Thermal Expansion and Magnetostriction of Laves-Phase Alloys: Fingerprints of Ferrimagnetic Phase Transitions

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

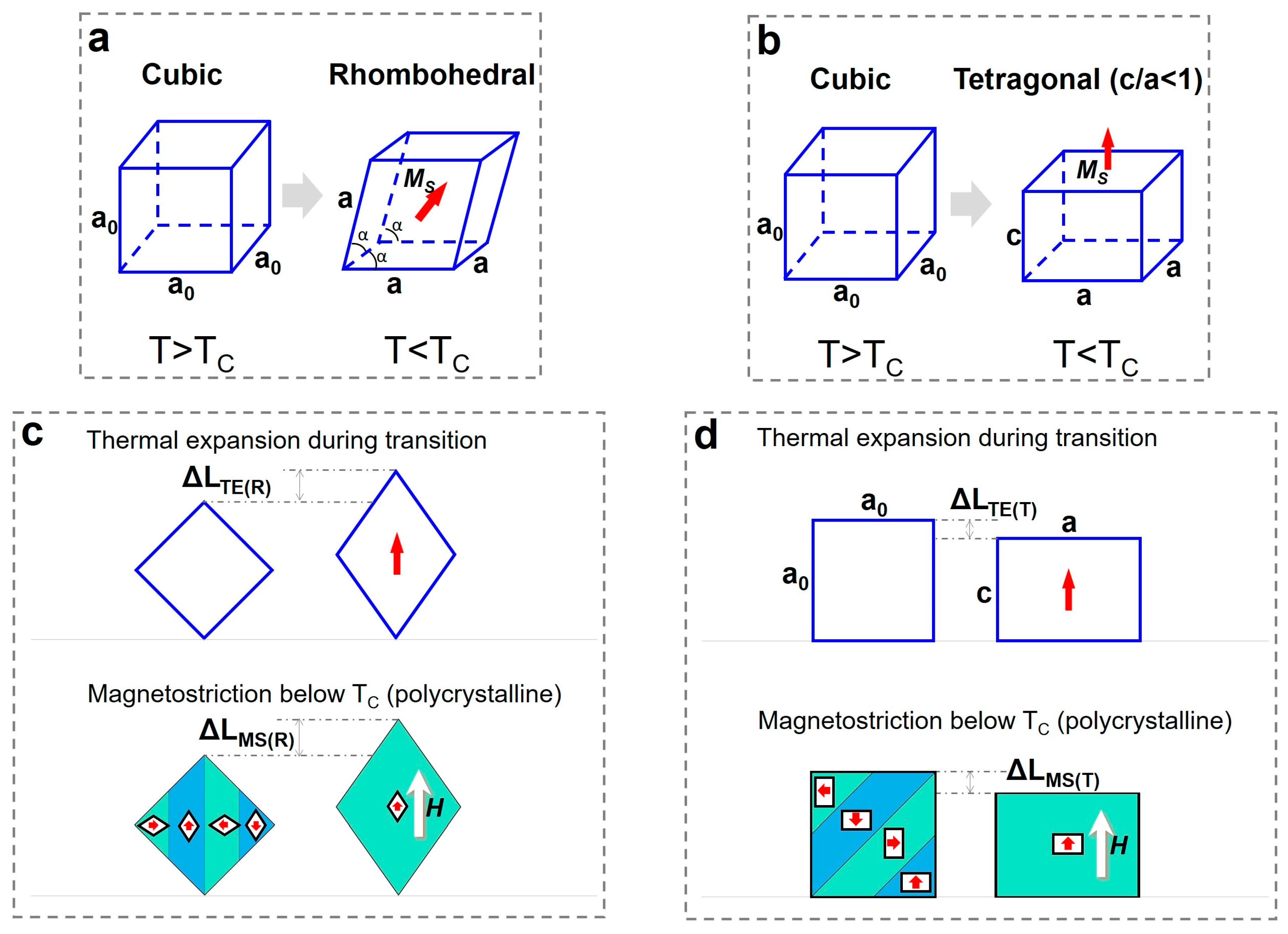

3.1. The Mechanism of Thermal Expansion and Magnetostriction Based on Structual Transition and Domain Switching

