Fabrication and Tribological Performance of Zr-Coated Carbide against 40Cr Hardened Steel

Abstract

:1. Introduction

2. Experimental Details

2.1. Preparation of Pure Zr Coating

2.2. Sliding Friction Tests

3. Results and Discussion

3.1. Properties of the Zr Coating

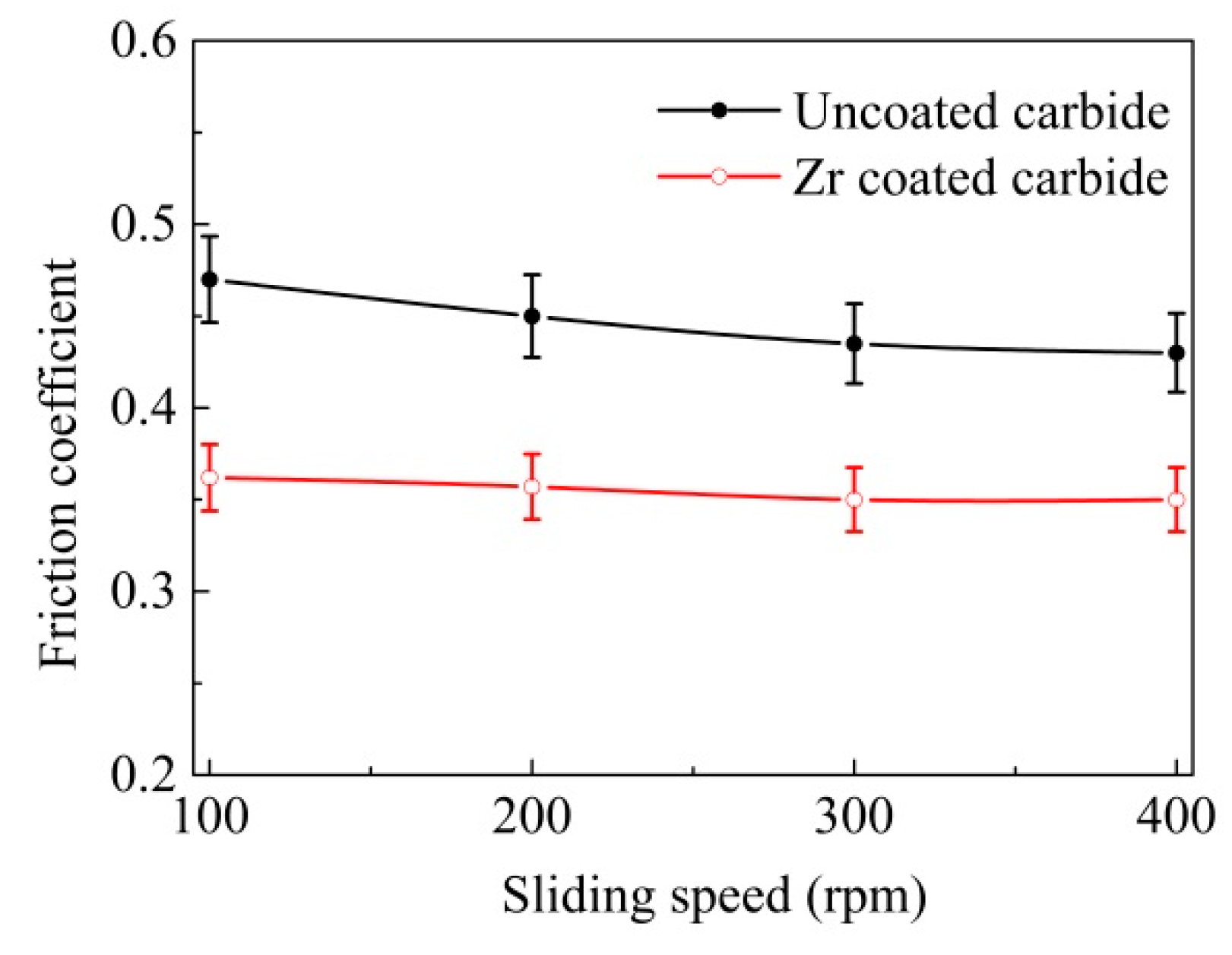

