0.2 C |

| Oxides MxM’yOz | ||

| ZnFe2O4 vs. Li [135] | 1250 mAh/g | after 50 cycles at 0.1 A/g |

| ZnFe2O4 vs. Li [136] | 750 mAh/g | after 50 cycles at 0.5 A/g |

| Mn0.5Co0.5Fe2O4/C vs. Li [137] | 610 mAh/g | after 50 cycles at 0.1 A/g |

| (Ni,Co)Ox vs. Li [139] | 850 mAh/g | after 50 cycles at 1 A/g |

| Cu1.5Mn1.5O4 vs. Li [140] | 460 mAh/g | after 50 cycles at 0.1 A/g |

| NiMoO4 vs. Li [141] | 1000 mAh/g | after 50 cycles at 1 A/g |

| TiNb2O7/C vs. Li [142] | 300 mAh/g | after 50 cycles at 0.25 C |

| Oxides LixMyOz (layered) | ||

| LiCoO2 vs. graphite [153] | 132 mAh/g | after 50 cycles at 0.3 mA/g |

| LiNi0.8Co0.2O2 vs. Li [167] | 160 mAh/g | after 50 cycles at 0.5 C |

| LiNi0.8Co0.15Al0.05O2 vs. Li [143] | 151 mAh/g | after 50 cycles at 2 C |

| LiNi0.6Co0.2Mn0.2O2 vs. Li [179] | 132 mAh/g at 50 °C | after 50 cycles at 0.16 A/g |

| LiNi0.6Co0.2Mn0.2O2 vs. Li [180] | 135 mAh/g | after 50 cycles at 0.08 A/g |

| LiNi0.6Co0.2Mn0.2O2/C vs. Li [182] | 154 mAh/g | after 50 cycles at 0.5 C |

| LiNi0.425Mn0.425Co0.15O2 vs. Li [155] | 110 mAh/g | after 50 cycles at 1 C |

| LiMn1/3Ni1/3Co1/3O2 (ZrO2-coated) vs. Li [156] | 140 mAh/g | after 50 cycles at 0.5 C |

| LiMn1/3Ni1/3Co1/3O2-0.1 LiF vs. Li [157] | 133 mAh/g | after 50 cycles at 0.32 A/g |

| LiMn1/3Ni1/3Co1/3O2 vs. Li [163] | 180 mAh/g | after 50 cycles at 0.2 C |

| LiMn1/3Ni1/3Co1/3O2 vs. Li [165] | 160 mAh/g | after 50 cycles at 1 C |

| 0.98 LiCoO2-0.02 Li2MnO3 vs. Li [173] | 140 mAh/g | after 50 cycles at 1 C |

| Li1.06Ni0.3Co0.4Mn0.3O2-d vs. Li [187] | 180 mAh/g | after 50 cycles at 0.03 A/g |

| Li1.11(Ni0.4Co0.2Mn0.4)0.89O2 vs. Li [152] | 187 mAh/g at 50 °C | after 50 cycles at 0.1 A/g |

| 0.7 LiMn0.337Ni0.487Co0.137Cr0.04O2 -0.3 Li2MnO3 vs. Li [146] | 158 mAh/g | after 20 cycles at 0.05 A/g + 30 cycles at 0.25 A/g |

| 0.7 LiMn0.5Ni0.4Co0.1O2 -0.3 Li2MnO3 vs. Li [148] | 200 mAh/g | after 50 cycles at 0.05 A/g (0.2 C) |

| Li1.17(Mn1/3Ni1/3Co1/3)0.83O2 vs. Li [151] | 177 mAh/g | after 50 cycles at 0.03 A/g |

| Li1.17Ni0.2Co0.05Mn0.58O2 (CeO2-coated) vs. Li [178] | 212 mAh/g | after 50 cycles at 0.3 A/g |

| Li1.17Ni0.25Mn0.58O2 (Li-Mn-PO4-coated) vs. Li [168] | 265 mAh/g | after 50 cycles at 0.03 A/g |

| Li1.17Ni0.25Mn0.55Sn0.03O2 vs. Li [169] | 170 mAh/g | after 50 cycles at 0.3 A/g |

| Li1.2Mn0.54Co0.13Ni0.13O2/C vs. Li [144] | 160 mAh/g | after 20 cycles at 0.2 C + 30 cycles at 1 C |

| Li1.2Mn0.54Ni0.13Co0.13O2/C vs. Li [147] | 177 mAh/g | after 20 cycles at 0.05 A/g + 30 cycles at 0.125 A/g |

| Li1.2Ni0.13Co0.13Mn0.54O2 vs. Li [188] | 160 mAh/g | after 50 cycles from 0.1 C to 0.5 C |

| Li1.2Mn0.54Ni0.13Co0.13O2 vs. Li [189] | 200 mAh/g | after 50 cycles at 1 C |

| Li1.2Ni0.13Co0.13Mn0.54O2/C vs. Li [177] | 175 mAh/g | after 50 cycles from 0.2 C to 5 C |

| Li1.2Ni0.2Mn0.6O2 vs. Li [164] | 150 mAh/g | after 50 cycles at 0.5 C |

| 0.5 LiMn1/3Ni1/3Co1/3O2 -0.5 Li2MnO3 vs. Li [149] | 189 mAh/g | after 50 cycles at 1 C |

| 0.5 LiMn1/3Ni1/3Co1/3O2 -0.5 Li2MnO3 vs. soft C [172] | 190 mAh/g | after 50 cycles at 1 C |

| 0.95 LiNiO2-0.05 Li2TiO3 vs. Li [184] | 175 mAh/g | after 50 cycles at 0.02 A/g |

| Oxides LixMyOz (others) | ||

| LiMn2O4 vs. Li [191] | 113 mAh/g | after 50 cycles at 1 C |

| LiMn2O4 vs. Li [192] | 117 mAh/g | after 50 cycles at 0.2 C |

| LiMn2O4 vs. Li [193] | 110 mAh/g | after 50 cycles at 0.2 C |

| LiMn2O4 vs. Li [194] | 113 mAh/g | after 50 cycles at 1 C |

| LiMn2O4 vs. Li [198] | 113 mAh/g | after 50 cycles at 1 C |

| LiMn2O4 vs. Li [199] | 106 mAh/g | after 50 cycles at 0.5 C |

| LiMn11/6Co1/6O4 vs. Li [201] | 112 mAh/g | after 50 cycles at 0.2 C |

| LiNi0.5Mn1.5O4 vs. Li [206] | 135 mAh/g | after 50 cycles at 0.15 C |

| LiNi0.5Mn1.5O4 vs. Li [207] | 132 mAh/g | after 50 cycles at 0.1 C |

| LiNi0.5Mn1.5O4 vs. Li [208] | 118 mAh/g | after 50 cycles at 2 C |

| LiNi0.5Mn1.5O4/C vs. Li [210] | 130 mAh/g | after 50 cycles at 0.5 C |

| LiNi0.5Mn1.47Ti0.03O4 vs. Li [211] | 125 mAh/g | after 50 cycles from 0.05 C to 5 C |

| LiNi0.5Mn1.4Fe0.1Ti0.03O4 vs. Li [212] | 170 mAh/g | after 50 cycles at 0.5 C |

| LiNi0.5Mn1.4Ru0.1Ti0.03O4 vs. Li [212] | 180 mAh/g | after 50 cycles at 0.5 C |

| LiNi0.3Mn1.5Co0.2O4 vs. Li [213] | 115 mAh/g at 60 °C | after 50 cycles at 3.5 C |

| LiNi0.45Mn1.5Co0.05O4 vs. Li [214] | 126 mAh/g | after 50 cycles at 0.15 C |

| Li4Ti5O12 vs. Li [216] | 147 mAh/g at 50 °C | after 50 cycles at 1 C |

| Li4Ti5O12 vs. Li [217] | 150 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12/C vs. Li [219] | 150 mAh/g | after 50 cycles at 2 C |

| Li4Ti5O12 vs. Li [220] | 150 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12 vs. Li [222] | 160 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12 vs. Li [223] | 175 mAh/g | after 50 cycles at 0.2 C |

| Li4Ti5O12/C vs. Li [226] | 165 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12 vs. Li [229] | 211 mAh/g | after 50 cycles at 2 C |

| Li4Ti5O12/C vs. Li [230] | 155 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12 vs. Li [233] | 162 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12 vs. Li [234] | 170 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12/C vs. Li [235] | 164 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12/TiO2 vs. Li [236] | 168 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12 vs. Li [239] | 168 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12 vs. Li [240] | 172 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12/C vs. Li [241] | 142 mAh/g | after 50 cycles at 10 C |

| Li4.3Ti5O12/C vs. Li [242] | 132 mAh/g | after 50 cycles at 3 C |

| Li4.3Ti5O12 vs. Li [243] | 140 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12/C vs. Li [245] | 158 mAh/g | after 50 cycles at 5 C |

| Li4Ti5O12/C vs. Li [246] | 167 mAh/g | after 50 cycles at 0.1 C |

| Li4Ti5O12/C vs. Li [247] | 143 mAh/g | after 50 cycles at 1 C |

| Li4Ti5O12/C vs. Li [248] | 146 mAh/g | after 50 cycles at 2 C |

| Li4Ti5O12 vs. Li [249] | 168 mAh/g | after 50 cycles at 1 C |

| Li3.98Al0.06Ti4.96O12/C vs. Li [250] | 160 mAh/g | after 50 cycles at 1 C |

| Li1.1V3O8/C vs. Li [254] | 225 mAh/g | after 50 cycles at 0.33 C |

| LiV3O8 vs. Li [255] | 260 mAh/g | after 50 cycles at 0.125 A/g |

| Li3VO4/C vs. Li [258] | 315 mAh/g | after 50 cycles at 10 C |

| Li3VO4/C vs. Li [259] | 400 mAh/g | after 50 cycles at 0.2 C |

| Li3VO4/C vs. Li [260] | 395 mAh/g | after 50 cycles at 0.5 C |

| Li4Mn5O12 vs. Li [262] | 128 mAh/g | after 50 cycles at 0.5 C |

| Oxides NaxMyOz | ||

| Na2/3Ni1/3Mn2/3O2 vs. Na [263] | 102 mAh/g | after 50 cycles at 0.1 C |

| Na2Ti3O7 vs. Na [265] | 95 mAh/g | after 50 cycles from 0.1 C to 5 C |

| Na4Mn9O18/C in aqueous Na-ion battery [266] | 85 mAh/g | after 50 cycles at 4 C |

| Na4Mn9O18/C in aqueous Na-ion battery [267] | 50 mAh/g | after 50 cycles at 4 C |

