Microstructure and Mechanical Properties of a Cold-Rolled Ultrafine-Grained Dual-Phase Steel

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

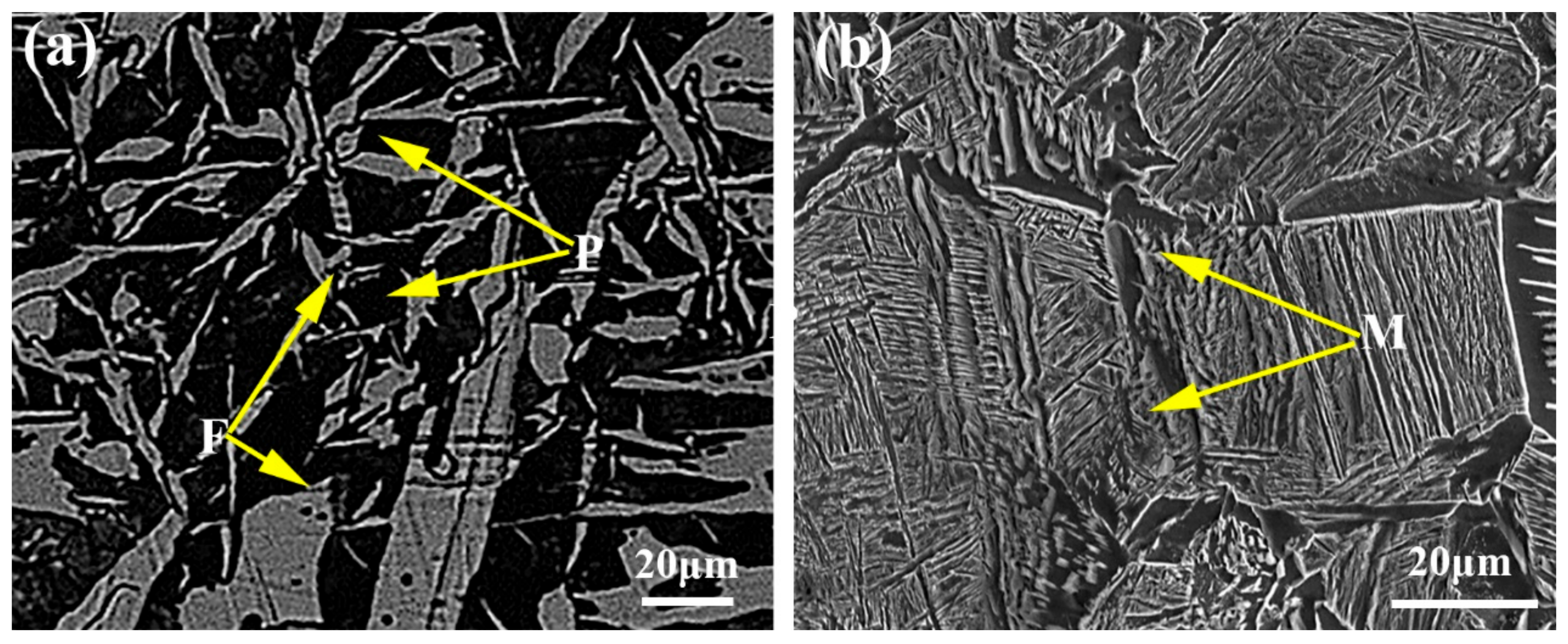

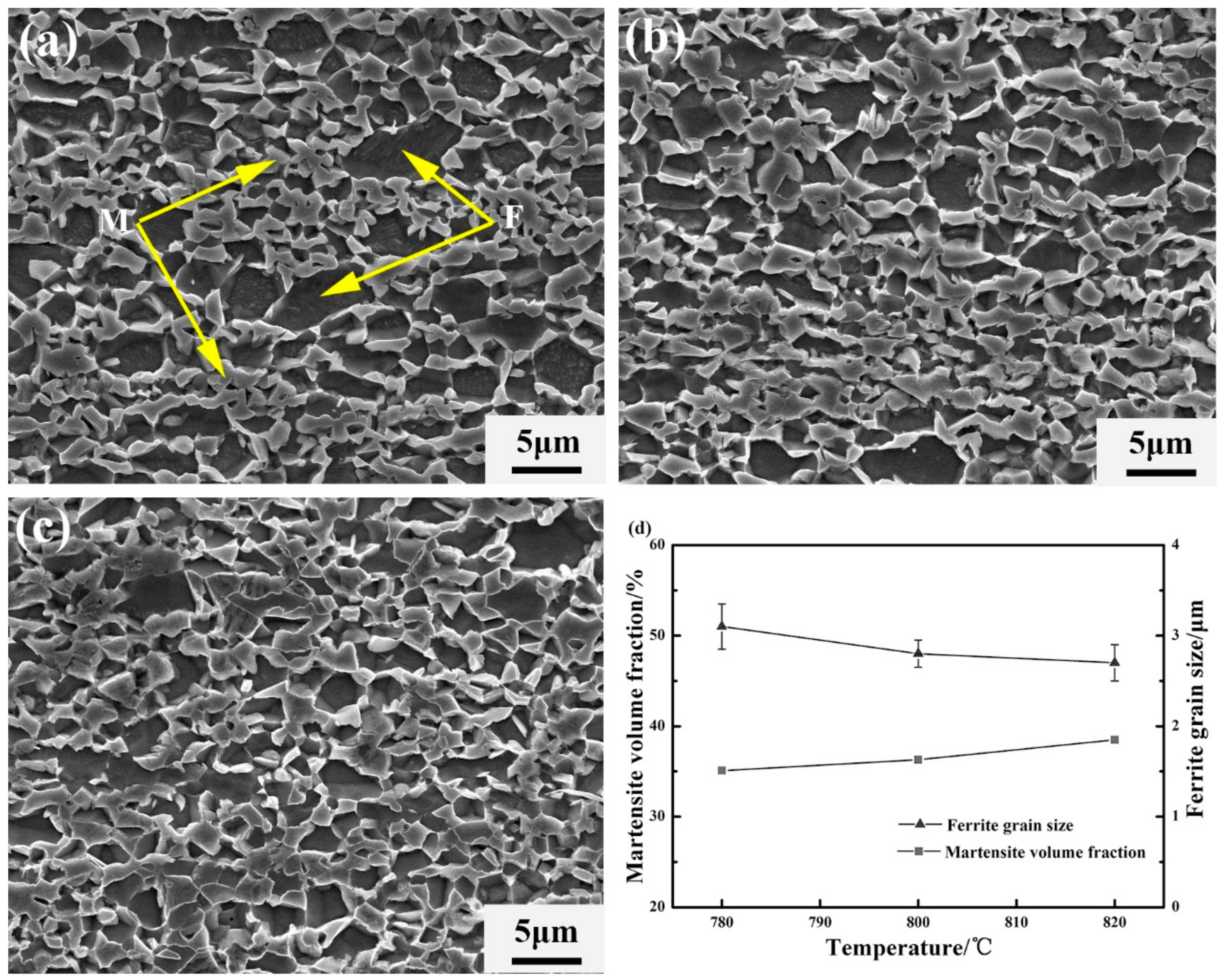

3.1. Microstructure Evolution During Processing

3.2. Tensile Properties

3.3. Fractography

4. Conclusions

- Ultrafine-grained ferrite–martensite dual-phase steels were produced by intercritically annealing the cold-rolled fibrous DP microstructure. The generated dual-phase steels consisted of UFG ferrite and uniformly distributed martensite islands. Ferrite grain size and martensite island size were ~2.7 μm and ~2.9 μm, respectively.

- The UFG-DP steels exhibit an excellent strain hardening behavior, which is affected by the grain refinement of both ferrite and martensite, enabling the simultaneous enhancement of UTS and UE to 1.2 GPa and 8%, respectively.

- The UFG-DP steels fractured in a partially brittle manner. A mixture of small dimples and cleavage facets was observed in the fracture surfaces. The fracture strain characterized by area reduction was decreased when the volume fraction of martensite was increased.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Ghassemi-Armaki, H.; Maaß, R.; Bhat, S.P.; Sriram, S.; Greer, J.R.; Kumar, K.S. Deformation response of ferrite and martensite in a dual-phase steel. Acta Mater. 2014, 62, 197–211. [Google Scholar] [CrossRef]

- Tasan, C.C.; Diehl, M.; Yan, D.; Bechtold, M.; Roters, F.; Schemmann, L. An overview of dual-phase steels: Advances in microstructure-oriented processing and micromechanically guided design. Ann. Rev. Mater. Res. 2015, 45, 391–431. [Google Scholar] [CrossRef]

