Influence of Pore Size Variation on Thermal Conductivity of Open-Porous Foams

Abstract

1. Introduction

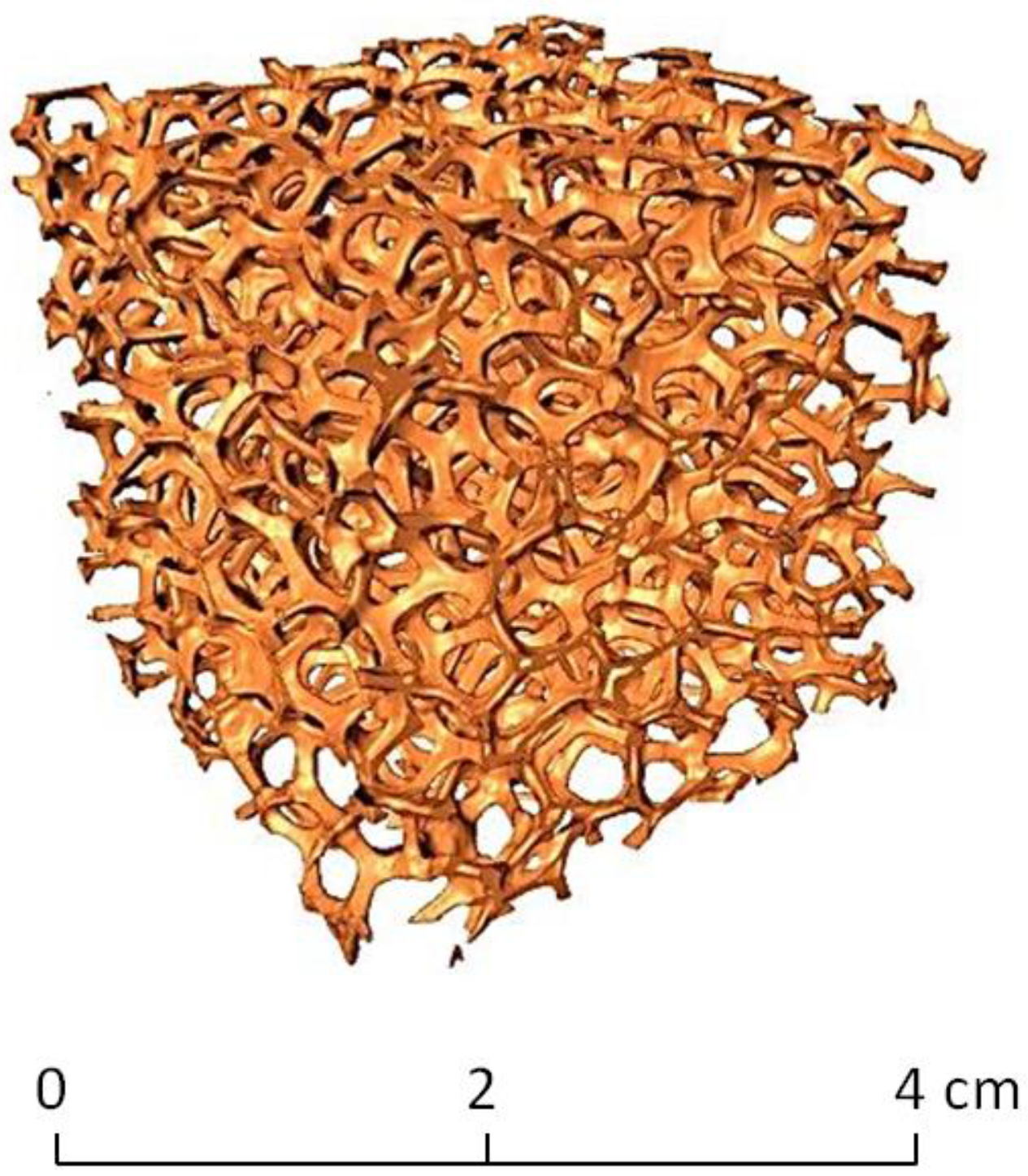

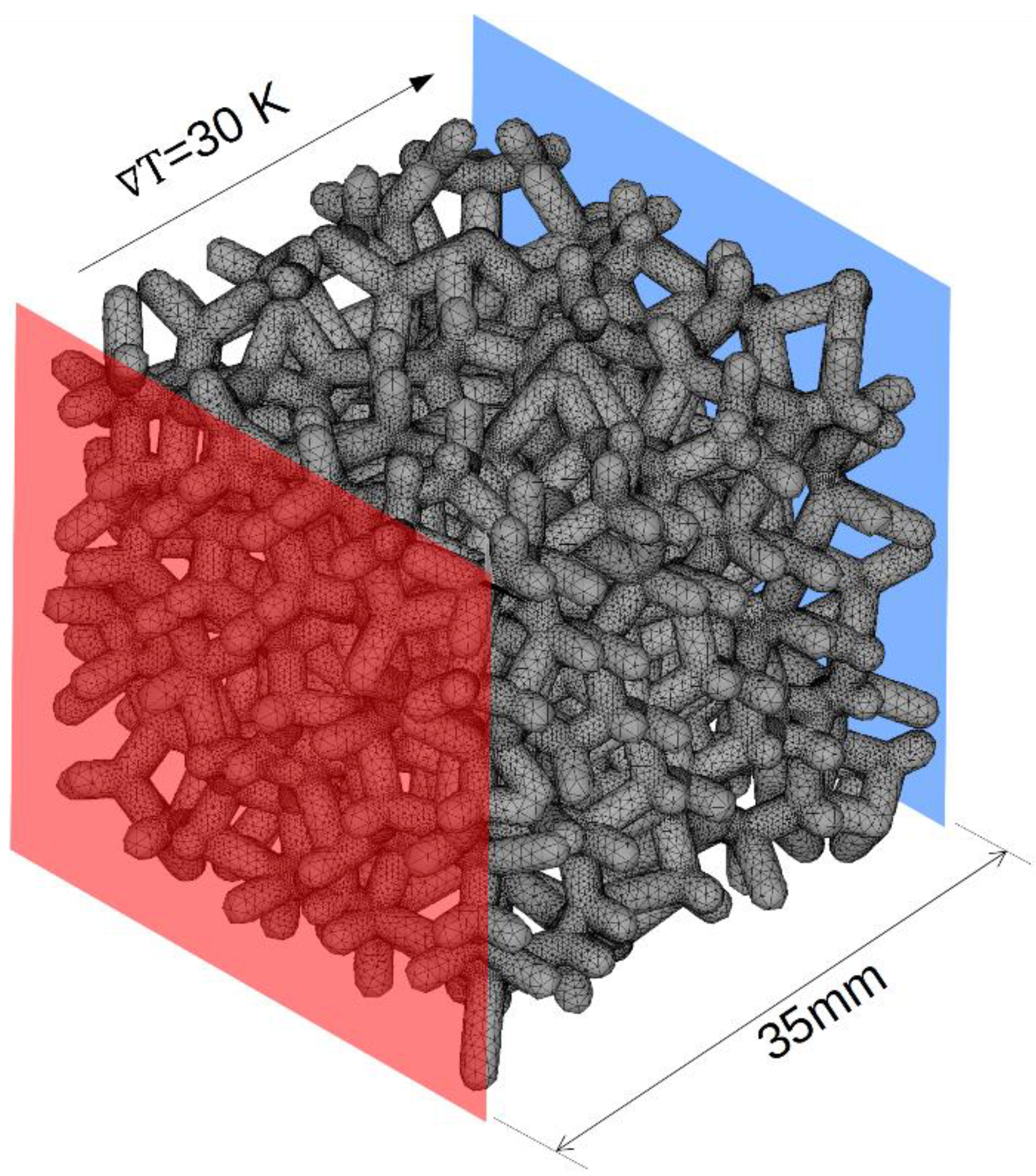