| Phosphates | ||

| LiFePO4/C vs. Li [271] | 159 mAh/g | after 50 cycles at 1 C |

| LiFePO4/C vs. Li [273] | 156 mAh/g | after 50 cycles at 1 C |

| LiFePO4/C vs. Li [275] | 137 mAh/g | after 50 cycles at 1 C |

| LiFePO4/C vs. Li [276] | 110 mAh/g | after 50 cycles at 1 C |

| LiFePO4/C vs. Li [278] | 154 mAh/g | after 50 cycles at 1 C |

| LiFePO4/C vs. Li [281] | 160 mAh/g | after 50 cycles at 0.1 C |

| LiFePO4/C vs. Li [282] | 150 mAh/g | after 50 cycles at 1 C |

| LiFePO4/C vs. Li [283] | 160 mAh/g | after 50 cycles at 1 C |

| LiFePO4/C vs. Li [284] | 159 mAh/g | after 50 cycles at 0.1 C |

| LiFePO4/C vs. Li [285] | 130 mAh/g | after 50 cycles at 5 C |

| LiFePO4/C vs. Li [286] | 110 mAh/g | after 50 cycles from 0.1 C to 2 C |

| LiFePO4/C vs. Li [289] | 110 mAh/g | after 50 cycles at 10 C |

| LiFePO4/C vs. Li [290] | 123 mAh/g | after 50 cycles at 10 C |

| LiFePO4/C vs. Li [291] | 162 mAh/g | after 50 cycles at 0.5 C |

| LiFePO4/C vs. Li [292] | 156 mAh/g | after 50 cycles at 1 C |

| LiFePO4/C vs. Li [293] | 120 mAh/g | after 50 cycles at 10 C |

| LiFePO4/C vs. Li [294] | 140 mAh/g | after 50 cycles at 2 C |

| LiFePO4/C vs. Li [295] | 137 mAh/g | after 50 cycles from 0.1 C to 4 C |

| LiFePO4/C vs. Li [296] | 149 mAh/g | after 50 cycles at 1 C |

| LiFePO4/C vs. Li [298] | 100 mAh/g | after 50 cycles at 3 C |

| LiFePO4/C vs. Li [299] | 147 mAh/g | after 50 cycles at 3 C |

| LiFePO4/C vs. Li [300] | 142 mAh/g | after 50 cycles at 0.1 C |

| LiFePO4/C vs. Li [304] | 110 mAh/g | after 50 cycles at 10 C |

| LiFePO4/C vs. Li [305] | 110 mAh/g | after 50 cycles at 10 C |

| LiFePO4/C vs. Li [306] | 120 mAh/g | after 50 cycles at 10 C |

| LiFePO4/C vs. Li [307] | 137 mAh/g | after 50 cycles at 1 C |

| LiFePO4/C vs. Li [308] | 152 mAh/g | after 50 cycles at 1 C |

| LiFePO4/C vs. Li [309] | 105 mAh/g | after 50 cycles at 1 C |

| LiFe0.6Mn0.4PO4/C vs. Li [315] | 137 mAh/g | after 50 cycles at 2 C |

| LiFe0.6Mn0.4PO4/C vs. Li [316] | 150 mAh/g | after 50 cycles at 0.5 C |

| LiMn0.5Fe0.5PO4/C vs. Li [318] | 150 mAh/g at 55 °C | after 50 cycles at 1 C |

| LiMn0.6Fe0.4PO4/C vs. Li [312] | 425 Wh/kg | after 50 cycles at 10 C |

| LiMn0.7Fe0.3PO4/C vs. Li [319] | 145 mAh/g | after 50 cycles at 5 C |

| LiMn0.75Fe0.25PO4/C vs. Li [310] | 120 mAh/g | after 50 cycles at 10 C |

| LiMn0.8Fe0.2PO4/C vs. Li [313] | 138 mAh/g | after 50 cycles at 5 C |

| LiMn0.8Fe0.2PO4/C vs. Li4Ti5O12 [313] | 122 mAh/g | after 50 cycles at 1 C |

| LiMn0.8Fe0.2PO4/C vs. Li [314] | 132 mAh/g | after 50 cycles at 5 C |

| LiMn0.85Fe0.15PO4/C vs. Li [317] | 136 mAh/g | after 50 cycles at 1 C |

| LiMn0.85Fe0.15PO4/C vs. Li [320] | 136 mAh/g | after 50 cycles at 1 C |

| Li(Mn0.85Fe0.15)0.92Ti0.08PO4/C vs. Li [323] | 144 mAh/g | after 50 cycles at 1 C |

| LiMn0.97Fe0.03PO4/C vs. Li [311] | 158 mAh/g | after 50 cycles at 0.5 C |

| LiMnPO4/C vs. Li [321] | 96 mAh/g | after 50 cycles at 0.05 C |

| LiVOPO4 vs. Li [324] | 50 mAh/g | after 50 cycles at 0.2 C |

| Li3V2(PO4)3/C vs. Li [325] | 143 mAh/g | after 50 cycles at 20 C |

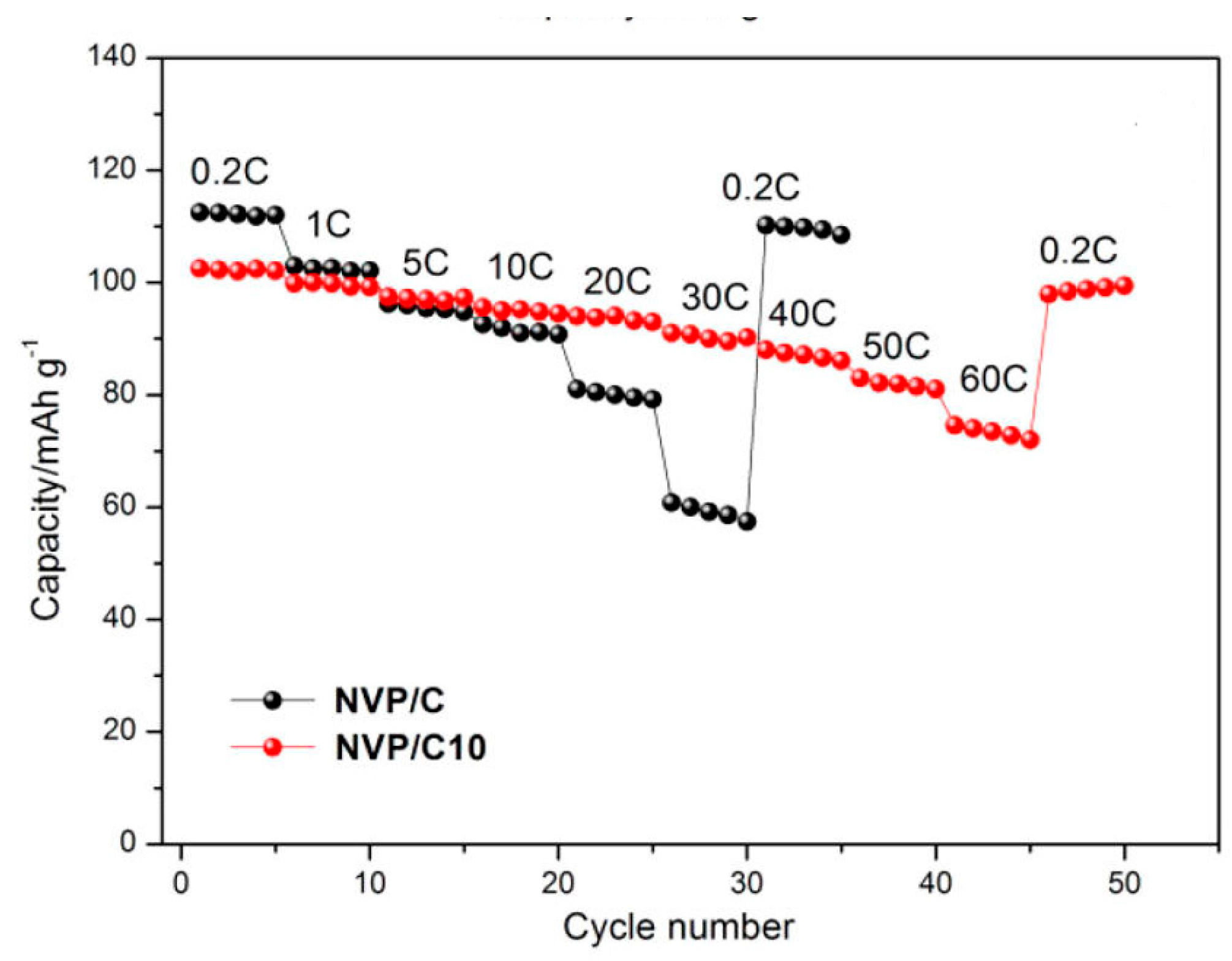

| Li3V2(PO4)3/C vs. Li [326] | 100 mAh/g | after 50 cycles from 0.2 C to 20 C |

| Li3V2(PO4)3/C vs. Li [327] | 127 mAh/g | after 50 cycles at 0.1 C |

| Li3V2(PO4)3/C vs. Li [328] | 131 mAh/g | after 50 cycles at 0.02 A/g |

| Li3V2(PO4)3/C vs. Li [329] | 149 mAh/g | after 50 cycles at 10 C |

| Li3V2(PO4)3/C vs. Li [330] | 118 mAh/g | after 50 cycles from 0.1 C to 5 C |

| Li3V2(PO4)3/C vs. Li [332] | 123 mAh/g | after 50 cycles at 2 C |

| Li3V2(PO4)3/C vs. Li [333] | 131 mAh/g | after 50 cycles at 0.1 C |

| Li3V2(PO4)3/C vs. Li [334] | 138 mAh/g | after 50 cycles at 1 C |

| Li3V2(PO4)3/C vs. Li [335] | 94 mAh/g | after 50 cycles at 1 C |

| NaTi2(PO4)3/C vs. Na [339] | 110 mAh/g | after 50 cycles from 0.2 C to 4 C |

| NaTi2(PO4)3/C vs. Na [340] | 128 mAh/g | after 50 cycles from 0.1 C to 5 C |

| NaTi2(PO4)3/C vs. Na3V2(PO4)3/C [340] | 98 mAh/g | after 50 cycles at 10 C |

| Na3V2(PO4)3/C vs. Na [342] | 92 mAh/g | after 50 cycles at 10 C |

| Na3V2(PO4)3/C vs. Na [344] | 103 mAh/g | after 50 cycles at 5 C |

| Na3V2(PO4)3/C vs. Na [345] | 93 mAh/g | after 50 cycles at 5 C |

| Na3V1.95Cu0.05(PO4)3/C vs. Na [346] | 103 mAh/g | after 50 cycles at 20 C |

| Pyrophosphates | ||

| Na2FeP2O7/C vs. Na [347] | 87 mAh/g | after 50 cycles at 0.1 C |

| Na2FeP2O7/C vs. hard carbon [347] | 62 mAh/g | after 50 cycles at 1 C |

| SnP2O7/C vs. Li [348] | 645 mAh/g | after 50 cycles at 0.1 C |

| Silicates | ||

| Li2FeSiO4/C vs. Li [349] | 137 mAh/g | after 50 cycles at 1 C |

| Li2FeSiO4/C vs. Li [350] | 140 mAh/g | after 50 cycles at 0.1 C |

| Li1.95Na0.05FeSiO4/C vs. Li [351] | 138 mAh/g | after 50 cycles at 2 C |

| Li2Fe0.5V0.5SiO4/C vs. Li [352] | 157 mAh/g | after 50 cycles at 0.5 C |

| Sulfides and selenides | ||

| MoS2/C vs. Li [353] | 800 mAh/g | after 50 cycles at 0.1 A/g |

| MoS2/C vs. Na [353] | 350 mAh/g | after 50 cycles at 0.1 A/g |

| FeSe2/C vs. Na [354] | 510 mAh/g | after 50 cycles at 0.5 A/g |

| MnS/C vs. Li [114] | 700 mAh/g | after 50 cycles at 0.5 A/g |

| NiS/C vs. Na [375] | 490 mAh/g | after 50 cycles at 0.3 A/g |

| Composites (not with carbon) | ||

| Sn–Sn2Co3@CoSnO3–Co3O4 vs. Li [355] | 1050 mAh/g | after 50 cycles at 1 A/g |

| 0.5 LiNi0.5Mn1.5O4-0.5 Li7La3Zr2O12 vs. Li [357] | 116 mAh/g | after 50 cycles at 1 C |