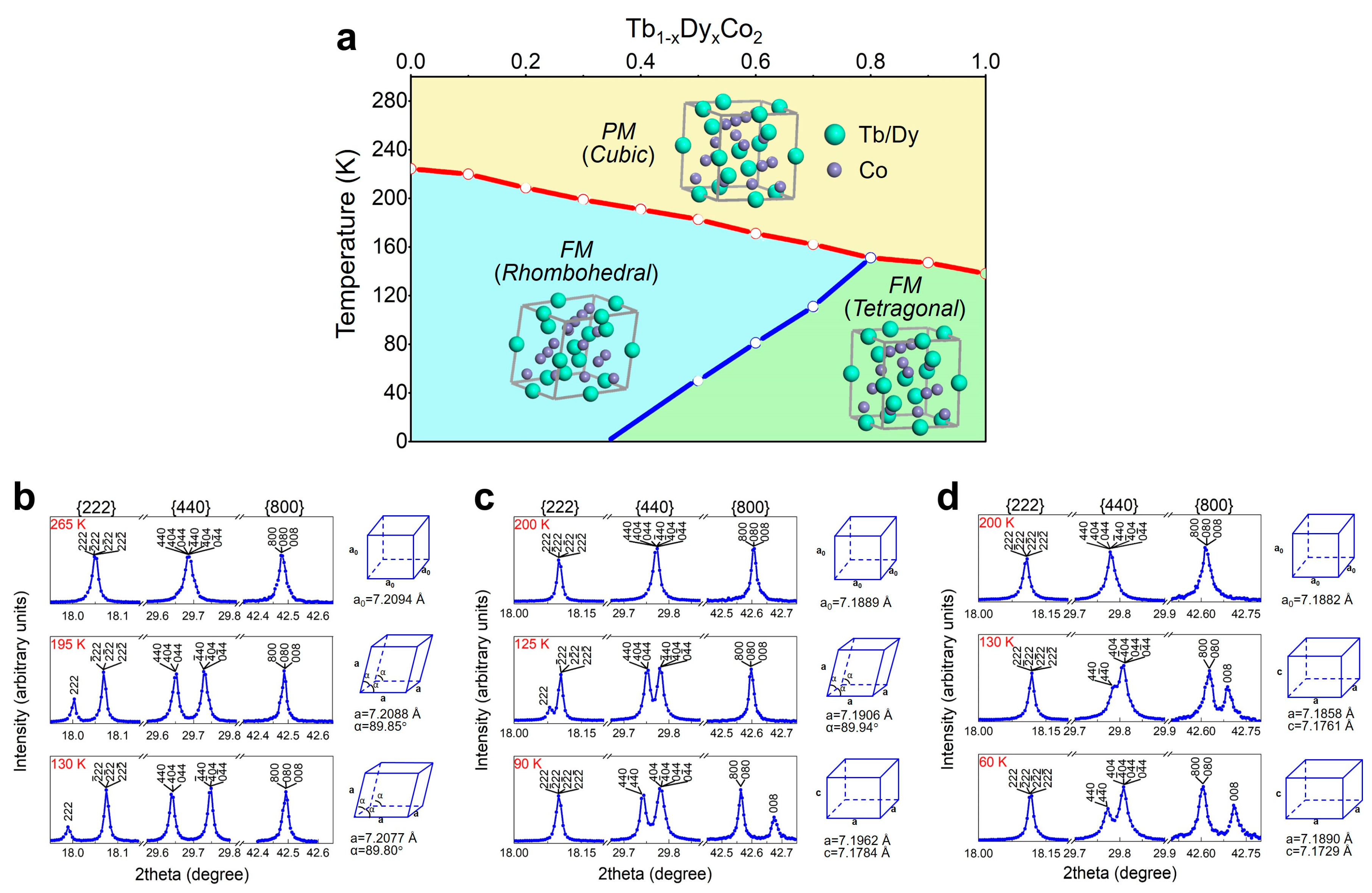

3.2. Crystal Structure Symmetry and Phase Diagram

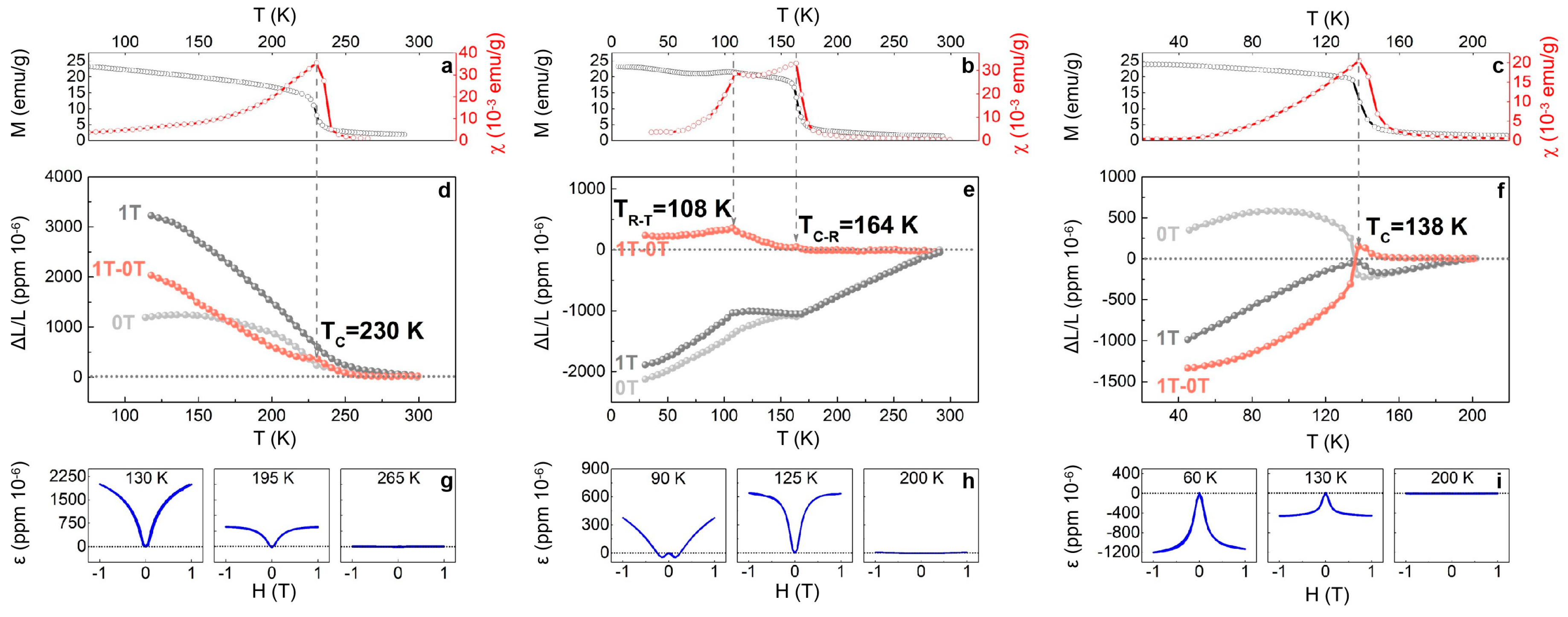

3.3. Magnetic Properties, Thermal Expansion, and Magnetostriction

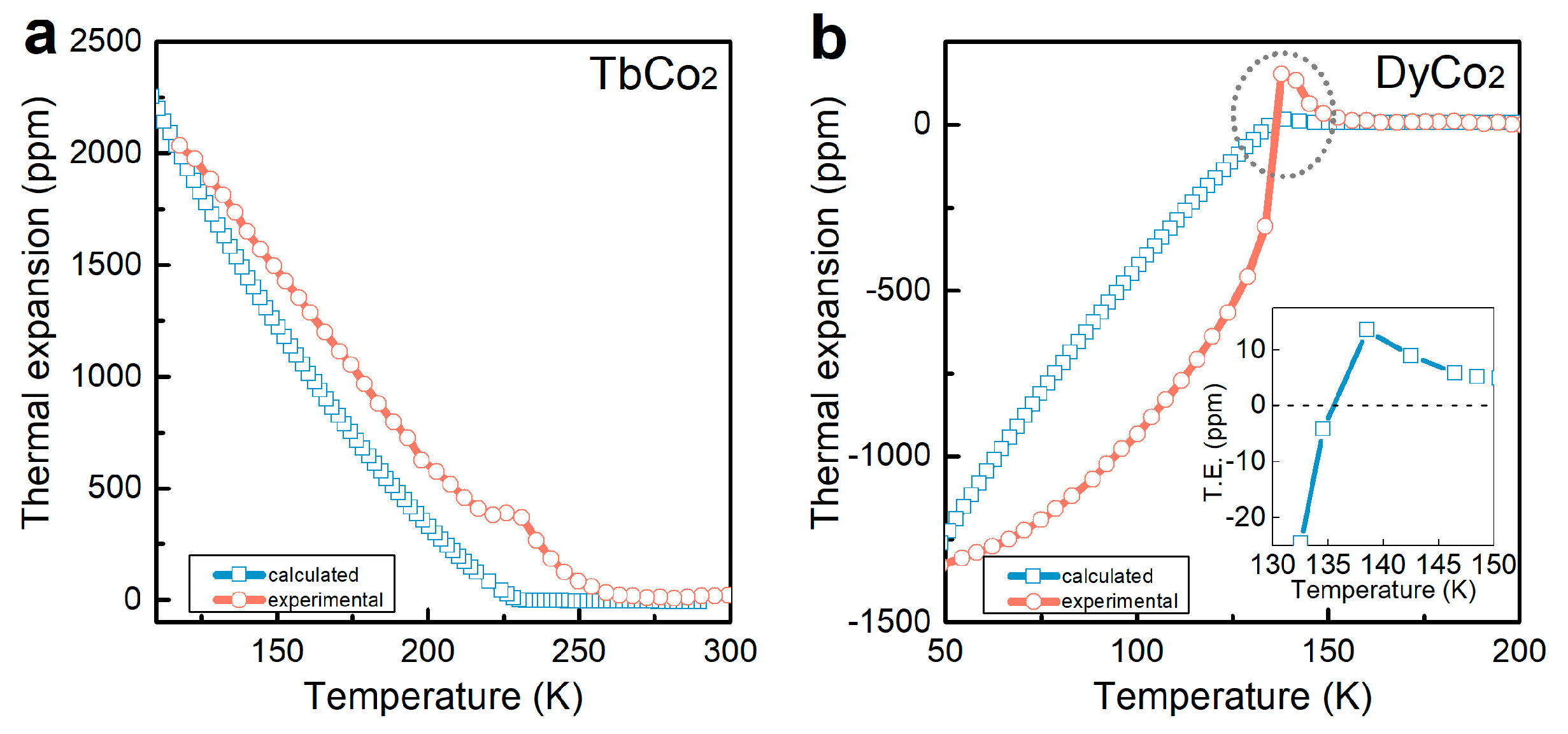

3.4. Deduction of Thermal Expansion with Landau Polynomials

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Clark, A.E. Ferromagnetic Materials—A Handbook on the Properties of Magnetically Ordered Substances; North-Holland Publishing Company: Amsterdam, the Netherland, 1980; Volume 1. [Google Scholar]

- David, J. Introduction to Magnetism and Magnetic Materials; Chapman&Hall: New York, NY, USA, 2003. [Google Scholar]

- Lacheisserie, E.D.T. Magnetostriction: Theory and Applications of Magnetoelasticity; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- Cullen, J.R.; Clark, A.E.; Hathaway, K.B. Materials Science and Technology; Cahn, R.W., Haasen, P., Kramer, E.J., Eds.; VCH: New York, NY, USA, 1994; Volume 3B, pp. 529–565. [Google Scholar]