3.2. Tribological Behaviors of Zr Coating

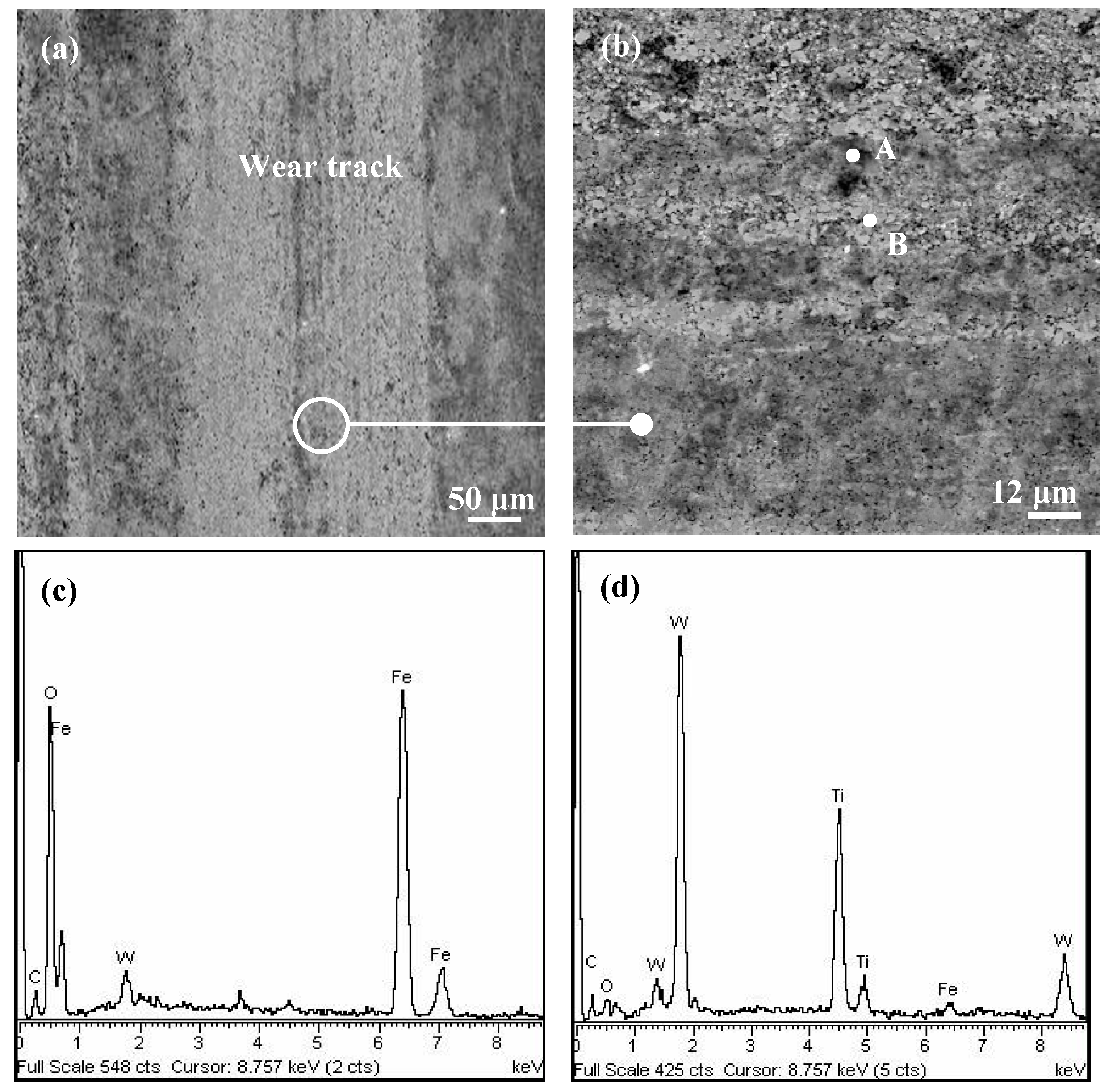

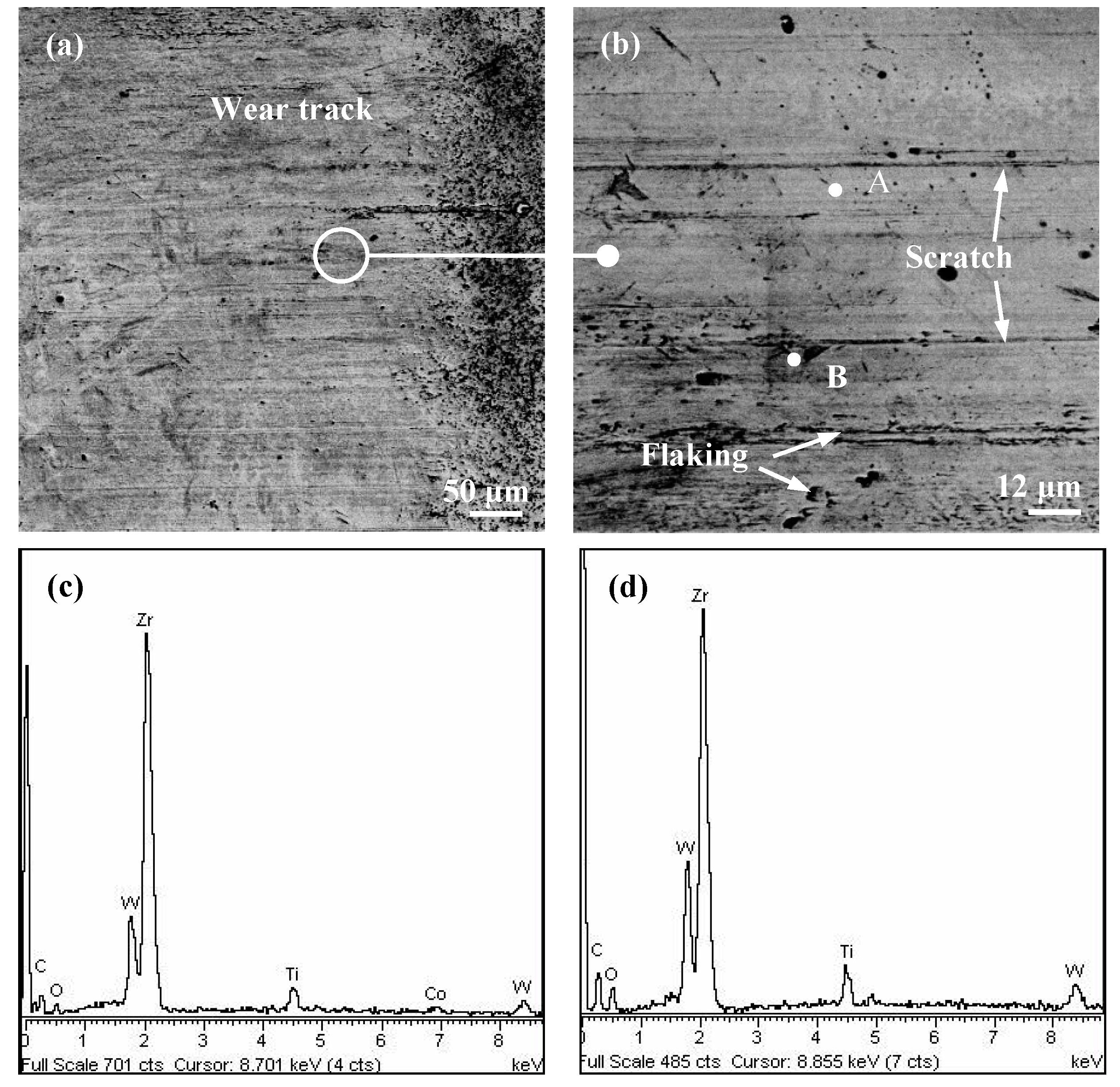

3.3. Wear Surface Studies

4. Conclusions

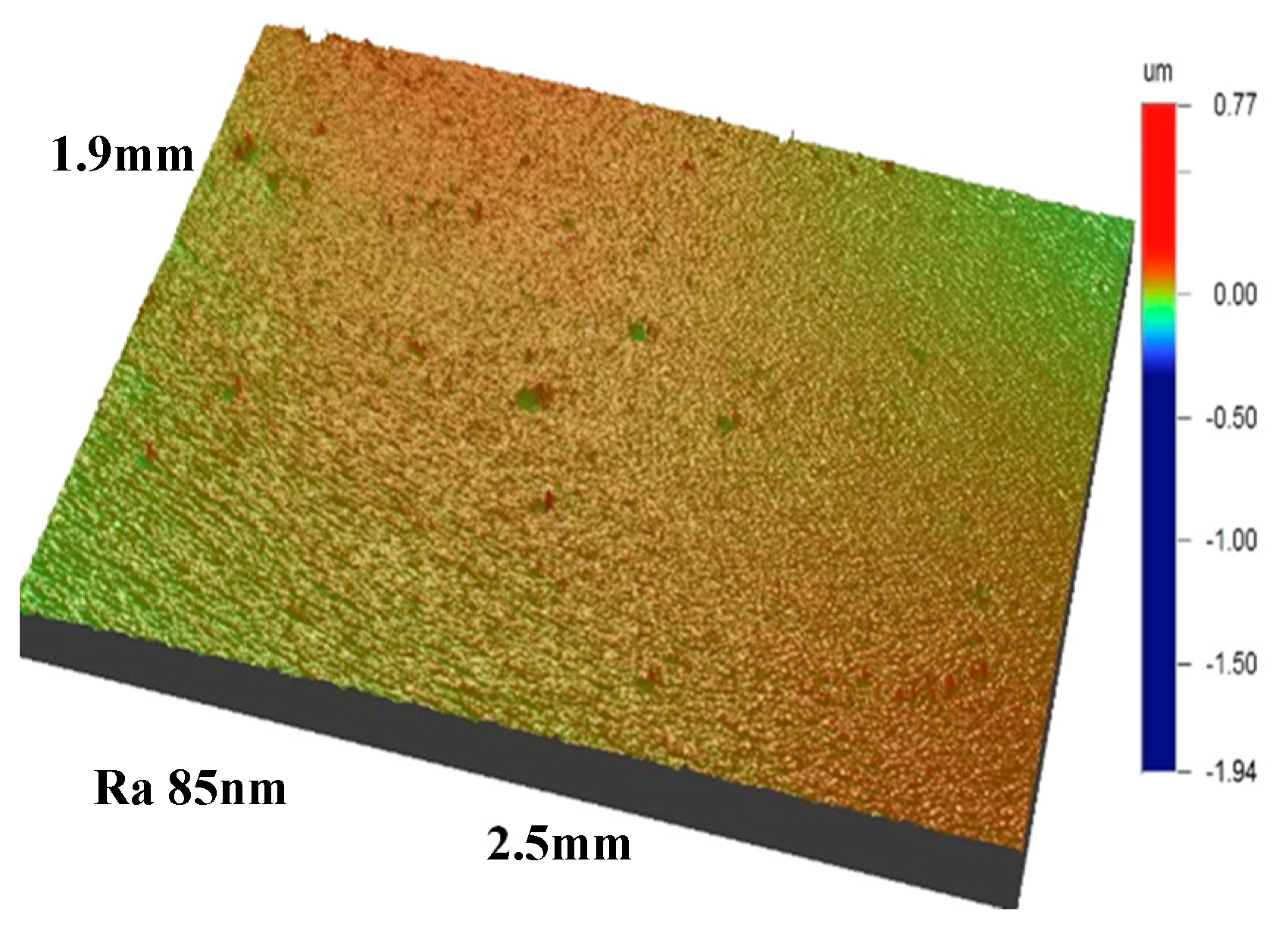

- PVD Zr coating deposited on the carbide surface exhibited excellent adhesive strength. The coating adhesion strength reached about 60 N. The surface micro-hardness of Zr coating was about 12 GPa, the coating thickness was about 3.0 µm, and the surface roughness Ra was about 85 nm;

- The average friction coefficient of Zr coated carbide was 20%–30% lower than that of the uncoated one under the same sliding test conditions. The coefficient of friction decreased with the increasing applied load, and changed slightly with varying sliding speed;

- The Zr coated carbide could reduce the adhesive wear compared with the uncoated one, and the main wear mechanisms of the Zr coating were abrasive wear, coating flaking, and delamination.