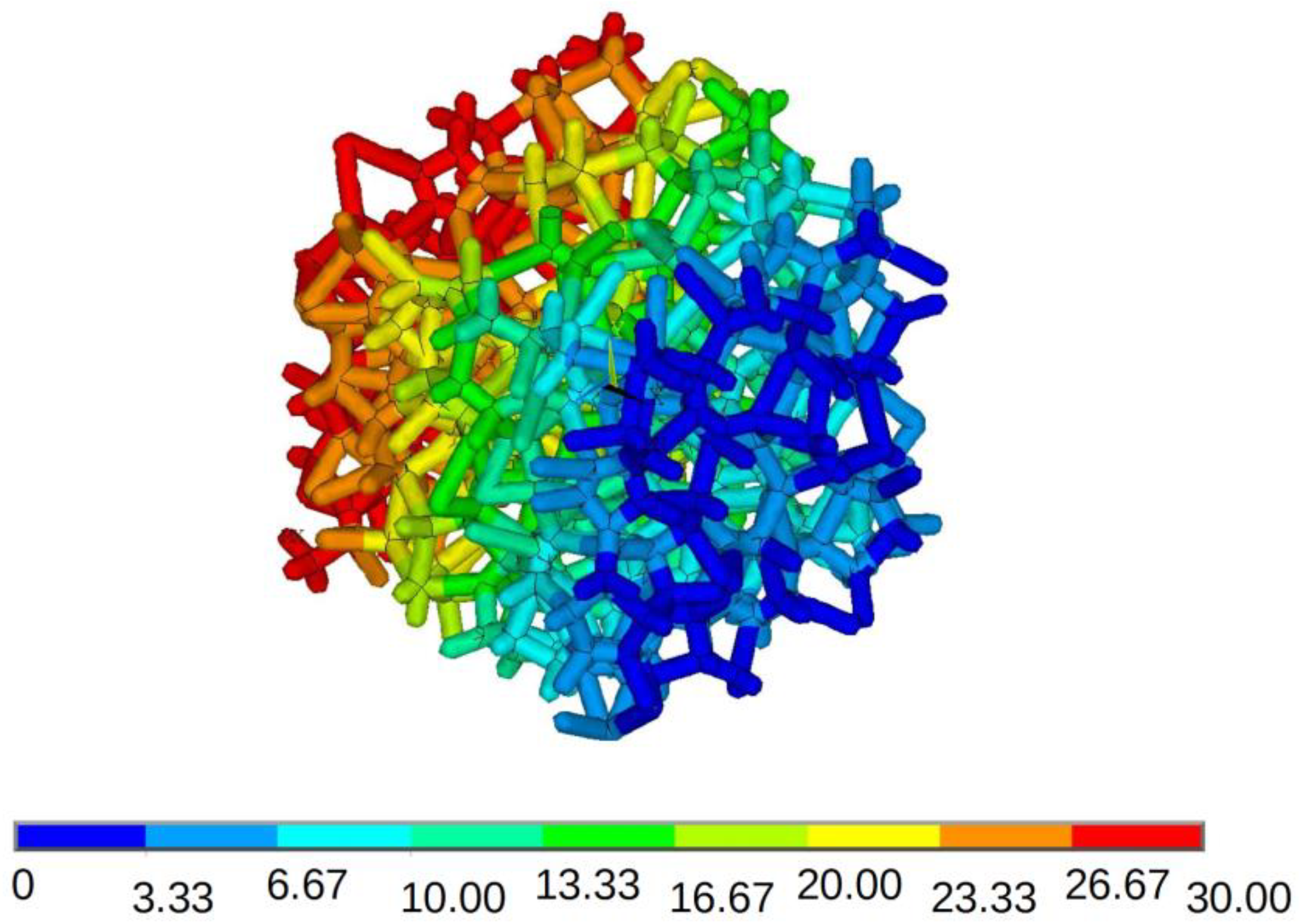

2. Materials and Methods

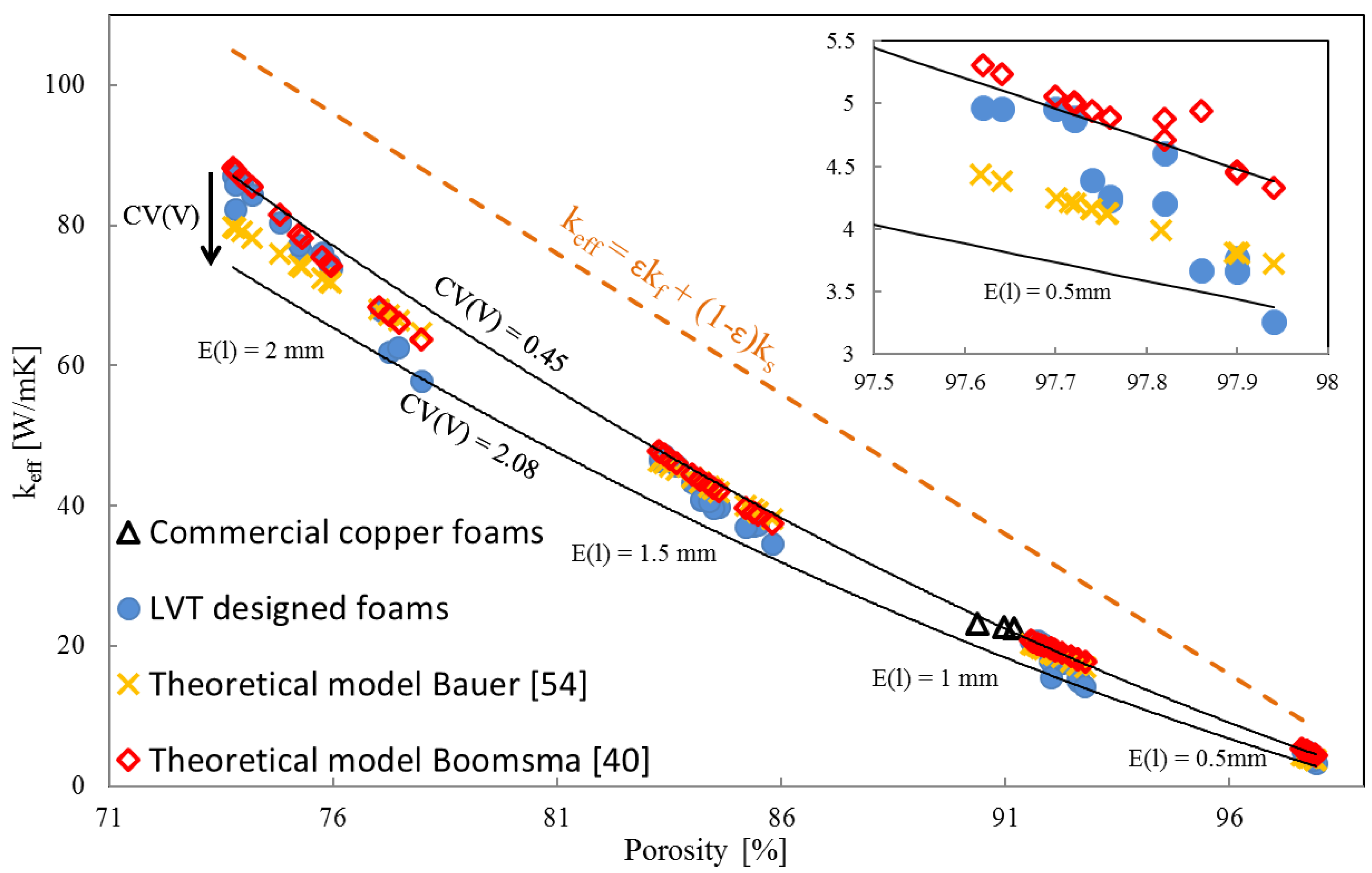

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| Symbol | Definition | Unit |

