Mechanical Properties of Aluminum Alloys under Low-Cycle Fatigue Loading

Abstract

:1. Introduction

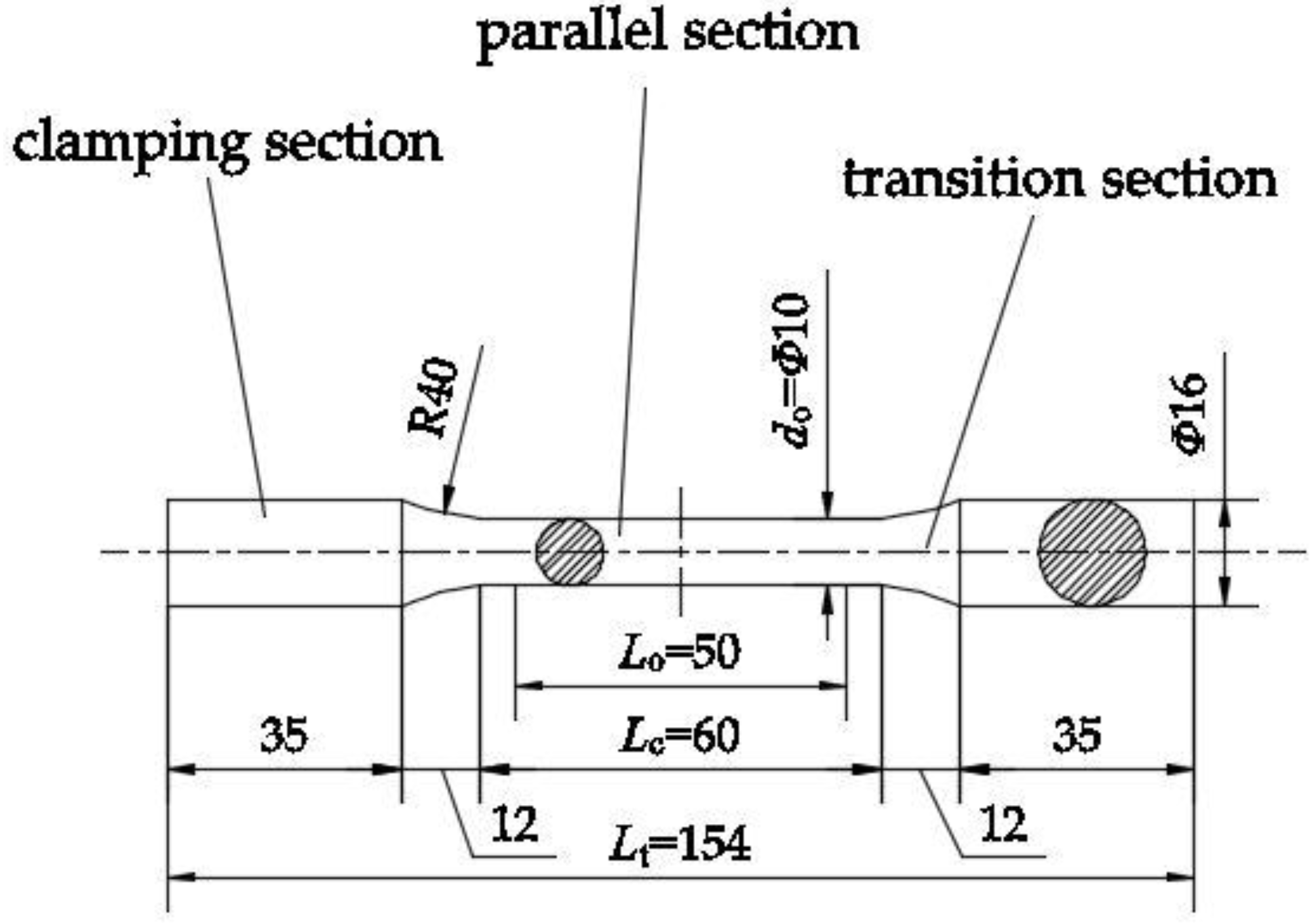

2. Experimental Setup

3. Results and Discussion

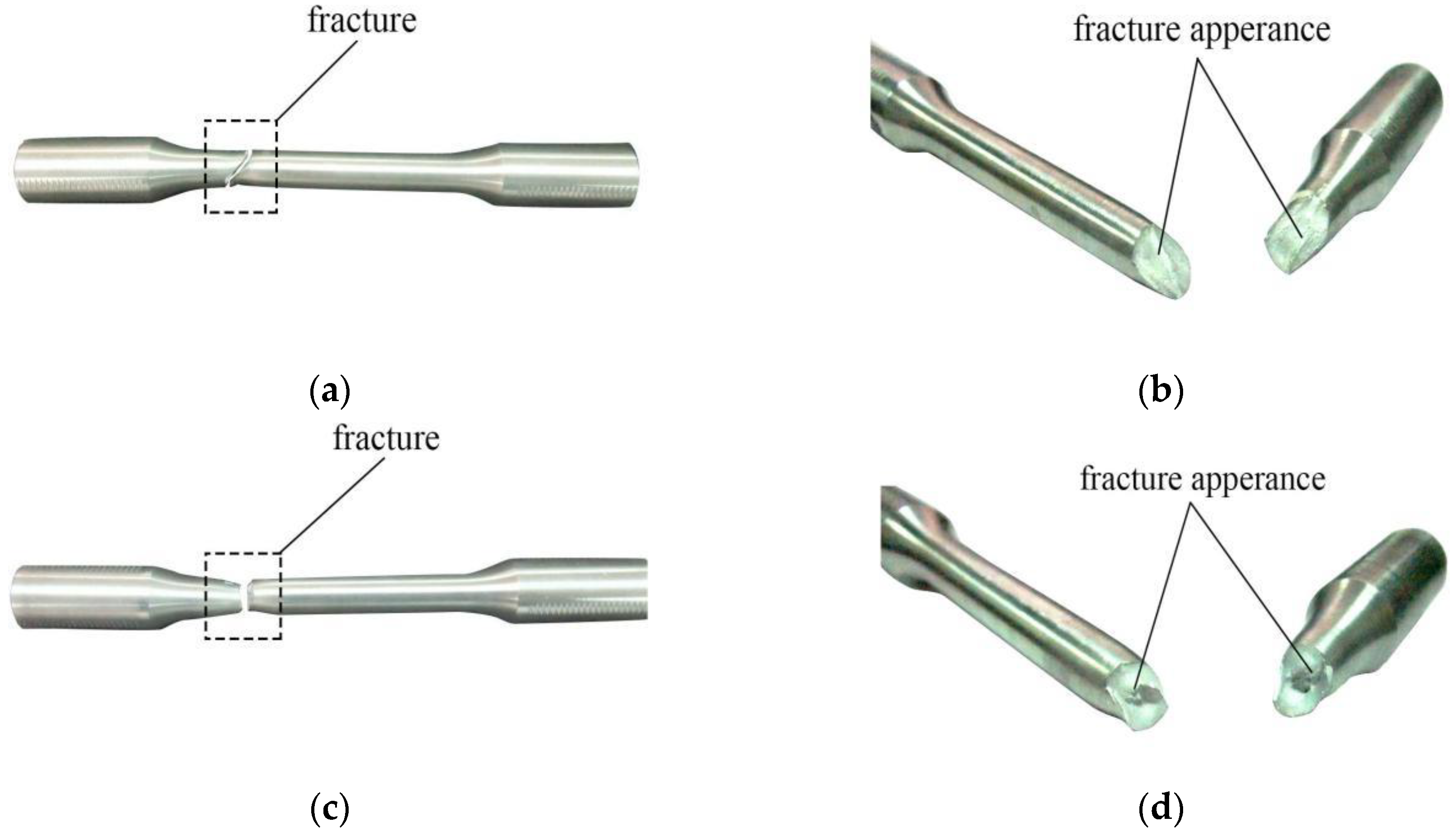