- O’Handley, R.C. Modern Magnetic Materials: Principles and Applications; JOHN WBkEY & SONS, INC.: New York, NY, USA, 1999. [Google Scholar]

- Lee, E.W. Magnetostriction and Magnetomechanical Effects. Rep. Prog. Phys. 1955, 18, 184–229. [Google Scholar] [CrossRef]

- Lee, E.W. Magnetostriction Curves of Polycrystalline Ferromagnetics. Proc. Phys. Soc. 1958, 72, 249–258. [Google Scholar] [CrossRef]

- Del Moral, A.; Melville, D. Magnetostriction of some cubic rare earth-Co2compounds in high magnetic fields. J. Phys. F: Phys. 1975, 5, 1767–1777. [Google Scholar] [CrossRef]

- Clark, A.E.; Cullen, J.R.; McMasters, O.D.; Callen, E.R. Rhombohedral distortion in highly magnetostrictive Laves phase compounds. AIP Conf. Proc. 1976, 29, 192–193. [Google Scholar]

- Lee, E.W.; Pourarian, F. Magnetoelastic Properties of (Rare-Earth)–Co2 Compounds. II. The Anisotropic Magnetostriction. Phys. Status Solidi 1976, 34, 383–390. [Google Scholar] [CrossRef]

- Lee, E.W.; Pourarian, F. Magnetoelastic Properties of (Rare-Earth) Co2 Compounds. I. Exchange-Striction. Phys. Status Solidi a-Appl. Res. 1976, 33, 483–489. [Google Scholar] [CrossRef]

- Minakata, R.; Shiga, M.; Nakamura, Y. Spontaneous Volume Magnetostriction of RCo 2 Compounds. J. Phys. Soc. 1976, 41, 1435–1436. [Google Scholar] [CrossRef]

- Cullen, J.R.; Clark, A.E. Magnetostriction and structural distortion in rare-earth intermetallics. Phys. B 1977, 15, 4510–4515. [Google Scholar] [CrossRef]

- Givord, F.; De La Bathie, R.P.; Sayetat, F.; Gignoux, D. Magnetic properties and spontaneous distortion in TbCo2. J. Phys. F: Phys. 1979, 9, 763–772. [Google Scholar]

- Duc, N.; Hien, T.; Brommer, P.; Franse, J. The magnetic behaviour of rare-earth—transition metal compounds. J. Magn. Magn. Mater. 1992, 104, 1252–1256. [Google Scholar] [CrossRef]

- Kamarád, J.; Arnold, Z.; Ibarra, M.R. Magnetic Phase Transitions and Magnetovolume Anomalies in Dyco2 and Gdmn2 Compounds under Pressure. J. Magn. Magn. Mater. 1995, 140–144, 837–838. [Google Scholar]

- Asamitsu, A.; Moritomo, Y.; Tomioka, Y.; Arima, T.; Tokura, Y. A structural phase transition induced by an external magnetic field. Nat. Cell Boil. 1995, 373, 407–409. [Google Scholar] [CrossRef]

- Tickle, R.; James, R.D.; Shield, T.; Wuttig, M.; Kokorin, V.V. Ferromagnetic Shape Memory in the Nimnga System. IEEE Trans. Magn. 1999, 35, 4301–4310. [Google Scholar] [CrossRef]

- Jcpds-International Centre for Diffraction Data. Available online: http://www.icdd.com/ (accessed on 30 September 2018).

- Wadhawan, V.K. Introduction to Ferroic Materials; Gordon and Breach: Amsterdam, the Netherland, 2000. [Google Scholar]

- Yang, S.; Ren, X. Noncubic crystallographic symmetry of a cubic ferromagnet: Simultaneous structural change at the ferromagnetic transition. Phys. B 2008, 77, 014407. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Bao, H.; Zhou, C.; Wang, Y.; Ren, X.; Matsushita, Y.; Katsuya, Y.; Tanaka, M.; Kobayashi, K.; Song, X.; et al. Large Magnetostriction from Morphotropic Phase Boundary in Ferromagnets. Phys. Lett. 2010, 104, 197201. [Google Scholar] [CrossRef] [PubMed]

