Electrical, Structural, Optical, and Adhesive Characteristics of Aluminum-Doped Tin Oxide Thin Films for Transparent Flexible Thin-Film Transistor Applications

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

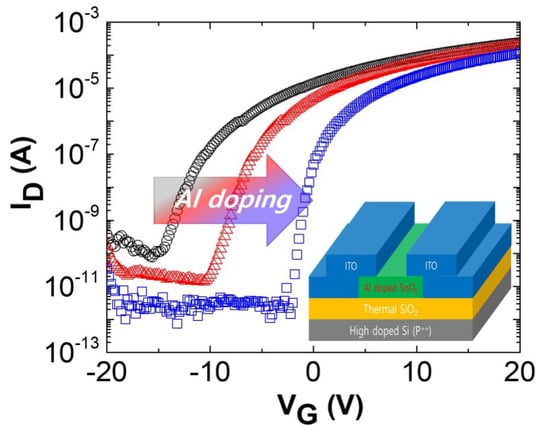

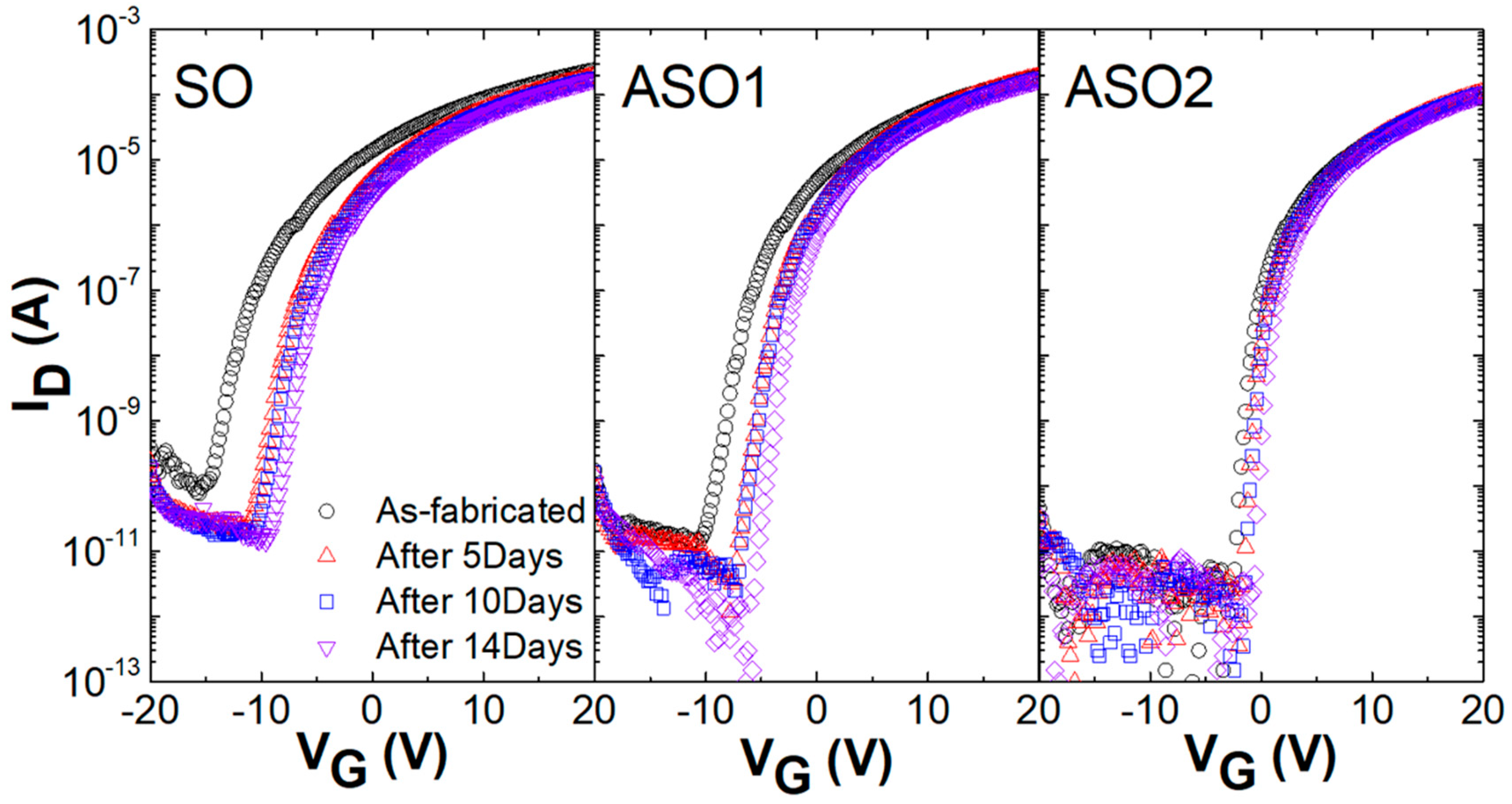

3.1. Electrical Characterization of Al-Doped SnOx Thin-Film Transistors

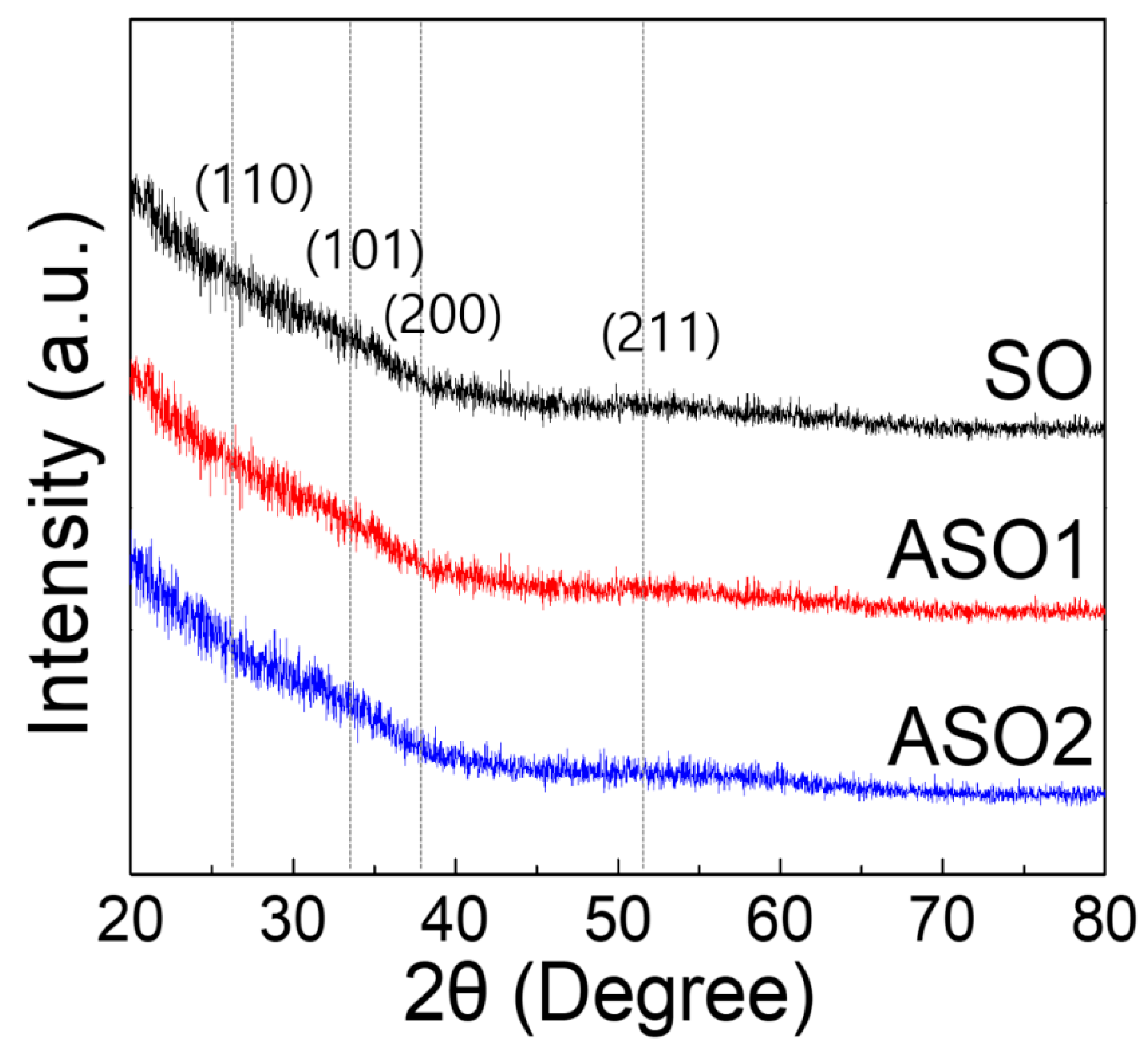

3.2. Structural and Optical Properties of Al-Doped SnOx Thin-Films

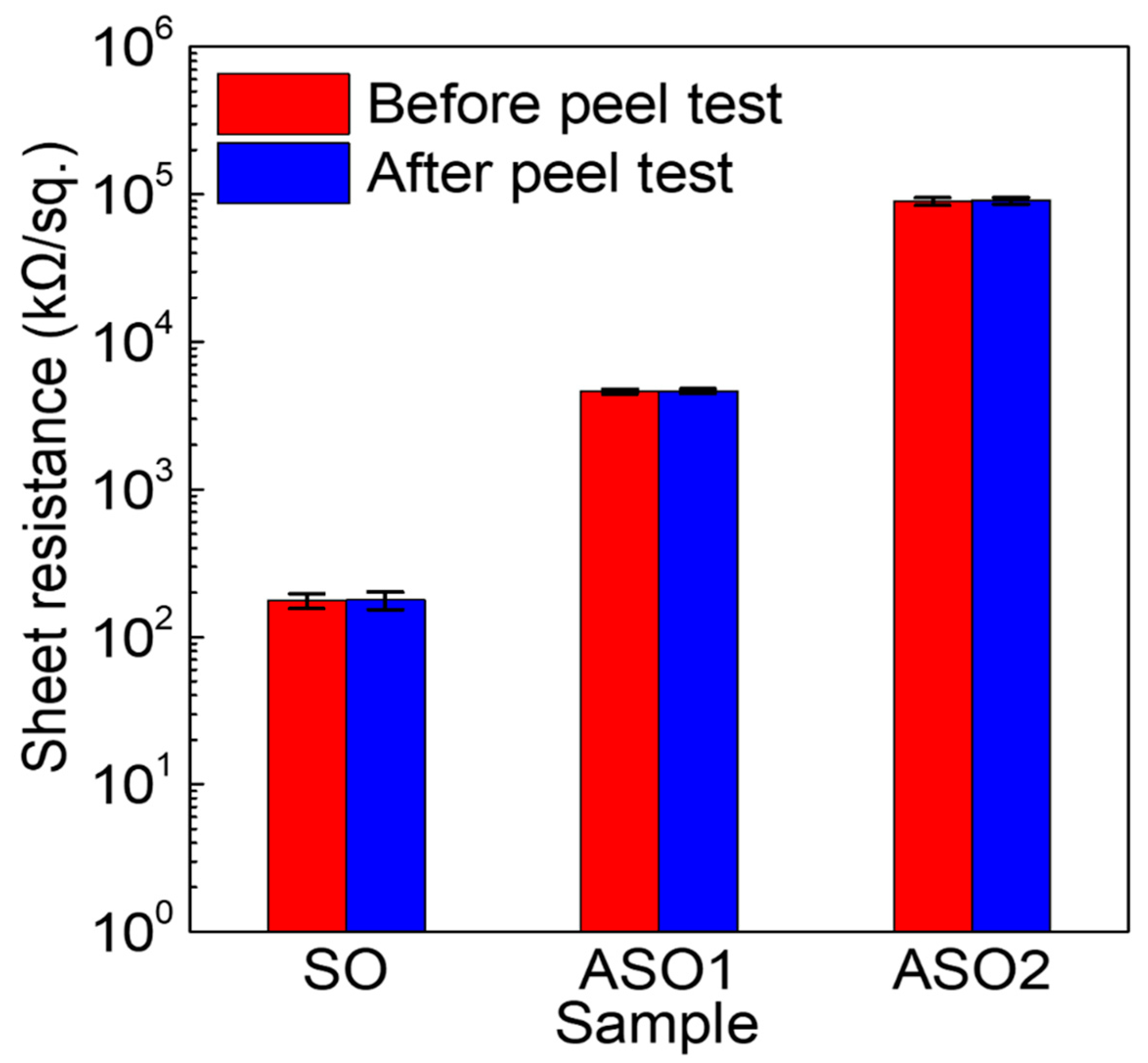

3.3. Adhesive Property between Al-Doped SnOx Thin-Films and Plastic Substrate

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Nomura, K.; Ohta, H.; Takagi, A.; Kamiya, T.; Hirano, M.; Hosono, H. Room-temperature fabrication of transparent flexible thin-film transistors using amorphous oxide semiconductors. Nature 2004, 432, 488–492. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.I.; Ji, K.H.; Jang, M.; Yang, H.; Choi, R.; Jeong, J.K. Ti-doped indium tin oxide thin films for transparent field-effect transistors: Control of charge-carrier density and crystalline structure. ACS Appl. Mater. Interfaces 2011, 3, 2522–2528. [Google Scholar] [CrossRef]

- Fortunato, E.M.C.; Barquinha, P.M.C.; Pimentel, A.C.M.B.G.; Concalves, A.M.F.; Marques, A.J.S.; Pereira, L.M.N.; Martins, R.F.P. Fully Transparent ZnO thin-film transistor produced at room temperature. Adv. Mater. 2005, 17, 590–594. [Google Scholar] [CrossRef]

- Maiolo, L.; Mirabella, S.; Maita, F.; Alberti, A.; Minotti, A.; Strano, V.; Pecora, A.; Shacham-Diamand, Y.; Fortunato, G. Flexible pH sensors based on polysilicon thin film transistor and ZnO nanowalls. Appl. Phys. Lett. 2014, 105, 093501. [Google Scholar] [CrossRef]

- Kim, H.Y.; Jung, E.A.; Mun, G.; Agbenteke, R.E.; Park, B.K.; Park, J.S.; Son, S.U.; Jeon, D.J.; Park, S.H.K.; Chang, T.M.; et al. Low-temperature growth of indium oxide thin film by plasma-enhanced atomic layer deposition using liquid dimethyl(N-ethoxy-2,2-dimethylpropanamido)indium for high-mobility thin film transistor application. ACS Appl. Mater. Interfaces 2016, 8, 26924–26931. [Google Scholar] [CrossRef]

- Sheng, J.; Jeong, H.-J.; Han, K.-L.; Hong, T.H.; Park, J.-S. Review of recent advances in flexible oxide semiconductor thin-film transistors. J. Inf. Disp. 2017, 18, 159–172. [Google Scholar] [CrossRef]

- Lee, H.; Zhang, X.; Kim, J.W.; Kim, E.-J.; Park, J. Investigation of the Electrical Characteristics of Bilayer ZnO/In2O3 Thin-Film Transistors Fabricated by Solution Processing. Materials 2018, 11, 2013. [Google Scholar] [CrossRef]

- Minami, T.; Miyata, T.; Ohtani, Y.; Kuboi, T. Effect of thickness on the stability of transparent conducting impurity-doped ZnO thin films in a high humidity environment. Phys. Status Solidi RRL 2007, 1, R31–R33. [Google Scholar] [CrossRef] [Green Version]

- Lewis, J. Material challenge for flexible organic devices. Mater. Today 2006, 9, 39–45. [Google Scholar] [CrossRef]

- Ramos, M.M.D. Theoretical study of metal-polyimide interfacial properties. Vacuum 2002, 64, 255–260. [Google Scholar] [CrossRef]

