High Sulfate Attack Resistance of Reinforced Concrete Flumes Containing Liquid Crystal Display (LCD) Waste Glass Powder

Abstract

:1. Introduction

2. Materials and Experimental Methods

2.1. Material Characterization and Mix Properties

2.2. Test for Slump of the LWGP Concrete (KS F 2402)

2.3. Test for the Compressive Strength of Concrete (KS F 2405)

2.4. Test for the Porosity and Pore Size Distribution

2.5. Test for the Sulfate Attack Resistance of Concrete

2.6. Manufacturing LWGP Concrete Flumes

2.7. Flexural Loads of the LWGP Concrete Flumes

3. Results and Discussion

3.1. Slump

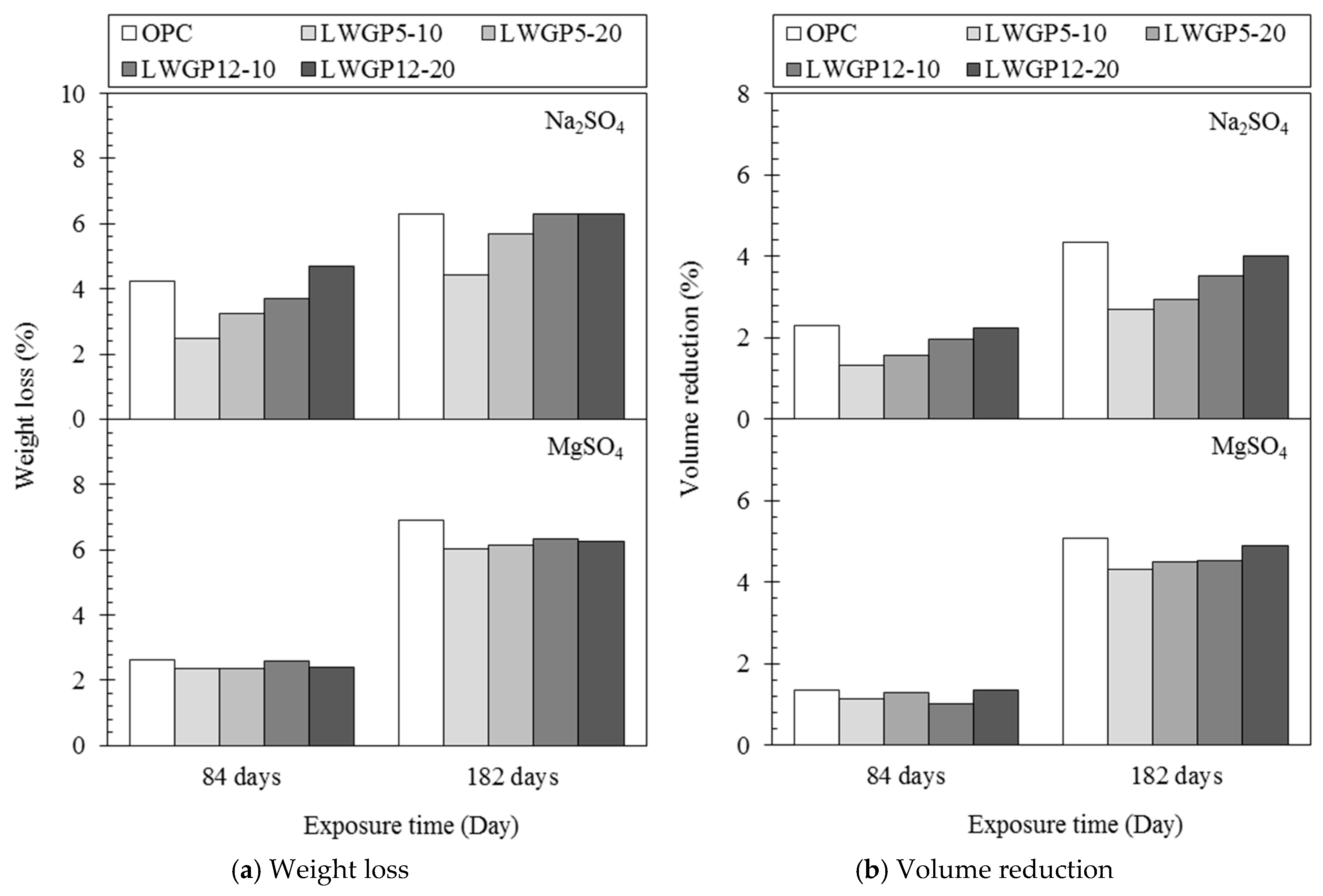

3.2. Changes in Weight and Volume

3.3. Compressive Strength and Strength Change

3.4. Pore Distribution of the Concrete Blended with the LWGP Powder

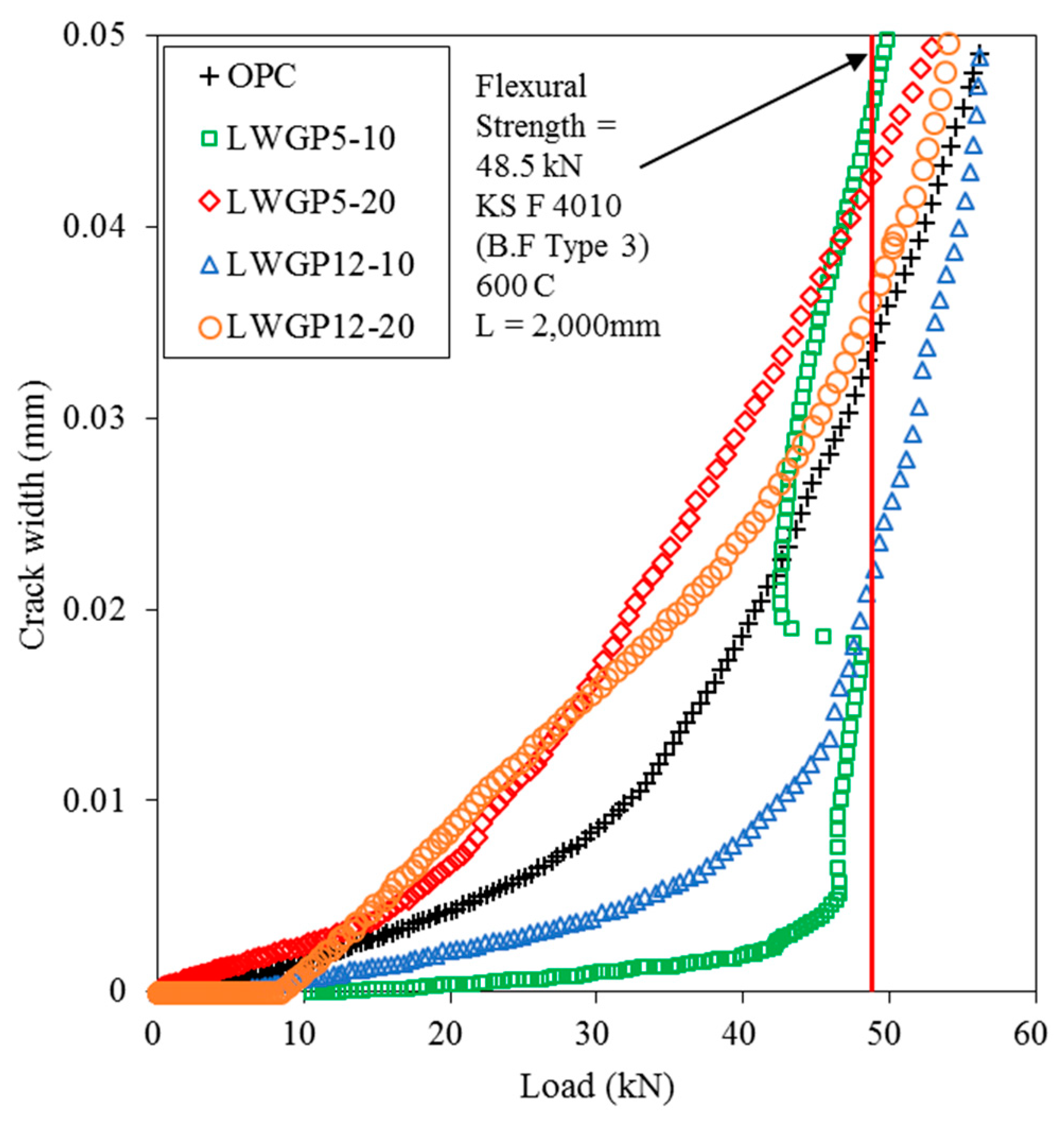

3.5. Flexural Capacity

4. Conclusions

- (1)

- The LWGP yielded large compressive strengths of 23.66 to 28.92 MPa at 28 days. LWGP5 especially resulted in a strength increase greater than those of OPC. By contrast, the strengths of the LWGP12 demonstrated a compressive strength smaller than those of OPC, regardless of the substituted ratios of the LWGP.

- (2)