| 3Li4Ti5O12.NiO [358] | 240 mAh/g | after 50 cycles at 1 C |

| 9 LiFePO4-1 Li3V2(PO4)3/C vs. Li [362] | 154 mAh/g | after 50 cycles at 1 C |

| 3 LiFePO4-1 Li3V2(PO4)3/C vs. Li [360] | 152 mAh/g | after 50 cycles at 1 C |

| 0.7 LiFePO4 -0.3 Li3V2(PO4)3/C vs. Li [359] | 120 mAh/g | after 50 cycles from 0.03 A/g to 1.5 A/g |

| 2 LiFePO4-1 Li3V2(PO4)3/C vs. Li [361] | 143 mAh/g | after 50 cycles at 0.1 C |

| 1 LiMnPO4-1 Li3V2(PO4)3/C vs. Li [364] | 123 mAh/g | after 50 cycles at 0.1 C |

| 1 LiMnPO4-2 Li3V2(PO4)3/C vs. Li [365] | 130 mAh/g | after 50 cycles at 0.1 C |

| Si-FeSi2-Cu3.17Si vs. Li [366] | 410 mAh/g | after 50 cycles at 0.5 C |

| MoS2–Ni9S8 vs. Na [367] | 500 mAh/g | after 50 cycles at 0.5 A/g |

| MoSe2-NiSe-C vs. Na [367] | 390 mAh/g | after 50 cycles at 0.5 A/g |

References

- Tarascon, J.-M. Key challenges in future Li-battery research. Philos. Trans. R. Soc. Math. Phys. Eng. Sci. 2010, 368, 3227–3241. [Google Scholar] [CrossRef] [PubMed]

- Croguennec, L.; Palacin, M.R. Recent Achievements on Inorganic Electrode Materials for Lithium-Ion Batteries. J. Am. Chem. Soc. 2015, 137, 3140–3156. [Google Scholar] [CrossRef] [PubMed]

- Stunda-Zujeva, A.; Irbe, Z.; Berzina-Cimdina, L. Controlling the morphology of ceramic and composite powders obtained via spray-drying—A review. Ceram. Int. 2017, 43, 11543–11551. [Google Scholar] [CrossRef]

- Jia, X.; Kan, Y.; Zhu, X.; Ning, G.; Lu, Y.; Wei, F. Building flexible Li4Ti5O12/CNT lithium-ion battery anodes with superior rate performance and ultralong cycling stability. Nano Energy 2014, 10, 344–352. [Google Scholar] [CrossRef]

- Ju, S.H.; Jang, H.C.; Kang, Y.C. Al-doped Ni-rich cathode powders prepared from the precursor powders with fine size and spherical shape. Electrochim. Acta 2007, 52, 7286–7292. [Google Scholar] [CrossRef]

- Jung, D.S.; Hwang, T.H.; Park, S.B.; Choi, J.W. Spray-drying Method for Large-Scale and High-Performance Silicon Negative Electrodes in Li-Ion Batteries. Nano Lett. 2013, 13, 2092–2097. [Google Scholar] [CrossRef] [PubMed]

- Chang, H.-Y.; Sheu, C.-I.; Cheng, S.-Y.; Wu, H.-C.; Guo, Z.-Z. Synthesis of Li1.1Ni1/3Co1/3Mn1/3O2 cathode material using spray-microwave method. J. Power Sources 2007, 174, 985–989. [Google Scholar] [CrossRef]

- Kim, J.H.; Kang, Y.C.; Choi, Y.J.; Kim, Y.S.; Lee, J.-H. Electrochemical properties of yolk-shell structured layered-layered composite cathode powders prepared by spray pyrolysis. Electrochim. Acta 2014, 144, 288–294. [Google Scholar] [CrossRef]

- Nandiyanto, A.B.D.; Okuyama, K. Progress in developing spray-drying methods for the production of controlled morphology particles: From the nanometer to submicrometer size ranges. Adv. Powder Technol. 2011, 22, 1–19. [Google Scholar] [CrossRef]

- Mezhericher, M.; Levy, A.; Borde, I. Theoretical Models of Single Droplet Drying Kinetics: A Review. Dry. Technol. 2010, 28, 278–293. [Google Scholar] [CrossRef]

- Zbicinski, I. Modeling and Scaling Up of Industrial Spray-dryers: A Review. J. Chem. Eng. Jpn. 2017, 50, 757–767. [Google Scholar] [CrossRef]

- Deshmukh, R.; Wagh, P.; Naik, J. Solvent evaporation and spray-drying technique for micro- and nanospheres/particles preparation: A review. Dry. Technol. 2016, 34, 1758–1772. [Google Scholar] [CrossRef]

- Singh, A.; van den Mooter, G. Spray-drying formulation of amorphous solid dispersions. Adv. Drug Deliv. Rev. 2016, 100, 27–50. [Google Scholar] [CrossRef] [PubMed]

- Gharsallaoui, A.; Roudaut, G.; Chambin, O.; Voilley, A.; Saurel, R. Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Res. Int. 2007, 40, 1107–1121. [Google Scholar] [CrossRef]

- Schuck, P.; Jeantet, R.; Bhandari, B.; Chen, X.D.; Perrone, Í.T.; de Carvalho, A.F.; Fenelon, M.; Kelly, P. Recent advances in spray-drying relevant to the dairy industry: A comprehensive critical review. Dry. Technol. 2016, 34, 1773–1790. [Google Scholar] [CrossRef]

- Masquelier, C.; Croguennec, L. Polyanionic (Phosphates, Silicates, Sulfates) Frameworks as Electrode Materials for Rechargeable Li (or Na) Batteries. Chem. Rev. 2013, 113, 6552–6591. [Google Scholar] [CrossRef] [PubMed]

- Kundu, D.; Talaie, E.; Duffort, V.; Nazar, L.F. The Emerging Chemistry of Sodium Ion Batteries for Electrochemical Energy Storage. Angew. Chem. Int. Ed. 2015, 54, 3431–3448. [Google Scholar] [CrossRef] [PubMed]

- Nayak, P.K.; Yang, L.; Brehm, W.; Adelhelm, P. From Lithium-Ion to Sodium-Ion Batteries: Advantages, Challenges, and Surprises. Angew. Chem. Int. Ed. 2018, 57, 102–120. [Google Scholar] [CrossRef] [PubMed]

- Toprakci, O.; Toprakci, H.A.K.; Ji, L.; Zhang, X. Fabrication and Electrochemical Characteristics of LiFePO4 Powders for Lithium-Ion Batteries. KONA Powder Part. J. 2010, 28, 50–73. [Google Scholar] [CrossRef]

- Lee, K.-J.; Kang, L.-S.; Uhm, S.; Yoon, J.S.; Kim, D.-W.; Hong, H.S. Synthesis and characterization of LiMnBO3 cathode material for lithium ion batteries. Curr. Appl. Phys. 2013, 13, 1440–1443. [Google Scholar] [CrossRef]

- Zhang, B.; Ming, L.; Zheng, J.; Zhang, J.; Shen, C.; Han, Y.; Wang, J.; Qin, S. Synthesis and characterization of multi-layer core-shell structural LiFeBO3/C as a novel Li-battery cathode material. J. Power Sources 2014, 261, 249–254. [Google Scholar] [CrossRef]

- Zhang, B.; Ming, L.; Tong, H.; Zhang, J.; Zheng, J.; Wang, X.; Li, H.; Cheng, L. Ni-doping to improve the performance of LiFeBO3/C cathode material for lithium-ion batteries. J. Alloys Compd. 2018, 740, 382–388. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, D.; Fu, A.; Liu, X.; Wang, Y.; Li, Y.; Guo, P.; Li, H.; Zhao, X.S. Mesoporous carbon spheres with tunable porosity prepared by a template-free method for advanced lithium–sulfur batteries. Mater. Sci. Eng. B 2018, 227, 9–15. [Google Scholar] [CrossRef]

- Ye, X.; Ma, J.; Hu, Y.-S.; Wei, H.; Ye, F. MWCNT porous microspheres with an efficient 3D conductive network for high performance lithium–sulfur batteries. J. Mater. Chem. A 2016, 4, 775–780. [Google Scholar] [CrossRef]

- Chen, M.; Wang, Z.; Wang, A.; Li, W.; Liu, X.; Fu, L.; Huang, W. Novel self-assembled natural graphite based composite anodes with improved kinetic properties in lithium-ion batteries. J. Mater. Chem. A 2016, 4, 9865–9872. [Google Scholar] [CrossRef]

- Deng, T.; Zhou, X. The preparation of porous graphite and its application in lithium ion batteries as anode material. J. Solid State Electrochem. 2016, 20, 2613–2618. [Google Scholar] [CrossRef]

- Ma, Z.; Cui, Y.; Xiao, X.; Deng, Y.; Song, X.; Zuo, X.; Nan, J. A reconstructed graphite-like carbon micro/nano-structure with higher capacity and comparative voltage plateau of graphite. J. Mater. Chem. A 2016, 4, 11462–11471. [Google Scholar] [CrossRef]

- Ma, Z.; Cui, Y.; Zuo, X.; Sun, Y.; Xiao, X.; Nan, J. Self-assembly flower-like porous carbon nanosheet powders for higher lithium-ion storage capacity. Electrochim. Acta 2015, 184, 308–315. [Google Scholar] [CrossRef]

- Ma, Z.; Zhuang, Y.; Deng, Y.; Song, X.; Zuo, X.; Xiao, X.; Nan, J. From spent graphite to amorphous sp2+sp3 carbon-coated sp2 graphite for high-performance lithium ion batteries. J. Power Sources 2018, 376, 91–99. [Google Scholar] [CrossRef]

- Mei, R.; Song, X.; Hu, Y.; Yang, Y.; Zhang, J. Hollow reduced graphene oxide microspheres as a high-performance anode material for Li-ion batteries. Electrochim. Acta 2015, 153, 540–545. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Y.; Chong, C.; Wang, J.; Shi, Z.; Pan, J. Phenolic formaldehyde resin/graphene composites as lithium-ion batteries anode. Mater. Lett. 2016, 170, 217–220. [Google Scholar] [CrossRef]

- Yuan, T.; Zhang, W.; Li, W.-T.; Song, C.; He, Y.-S.; Razal, J.M.; Ma, Z.-F.; Chen, J. N-doped pierced graphene microparticles as a highly active electrocatalyst for Li-air batteries. 2D Mater. 2015, 2, 024002. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, M.; Wang, Y.; Zhang, Z.; Kan, G.; Wang, C.; Zhong, Z.; Su, F. Graphitized porous carbon microspheres assembled with carbon black nanoparticles as improved anode materials in Li-ion batteries. J. Mater. Chem. A 2014, 2, 10161. [Google Scholar] [CrossRef]