Author Contributions

Funding

Conflicts of Interest

References

- Ai, X. High Speed Machining Technology; National Defense Industry Press: Beijing, China, 2004. [Google Scholar]

- Yang, J.G.; Tan, D.Q.; Hao, H. Cemented Carbide; Central South University Press: Changsha, China, 2012. [Google Scholar]

- Dong, H.K.; Kang, M.C.; Kim, J.S.; Ok, J.T.; Kim, K.H. A comparative study on cutting performance of TiN-coated tungsten carbide cutting tool with a cobalt interlayer. Surf. Coat. Technol. 2005, 200, 1933–1938. [Google Scholar] [CrossRef]

- Haubner, R.; Lessiak, M.; Pitonak, R.; Köpf, A.; Weissenbacher, R. Evolution of conventional hard coatings for its use on cutting tools. J. Refract. Met. Hard Mater. 2016, 62, 210–218. [Google Scholar] [CrossRef]

- Manaud, J.P.; Poulon, A.; Gomez, S.; Petitcorps, Y.L. A comparative study of CrN, ZrN, NbN and TaN layers as cobalt diffusion barriers for CVD diamond deposition on WC-Co tools. Surf. Coat. Technol. 2007, 202, 222–231. [Google Scholar] [CrossRef]

- Deng, J.X.; Liu, J.H.; Zhao, J.L.; Song, W.L.; Niu, M. Friction and wear behaviors of the PVD ZrN coated carbide in sliding wear tests and in machining processes. Wear 2008, 264, 298–307. [Google Scholar] [CrossRef]

- Xiao, B.J.; Chen, Y.; Dai, W.; Kwork, K.Y.; Zhang, T.F.; Wang, Q.M.; Cheng, Y.W.; Kwang, H.K. Microstructure, mechanical properties and cutting performance of AlTiN coatings prepared via arc ion plating using the arc splitting technique. Surf. Coat. Technol. 2017, 311, 98–103. [Google Scholar] [CrossRef]

- Zheng, G.M.; Li, L.; Li, Z.Y.; Gao, J.; Niu, Z.W. Wear mechanisms of coated tools in high-speed hard turning of high strength steel. Int. J. Adv. Manuf. Technol. 2018, 94, 4553–4563. [Google Scholar] [CrossRef]

- Arulkirubakaran, D.; Senthilkumar, V. Performance of TiN and TiAlN coated micro-grooved tools during machining of Ti-6Al-4V alloy. J. Refract. Met. Hard Mater. 2017, 62, 47–57. [Google Scholar] [CrossRef]

- Li, S.P.; Deng, J.X.; Yan, G.Y.; Cheng, H.W. Effects of nitrogen flowrates on properties of TiSiN coatings deposited by arc ion plating combining with medium-frequency magnetron sputtering. J. Refract. Met. Hard Mater. 2014, 42, 108–115. [Google Scholar] [CrossRef]

- Chowdhury, M.S.I.; Chowdhury, S.; Yamamoto, K.; Beake, B.D.; Bose, B.; Elfizy, A.; Cavelli, D.; Dosbaeva, G.; Aramesh, M.; Fox-Rabinovich, G.S.; et al. Wear behaviour of coated carbide tools during machining of Ti6Al4V aerospace alloy associated with strong built up edge formation. Surf. Coat. Technol. 2017, 313, 319–327. [Google Scholar] [CrossRef]

- Yan, P.; Chen, K.; Wang, Y.; Zhou, H.; Peng, Z.; Jiao, L.; Wang, X.B. Design and performance of property gradient ternary nitride coating based on process control. Materials 2018, 11, 758. [Google Scholar] [CrossRef] [PubMed]

- Ma, Q.; Li, L.; Xu, Y.; Ma, X.; Xu, Y.; Liu, H. Effect of Ti content on the microstructure and mechanical properties of TiAlSiN nanocomposite coatings. J. Refract. Met. Hard Mater. 2016, 59, 114–120. [Google Scholar] [CrossRef]

- Bushlya, V.; Johansson, D.; Lenrick, F.; Ståhl, J.E.; Schultheiss, F. Wear mechanisms of uncoated and coated cemented carbide tools in machining lead-free silicon brass. Wear 2017, 376–377, 143–151. [Google Scholar] [CrossRef]

- Cai, F.; Huang, X.; Yang, Q.; Wei, R.H.; Nagy, D. Microstructure and tribological properties of CrN and CrSiCN coatings. Surf. Coat. Technol. 2010, 205, 182–188. [Google Scholar] [CrossRef]