- A pore decrease of 25.4% compared with OPC was observed at 28 days when the LWGP5-20 powder was used with concrete. The capillary pores (below 10 μm) related with the ion penetrations were found in the order of OPC (17.79%), LWGP12-10 (16.32%), LWGP12-20 (16.24%), LWGP5-10 (13.79%), and LWGP5-20 (13.27%). The capillary pores occupied by Ca(OH)2 decreased, whereas the gel pores increased by forming the C–S–H gel. This led to pore reduction and a higher strength development.

- (3)

- The reduction ratios of the weight and the volume for concretes with the mixture of LWGP powders were smaller than with OPC. The reduction ratios of the weight and the volume of the LWGP5-10 concrete were the lowest as 4.41% and 2.70% when they were immersed in the Na2SO4 solution for 182 days, whereas those were 6.04% and 4.32% when immersed in the MgSO4 solution. This trend was found to be similar to that of the compressive concrete strength immersed in the sulfate solution.

- (4)

- The maximum flexural load of the LWGP concrete flume was the highest at 69.92 kN in the LWGP5-10 contained concrete, while the LWGP10 contained concrete flumes smaller than the OPC concrete flumes. The flexural load of the concrete was generally increased or decreased in proportion to the compressive strength; hence, the tendency similarity was confirmed. Moreover, the opposite case was that the decrease of the flexural load of the concrete flume with LWGP10 also had the same tendency.