- Zhuang, H.; Deng, W.; Wang, W.; Liu, Z. Facile fabrication of nanoporous graphene powder for high-rate lithium–sulfur batteries. RSC Adv. 2017, 7, 5177–5182. [Google Scholar] [CrossRef]

- Zhou, G.; Wang, D.-W.; Shan, X.; Li, N.; Li, F.; Cheng, H.-M. Hollow carbon cage with nanocapsules of graphitic shell/nickel core as an anode material for high rate lithium ion batteries. J. Mater. Chem. 2012, 22, 11252. [Google Scholar] [CrossRef]

- Lee, G.-H.; Jo, M.R.; Zhang, K.; Kang, Y.-M. A reduced graphene oxide-encapsulated phosphorus/carbon composite as a promising anode material for high-performance sodium-ion batteries. J. Mater. Chem. A 2017, 5, 3683–3690. [Google Scholar] [CrossRef]

- He, J.; Zhou, K.; Chen, Y.; Xu, C.; Lin, J.; Zhang, W. Wrinkled sulfur@graphene microspheres with high sulfur loading as superior-capacity cathode for LiS batteries. Mater. Today Energy 2016, 1, 11–16. [Google Scholar] [CrossRef]

- Ma, J.; Fang, Z.; Yan, Y.; Yang, Z.; Gu, L.; Hu, Y.-S.; Li, H.; Wang, Z.; Huang, X. Novel Large-Scale Synthesis of a C/S Nanocomposite with Mixed Conducting Networks through a Spray-drying Approach for Li-S Batteries. Adv. Energy Mater. 2015, 5, 1500046. [Google Scholar] [CrossRef]

- Tian, Y.; Sun, Z.; Zhang, Y.; Wang, X.; Bakenov, Z.; Yin, F. Micro-Spherical Sulfur/Graphene Oxide Composite via Spray-drying for High Performance Lithium Sulfur Batteries. Nanomaterials 2018, 8, 50. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Lu, H.; Xiao, L.; Ai, X.; Yang, H.; Cao, Y. Electrochemical properties and morphological evolution of pitaya-like Sb@C microspheres as high-performance anode for sodium ion batteries. J. Mater. Chem. A 2015, 3, 5708–5713. [Google Scholar] [CrossRef]

- Bao, Q.; Huang, Y.-H.; Lan, C.-K.; Chen, B.-H.; Duh, J.-G. Scalable Upcycling Silicon from Waste Slicing Sludge for High-performance Lithium-ion Battery Anodes. Electrochim. Acta 2015, 173, 82–90. [Google Scholar] [CrossRef]

- Bie, Y.; Yu, J.; Yang, J.; Lu, W.; Nuli, Y.; Wang, J. Porous microspherical silicon composite anode material for lithium ion battery. Electrochim. Acta 2015, 178, 65–73. [Google Scholar] [CrossRef]

- Chen, H.; Hou, X.; Qu, L.; Qin, H.; Ru, Q.; Huang, Y.; Hu, S.; Lam, K. Electrochemical properties of core–shell nano-Si@carbon composites as superior anode materials for high-performance Li-ion batteries. J. Mater. Sci. Mater. Electron. 2017, 28, 250–258. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Z.; Hou, X.; Fu, L.; Wang, S.; Hu, X.; Qin, H.; Wu, Y.; Ru, Q.; Liu, X. Mass-producible method for preparation of a carbon-coated graphite@plasma nano-silicon@carbon composite with enhanced performance as lithium ion battery anode. Electrochim. Acta 2017, 249, 113–121. [Google Scholar] [CrossRef]

- Chen, L.; Xie, X.; Wang, B.; Wang, K.; Xie, J. Spherical nanostructured Si/C composite prepared by spray-drying technique for lithium ion batteries anode. Mater. Sci. Eng. B 2006, 131, 186–190. [Google Scholar] [CrossRef]

- Fan, X.; Jiang, X.; Wang, W.; Liu, Z. Green synthesis of nanoporous Si/C anode using NaCl template with improved cycle life. Mater. Lett. 2016, 180, 109–113. [Google Scholar] [CrossRef]

- Feng, X.; Cui, H.; Miao, R.; Yan, N.; Ding, T.; Xiao, Z. Nano/micro-structured silicon@carbon composite with buffer void as anode material for lithium ion battery. Ceram. Int. 2016, 42, 589–597. [Google Scholar] [CrossRef]

- Feng, X.; Ding, T.; Cui, H.; Yan, N.; Wang, F. A Low-Cost Nano/Micro Structured-Silicon-MWCNTs from Nano-Silica for Lithium Storage. Nano 2016, 11, 1650031. [Google Scholar] [CrossRef]

- Feng, X.; Yang, J.; Bie, Y.; Wang, J.; Nuli, Y.; Lu, W. Nano/micro-structured Si/CNT/C composite from nano-SiO2 for high power lithium ion batteries. Nanoscale 2014, 6, 12532–12539. [Google Scholar] [CrossRef] [PubMed]

- Gan, L.; Guo, H.; Wang, Z.; Li, X.; Peng, W.; Wang, J.; Huang, S.; Su, M. A facile synthesis of graphite/silicon/graphene spherical composite anode for lithium-ion batteries. Electrochim. Acta 2013, 104, 117–123. [Google Scholar] [CrossRef]

- He, Y.-S.; Gao, P.; Chen, J.; Yang, X.; Liao, X.-Z.; Yang, J.; Ma, Z.-F. A novel bath lily-like graphene sheet-wrapped nano-Si composite as a high performance anode material for Li-ion batteries. RSC Adv. 2011, 1, 958. [Google Scholar] [CrossRef]

- Hou, X.; Wang, J.; Zhang, M.; Liu, X.; Shao, Z.; Li, W.; Hu, S. Facile spray-drying/pyrolysis synthesis of intertwined SiO@CNFs&G composites as superior anode materials for Li-ion batteries. RSC Adv. 2014, 4, 34615–34622. [Google Scholar]

- Lai, J.; Guo, H.; Wang, Z.; Li, X.; Zhang, X.; Wu, F.; Yue, P. Preparation and characterization of flake graphite/silicon/carbon spherical composite as anode materials for lithium-ion batteries. J. Alloys Compd. 2012, 530, 30–35. [Google Scholar] [CrossRef]

- Lee, J.; Moon, J.H. Spherical graphene and Si nanoparticle composite particles for high-performance lithium batteries. Korean J. Chem. Eng. 2017, 34, 3195–3199. [Google Scholar] [CrossRef]

- Li, C.; Ju, Y.; Qi, L.; Yoshitake, H.; Wang, H. A micro-sized Si-CNT anode for practical application via a one-step, low-cost and green method. RSC Adv. 2017, 7, 54844–54851. [Google Scholar] [CrossRef]

- Li, J.; Wang, J.; Yang, J.; Ma, X.; Lu, S. Scalable synthesis of a novel structured graphite/silicon/pyrolyzed-carbon composite as anode material for high-performance lithium-ion batteries. J. Alloys Compd. 2016, 688, 1072–1079. [Google Scholar] [CrossRef]

- Li, J.; Yang, J.-Y.; Wang, J.-T.; Lu, S.-G. A scalable synthesis of silicon nanoparticles as high-performance anode material for lithium-ion batteries. Rare Met. 2017. [Google Scholar] [CrossRef]

- Li, M.; Hou, X.; Sha, Y.; Wang, J.; Hu, S.; Liu, X.; Shao, Z. Facile spray-drying/pyrolysis synthesis of core-shell structure graphite/silicon-porous carbon composite as a superior anode for Li-ion batteries. J. Power Sources 2014, 248, 721–728. [Google Scholar] [CrossRef]

- Li, S.; Qin, X.; Zhang, H.; Wu, J.; He, Y.-B.; Li, B.; Kang, F. Silicon/carbon composite microspheres with hierarchical core-shell structure as anode for lithium ion batteries. Electrochem. Commun. 2014, 49, 98–102. [Google Scholar] [CrossRef]

- Lin, J.; He, J.; Chen, Y.; Li, Q.; Yu, B.; Xu, C.; Zhang, W. Pomegranate-Like Silicon/Nitrogen-doped Graphene Microspheres as Superior-Capacity Anode for Lithium-Ion Batteries. Electrochim. Acta 2016, 215, 667–673. [Google Scholar] [CrossRef]

- Liu, X.; Wang, Z.; Guo, H.; Li, X.; Zhou, R.; Zhou, Y. Chitosan: A N-doped carbon source of silicon-based anode material for lithium ion batteries. Ionics 2017, 23, 2311–2318. [Google Scholar] [CrossRef]

- Paireau, C.; Jouanneau, S.; Ammar, M.-R.; Simon, P.; Béguin, F.; Raymundo-Piñero, E. Si/C composites prepared by spray-drying from cross-linked polyvinyl alcohol as Li-ion batteries anodes. Electrochim. Acta 2015, 174, 361–368. [Google Scholar] [CrossRef]

- Pan, Q.; Zuo, P.; Lou, S.; Mu, T.; Du, C.; Cheng, X.; Ma, Y.; Gao, Y.; Yin, G. Micro-sized spherical silicon@carbon@graphene prepared by spray-drying as anode material for lithium-ion batteries. J. Alloys Compd. 2017, 723, 434–440. [Google Scholar] [CrossRef]

- Ren, W.; Zhang, Z.; Wang, Y.; Tan, Q.; Zhong, Z.; Su, F. Preparation of porous silicon/carbon microspheres as high performance anode materials for lithium ion batteries. J. Mater. Chem. A 2015, 3, 5859–5865. [Google Scholar] [CrossRef]

- Su, M.; Wang, Z.; Guo, H.; Li, X.; Huang, S.; Gan, L.; Xiao, W. Enhanced cycling performance of Si/C composite prepared by spray-drying as anode for Li-ion batteries. Powder Technol. 2013, 249, 105–109. [Google Scholar] [CrossRef]

- Su, M.; Wang, Z.; Guo, H.; Li, X.; Huang, S.; Xiao, W.; Gan, L. Enhancement of the Cyclability of a Si/Graphite@Graphene composite as anode for Lithium-ion batteries. Electrochim. Acta 2014, 116, 230–236. [Google Scholar] [CrossRef]

- Tao, H.; Xiong, L.; Zhu, S.; Zhang, L.; Yang, X. Porous Si/C/reduced graphene oxide microspheres by spray-drying as anode for Li-ion batteries. J. Electroanal. Chem. 2017, 797, 16–22. [Google Scholar] [CrossRef]

- Wang, A.; Liu, F.; Wang, Z.; Liu, X. Self-assembly of silicon/carbon hybrids and natural graphite as anode materials for lithium-ion batteries. RSC Adv. 2016, 6, 104995–105002. [Google Scholar] [CrossRef]

- Wang, J.; Hou, X.; Zhang, M.; Li, Y.; Wu, Y.; Liu, X.; Hu, S. 3-Aminopropyltriethoxysilane-Assisted Si@SiO2/CNTs Hybrid Microspheres as Superior Anode Materials for Li-ion Batteries. Silicon 2017, 9, 97–104. [Google Scholar] [CrossRef]

- Wang, Z.; Mao, Z.; Lai, L.; Okubo, M.; Song, Y.; Zhou, Y.; Liu, X.; Huang, W. Sub-micron silicon/pyrolyzed carbon@natural graphite self-assembly composite anode material for lithium-ion batteries. Chem. Eng. J. 2017, 313, 187–196. [Google Scholar] [CrossRef]