| CV(V) | Coefficient of variation for pore volume distribution | - |

| ∇ T | Temperature gradient | K |

| ε | Porosity | % |

| E(l) | Mean strut diameter | mm |

| SD(V) | Standard deviation of pore volumes | - |

| k | Thermal conductivity | W/(mK) |

| keff | Effective thermal conductivity | W/(mK) |

| kf | Thermal conductivity of fluid phase | W/(mK) |

| ks | Thermal conductivity of solid phase | W/(mK) |

| LVT | Laguerre-Voronoi Tessellation | - |

| n | Pore shape factor | - |

| q | Heat flux | W/m2 |

| ppi | Pores Per Inch | - |

| SEM | Scanning Electron Microscopy | - |

References

- Han, X.-H.; Wang, Q.; Park, Y.-G.; T’Joen, C.; Sommers, A.; Jacobi, A. A Review of Metal Foam and Metal Matrix Composites for Heat Exchangers and Heat Sinks. Heat Transf. Eng. 2012, 33, 991–1009. [Google Scholar] [CrossRef]

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar] [CrossRef]

- Boomsma, K.; Poulikakos, D.; Zwick, F. Metal foams as compact high performance heat exchangers. Mech. Mater. 2003, 35, 1161–1176. [Google Scholar] [CrossRef]

- Rodríguez-Pérez, M.A. Crosslinked polyolefin foams: Production, structure, properties, and applications. Adv. Polym. Sci. 2005, 184, 97–126. [Google Scholar] [CrossRef]

- Sharif, S.M.; Ahmad, Z.A.; Othman, M.R. Tubular Ceramic Foam via Polymeric Sponge Method. Int. J. Sci. Technol. Res. 2013, 2, 282–284. [Google Scholar]

- Ashby, M.F.; Evans, A.; Fleck, N.A.; Gibson, L.J.; Hutchinson, J.W.; Wadley, H.N. Metal foams: A design guide. Mater. Des. 2002, 23, 119. [Google Scholar] [CrossRef]

- Wadley, H.N.G. Cellular metals manufacturing. Adv. Eng. Mater. 2002, 4, 726–733. [Google Scholar] [CrossRef]

- Montanaro, L.; Jorand, Y.; Fantozzi, G.; Negro, A. Ceramic foams by powder processing. J. Eur. Ceram. Soc. 1998, 18, 1339–1350. [Google Scholar] [CrossRef]

- Liu, R.; Antoniou, A. A relationship between the geometrical structure of a nanoporous metal foam and its modulus. Acta Mater. 2013, 61, 2390–2402. [Google Scholar] [CrossRef]

- Pia, G.; Delogu, F. On the elastic deformation behavior of nanoporous metal foams. Scr. Mater. 2013, 69, 781–784. [Google Scholar] [CrossRef]

- Ko, W.L. Deformations of Foamed Elastomers. J. Cell. Plast. 1965, 1, 45–50. [Google Scholar] [CrossRef]

- Buffel, B.; Desplentere, F.; Bracke, K.; Verpoest, I. Modelling open cell-foams based on the Weaire-Phelan unit cell with a minimal surface energy approach. Int. J. Solids Struct. 2014, 51, 3461–3470. [Google Scholar] [CrossRef]

- Lautensack, C.; Sych, T. 3D Image Analysis of Open Foams Using Random Tessellations. Image Anal. Stereol. 2006, 25, 87–93. [Google Scholar] [CrossRef]

- Watson, D. Spatial tessellations: Concepts and applications of voronoi diagrams. Comput. Geosci. 1993, 19, 1209–1210. [Google Scholar] [CrossRef]

- Ferenc, J.S.; Néda, Z. On the size distribution of Poisson Voronoi cells. Phys. A Stat. Mech. Its Appl. 2007, 385, 518–526. [Google Scholar] [CrossRef]