- (5)

- The flexural loads of all the LWGP concrete flumes with a crack width of 0.05 mm were greater than the 48.5 kN required by the KS code, but smaller than the flexural loads of OPC. The initial cracks were effectively controlled for LWGP5-10 and LWGP12-10 before the critical load.

- (6)

- The durability of the conventional reinforced concrete flumes against the sulfate attack resistance was improved by substituting cement by LWGP, thereby extending the use of the new reinforced concrete flumes to the replacement of conventional reinforced concrete flumes. The applicability was also validated by the flexural test complying with KS.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; Zhang, F.; Deng, D.; Xie, Y.; Long, G.; Tang, X. Physical sulfate attack on concrete lining–A field case analysis. Case Stud. Constr. Mater. 2017, 6, 206–212. [Google Scholar] [CrossRef]

- Yoshida, N.; Matsunami, Y.; Nagayama, M.; Sakai, E. Salt weathering in residential concrete foundation exposed to sulfate-bearing ground. J. Adv. Concr. Technol. 2010, 8, 121–134. [Google Scholar] [CrossRef]

- Haynes, H.; O’Neill, R.; Neff, M.; Mehta, P.K. Salt weathering distress on concrete exposed to sodium sulfate environment. ACI Mater. J. 2008, 105, 35–43. [Google Scholar]