- Wang, X.G.; Wang, L.; Huang, M.X. Kinematic and thermal characteristics of Lüders and Portevin-Le Châtelier bands in a medium Mn transformation-induced plasticity steel. Acta Mater. 2017, 124, 17–29. [Google Scholar] [CrossRef]

- Kang, J.Y.; Lee, H.C.; Han, S.H. Effect of Al and Mo on the textures and microstructures of dual phase steels. Mater. Sci. Eng. A 2011, 530, 183–190. [Google Scholar] [CrossRef]

- Lai, Q.; Bouaziz, O.; Gouné, M.; Perlade, A.; Bréchet, Y.; Pardoen, T. Microstructure refinement of dual-phase steels with 3.5 wt % mn: Influence on plastic and fracture behavior. Mater. Sci. Eng. A 2015, 638, 78–89. [Google Scholar] [CrossRef]

- Peranio, N.; Li, Y.J.; Roters, F.; Raabe, D. Microstructure and texture evolution in dual-phase steels: Competition between recovery, recrystallization, and phase transformation. Mater. Sci. Eng. A 2010, 527, 4161–4168. [Google Scholar] [CrossRef]

- Peng-Heng, C.; Preban, A.G. The effect of ferrite grain size and martensite volume fraction on the tensile properties of dual phase steel. Acta Mater. 1985, 33, 897–903. [Google Scholar] [CrossRef]

- Schino, A.D.; Guarnaschelli, C. Microstructure and cleavage resistance of high strength steels. Mater. Sci. Forum 2010, 638–642, 3188–3193. [Google Scholar] [CrossRef]

- Schino, A.D.; Nunzio, P.E.D. Effect of Nb microalloying on the heat affected zone microstructure of girth welded joints. Mater. Lett. 2017, 186, 86–89. [Google Scholar] [CrossRef]

- Bag, A.; Ray, K.K.; Dwarakadasa, E.S. Influence of martensite content and morphology on tensile and impact properties of high-martensite dual-phase steels. Metall. Mater. Trans. A 1999, 30, 1193–1202. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Raabe, D. Effect of grain refinement to 1 μm on strength and toughness of dual-phase steels. Mater. Sci. Eng. A 2010, 527, 7832–7840. [Google Scholar] [CrossRef]

- Terao, N.; Cauwe, B. Influence of additional elements (Mo, Nb, Ta and B) on the mechanical properties of high-manganese dual-phase steels. Mater. Sci. 1988, 23, 1769–1778. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Raabe, D. Microstructure control during fabrication of ultrafine grained dual-phase steel: Characterization and effect of intercritical annealing parameters. ISIJ Int. 2012, 52, 874–883. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Raabe, D. Ultrafine grained ferrite/martensite dual phase steel fabricated by large strain warm deformation and subsequent intercritical annealing. ISIJ Int. 2008, 48, 1096–1101. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Adachi, Y.; Ponge, D. Deformation and fracture mechanisms in fine- and ultrafine-grained ferrite/martensite dual-phase steels and the effect of aging. Acta Mater. 2011, 59, 658–670. [Google Scholar] [CrossRef]

- Azizi-Alizamini, H.; Militzer, M.; Poole, W.J. Formation of ultrafine grained dual phase steels through rapid heating. ISIJ Int. 2011, 51, 958–964. [Google Scholar] [CrossRef]

- Son, Y.I.; Lee, Y.K.; Park, K.T.; Lee, C.S.; Shin, D.H. Ultrafine grained ferrite–martensite dual phase steels fabricated via equal channel angular pressing: Microstructure and tensile properties. Acta Mater. 2005, 53, 3125–3134. [Google Scholar] [CrossRef]

- Tsuji, N.; Kamikawa, N.; Ueji, R.; Takata, N.; Koyama, H.; Terada, D. Managing both strength and ductility in ultrafine grained steels. ISIJ Int. 2008, 48, 1114–1121. [Google Scholar] [CrossRef]

- Delincé, M.; Bréchet, Y.; Embury, J.D.; Geers, M.G.D.; Jacques, P.J.; Pardoen, T. Structure–property optimization of ultrafine-grained dual-phase steels using a microstructure-based strain hardening model. Acta Mater. 2007, 55, 2337–2350. [Google Scholar] [CrossRef]

- Dong, H.S.; Kim, B.C.; Park, K.T.; Choo, W.Y. Microstructural changes in equal channel angular pressed low carbon steel by static annealing. Acta Mater. 2000, 48, 3245–3252. [Google Scholar]