- Redenbach, C. Microstructure models for cellular materials. Comput. Mater. Sci. 2009, 44, 1397–1407. [Google Scholar] [CrossRef]

- Fan, Z.; Wu, Y.; Zhao, X.; Lu, Y. Simulation of polycrystalline structure with Voronoi diagram in Laguerre geometry based on random closed packing of spheres. Comput. Mater. Sci. 2004, 29, 301–308. [Google Scholar] [CrossRef]

- Wejrzanowski, T.; Skibinski, J.; Szumbarski, J.; Kurzydlowski, K.J. Structure of foams modeled by Laguerre-Voronoi tessellations. Comput. Mater. Sci. 2013, 67, 216–221. [Google Scholar] [CrossRef]

- Cwieka, K.; Wejrzanowski, T.; Kurzydlowski, K.J. Incorporation of the Pore Size Variation to Modeling of the Elastic Behaviour of Metallic Open-Cell Foams. Arch. Metall. Mater. 2017, 62, 269–272. [Google Scholar] [CrossRef][Green Version]

- Veyhl, C.; Belova, I.V.; Murch, G.E.; Fiedler, T. Finite element analysis of the mechanical properties of cellular aluminium based on micro-computed tomography. Mater. Sci. Eng. A 2011, 528, 4550–4555. [Google Scholar] [CrossRef]

- Magnico, P. Analysis of permeability and effective viscosity by CFD on isotropic and anisotropic metallic foams. Chem. Eng. Sci. 2009, 64, 3564–3575. [Google Scholar] [CrossRef]

- Laschet, G.; Kashko, T.; Angel, S.; Scheele, J.; Nickel, R.; Bleck, W.; Bobzin, K. Microstructure based model for permeability predictions of open-cell metallic foams via homogenization. Mater. Sci. Eng. A 2008, 472, 214–226. [Google Scholar] [CrossRef]

- Petrasch, J.; Meier, F.; Friess, H.; Steinfeld, A. Tomography based determination of permeability, Dupuit-Forchheimer coefficient, and interfacial heat transfer coefficient in reticulate porous ceramics. Int. J. Heat Fluid Flow. 2008, 29, 315–326. [Google Scholar] [CrossRef]

- Fiedler, T.; Belova, I.V.; Murch, G.E. μ-CT-based finite element analysis on imperfections in open-celled metal foam: Mechanical properties. Scr. Mater. 2012, 67, 455–458. [Google Scholar] [CrossRef]

- Ashby, M.F. The mechanical properties of cellular solids. Metall. Trans. A 1983, 14, 1755–1769. [Google Scholar] [CrossRef]

- Lu, G.; Lu, G.Q.; Xiao, Z.M. Mechanical properties of porous materials. J. Porous Mater. 1999, 6, 359–368. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Calmidi, V.V.; Mahajan, R.L. Thermophysical properties of high porosity metal foams. Int. J. Heat Mass Transf. 2002, 45, 1017–1031. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. The Mechanics of Three-Dimensional Cellular Materials. Proc. R. Soc. A Math. Phys. Eng. Sci. 1982, 382, 43–59. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. A Variational approach to the theory of the effective magnetic permeability of multiphase materials. J. Appl. Phys. 1962, 33, 3125–3131. [Google Scholar] [CrossRef]

- Edouard, D.; Lacroix, M.; Huu, C.P.; Luck, F. Pressure drop modeling on SOLID foam: State-of-the art correlation. Chem. Eng. J. 2008, 144, 299–311. [Google Scholar] [CrossRef]

- Dukhan, N.; Patel, P. Equivalent particle diameter and length scale for pressure drop in porous metals. Exp. Therm. Fluid Sci. 2008, 32, 1059–1067. [Google Scholar] [CrossRef]

- Medraj, M.; Baril, E.; Loya, V.; Lefebvre, L.P. The effect of microstructure on the permeability of metallic foams. J. Mater. Sci. 2007, 42, 4372–4383. [Google Scholar] [CrossRef]