- Lee, S. Magnesium sulfate attack and deterioration mode of matakaolin blended cement matrix. J. Korea Concr. Inst. 2009, 21, 21–27. [Google Scholar] [CrossRef]

- Kim, M.; Baek, D. Unit weight and compressive strength of cement mortars using crushed sand under sulfate attacks. J. Korean Soc. Civ. Eng. 2007, 27, 585–591. [Google Scholar]

- Moon, H.; Lee, S.; Kim, H.; Kim, S. Evaluation on the resistance of Portland cement mortars due to chemical attack. J. Korean Soc. Civ. Eng. 2002, 22, 181–191. [Google Scholar]

- Santhanam, M.; Cohen, M.D.; Olek, J. Mechanism of sulfate attack: A fresh look part 2: Proposed Mechanisms. Cem. Concr. Res. 2003, 33, 341–346. [Google Scholar] [CrossRef]

- Moon, H.Y.; Jeon, J.K.; Kim, H.S. Resistance on the sulfuric acid corrosion of cement matrix containing mineral admixture. J. Korean Soc. Civ. Eng. 2005, 25, 225–232. [Google Scholar]

- Wee, T.H.; Suryavanshi, A.K.; Wong, S.F.; Rahman, A.K.M.A. Sulfate resistance of concrete containing mineral admixtures. ACI Mater. J. 2000, 97, 536–549. [Google Scholar]

- Shin, D.; Kang, L.; Park, J.L.; Lee, C.G.; Yoon, J.; Hong, H.S. Current research trend on recycling of waste flat panel display panel glass. J. Korean Inst. Resour. Recycl. 2015, 24, 58–65. [Google Scholar] [CrossRef]

- Kim, K.; Kim, K.; Hwang, J. LCD waste glass as a substitute for feldspar in the porcelain sanitary ware production. Ceram. Int. 2015, 41, 7097–7102. [Google Scholar] [CrossRef]

- Lee, C.T. Synthesis of zeolite from waste LCD panel glass. Appl. Chem. Eng. 2017, 28, 521–528. [Google Scholar] [CrossRef]

- Kim, S.K.; Hanif, A.; Jang, I.Y. Incorporating liquid crystal display (LCD) glass waste as supplementary cementing material (SCM) in cement mortars-rationale based on hydration, Durability, and Pore Characteristics. Materials 2018, 11, 2538. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.K.; Kang, S.T.; Kim, J.K.; Jang, I.Y. Effects of particle size and cement replacement of LCD glass powder in concrete. Adv. Mater. Sci. Eng. 2017, 2017, 1–12. [Google Scholar] [CrossRef]

- Kim, S.K.; Jang, P.K.; Jang, I.Y. Material bahavior and strength character of 150 MPa ultra high strength concrete using LCD glass powder as fine aggregate. J. Korea Concr. Inst. 2017, 29, 615–623. [Google Scholar] [CrossRef]

- Wang, H.Y. A study of the effects of LCD glass sand on the properties of concrete. Waste Manag. 2009, 29, 335–341. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.Y.; Huang, W.L. Durability of self-consolidating concrete using waste LCD glass. Constr. Build. Mater. 2010, 24, 1008–1013. [Google Scholar] [CrossRef]

- Wang, H.; Hou, T. A study of elevated temperatures on the strength properties of LCD glass powder cement mortars. Integr. Waste Manag. 2011, 1. [Google Scholar] [CrossRef]

- KS F 4010 Reinforced concrete flumes and bench flumes; Korean Standards Association: Seoul, Korea, 2010.