- Xu, Q.; Li, J.-Y.; Sun, J.-K.; Yin, Y.-X.; Wan, L.-J.; Guo, Y.-G. Watermelon-Inspired Si/C Microspheres with Hierarchical Buffer Structures for Densely Compacted Lithium-Ion Battery Anodes. Adv. Energy Mater. 2017, 7, 1601481. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Z.; Zhou, R.; Guo, H.; Li, X. Effects of lithium fluoride coating on the performance of nano-silicon as anode material for lithium-ion batteries. Mater. Lett. 2016, 184, 65–68. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, Z.; Zhou, Y.; Guo, H.; Li, X. Synthesis of porous Si/graphite/carbon nanotubes@C composites as a practical high-capacity anode for lithium-ion batteries. Mater. Lett. 2017, 199, 84–87. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, H.; Jin, H.; Li, C.; Bai, Y.; Lian, K. Flower-like carbon with embedded silicon nano particles as an anode material for Li-ion batteries. RSC Adv. 2017, 7, 30032–30037. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Y.; Kan, G.; Zhang, Z.; Wang, C.; Zhong, Z.; Su, F. Scalable synthesis of porous silicon/carbon microspheres as improved anode materials for Li-ion batteries. RSC Adv. 2014, 4, 43114–43120. [Google Scholar] [CrossRef]

- Zhang, M.; Hou, X.; Wang, J.; Li, M.; Hu, S.; Shao, Z.; Liu, X. Interweaved Si@C/CNTs&CNFs composites as anode materials for Li-ion batteries. J. Alloys Compd. 2014, 588, 206–211. [Google Scholar]

- Zhang, Y.; Li, K.; Ji, P.; Chen, D.; Zeng, J.; Sun, Y.; Zhang, P.; Zhao, J. Silicon-multi-walled carbon nanotubes-carbon microspherical composite as high-performance anode for lithium-ion batteries. J. Mater. Sci. 2017, 52, 3630–3641. [Google Scholar] [CrossRef]

- Zhou, Y.; Guo, H.; Wang, Z.; Li, X.; Zhou, R.; Peng, W. Improved electrochemical performance of Si/C material based on the interface stability. J. Alloys Compd. 2017, 725, 1304–1312. [Google Scholar] [CrossRef]

- Ogata, K.; Jeon, S.; Ko, D.-S.; Jung, I.S.; Kim, J.H.; Ito, K.; Kubo, Y.; Takei, K.; Saito, S.; Cho, Y.-H. Evolving affinity between Coulombic reversibility and hysteretic phase transformations in nano-structured silicon-based lithium-ion batteries. Nat. Commun. 2018, 9, 479. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Wang, X.; Ying, H.; Wang, G.; Han, W.-Q. Facial Synthesis of Three-Dimensional Cross-Linked Cage for High-Performance Lithium Storage. ACS Appl. Mater. Interfaces 2016, 8, 15279–15287. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Gao, M.; Pan, H.; Liu, Y.; Wang, J.; Li, S.; Ge, H. Enhanced cycle stability of micro-sized Si/C anode material with low carbon content fabricated via spray-drying and in situ carbonization. J. Alloys Compd. 2014, 604, 130–136. [Google Scholar] [CrossRef]

- Ying, H.; Zhang, S.; Meng, Z.; Sun, Z.; Han, W.-Q. Ultrasmall Sn nanodots embedded inside N-doped carbon microcages as high-performance lithium and sodium ion battery anodes. J. Mater. Chem. A 2017, 5, 8334–8342. [Google Scholar] [CrossRef]

- Youn, H.-C.; Jeong, J.H.; Roh, K.C.; Kim, K.-B. Graphene–Selenium Hybrid Microballs as Cathode Materials for High-performance Lithium–Selenium Secondary Battery Applications. Sci. Rep. 2016, 6, 30865. [Google Scholar] [CrossRef] [PubMed]

- Gocheva, I.D.; Okada, S.; Yamaki, J. Electrochemical Properties of Trirutile-type Li2TiF6 as Cathode Active Material in Li-ion Batteries. Electrochemistry 2010, 78, 471–474. [Google Scholar] [CrossRef]

- Lieser, G.; de Biasi, L.; Scheuermann, M.; Winkler, V.; Eisenhardt, S.; Glatthaar, S.; Indris, S.; Gesswein, H.; Hoffmann, M.J.; Ehrenberg, H. Sol-Gel Processing and Electrochemical Conversion of Inverse Spinel-Type Li2NiF4. J. Electrochem. Soc. 2015, 162, A679–A686. [Google Scholar] [CrossRef]

- Lieser, G.; Schroeder, M.; Geßwein, H.; Winkler, V.; Glatthaar, S.; Yavuz, M.; Binder, J.R. Sol-gel processing and electrochemical characterization of monoclinic Li3FeF6. J. Sol-Gel Sci. Technol. 2014, 71, 50–59. [Google Scholar] [CrossRef]

- Brisbois, M.; Caes, S.; Sougrati, M.T.; Vertruyen, B.; Schrijnemakers, A.; Cloots, R.; Eshraghi, N.; Hermann, R.P.; Mahmoud, A.; Boschini, F. Na2FePO4F/multi-walled carbon nanotubes for lithium-ion batteries: Operando Mössbauer study of spray-dried composites. Sol. Energy Mater. Sol. Cells 2016, 148, 67–72. [Google Scholar] [CrossRef]

- Brisbois, M.; Krins, N.; Hermann, R.P.; Schrijnemakers, A.; Cloots, R.; Vertruyen, B.; Boschini, F. Spray-drying synthesis of Na2FePO4F/carbon powders for lithium-ion batteries. Mater. Lett. 2014, 130, 263–266. [Google Scholar] [CrossRef]

- Mahmoud, A.; Caes, S.; Brisbois, M.; Hermann, R.P.; Berardo, L.; Schrijnemakers, A.; Malherbe, C.; Eppe, G.; Cloots, R.; Vertruyen, B. Spray-drying as a tool to disperse conductive carbon inside Na2FePO4F particles by addition of carbon black or carbon nanotubes to the precursor solution. J. Solid State Electrochem. 2018, 22, 103–112. [Google Scholar] [CrossRef]

- Lin, X.; Hou, X.; Wu, X.; Wang, S.; Gao, M.; Yang, Y. Exploiting Na2MnPO4F as a high-capacity and well-reversible cathode material for Na-ion batteries. RSC Adv. 2014, 4, 40985–40993. [Google Scholar] [CrossRef]

- Wu, L.; Hu, Y.; Zhang, X.; Liu, J.; Zhu, X.; Zhong, S. Synthesis of carbon-coated Na2MnPO4F hollow spheres as a potential cathode material for Na-ion batteries. J. Power Sources 2018, 374, 40–47. [Google Scholar] [CrossRef]

- Zou, H.; Li, S.; Wu, X.; McDonald, M.J.; Yang, Y. Spray-Drying Synthesis of Pure Na2CoPO4F as Cathode Material for Sodium Ion Batteries. ECS Electrochem. Lett. 2015, 4, A53–A55. [Google Scholar] [CrossRef]

- Eshraghi, N.; Caes, S.; Mahmoud, A.; Cloots, R.; Vertruyen, B.; Boschini, F. Sodium vanadium (III) fluorophosphate/carbon nanotubes composite (NVPF/CNT) prepared by spray-drying: Good electrochemical performance thanks to well-dispersed CNT network within NVPF particles. Electrochim. Acta 2017, 228, 319–324. [Google Scholar] [CrossRef]

- Yin, Y.; Xiong, F.; Pei, C.; Xu, Y.; An, Q.; Tan, S.; Zhuang, Z.; Sheng, J.; Li, Q.; Mai, L. Robust three-dimensional graphene skeleton encapsulated Na3V2O2(PO4)2F nanoparticles as a high-rate and long-life cathode of sodium-ion batteries. Nano Energy 2017, 41, 452–459. [Google Scholar] [CrossRef]

- Zhang, H.; Deng, Q.; Zhou, A.; Liu, X.; Li, J. Porous Li2C8H4O4 coated with N-doped carbon by using CVD as an anode material for Li-ion batteries. J. Mater. Chem. A 2014, 2, 5696–5702. [Google Scholar] [CrossRef]

- Deng, Q.; Wang, Y.; Zhao, Y.; Li, J. Disodium terephthalate/multiwall-carbon nanotube nanocomposite as advanced anode material for Li-ion batteries. Ionics 2017, 23, 2613–2619. [Google Scholar] [CrossRef]

- Wu, X.; Ma, J.; Ma, Q.; Xu, S.; Hu, Y.-S.; Sun, Y.; Li, H.; Chen, L.; Huang, X. A spray-drying approach for the synthesis of a Na2C6H2O4/CNT nanocomposite anode for sodium-ion batteries. J. Mater. Chem. A 2015, 3, 13193–13197. [Google Scholar] [CrossRef]

- Qian, X.; Zhao, D.; Jin, L.; Yao, S.; Rao, D.; Shen, X.; Zhou, Y.; Xi, X. A separator modified by spray-dried hollow spherical cerium oxide and its application in lithium sulfur batteries. RSC Adv. 2016, 6, 114989–114996. [Google Scholar] [CrossRef]

- Hong, S.-H.; Song, M.Y. Syntheses of nano-sized Co-based powders by carbothermal reduction for anode materials of lithium ion batteries. Ceram. Int. 2018, 44, 4225–4229. [Google Scholar] [CrossRef]

- Kim, J.H.; Kang, Y.C. Electrochemical properties of micron-sized, spherical, meso- and macro-porous Co3O4 and CoO–carbon composite powders prepared by a two-step spray-drying process. Nanoscale 2014, 6, 4789. [Google Scholar] [CrossRef] [PubMed]

- Park, G.D.; Lee, J.-H.; Lee, J.-K.; Kang, Y.C. Effect of esterification reaction of citric acid and ethylene glycol on the formation of multi-shelled cobalt oxide powders with superior electrochemical properties. Nano Res. 2014, 7, 1738–1748. [Google Scholar] [CrossRef]

- Son, M.Y.; Kim, J.H.; Kang, Y.C. Study of Co3O4 mesoporous nanosheets prepared by a simple spray-drying process and their electrochemical properties as anode material for lithium secondary batteries. Electrochim. Acta 2014, 116, 44–50. [Google Scholar] [CrossRef]

- Xiang, Y.; Chen, Z.; Chen, C.; Wang, T.; Zhang, M. Design and synthesis of Cr2O3@C@G composites with yolk-shell structure for Li + storage. J. Alloys Compd. 2017, 724, 406–412. [Google Scholar] [CrossRef]

- Jeon, K.M.; Kim, J.H.; Choi, Y.J.; Kang, Y.C. Electrochemical properties of hollow copper (II) oxide nanopowders prepared by salt-assisted spray-drying process applying nanoscale Kirkendall diffusion. J. Appl. Electrochem. 2016, 46, 469–477. [Google Scholar] [CrossRef]

- Park, G.D.; Kang, Y.C. Superior Lithium-Ion Storage Properties of Mesoporous CuO-Reduced Graphene Oxide Composite Powder Prepared by a Two-Step Spray-Drying Process. Chem. Eur. J. 2015, 21, 9179–9184. [Google Scholar] [CrossRef] [PubMed]