- Wu, Z.; Zhou, F.; Wang, Q.; Zhou, Z.; Yan, J.; Li, K. Influence of trimethylsilane flow on the microstructure, mechanical and tribological properties of CrSiCN coatings in water lubrication. Appl. Surf. Sci. 2015, 355, 516–530. [Google Scholar] [CrossRef]

- Lorenzo-Martin, C.; Ajayi, O.; Erdemir, A.; Wei, R. Tribological performance of quaternary CrSiCN coatings under dry and lubricated conditions. Wear 2017, 376–377, 1682–1690. [Google Scholar] [CrossRef]

- Shi, M.S. Solid Lubricating Materials; China Chemical Industry Press: Beijing, China, 2000. [Google Scholar]

- Lian, Y.S.; Deng, J.X.; Li, S.P.; Xing, Y.Q.; Chen, Y.Y. Preparation and cutting performance of WS2, soft-coated tools. Int. J. Adv. Manuf. Technol. 2013, 67, 1027–1033. [Google Scholar] [CrossRef]

- Deng, J.X.; Lian, Y.S.; Wu, Z.; Xing, Y.Q. Performance of femtosecond laser-textured cutting tools deposited with WS2, solid lubricant coatings. Surf. Coat. Technol. 2013, 222, 135–143. [Google Scholar] [CrossRef]

- Lian, Y.S.; Deng, J.X.; Yan, G.Y.; Cheng, H.W.; Zhao, J. Preparation of tungsten disulfide (WS2) soft-coated nano-textured self-lubricating tool and its cutting performance. Int. J. Adv. Manuf. Technol. 2013, 68, 2033–2042. [Google Scholar] [CrossRef]

- Qin, Y.K.; Xiong, D.S.; Li, J.L. Tribological properties of laser surface textured and plasma electrolytic oxidation duplex-treated Ti6Al4V alloy deposited with MoS2 film. Surf. Coat. Technol. 2015, 269, 266–272. [Google Scholar] [CrossRef]

- Zhang, K.D.; Deng, J.X.; Lei, S.T.; Yu, X. Effect of micro/nano-textures and burnished MoS2 addition on the tribological properties of PVD TiAlN coatings against AISI 316 stainless steel. Surf. Coat. Technol. 2016, 291, 282–395. [Google Scholar] [CrossRef]

- Watanabe, S.; Noshiro, J.; Miyake, S. Tribological characteristics of WS2/MoS2 solid lubricating multilayer films. Surf. Coat. Technol. 2004, 183, 347–351. [Google Scholar] [CrossRef]

- Song, W.L.; Deng, J.X.; Zhang, H.; Yan, P. Study on cutting forces and experiment of MoS2/Zr-coated cemented carbide tool. Int. J. Adv. Manuf. Technol. 2010, 49, 903–909. [Google Scholar] [CrossRef]

- Xing, Y.Q.; Deng, J.X.; Zhou, Y.H.; Li, S.P. Fabrication and tribological properties of Al2O3/TiC ceramic with nano-textures and WS2/Zr soft-coatings. Surf. Coat. Technol. 2014, 258, 699–710. [Google Scholar] [CrossRef]

- Martins, R.C.; Paulo, S.M.; Seabra, J.O. MoS2/Ti low-friction coating for gears. Tribol. Int. 2006, 39, 1686–1697. [Google Scholar] [CrossRef]

- Renevier, N.M.; Oosterling, H.; König, U.; Dautzenberg, H.; Kim, B.J.; Geppert, L. Performance and limitations of MoS2/Ti composite coated inserts. Surf. Coat. Technol. 2003, 172, 13–23. [Google Scholar] [CrossRef]

- Rigato, V.; Maggioni, G.; Patelli, A.; Boscarino, D.; Renevier, N.M.; Teer, D.G. Properties of sputter-deposited MoS2/metal composite coatings deposited by closed field unbalanced magnetron sputter ion plating. Surf. Coat. Technol. 2000, 131, 206–210. [Google Scholar] [CrossRef]

- Renevier, N.M.; Hamphire, J.; Fox, V.C. Advantages of using self-lubricating, hard, wear-resistant MoS2-based coatings. Surf. Coat. Technol. 2001, 142–144, 67–77. [Google Scholar] [CrossRef]