- Higgins, D.D.; Crammond, N.J. Resistance of concrete containing ggbs to the thaumasite form of sulfate attack. Cem. Concr. Compos. 2003, 25, 921–929. [Google Scholar] [CrossRef]

- Roziere, E.; loukili, A.; El Hachem, R.; Grondin, F. Durability of concrete exposed to leaching and external sulphate attacks. Cem. Concr. Compos. 2009, 39, 1188–1198. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.W. Properties of fired bricks incorporating TFT-LCD waste glass powder with reservoir sediments. Sustainability 2018, 10, 2503. [Google Scholar] [CrossRef]

- ASTM C127-15 Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate; ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C128-15 Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate; ASTM International: West Conshohocken, PA, USA, 2015.

- KS F 2402-2017 Standard Test Method for Concrete Slump; Korean Standards Association: Seoul, Korea, 2017.

- KS F 2405-2017 Standard Test Method for Compressive Strength of Concrete; Korean Standards Association: Seoul, Korea, 2017.

- ASTM C1012-18b Standard Test Methods for Length Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution; ASTM International: West Conshohocken, PA, USA, 2018.

- Kim, S.K.; Lee, K.W.; Song, J.H.; Jang, I.Y. Durability performance evaluations on resistance to chloride attack for concrete using LCD waste glass powder. J. Korean Recycl. Constr. Resour. Inst. 2018, 4, 289–296. [Google Scholar] [CrossRef]

- Yu, H.; Yang, J.; Rong, H. Research on decalcification degradation process of cement stone. J. Wuhan Univ. Technol. 2015, 30, 369–374. [Google Scholar] [CrossRef]

- Zheng, K. Recycled Glass Concrete. Eco-Efficient Concrete; Chapter 11; Woodhead publishing: Cambridge, UK, 2013; ISBN 0128089016, 9780128089019. [Google Scholar]

- Yang, H.J.; Jin, S.H.; Ann, K.Y. Chloride transport of high alumina cement mortar exposed to a saline solution. Adv. Mater. Sci. Eng. 2016, 2016, 1–8. [Google Scholar] [CrossRef]

- Park, K.; Cho, Y.; Shin, D. Effects of magnesium and sulfate ions on the sulfate attack resistance of alkali-activated materials. J. Korea Concr. Inst. 2017, 29, 415–424. [Google Scholar] [CrossRef]

- Rasheeduzzafar, O.S.B.; Al-Amoudi, O.S.B.; Abduljauwad, S.N.; Maslehuddin, M. Magnesium—sodium sulfate attack in plain and blended cements. J. Mater. Civ. Eng. 1994, 6, 201–222. [Google Scholar] [CrossRef]

- Neville, A. The confused world of sulfate attack on concrete. Cem. Concr. Res. 2004, 34, 1275–1296. [Google Scholar] [CrossRef]

- Al-Amoudi, O.S.B. Attack on plain and blended cements exposed to aggressive sulfate environments. Cem. Concr. Compos. 2002, 24, 305–316. [Google Scholar] [CrossRef]

- Hanif, A.; Parthasarathy, P.; Ma, H.; Fan, T.; Li, Z. Properties improvement of fly ash cenosphere modified cement pastes using nano-silica. Cem. Concr. Compos. 2017, 81, 35–48. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties and Materials, 4th ed.; McGraw-Hill Companies: New York, USA, 2013. [Google Scholar]

- Aligizaki, K.K. Pore Structure of Cement-Based Materials: Testing, Interpretation and Requirements; Taylor & Francis: London, UK; New York, NY, USA, 2006; ISBN 9780419228004. [Google Scholar]

- Allen, A.J.; Thomas, J.J.; Jennings, H.M. Composition and density of nanoscale calcium-silicate-hydrate in cement. Nat. Mater. 2007, 6, 311–316. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Wu, S.; Zhou, J. Influence of porosity on compressive and tensile strength of cement mortar. Constr. Build. Mater. 2013, 40, 869–874. [Google Scholar] [CrossRef]