- Won, J.M.; Kim, J.H.; Choi, Y.J.; Cho, J.S.; Kang, Y.C. Electrochemical properties of CuO hollow nanopowders prepared from formless Cu-C composite via nanoscale Kirkendall diffusion process. J. Alloys Compd. 2016, 671, 74–83. [Google Scholar] [CrossRef]

- Padashbarmchi, Z.; Hamidian, A.H.; Zhang, H.; Zhou, L.; Khorasani, N.; Kazemzad, M.; Yu, C. A systematic study on the synthesis of α-Fe2O3 multi-shelled hollow spheres. RSC Adv. 2015, 5, 10304–10309. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, X.; Huang, X.; Zhou, L. Encapsulation of α-Fe2O3 nanoparticles in graphitic carbon microspheres as high-performance anode materials for lithium-ion batteries. Nanoscale 2015, 7, 3270–3275. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.-W.; Wang, J.; Gao, P.; Yang, X.; He, Y.-S.; Liao, X.-Z.; Yang, J.; Ma, Z.-F. Facile Spray-drying Route for the Three-Dimensional Graphene-Encapsulated Fe2O3 Nanoparticles for Lithium Ion Battery Anodes. Ind. Eng. Chem. Res. 2013, 52, 1197–1204. [Google Scholar] [CrossRef]

- Zhou, L.; Xu, H.; Zhang, H.; Yang, J.; Hartono, S.B.; Qian, K.; Zou, J.; Yu, C. Cheap and scalable synthesis of α-Fe2O3 multi-shelled hollow spheres as high-performance anode materials for lithium ion batteries. Chem. Commun. 2013, 49, 8695. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Tian, H.; Wang, X.; Xin, F.; Han, W. Three-dimensional interconnected network GeOx/multi-walled CNT composite spheres as high-performance anodes for lithium ion batteries. J. Mater. Chem. A 2015, 3, 19393–19401. [Google Scholar] [CrossRef]

- Jia, H.; Kloepsch, R.; He, X.; Badillo, J.P.; Winter, M.; Placke, T. One-step synthesis of novel mesoporous three-dimensional GeO2 and its lithium storage properties. J Mater Chem A 2014, 2, 17545–17550. [Google Scholar] [CrossRef]

- Qian, X.; Zhao, D.; Jin, L.; Shen, X.; Yao, S.; Rao, D.; Zhou, Y.; Xi, X. ming Hollow spherical Lanthanum oxide coated separator for high electrochemical performance lithium-sulfur batteries. Mater. Res. Bull. 2017, 94, 104–112. [Google Scholar] [CrossRef]

- Jeon, K.M.; Cho, J.S.; Kang, Y.C. Electrochemical properties of MnS-C and MnO-C composite powders prepared via spray-drying process. J. Power Sources 2015, 295, 9–15. [Google Scholar] [CrossRef]

- Park, G.D.; Kim, J.H.; Choi, Y.J.; Kang, Y.C. Large-Scale Production of MoO3-Reduced Graphene Oxide Powders with Superior Lithium Storage Properties by Spray-Drying Process. Electrochim. Acta 2015, 173, 581–587. [Google Scholar] [CrossRef]

- Tao, Y.; Wei, Y.; Liu, Y.; Wang, J.; Qiao, W.; Ling, L.; Long, D. Kinetically-enhanced polysulfide redox reactions by Nb2O5 nanocrystals for high-rate lithium–sulfur battery. Energy Environ. Sci. 2016, 9, 3230–3239. [Google Scholar] [CrossRef]

- Xiao, A.; Zhou, S.; Zuo, C.; Zhuan, Y.; Ding, X. Synthesis of nickel oxide nanospheres by a facile spray-drying method and their application as anode materials for lithium ion batteries. Mater. Res. Bull. 2015, 70, 200–203. [Google Scholar] [CrossRef]

- Li, Y.; Hou, X.; Wang, J.; Mao, J.; Gao, Y.; Hu, S. Catalyst Ni-assisted synthesis of interweaved SiO/G/CNTs&CNFs composite as anode material for lithium-ion batteries. J. Mater. Sci. Mater. Electron. 2015, 26, 7507–7514. [Google Scholar]

- Yang, X.; Zhang, P.; Shi, C.; Wen, Z. Porous Graphite/Silicon Micro-Sphere Prepared by In-Situ Carbothermal Reduction and Spray-drying for Lithium Ion Batteries. ECS Solid State Lett. 2012, 1, M5–M7. [Google Scholar] [CrossRef]

- Wu, H.; Tang, Q.; Fan, H.; Liu, Z.; Hu, A.; Zhang, S.; Deng, W.; Chen, X. Dual-Confined and Hierarchical-Porous Graphene/C/SiO2 Hollow Microspheres through Spray-drying Approach for Lithium-Sulfur Batteries. Electrochim. Acta 2017, 255, 179–186. [Google Scholar] [CrossRef]

- Jiao, M.; Liu, K.; Shi, Z.; Wang, C. SiO2/Carbon Composite Microspheres with Hollow Core-Shell Structure as a High-Stability Electrode for Lithium-Ion Batteries. ChemElectroChem 2017, 4, 542–549. [Google Scholar] [CrossRef]

- Choi, S.H.; Kang, Y.C. Kilogram-Scale Production of SnO2 Yolk-Shell Powders by a Spray-Drying Process Using Dextrin as Carbon Source and Drying Additive. Chem. Eur. J. 2014, 20, 5835–5839. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.; Kong, Z.; Liu, X.; Fu, A.; Wang, Y.; Guo, Y.-G.; Guo, P.; Li, H.; Zhao, X.S. Spray-Drying-Induced Assembly of Skeleton-Structured SnO2/Graphene Composite Spheres as Superior Anode Materials for High-Performance Lithium-Ion Batteries. ACS Appl. Mater. Interfaces 2018, 10, 2515–2525. [Google Scholar] [CrossRef] [PubMed]

- Cho, J.S.; Ju, H.S.; Kang, Y.C. Applying Nanoscale Kirkendall Diffusion for Template-Free, Kilogram-Scale Production of SnO2 Hollow Nanospheres via Spray-drying System. Sci. Rep. 2016, 6, 23915. [Google Scholar] [CrossRef] [PubMed]

- Chunju, L.; Hu, T.; Shu, K.; Chen, D.; Tian, G. Porous TiO2 nanowire microsphere constructed by spray-drying and its electrochemical lithium storage properties. Microsc. Res. Tech. 2014, 77, 170–175. [Google Scholar] [CrossRef] [PubMed]

- He, Y.-B.; Liu, M.; Xu, Z.-L.; Zhang, B.; Li, B.; Kang, F.; Kim, J.-K. Li-ion Reaction to Improve the Rate Performance of Nanoporous Anatase TiO2 Anodes. Energy Technol. 2013, 1, 668–674. [Google Scholar] [CrossRef]

- Mondal, A.; Maiti, S.; Singha, K.; Mahanty, S.; Panda, A.B. TiO2-rGO nanocomposite hollow spheres: Large scale synthesis and application as an efficient anode material for lithium-ion batteries. J. Mater. Chem. A 2017, 5, 23853–23862. [Google Scholar] [CrossRef]

- Park, G.D.; Lee, J.; Piao, Y.; Kang, Y.C. Mesoporous graphitic carbon-TiO2 composite microspheres produced by a pilot-scale spray-drying process as an efficient sulfur host material for Li-S batteries. Chem. Eng. J. 2018, 335, 600–611. [Google Scholar] [CrossRef]

- Sakao, M.; Kijima, N.; Akimoto, J.; Okutani, T. Synthesis and Electrochemical Properties of Porous Titania Prepared by Spray-drying of Titania Nanosheets. Chem. Lett. 2012, 41, 1515–1517. [Google Scholar] [CrossRef]

- Sakao, M.; Kijima, N.; Yoshinaga, M.; Akimoto, J.; Okutani, T. Synthesis and Electrochemical Properties of Porous Titania Fabricated from Nanosheets. Key Eng. Mater. 2013, 566, 111–114. [Google Scholar] [CrossRef]

- Ventosa, E.; Mei, B.; Xia, W.; Muhler, M.; Schuhmann, W. TiO2(B)/Anatase Composites Synthesized by Spray-drying as High Performance Negative Electrode Material in Li-Ion Batteries. ChemSusChem 2013, 6, 1312–1315. [Google Scholar] [CrossRef] [PubMed]

- Wilhelm, O.; Pratsinis, S.; de Chambrier, E.; Crouzet, M.; Exnar, I. Electrochemical performance of granulated titania nanoparticles. J. Power Sources 2004, 134, 197–201. [Google Scholar] [CrossRef]

- Zhu, X.; Li, Q.; Fang, Y.; Liu, X.; Xiao, L.; Ai, X.; Yang, H.; Cao, Y. Graphene-Modified TiO2 Microspheres Synthesized by a Facile Spray-Drying Route for Enhanced Sodium-Ion Storage. Part. Part. Syst. Charact. 2016, 33, 545–552. [Google Scholar] [CrossRef]

- Li, Q.; Chen, Y.; He, J.; Fu, F.; Qi, F.; Lin, J.; Zhang, W. Carbon Nanotube Modified V2O5 Porous Microspheres as Cathodes for High-Performance Lithium-Ion Batteries. Energy Technol. 2017, 5, 665–669. [Google Scholar] [CrossRef]

- Mao, J.; Hou, X.; Chen, H.; Ru, Q.; Hu, S.; Lam, K. Facile spray-drying synthesis of porous structured ZnFe2O4 as high-performance anode material for lithium-ion batteries. J. Mater. Sci. Mater. Electron. 2017, 28, 3709–3715. [Google Scholar] [CrossRef]

- Won, J.M.; Choi, S.H.; Hong, Y.J.; Ko, Y.N.; Kang, Y.C. Electrochemical properties of yolk-shell structured ZnFe2O4 powders prepared by a simple spray-drying process as anode material for lithium-ion battery. Sci. Rep. 2014, 4, 5857. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Ren, W.; Wang, Y.; Yang, J.; Tan, Q.; Zhong, Z.; Su, F. Mn0.5Co0.5Fe2O4 nanoparticles highly dispersed in porous carbon microspheres as high performance anode materials in Li-ion batteries. Nanoscale 2014, 6, 6805. [Google Scholar] [CrossRef] [PubMed]

- Mondal, A.; Maiti, S.; Mahanty, S.; Baran Panda, A. Large-scale synthesis of porous NiCo2O4 and rGO-NiCo2O4 hollow-spheres with superior electrochemical performance as a faradaic electrode. J. Mater. Chem. A 2017, 5, 16854–16864. [Google Scholar] [CrossRef]

- Choi, S.H.; Park, S.K.; Lee, J.-K.; Kang, Y.C. Facile synthesis of multi-shell structured binary metal oxide powders with a Ni/Co mole ratio of 1:2 for Li-Ion batteries. J. Power Sources 2015, 284, 481–488. [Google Scholar] [CrossRef]

- Quan, J.; Mei, L.; Ma, Z.; Huang, J.; Li, D. Cu1.5Mn1.5O4 spinel: A novel anode material for lithium-ion batteries. RSC Adv. 2016, 6, 55786–55791. [Google Scholar] [CrossRef]