- Wejrzanowski, T.; Ibrahim, S.H.; Skibiński, J.; Cwieka, K.; Kurzydlowski, K.J. Appropriate models for simulating open-porous materials. Image Anal. Stereol. 2017, 36, 107–112. [Google Scholar] [CrossRef][Green Version]

- Ibrahim, S.H.; Skibinski, J.; Oliver, G.J.; Wejrzanowski, T. Microstructure effect on the permeability of the tape-cast open-porous materials. Mater. Des. 2019, 167, 107639. [Google Scholar] [CrossRef]

- Ghosh, I. Heat transfer correlation for high-porosity open-cell foam. Int. J. Heat Mass Transf. 2009, 52, 1488–1494. [Google Scholar] [CrossRef]

- Wang, H.; Guo, L. Experimental investigation on pressure drop and heat transfer in metal foam filled tubes under convective boundary condition. Chem. Eng. Sci. 2016, 155, 438–448. [Google Scholar] [CrossRef]

- Azzi, W.; Roberts, W.L.; Rabiei, A. A study on pressure drop and heat transfer in open cell metal foams for jet engine applications. Mater. Des. 2007, 28, 569–574. [Google Scholar] [CrossRef]

- Mendes, M.A.A.; Ray, S.; Trimis, D. A simple and efficient method for the evaluation of effective thermal conductivity of open-cell foam-like structures. Int. J. Heat Mass Transf. 2013, 66, 412–422. [Google Scholar] [CrossRef]

- Baillis, D.; Coquard, R. Radiative and conductive thermal properties of foams. In Cellular and Porous Materials: Thermal Properties Simulation and Prediction; Öchsner, A., Murch, G.E., de Lemos, M.J.S., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2008; pp. 343–384. ISBN 9783527319381. [Google Scholar]

- Boomsma, K.; Poulikakos, D. On the effective thermal conductivity of a three-dimensionally structured fluid-saturated metal foam. Int. J. Heat Mass Transf. 2001, 44, 827–836. [Google Scholar] [CrossRef]

- Zhao, C.Y. Review on thermal transport in high porosity cellular metal foams with open cells. Int. J. Heat Mass Transf. 2012, 55, 3618–3632. [Google Scholar] [CrossRef]

- Bağcı, Ö.; Dukhan, N. Experimental hydrodynamics of high-porosity metal foam: Effect of pore density. Int. J. Heat Mass Transf. 2016, 103, 879–885. [Google Scholar] [CrossRef]

- Ambrosio, G.; Bianco, N.; Chiu, W.K.S.; Iasiello, M.; Naso, V.; Oliviero, M. The effect of open-cell metal foams strut shape on convection heat transfer and pressure drop. Appl. Therm. Eng. 2016, 103, 333–343. [Google Scholar] [CrossRef]

- Coquard, R.; Baillis, D. Numerical investigation of conductive heat transfer in high-porosity foams. Acta Mater. 2009, 57, 5466–5479. [Google Scholar] [CrossRef]

- Coquard, R.; Baillis, D. Conductive Heat Transfer in Metallic/Ceramic Open-Cell Foams. Adv. Eng. Mater. 2008, 10, 323–337. [Google Scholar] [CrossRef]

- Coquard, R.; Rochais, D.; Baillis, D. Conductive and Radiative Heat Transfer in Ceramic and Metal Foams at Fire Temperatures. Fire Technol. 2012, 48, 699–732. [Google Scholar] [CrossRef]

- Baillis, D.; Coquard, R.; Cunsolo, S. Effective conductivity of Voronoi’s closed- and open-cell foams: Analytical laws and numerical results. J. Mater. Sci. 2017, 52, 11146–11167. [Google Scholar] [CrossRef]

- Randrianalisoa, J.H.; Coquard, R.; Baillis, D. Microscale direct calculation of solid phase conductivity of Voronoi’s foams. J. Porous Media 2013, 16, 411–426. [Google Scholar] [CrossRef]