- Nunes, C.; Slížková, Z.; Stefanidou, M.; Němeček, J. Microstructure of lime and lime-pozzolana pastes with nanosilica. Cem. Concr. Res. 2016, 83, 152–163. [Google Scholar] [CrossRef]

| Oxide Composition | Specific Gravity | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | Na2O | K2O | MgO | ||

| OPC | 65.42 | 19.09 | 4.06 | 3.11 | 3.79 | 0.10 | 1.58 | 2.85 | 3.15 |

| LWGP5 | 10.00 | 66.90 | 18.21 | 0.08 | – | 0.23 | 0.05 | 0.44 | 2.79 |

| LWGP12 | 10.3 | 65.7 | 18.0 | 0.14 | – | 0.18 | 0.04 | 0.42 | 2.81 |

| Fineness Modulus | Water Absorption* (%) | Specific Gravity (N/m3) | |

|---|---|---|---|

| Fine aggregate | 2.94 | 1.3 | 2.56 |

| Coarse aggregate | 6.51 | 1.2 | 2.59 |

| W/B (%) | S/a (%) | Unit Weight (kg/m3) | |||||

|---|---|---|---|---|---|---|---|

| Water | Cement | LWGP5, LWGP12 | Fine Aggregate | Coarse Aggregate | |||

| 47.2 | 39.6 | 150 | 360 | 0% | 0 | 400 | 1109 |

| 324 | 10% | 36 | |||||

| 288 | 20% | 72 | |||||

| Porosity | 28 days | |||||

|---|---|---|---|---|---|---|

| OPC | LWGP 5-10 | LWGP 5-20 | LWGP 12-10 | LWGP 12-20 | ||

| Void | > 10 μm | 2.88 | 1.76 | 2.17 | 3.69 | 3.41 |

| Large-capillary | 0.05–10 μm | 9.74 | 5.41 | 3.41 | 8.49 | 9.11 |

| Medium-capillary | 0.01–0.05 μm | 4.30 | 5.07 | 6.33 | 3.46 | 3.01 |

| Small-capillary | < 0.01μm | 0.87 | 1.56 | 1.36 | 0.69 | 0.72 |

| Total | 17.79 | 13.79 | 13.27 | 16.32 | 16.24 | |

| Flexural Loads of the Reinforced Concrete Flumes | ||||

|---|---|---|---|---|

| Pu(kN) | Pcr(kN) | Wcr(mm) | Normalized Pcr/Wcr(%) | |

| OPC | 65.66 | 56.59 | 0.0501 | 100 |

| LWGP5-10 | 69.92 | 50.01 | 0.0504 | 87.85 |

| LWGP5-20 | 67.99 | 52.89 | 0.0507 | 92.36 |

| LWGP12-10 | 62.21 | 56.10 | 0.0505 | 98.35 |

| LWGP12-20 | 58.56 | 53.89 | 0.0508 | 93.92 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-K.; Hong, W.-K. High Sulfate Attack Resistance of Reinforced Concrete Flumes Containing Liquid Crystal Display (LCD) Waste Glass Powder. Materials 2019, 12, 2031. https://doi.org/10.3390/ma12122031

Kim S-K, Hong W-K. High Sulfate Attack Resistance of Reinforced Concrete Flumes Containing Liquid Crystal Display (LCD) Waste Glass Powder. Materials. 2019; 12(12):2031. https://doi.org/10.3390/ma12122031

Chicago/Turabian StyleKim, Seong-Kyum, and Won-Kee Hong. 2019. "High Sulfate Attack Resistance of Reinforced Concrete Flumes Containing Liquid Crystal Display (LCD) Waste Glass Powder" Materials 12, no. 12: 2031. https://doi.org/10.3390/ma12122031

APA StyleKim, S.-K., & Hong, W.-K. (2019). High Sulfate Attack Resistance of Reinforced Concrete Flumes Containing Liquid Crystal Display (LCD) Waste Glass Powder. Materials, 12(12), 2031. https://doi.org/10.3390/ma12122031