- Park, J.-S.; Cho, J.S.; Kang, Y.C. Scalable synthesis of NiMoO4 microspheres with numerous empty nanovoids as an advanced anode material for Li-ion batteries. J. Power Sources 2018, 379, 278–287. [Google Scholar] [CrossRef]

- Zhu, G.; Li, Q.; Zhao, Y.; Che, R. Nanoporous TiNb2O7/C Composite Microspheres with Three-Dimensional Conductive Network for Long-Cycle-Life and High-Rate-Capability Anode Materials for Lithium-Ion Batteries. ACS Appl. Mater. Interfaces 2017, 9, 41258–41264. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Li, P.; Zhao, S.; Zhuang, Y.; Zhao, S.; Zhou, Q.; Zheng, J. Influence of integrated microstructure on the performance of LiNi0.8Co0.15Al0.05O2 as a cathodic material for lithium ion batteries. RSC Adv. 2017, 7, 29233–29239. [Google Scholar] [CrossRef]

- Cheng, J.; Li, X.; He, Z.; Wang, Z.; Guo, H.; Peng, W. Significant improved electrochemical performance of layered Li1.2Mn0.54Co0.13Ni0.13O2 via graphene surface modification. Mater. Technol. 2016, 31, 658–665. [Google Scholar] [CrossRef]

- Duvigneaud, P.H.; Segato, T. Synthesis and characterisation of LiNi1−x−yCoxAlyO2 cathodes for lithium-ion batteries by the PVA precursor method. J. Eur. Ceram. Soc. 2004, 24, 1375–1380. [Google Scholar] [CrossRef]

- He, Z.; Wang, Z.; Cheng, L.; Zhu, Z.; Li, T.; Li, X.; Guo, H. Structural and electrochemical characterization of layered 0.3Li2MnO3·0.7LiMn0.35−x/3Ni0.5−x/3Co0.15−x/3CrxO2 cathode synthesized by spray-drying. Adv. Powder Technol. 2014, 25, 647–653. [Google Scholar] [CrossRef]

- He, Z.; Wang, Z.; Guo, H.; Li, X.; Xianwen, W.; Yue, P.; Wang, J. A simple method of preparing graphene-coated Li[Li0.2Mn0.54Ni0.13Co0.13]O2 for lithium-ion batteries. Mater. Lett. 2013, 91, 261–264. [Google Scholar] [CrossRef]

- He, Z.; Wang, Z.; Guo, H.; Li, X.; Yue, P.; Wang, J.; Xiong, X. Synthesis and electrochemical performance of xLi2MnO3·(1−x)LiMn0.5Ni0.4Co0.1O2 for lithium ion battery. Powder Technol. 2013, 235, 158–162. [Google Scholar] [CrossRef]

- Hou, M.; Guo, S.; Liu, J.; Yang, J.; Wang, Y.; Wang, C.; Xia, Y. Preparation of lithium-rich layered oxide micro-spheres using a slurry spray-drying process. J. Power Sources 2015, 287, 370–376. [Google Scholar] [CrossRef]

- Hu, S.-K.; Cheng, G.-H.; Cheng, M.-Y.; Hwang, B.-J.; Santhanam, R. Cycle life improvement of ZrO2-coated spherical LiNi1/3Co1/3Mn1/3O2 cathode material for lithium ion batteries. J. Power Sources 2009, 188, 564–569. [Google Scholar] [CrossRef]

- Kim, J.-M.; Kumagai, N.; Kadoma, Y.; Yashiro, H. Synthesis and electrochemical properties of lithium non-stoichiometric Li1+x(Ni1/3Co1/3Mn1/3)O2+δ prepared by a spray-drying method. J. Power Sources 2007, 174, 473–479. [Google Scholar] [CrossRef]

- Kim, J.-M.; Kumagai, N.; Cho, T.-H. Synthesis, Structure, and Electrochemical Characteristics of Overlithiated Li[1+x](Ni[z]Co[1−2z]Mn[z])[1−x]O2 (z = 0.1 – 0.4 and x = 0.0 – 0.1) Positive Electrodes Prepared by Spray-Drying Method. J. Electrochem. Soc. 2008, 155, A82. [Google Scholar] [CrossRef]

- Konstantinov, K.; Wang, G.X.; Yao, J.; Liu, H.K.; Dou, S.X. Stoichiometry-controlled high-performance LiCoO2 electrode materials prepared by a spray solution technique. J. Power Sources 2003, 119, 195–200. [Google Scholar] [CrossRef]

- Li, D.-C.; Muta, T.; Zhang, L.-Q.; Yoshio, M.; Noguchi, H. Effect of synthesis method on the electrochemical performance of LiNi1/3Mn1/3Co1/3O2. J. Power Sources 2004, 132, 150–155. [Google Scholar] [CrossRef]

- Li, D.-C.; Noguchi, H.; Yoshio, M. Electrochemical characteristics of LiNi0.5−xMn0.5−xCo2xO2 (0 <x ≤ 0.1) prepared by spray-dry method. Electrochim. Acta 2004, 50, 427–430. [Google Scholar]

- Li, D.; Kato, Y.; Kobayakawa, K.; Noguchi, H.; Sato, Y. Preparation and electrochemical characteristics of LiNi1/3Mn1/3Co1/3O2 coated with metal oxides coating. J. Power Sources 2006, 160, 1342–1348. [Google Scholar] [CrossRef]

- Li, D.; Sasaki, Y.; Kobayakawa, K.; Noguchi, H.; Sato, Y. Preparation, morphology and electrochemical characteristics of LiNi1/3Mn1/3Co1/3O2 with LiF addition. Electrochim. Acta 2006, 52, 643–648. [Google Scholar] [CrossRef]

- Li, J.; Wang, L.; Chen, J.; He, X. Li Storage Properties of (1-x-y)Li[Li1/3Mn2/3]O2-xLiFeO2-yLiNiO2 Solid Solution Cathode Materials. ECS Trans. 2014, 62, 79–87. [Google Scholar] [CrossRef]

- Li, L.; Meyer, W.H.; Wegner, G.; Wohlfahrt-Mehrens, M. Synthesis of Submicrometer-Sized Electrochemically Active Lithium Cobalt Oxide via a Polymer Precursor. Adv. Mater. 2005, 17, 984–988. [Google Scholar] [CrossRef]

- Li, Y.; Wan, C.; Wu, Y.; Jiang, C.; Zhu, Y. Synthesis and characterization of ultrafine LiCoO2 powders by a spray-drying method. J. Power Sources 2000, 85, 294–298. [Google Scholar] [CrossRef]

- Lin, B.; Wen, Z.; Gu, Z.; Xu, X. Preparation and electrochemical properties of Li[Ni1/3Co1/3Mn1−x/3Zrx/3]O2 cathode materials for Li-ion batteries. J. Power Sources 2007, 174, 544–547. [Google Scholar] [CrossRef]

- Lin, B.; Wen, Z.; Gu, Z.; Huang, S. Morphology and electrochemical performance of Li[Ni1/3Co1/3Mn1/3]O2 cathode material by a slurry spray-drying method. J. Power Sources 2008, 175, 564–569. [Google Scholar] [CrossRef]

- Lin, B.; Wen, Z.; Wang, X.; Liu, Y. Preparation and characterization of carbon-coated Li[Ni1/3Co1/3Mn1/3]O2 cathode material for lithium-ion batteries. J. Solid State Electrochem. 2010, 14, 1807–1811. [Google Scholar] [CrossRef]

- Lin, M.-H.; Cheng, J.-H.; Huang, H.-F.; Chen, U.-F.; Huang, C.-M.; Hsieh, H.-W.; Lee, J.-M.; Chen, J.-M.; Su, W.-N.; Hwang, B.-J. Revealing the mitigation of intrinsic structure transformation and oxygen evolution in a layered Li1.2Ni0.2Mn0.6O2 cathode using restricted charging protocols. J. Power Sources 2017, 359, 539–548. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, K.; He, J.; Chu, X.; He, Y.-B.; Wu, M.; Li, B.; Kang, F. In-situ polymerized lithium polyacrylate (PAALi) as dual-functional lithium source for high-performance layered oxide cathodes. Electrochim. Acta 2017, 249, 43–51. [Google Scholar] [CrossRef]

- Liu, Z.; Hu, G.; Peng, Z.; Deng, X.; Liu, Y. Synthesis and characterization of layered Li(Ni1/3Mn1/3Co1/3)O2 cathode materials by spray-drying method. Trans. Nonferrous Met. Soc. China 2007, 17, 291–295. [Google Scholar] [CrossRef]

- Oh, S.H.; Jeong, W.T.; Cho, W.I.; Cho, B.W.; Woo, K. Electrochemical characterization of high-performance LiNi0.8Co0.2O2 cathode materials for rechargeable lithium batteries. J. Power Sources 2005, 140, 145–150. [Google Scholar] [CrossRef]

- Qiao, Q.Q.; Zhang, H.Z.; Li, G.R.; Ye, S.H.; Wang, C.W.; Gao, X.P. Surface modification of Li-rich layered Li(Li0.17Ni0.25Mn0.58)O2 oxide with Li–Mn–PO4 as the cathode for lithium-ion batteries. J. Mater. Chem. A 2013, 1, 5262. [Google Scholar] [CrossRef]

- Qiao, Q.-Q.; Qin, L.; Li, G.-R.; Wang, Y.-L.; Gao, X.-P. Sn-stabilized Li-rich layered Li(Li0.17Ni0.25Mn0.58)O2 oxide as a cathode for advanced lithium-ion batteries. J. Mater. Chem. A 2015, 3, 17627–17634. [Google Scholar] [CrossRef]

- Qin, L.; Wen, Y.; Xue-Ping, G. Surface Modification of Li-rich Layered Li(Li0.17Ni0.2Mn0.58Co0.05)O2 Oxide with TiO2(B) as the Cathode for Lithium-ion Batteries. J. Inorg. Mater. 2014, 29, 1257. [Google Scholar] [CrossRef]

- Sun, Y.; Xia, Y.; Shiosaki, Y.; Noguchi, H. Preparation and electrochemical properties of LiCoO2-LiNi0.5Mn0.5O2-Li2MnO3 solid solutions with high Mn contents. Electrochim. Acta 2006, 51, 5581–5586. [Google Scholar] [CrossRef]

- Wang, T.; Chen, Z.; Zhao, R.; Li, A.; Chen, H. A New High Energy Lithium ion Batteries Consisting of 0.5Li2MnO3·0.5LiMn0.33Ni0.33Co0.33O2 and Soft Carbon Components. Electrochim. Acta 2016, 194, 1–9. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Z.; Guo, H.; Peng, W.; Li, X. Synthesis of Li2MnO3-stabilized LiCoO2 cathode material by spray-drying method and its high-voltage performance. J. Alloys Compd. 2015, 626, 228–233. [Google Scholar] [CrossRef]

- Watanabe, A.; Matsumoto, F.; Fukunishi, M.; Kobayashi, G.; Ito, A.; Hatano, M.; Ohsawa, Y.; Sato, Y. Relationship between Electrochemical Pre-Treatment and Cycle Performance of a Li-Rich Solid-Solution Layered Li1-alpha[Ni0.18Li0.20+d]alphaCo0.03Mn0.58]O2 Cathode for Li-Ion Secondary Batteries. Electrochemistry 2012, 80, 561–565. [Google Scholar] [CrossRef]