- Park, K.T.; Han, S.Y.; Ahn, B.D.; Shin, D.H.; Lee, Y.K.; Um, K.K. Ultrafine grained dual phase steel fabricated by equal channel angular pressing and subsequent intercritical annealing. Scr. Mater. 2004, 51, 909–913. [Google Scholar] [CrossRef]

- Tsuji, N. Advanced Steels; Springer: Berlin/Heidelberg, Germany, 2011; pp. 119–129. [Google Scholar]

- Chbihi, A.; Barbier, D.; Germain, L.; Hazotte, A.; Gouné, M. Interactions between ferrite recrystallization and austenite formation in high-strength steels. Mater. Sci. 2014, 49, 3608–3621. [Google Scholar] [CrossRef]

- Nakada, N.; Arakawa, Y.; Park, K.S. Dual phase structure formed by partial reversion of cold-deformed martensite. Mater. Sci. Eng. A 2012, 553, 128–133. [Google Scholar] [CrossRef]

- Huang, J.; Poole, W.J.; Militzer, M. Austenite formation during intercritical annealing. Metall. Mater. Trans. A 2004, 35, 3363–3375. [Google Scholar] [CrossRef]

- Mohsen, A.A.; Goodarzi, M.; Kheirandish, S. Kinetics of austenite formation in dual phase steels. ISIJ Int. 2008, 48, 1251–1255. [Google Scholar]

- Ma, X.L.; Huang, C.X.; Xu, W.Z. Strain hardening and ductility in a coarse-grain/nanostructure laminate material. Scr. Mater. 2015, 103, 57–60. [Google Scholar] [CrossRef] [Green Version]

- Considère, M. Memoir on the use of iron and steel in structures. Ann. Ponts Chaussees 1885, 9, 574. [Google Scholar]

- Wei, R.; Enomoto, M.; Hadian, R.; Zurob, H.S.; Purdy, G.R. Growth of austenite from as-quenched martensite during intercritical annealing in an Fe-0.1C-3Mn-1.5Si alloy. Acta Mater. 2013, 61, 697–707. [Google Scholar] [CrossRef]

- Krauss, G. Martensite in steel: Strength and structure. Mater. Sci. Eng. A 1999, 99, 40–57. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, S.B.; Ray, K.K. Influence of bainite/martensite-content on the tensile properties of low carbon dual-phase steels. Mater. Sci. Eng. A 2008, 474, 270–282. [Google Scholar] [CrossRef]

- Kocks, U.F.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Kunio, T.; Shimizu, M.; Yamada, K.; Suzuki, H. An effect of the second phase morphology on the tensile fracture characteristics of carbon steels. Eng. Fract. Mech. 1975, 7, 411–417. [Google Scholar] [CrossRef]

- Uggowitzer, P.; Stüwe, H.P. The tensile fracture of ferritic-martensitic carbon steels. Mater. Sci. Eng. 1982, 55, 181–189. [Google Scholar] [CrossRef]

| Element | Content |

|---|---|

| C | 0.19 |

| Mn | 1.01 |

| Si | 1.46 |

| Fe | Balance |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Z.; Gao, B.; Lai, Q.; Chen, X.; Cao, Y.; Liu, M.; Zhou, H. Microstructure and Mechanical Properties of a Cold-Rolled Ultrafine-Grained Dual-Phase Steel. Materials 2018, 11, 1399. https://doi.org/10.3390/ma11081399

Pan Z, Gao B, Lai Q, Chen X, Cao Y, Liu M, Zhou H. Microstructure and Mechanical Properties of a Cold-Rolled Ultrafine-Grained Dual-Phase Steel. Materials. 2018; 11(8):1399. https://doi.org/10.3390/ma11081399

Chicago/Turabian StylePan, Zhiyi, Bo Gao, Qingquan Lai, Xuefei Chen, Yang Cao, Manping Liu, and Hao Zhou. 2018. "Microstructure and Mechanical Properties of a Cold-Rolled Ultrafine-Grained Dual-Phase Steel" Materials 11, no. 8: 1399. https://doi.org/10.3390/ma11081399

APA StylePan, Z., Gao, B., Lai, Q., Chen, X., Cao, Y., Liu, M., & Zhou, H. (2018). Microstructure and Mechanical Properties of a Cold-Rolled Ultrafine-Grained Dual-Phase Steel. Materials, 11(8), 1399. https://doi.org/10.3390/ma11081399