- Skibinski, J.; Cwieka, K.; Kowalkowski, T.; Wysocki, B.; Wejrzanowski, T.; Kurzydlowski, K.J. The influence of pore size variation on the pressure drop in open-cell foams. Mater. Des. 2015, 87, 650–655. [Google Scholar] [CrossRef]

- Roberts, A.P.; Garboczi, E.J. Elastic properties of model porous ceramics. J. Am. Ceram. Soc. 2000, 83, 3041–3048. [Google Scholar] [CrossRef]

- Regulski, W.; Szumbarski, J.; Łaniewski-Wołłk, Ł.; Gumowski, K.; Skibiński, J.; Wichrowski, M.; Wejrzanowski, T. Pressure drop in flow across ceramic foams—A numerical and experimental study. Chem. Eng. Sci. 2015, 137, 320–337. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Lu, W.; Zhao, C.Y.; Tassou, S.A. Thermal analysis on metal-foam filled heat exchangers. Part I: Metal-foam filled pipes. Int. J. Heat Mass Transf. 2006, 49, 2751–2761. [Google Scholar] [CrossRef]

- Bauer, T.H. A general analytical approach toward the thermal conductivity of porous media. Int. J. Heat Mass Transf. 1993, 36, 4181–4191. [Google Scholar] [CrossRef]

| CV(V) | 0.48 | 0.85 | 1.26 | 1.69 | 2.08 |

| E(V) | 0.175 | 0.175 | 0.175 | 0.175 | 0.175 |

| SD(V) | 0.0837 | 0.1503 | 0.2206 | 0.2967 | 0.3647 |

| Structure | Commercial Materials | Numerical Models | ||||

|---|---|---|---|---|---|---|

| 10 ppi No 1 | 10 ppi No 2 | 10 ppi No 3 | LVT CV(V) = 0.458 | LVT CV(V) = 0.478 | LVT CV(V) = 0.484 | |

| Porosity (%) | 90.98 | 90.37 | 91.19 | 91,71 | 91,78 | 91,85 |

| Mean pore diameter (mm) | 3.753 | 3.836 | 3.917 | 3.31 | 3.34 | 3.42 |

| Mean strut diameter (mm) | 1.144 | 1.192 | 1.137 | 1.00 | 1.00 | 1.00 |

| Structure | Commercial Materials | Numerical Models | ||||

|---|---|---|---|---|---|---|

| 10 ppi No 1 | 10 ppi No 2 | 10 ppi No 3 | LVT CV(V) = 0.458 | LVT CV(V) = 0.478 | LVT CV(V) = 0.484 | |

| keff (W/mK) | 22.71 | 23.20 | 22.54 | 20.52 | 20.44 | 20.38 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skibinski, J.; Cwieka, K.; Haj Ibrahim, S.; Wejrzanowski, T. Influence of Pore Size Variation on Thermal Conductivity of Open-Porous Foams. Materials 2019, 12, 2017. https://doi.org/10.3390/ma12122017

Skibinski J, Cwieka K, Haj Ibrahim S, Wejrzanowski T. Influence of Pore Size Variation on Thermal Conductivity of Open-Porous Foams. Materials. 2019; 12(12):2017. https://doi.org/10.3390/ma12122017

Chicago/Turabian StyleSkibinski, Jakub, Karol Cwieka, Samih Haj Ibrahim, and Tomasz Wejrzanowski. 2019. "Influence of Pore Size Variation on Thermal Conductivity of Open-Porous Foams" Materials 12, no. 12: 2017. https://doi.org/10.3390/ma12122017

APA StyleSkibinski, J., Cwieka, K., Haj Ibrahim, S., & Wejrzanowski, T. (2019). Influence of Pore Size Variation on Thermal Conductivity of Open-Porous Foams. Materials, 12(12), 2017. https://doi.org/10.3390/ma12122017