- Hull, T.R.; Colligon, J.S.; Hill, A.E. Measurement of thin film adhesion. Vacuum 1987, 37, 327–330. [Google Scholar] [CrossRef]

- Lee, C.-K.; Park, S.Y.; Jung, H.Y.; Lee, C.K.; Son, B.-G.; Kim, H.J.; Lee, Y.-J.; Joo, Y.-C.; Jeong, J.K. High performance Zn-Sn-O thin film transistors with Cu Source/drain electrode. Phys. Status Solidi RRL 2013, 7, 196–198. [Google Scholar] [CrossRef]

- Hamilton, M.C.; Martin, S.; Kanicki, J. Field-effect mobility of organic polymer thin-film transistors. Chem. Mater. 2004, 16, 4699–4704. [Google Scholar] [CrossRef]

- Li, J.; Ding, X.-W.; Zhang, J.-H.; Zhang, H.; Jiang, W.-Y.; Zhang, Z.-L. Improving electrical performance and bias stability of HfInZnO-TFT with optimizing the channel thickness. AIP Adv. 2013, 3, 102132. [Google Scholar] [CrossRef] [Green Version]

- Han, S.J.; Kim, S.; Ahn, J.; Jeong, J.K.; Yang, H.; Kim, H.J. Composition-dependent structural and electrical properties of p-type SnOx thin films prepared by reactive DC magnetron sputtering: Effects of oxygen pressure and heat treatment. RSC Adv. 2016, 6, 71757–71766. [Google Scholar] [CrossRef]

- Lee, P.-M.; Liu, Y.-S.; Villamagua, L.; Stashans, A.; Carini, M.; Liu, C.-Y. Experimental observation and computer simulation of Al/Sn substitution in p-type aluminum nitride-doped tin oxide thin film. J. Phys. Chem. C 2016, 120, 4211–4218. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Khan, S.; Ghosh, P.K.; Mitra, M.K.; Chattopadhyay, K.K. Effect of Al doping on the conductivity type inversion and electro-optical properties of SnO2 thin films synthesized by sol-gel technique. J. Sol-Gel Sci. Technol. 2006, 39, 241–247. [Google Scholar] [CrossRef]

- Chu, H.-C.; Shen, Y.-S.; Hsieh, C.-H.; Huang, J.-H.; Wu, Y.-H. Low-voltage operation of ZrO2-gated n-type thin film transistors based on a channel formed by hybrid phases of SnO and SnO2. ACS Appl. Mater. Interfaces 2015, 7, 15129–15137. [Google Scholar] [CrossRef]

- Huh, M.S.; Yang, B.S.; Oh, S.; Yoon, K.; Jeong, J.K.; Hwang, C.S.; Kim, H.J. Improvement in the Performance of Tin Oxide Thin-Film Transistors by Alumina Doping. Electochem. Solid-State Lett. 2009, 12, H385–H387. [Google Scholar] [CrossRef]

- Saji, K.J.; Mary, A.P.R. Tin oxide based P and N-type thin film transistors developed by RF sputtering. ECS J. Solid State Sci. Technol. 2015, 4, Q101–Q104. [Google Scholar] [CrossRef]

- Lee, B.K.; Jung, E.; Kim, S.H.; Moon, D.C.; Lee, S.S.; Park, B.K.; Hwang, J.H.; Chung, T.M.; Kim, C.G.; An, K.S. Physical/chemical properties of tin oxide thin film transistors prepared using plasma-enhanced atomic layer deposition. Mater. Res. Bull. 2012, 47, 3052–3055. [Google Scholar] [CrossRef]

- Lide, D.R. CRC Handbook of Chemistry and Physics, 87th ed. J. Am. Chem. Soc. 2007, 129, 724. [Google Scholar] [CrossRef]

- Jeong, J.K. The status and perspectives of metal oxide thin-film transistors for active matrix flexible displays. Semicond. Sci. Technol. 2011, 26, 034008. [Google Scholar] [CrossRef]

- Chong, E.; Chun, Y.S.; Kim, S.H.; Lee, S.Y. Effect of oxygen on the threshold voltage of a-IGZO TFT. J. Electr. Eng. Technol. 2011, 6, 539–542. [Google Scholar] [CrossRef] [Green Version]