- Wu, H.M.; Tu, J.P.; Chen, X.T.; Yuan, Y.F.; Li, Y.; Zhao, X.B.; Cao, G.S. Synthesis and characterization of LiNi0.8Co0.2O2 as cathode material for lithium-ion batteries by a spray-drying method. J. Power Sources 2006, 159, 291–294. [Google Scholar] [CrossRef]

- Xia, L.; Li, S.-L.; Ai, X.-P.; Yang, H.-X.; Cao, Y.-L. Temperature-sensitive cathode materials for safer lithium-ion batteries. Energy Environ. Sci. 2011, 4, 2845. [Google Scholar] [CrossRef]

- Yang, S.; Huang, G.; Hu, S.; Hou, X.; Huang, Y.; Yue, M.; Lei, G. Improved electrochemical performance of the Li1.2Ni0.13Co0.13Mn0.54O2 wired by CNT networks for lithium-ion batteries. Mater. Lett. 2014, 118, 8–11. [Google Scholar] [CrossRef]

- Yuan, W.; Zhang, H.Z.; Liu, Q.; Li, G.R.; Gao, X.P. Surface modification of Li(Li0.17Ni0.2Co0.05Mn0.58)O2 with CeO2 as cathode material for Li-ion batteries. Electrochim. Acta 2014, 135, 199–207. [Google Scholar] [CrossRef]

- Yue, P.; Wang, Z.; Guo, H.; Wu, F.; He, Z.; Li, X. Effect of synthesis routes on the electrochemical performance of Li[Ni0.6Co0.2Mn0.2]O2 for lithium ion batteries. J. Solid State Electrochem. 2012, 16, 3849–3854. [Google Scholar] [CrossRef]

- Yue, P.; Wang, Z.; Peng, W.; Li, L.; Chen, W.; Guo, H.; Li, X. Spray-drying synthesized LiNi0.6Co0.2Mn0.2O2 and its electrochemical performance as cathode materials for lithium ion batteries. Powder Technol. 2011, 214, 279–282. [Google Scholar] [CrossRef]

- Yue, P.; Wang, Z.; Peng, W.; Li, L.; Guo, H.; Li, X.; Hu, Q.; Zhang, Y. Preparation and electrochemical properties of submicron LiNi0.6Co0.2Mn0.2O2 as cathode material for lithium ion batteries. Scr. Mater. 2011, 65, 1077–1080. [Google Scholar] [CrossRef]

- Yue, P.; Wang, Z.; Zhang, Q.; Yan, G.; Guo, H.; Li, X. Synthesis and electrochemical performance of LiNi0.6Co0.2Mn0.2O2/reduced graphene oxide cathode materials for lithium-ion batteries. Ionics 2013, 19, 1329–1334. [Google Scholar] [CrossRef]

- Zhang, L.; Li, D.; Wang, X.; Noguchi, H.; Yoshio, M. Properties of Li-Ni-Mn-O electrode materials prepared from solution spray synthesized powders. Mater. Lett. 2005, 59, 2693–2697. [Google Scholar] [CrossRef]

- Zhang, L.; Muta, T.; Noguchi, H.; Wang, X.; Zhou, M.; Yoshio, M. Peculiar electrochemical behaviors of (1−x)LiNiO2·xLi2TiO3 cathode materials prepared by spray-drying. J. Power Sources 2003, 117, 137–142. [Google Scholar] [CrossRef]

- Zhang, L.; Noguchi, H.; Li, D.; Muta, T.; Wang, X.; Yoshio, M.; Taniguchi, I. Synthesis and electrochemistry of cubic rocksalt Li–Ni–Ti–O compounds in the phase diagram of LiNiO2–LiTiO2–Li[Li1/3Ti2/3]O2. J. Power Sources 2008, 185, 534–541. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, X.; Muta, T.; Li, D.; Noguchi, H.; Yoshio, M.; Ma, R.; Takada, K.; Sasaki, T. The effects of extra Li content, synthesis method, sintering temperature on synthesis and electrochemistry of layered LiNi1/3Mn1/3Co1/3O2. J. Power Sources 2006, 162, 629–635. [Google Scholar] [CrossRef]

- Kim, J.-M.; Kumagai, N.; Komaba, S. Improved electrochemical properties of Li1+x(Ni0.3Co0.4Mn0.3)O2−δ (x = 0, 0.03 and 0.06) with lithium excess composition prepared by a spray-drying method. Electrochim. Acta 2006, 52, 1483–1490. [Google Scholar] [CrossRef]

- Gao, J.; Huang, Z.; Li, J.; He, X.; Jiang, C. Preparation and characterization of Li1.2Ni0.13Co0.13Mn0.54O2 cathode materials for lithium-ion battery. Ionics 2014, 20, 301–307. [Google Scholar] [CrossRef]

- Wang, Z.; Yin, Y.; Ren, Y.; Wang, Z.; Gao, M.; Ma, T.; Zhuang, W.; Lu, S.; Fan, A.; Amine, K. High performance lithium-manganese-rich cathode material with reduced impurities. Nano Energy 2017, 31, 247–257. [Google Scholar] [CrossRef]

- Ji, M.-J.; Kim, E.-K.; Ahn, Y.-T.; Choi, B.-H. Crystallinity and Battery Properties of Lithium Manganese Oxide Spinel with Lithium Titanium Oxide Spinel Coating Layer on Its Surface. J. Korean Ceram. Soc. 2010, 47, 633–637. [Google Scholar] [CrossRef]

- Tu, J.P.; Wu, H.M.; Yang, Y.Z.; Zhang, W.K. Spray-drying technology for the synthesis of nanosized LiMn2O4 cathode material. Mater. Lett. 2007, 61, 864–867. [Google Scholar] [CrossRef]

- Wan, C.; Cheng, M.; Wu, D. Synthesis of spherical spinel LiMn2O4 with commercial manganese carbonate. Powder Technol. 2011, 210, 47–51. [Google Scholar] [CrossRef]

- Wan, C.; Wu, M.; Wu, D. Synthesis of spherical LiMn2O4 cathode material by dynamic sintering of spray-dried precursors. Powder Technol. 2010, 199, 154–158. [Google Scholar] [CrossRef]

- Wu, H.M.; Tu, J.P.; Yang, Y.Z.; Shi, D.Q. Spray-drying process for synthesis of nanosized LiMn2O4 cathode. J. Mater. Sci. 2006, 41, 4247–4250. [Google Scholar] [CrossRef]

- Wu, H.M.; Tu, J.P.; Chen, X.T.; Li, Y.; Zhao, X.B.; Cao, G.S. Electrochemical study on LiMn2O4 as cathode material for lithium ion batteries. J. Electroanal. Chem. 2006, 586, 180–183. [Google Scholar] [CrossRef]

- Wu, H.M.; Tu, J.P.; Yuan, Y.F.; Li, Y.; Zhao, X.B.; Cao, G.S. Structural, morphological and electrochemical characteristics of spinel LiMn2O4 prepared by spray-drying method. Scr. Mater. 2005, 52, 513–517. [Google Scholar] [CrossRef]

- Wu, H.M.; Tu, J.P.; Yuan, Y.F.; Li, Y.; Zhao, X.B.; Cao, G.S. Preparation of LiMn2O4 by two methods for lithium ion batteries. Mater. Chem. Phys. 2005, 93, 461–465. [Google Scholar] [CrossRef]

- Wu, H.M.; Tu, J.P.; Yuan, Y.F.; Li, Y.; Zhang, W.K.; Huang, H. Electrochemical performance of nanosized LiMn2O4 for lithium-ion batteries. Phys. B Condens. Matter 2005, 369, 221–226. [Google Scholar] [CrossRef]

- Wu, H.M.; Tu, J.P.; Yuan, Y.F.; Li, Y.; Zhao, X.B.; Cao, G.S. Synthesis and electrochemical characteristics of spinel LiMn2O4 via a precipitation spray-drying process. Mater. Sci. Eng. B 2005, 119, 75–79. [Google Scholar] [CrossRef]

- Huang, H.; Wang, C.; Zhang, W.K.; Gan, Y.P.; Kang, L. Electrochemical study on LiCo1/6Mn11/6O4 as cathode material for lithium ion batteries at elevated temperature. J. Power Sources 2008, 184, 583–588. [Google Scholar] [CrossRef]

- Zhang, W.K.; Wang, C.; Huang, H.; Gan, Y.P.; Wu, H.M.; Tu, J.P. Synthesis and electrochemical properties of spinel LiCo1/6Mn11/6O4 powders by a spray-drying method. J. Alloys Compd. 2008, 465, 250–254. [Google Scholar] [CrossRef]

- Jiang, Q.; Hu, G.; Peng, Z.; Du, K.; Cao, Y.; Tang, D. Preparation of spherical spinel LiCr0.04Mn1.96O4 cathode materials based on the slurry spray-drying method. Rare Met. 2009, 28, 618–623. [Google Scholar] [CrossRef]

- Peng, Z.D.; Jiang, Q.L.; Du, K.; Wang, W.G.; Hu, G.R.; Liu, Y.X. Effect of Cr-sources on performance of Li1.05Cr0.04Mn1.96O4 cathode materials prepared by slurry spray-drying method. J. Alloys Compd. 2010, 493, 640–644. [Google Scholar] [CrossRef]

- Wu, H.M.; Tu, J.P.; Chen, X.T.; Li, Y.; Zhao, X.B.; Cao, G.S. Effects of Ni-ion doping on electrochemical characteristics of spinel LiMn2O4 powders prepared by a spray-drying method. J. Solid State Electrochem. 2006, 11, 173–176. [Google Scholar] [CrossRef]

- Wu, H.M.; Tu, J.P.; Chen, X.T.; Shi, D.Q.; Zhao, X.B.; Cao, G.S. Synthesis and characterization of abundant Ni-doped LiNixMn2−xO4 (x = 0.1–0.5) powders by spray-drying method. Electrochim. Acta 2006, 51, 4148–4152. [Google Scholar] [CrossRef]

- Li, D.; Ito, A.; Kobayakawa, K.; Noguchi, H.; Sato, Y. Electrochemical characteristics of LiNi0.5Mn1.5O4 prepared by spray-drying and post-annealing. Electrochim. Acta 2007, 52, 1919–1924. [Google Scholar] [CrossRef]

- He, S.; Zhang, Q.; Liu, W.; Fang, G.; Sato, Y.; Zheng, J.; Li, D. Influence of post-annealing in N2 on structure and electrochemical characteristics of LiNi0.5Mn1.5O4. Chem. Res. Chin. Univ. 2013, 29, 329–332. [Google Scholar] [CrossRef]

- Risthaus, T.; Wang, J.; Friesen, A.; Wilken, A.; Berghus, D.; Winter, M.; Li, J. Synthesis of spinel LiNi0.5Mn1.5O4 with secondary plate morphology as cathode material for lithium ion batteries. J. Power Sources 2015, 293, 137–142. [Google Scholar] [CrossRef]

- Wu, H.M.; Tu, J.P.; Yuan, Y.F.; Li, Y.; Zhao, X.B.; Cao, G.S. Electrochemical and ex situ XRD studies of a LiMn1.5Ni0.5O4 high-voltage cathode material. Electrochim. Acta 2005, 50, 4104–4108. [Google Scholar] [CrossRef]