- Bülbül, F. The Structural and Tribological Properties of MoS2-Ti Composite Solid Lubricants. Tribol. T. 2004, 47, 218–226. [Google Scholar] [CrossRef]

- Kao, W.H. Tribological properties and high speed drilling application of MoS2-Cr coatings. Wear 2005, 258, 812–825. [Google Scholar] [CrossRef]

- Deng, J.X.; Song, W.L.; Zhang, H.; Zhao, J.L. Friction and wear behaviours of MoS2/Zr coatings against hardened steel. Surf. Eng. 2008, 24, 410–415. [Google Scholar] [CrossRef]

- Xing, Y.Q.; Deng, J.X.; Wang, X.; Meng, R. Effect of laser surface textures combined with multi-solid lubricant coatings on the tribological properties of Al2O3/TiC ceramic. Wear 2015, 342–343, 1–12. [Google Scholar] [CrossRef]

- Song, W.L.; Wang, Z.C.; Deng, J.X.; Zhou, K.; Wang, S.J.; Guo, Z.X. Cutting temperature analysis and experiment of Ti-MoS2/Zr-coated cemented carbide tool. Int. J. Adv. Manuf. Technol. 2017, 93, 799–809. [Google Scholar] [CrossRef]

- Saklakoglu, N.; Saklakoglu, I.E.; Ceyhun, V.; Monteiro, O.R.; Brown, I.G. Sliding wear behavior of Zr-ion-implanted D3 tool steel. Tribol. Int. 2007, 40, 794–799. [Google Scholar] [CrossRef]

- Wang, Y.H.; Zang, J.B.; Wang, M.Z.; Guan, Y.; Zheng, Y.Z. Properties and applications of Ti-coated diamond grits. J. Mater. Process Tech. 2002, 129, 369–372. [Google Scholar] [CrossRef]

- Wen, S.Z. Principle of Tribology; Tinghua University Press: Beijing, China, 2012. [Google Scholar]

| Composition (wt. %) | Density (g/cm3) | Hardness (GPa) | Flexural Strength (MPa) | Young′s Modulus (GPa) | Thermal Expansion Coefficient (10−6/K) | Poisson′s Ratio |

|---|---|---|---|---|---|---|

| WC + 14%TiC + 6%Co | 11.6 | 15.4 | 1200 | 510 | 6.50 | 0.25 |

| Substrate | Base Pressure (Pa) | Temperature (°C) | Ar Pressure (Pa) | Zr Current (A) | Deposition Temperature (°C) | Deposition Time (min) |

|---|---|---|---|---|---|---|

| Cemented carbide | 6.5×10−3 | 220 | 0.6 | 90 | 250 | 90 |

| Element Content (Unit) | Point A in Figure 2a (wt. %) | Point B in Figure 2a (wt. %) |

|---|---|---|

| Zr | 100 | 92.37 |

| W | 4.04 | |

| Ti | 2.51 | |

| C | 1.08 | |

| Total | 100.00 | 100.00 |

| Substrate | Coating | Micro-Hardness (GPa) | Thickness (μm) | Adhesion Strength (N) | Surface Roughness Ra (nm) |

|---|---|---|---|---|---|

| Cemented carbide | Zr | 12.0 ± 0.5 | 3.0 ± 0.1 | 60 ± 5 | 85 ± 5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, W.; Xia, Z.; Wang, S.; Zhang, X. Fabrication and Tribological Performance of Zr-Coated Carbide against 40Cr Hardened Steel. Materials 2018, 11, 1248. https://doi.org/10.3390/ma11071248

Song W, Xia Z, Wang S, Zhang X. Fabrication and Tribological Performance of Zr-Coated Carbide against 40Cr Hardened Steel. Materials. 2018; 11(7):1248. https://doi.org/10.3390/ma11071248

Chicago/Turabian StyleSong, Wenlong, Zixiang Xia, Shoujun Wang, and Xuan Zhang. 2018. "Fabrication and Tribological Performance of Zr-Coated Carbide against 40Cr Hardened Steel" Materials 11, no. 7: 1248. https://doi.org/10.3390/ma11071248

APA StyleSong, W., Xia, Z., Wang, S., & Zhang, X. (2018). Fabrication and Tribological Performance of Zr-Coated Carbide against 40Cr Hardened Steel. Materials, 11(7), 1248. https://doi.org/10.3390/ma11071248