- Bergstrom, R.; Wuttig, M.; Cullen, J.; Zavalij, P.; Briber, R.; Dennis, C.; Garlea, V.O.; Laver, M. Morphotropic Phase Boundaries in Ferromagnets: Tb1-xDyxFe2 Alloys. Phys. Lett. 2013, 111, 017203. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Ren, S.; Bao, H.; Yang, S.; Yao, Y.; Ji, Y.; Ren, X.; Matsushita, Y.; Katsuya, Y.; Tanaka, M.; et al. Inverse Effect of Morphotropic Phase Boundary on the Magnetostriction of Ferromagnetic Tb1-xGdxCo2. Phys. Rev. B 2014, 89, 100101. [Google Scholar] [CrossRef]

- Zener, C. Interaction between the D Shells in the Transition Metals. Phys. Rev. 1951, 81, 440–444. [Google Scholar] [CrossRef]

- Nlebedim, I.C.; Ranvah, N.; Melikhov, Y.; Williams, P.I.; Snyder, J.E.; Moses, A.J.; Jiles, D.C. Magnetic and Magnetomechanical Properties of CoAlxFe2-xO4 for Stress Sensor and Actuator Applications. IEEE Trans. Magn. 2009, 45, 4120–4123. [Google Scholar] [CrossRef]

- Nlebedim, I.C.; Ranvah, N.; Melikhov, Y.; Williams, P.I.; Snyder, J.E.; Moses, A.J.; Jiles, D.C. Effect of Temperature Variation on the Magnetostrictive Properties of Coalxfe2-xO4. J. Appl. Phys. 2010, 107, 09A936. [Google Scholar] [CrossRef]

- Sablik, M.; Jiles, D. Coupled magnetoelastic theory of magnetic and magnetostrictive hysteresis. IEEE Trans. Magn. 1993, 29, 2113–2123. [Google Scholar] [CrossRef]

- Arnold, H.; Elmen, G. Permalloy, an alloy of remarkable magnetic properties. J. Frankl. Inst. 1923, 195, 621–632. [Google Scholar] [CrossRef]

- McKeehan, L.W.; Cioffi, P.P. Magnetostriction in Permalloy. Phys. Rev. 1926, 28, 146–157. [Google Scholar] [CrossRef]

- Kittel, C. Physical Theory of Ferromagnetic Domains. Rev. Phys. 1949, 21, 541–583. [Google Scholar] [CrossRef]

- Ahn, K.H.; Lookman, T.; Bishop, A.R. Strain-induced metal–insulator phase coexistence in perovskite manganites. Nat. Cell Boil. 2004, 428, 401–404. [Google Scholar] [CrossRef] [PubMed]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, C.; Bao, H.; Matsushita, Y.; Chang, T.; Chen, K.; Zhang, Y.; Tian, F.; Zuo, W.; Song, X.; Yang, S.; et al. Thermal Expansion and Magnetostriction of Laves-Phase Alloys: Fingerprints of Ferrimagnetic Phase Transitions. Materials 2019, 12, 1755. https://doi.org/10.3390/ma12111755

Zhou C, Bao H, Matsushita Y, Chang T, Chen K, Zhang Y, Tian F, Zuo W, Song X, Yang S, et al. Thermal Expansion and Magnetostriction of Laves-Phase Alloys: Fingerprints of Ferrimagnetic Phase Transitions. Materials. 2019; 12(11):1755. https://doi.org/10.3390/ma12111755

Chicago/Turabian StyleZhou, Chao, Huixin Bao, Yoshitaka Matsushita, Tieyan Chang, Kaiyun Chen, Yin Zhang, Fanghua Tian, Wenliang Zuo, Xiaoping Song, Sen Yang, and et al. 2019. "Thermal Expansion and Magnetostriction of Laves-Phase Alloys: Fingerprints of Ferrimagnetic Phase Transitions" Materials 12, no. 11: 1755. https://doi.org/10.3390/ma12111755