- Yan, Y.; Al-Jassim, M.M.; Wei, S.-H. Oxygen-vacancy mediated adsorption and reaction of molecular oxygen on the ZnO (10-10) surface. Phys. Rev. B 2005, 72, 161307. [Google Scholar] [CrossRef]

- Moulder, J.F.; Stickle, W.F.; Sobol, P.E.; Bomben, K.D. Handbook of X-ray Photoelectron Spectroscopy, 1st ed.; Perkin-Elmer: Minnesota, MN, USA, 1992; p. 127. ISBN 978-0-96-270262-4. [Google Scholar]

- Jaiswar, S.; Mandal, K.D. Evidence of enhanced oxygen vacancy defects inducing ferromagnetism in multiferroic CaMn7O12 manganite with sinteing time. J. Phys. Chem. C 2017, 121, 19586–19601. [Google Scholar] [CrossRef]

- Nguyen, A.H.-T.; Nguyen, M.-C.; Choi, J.; Han, S.; Kim, J.; Choi, R. Electrical performance enhancement of p-type tin oxide channel thin film transistor using aluminum doping. Thin Solid Films 2017, 641, 24–27. [Google Scholar] [CrossRef]

- Wang, B.; Yu, X.; Guo, P.; Huang, W.; Zeng, L.; Zhou, N.; Chi, L.; Bedzyk, M.J.; Chang, R.P.H.; Marks, T.J.; et al. Solution-processed all-oxide transparent high-performance transistors fabricated by spray-combustion synthesis. Adv. Electron. Mater. 2016, 2, 1500427. [Google Scholar] [CrossRef]

| Sample | Vth [V] | Ion/Ioff | μsat [cm2 V−1 s−1] | SS [V dec−1] | H [V] | Al [at %] |

|---|---|---|---|---|---|---|

| SO | −13.4 | 3.11 × 106 | 2.24 | 2.37 | 2.67 | 0 |

| ASO1 | −8.0 | 1.38 × 107 | 2.30 | 1.28 | 2.15 | 1.20 |

| ASO2 | −1.0 | 7.86 × 107 | 2.24 | 0.68 | 1.13 | 2.24 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-H.; Kwon, K.; Kim, K.; Yoon, J.S.; Choi, D.-S.; Yoo, Y.; Kim, C.; Kang, S.; Kim, J.H. Electrical, Structural, Optical, and Adhesive Characteristics of Aluminum-Doped Tin Oxide Thin Films for Transparent Flexible Thin-Film Transistor Applications. Materials 2019, 12, 137. https://doi.org/10.3390/ma12010137

Lee S-H, Kwon K, Kim K, Yoon JS, Choi D-S, Yoo Y, Kim C, Kang S, Kim JH. Electrical, Structural, Optical, and Adhesive Characteristics of Aluminum-Doped Tin Oxide Thin Films for Transparent Flexible Thin-Film Transistor Applications. Materials. 2019; 12(1):137. https://doi.org/10.3390/ma12010137

Chicago/Turabian StyleLee, Seung-Hun, Kihwan Kwon, Kwanoh Kim, Jae Sung Yoon, Doo-Sun Choi, Yeongeun Yoo, Chunjoong Kim, Shinill Kang, and Jeong Hwan Kim. 2019. "Electrical, Structural, Optical, and Adhesive Characteristics of Aluminum-Doped Tin Oxide Thin Films for Transparent Flexible Thin-Film Transistor Applications" Materials 12, no. 1: 137. https://doi.org/10.3390/ma12010137

APA StyleLee, S. -H., Kwon, K., Kim, K., Yoon, J. S., Choi, D. -S., Yoo, Y., Kim, C., Kang, S., & Kim, J. H. (2019). Electrical, Structural, Optical, and Adhesive Characteristics of Aluminum-Doped Tin Oxide Thin Films for Transparent Flexible Thin-Film Transistor Applications. Materials, 12(1), 137. https://doi.org/10.3390/ma12010137