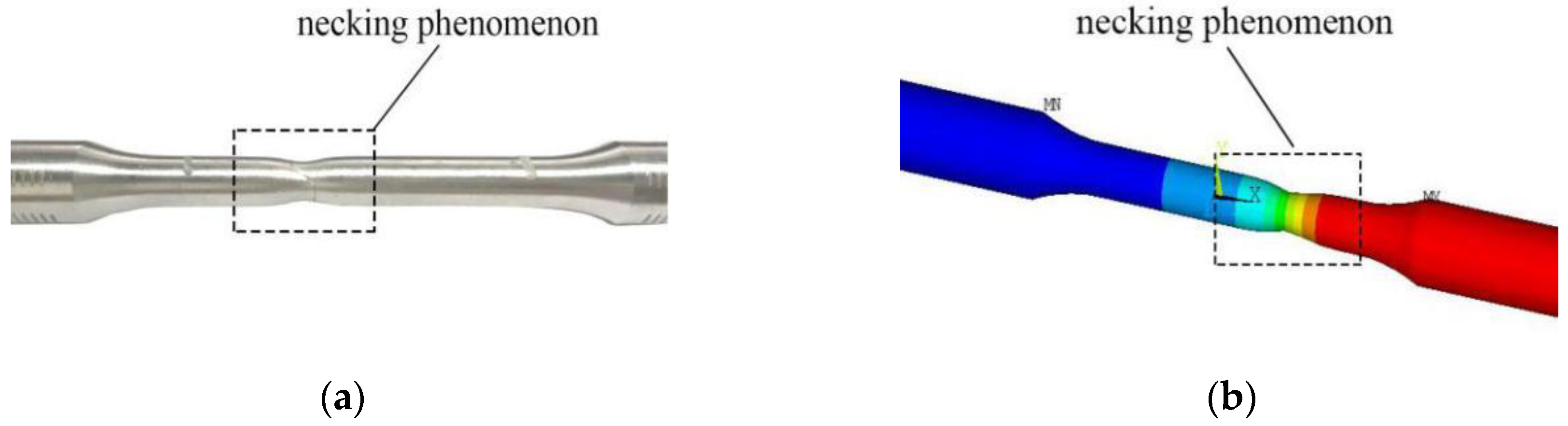

3.1. Fracture Features

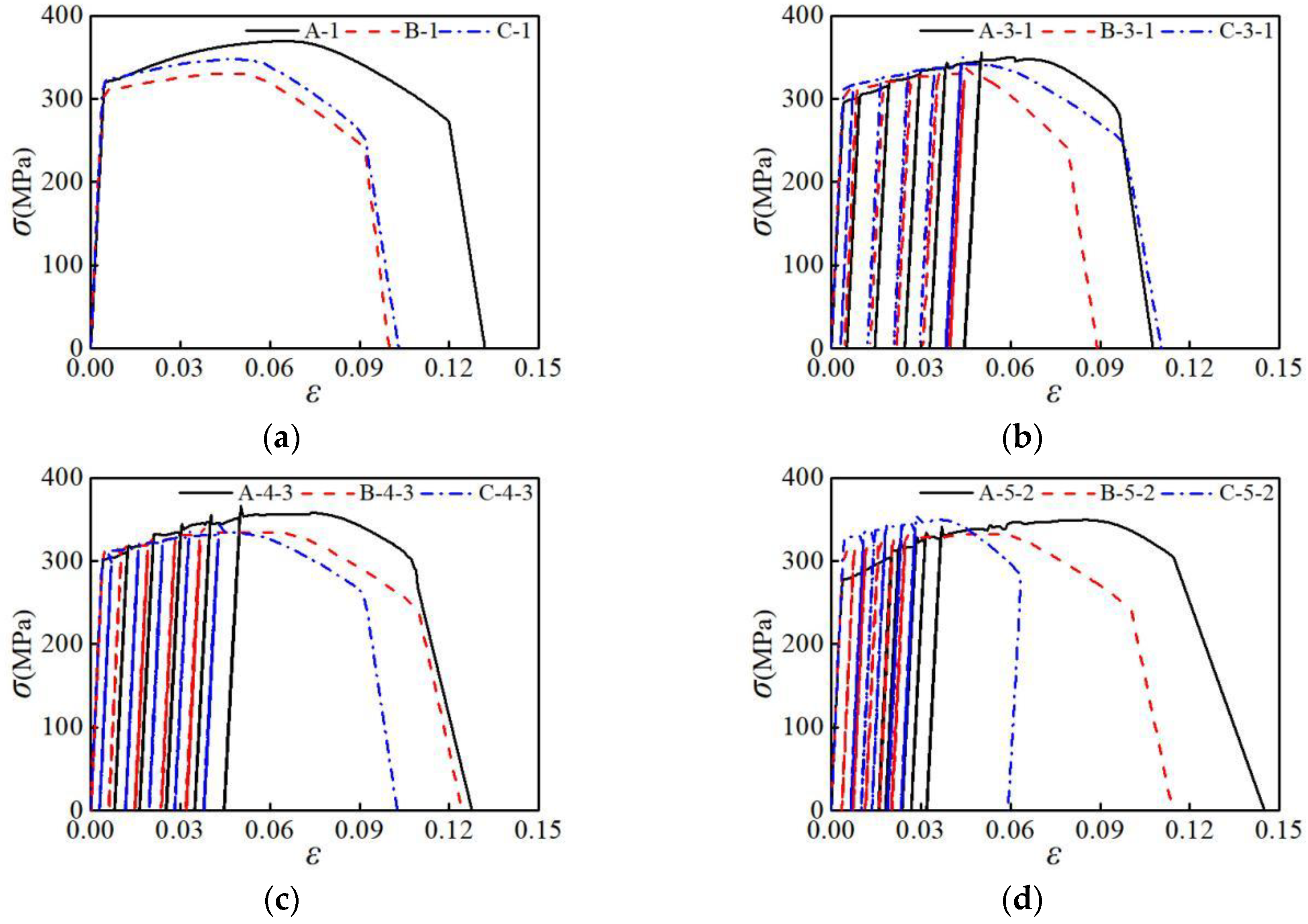

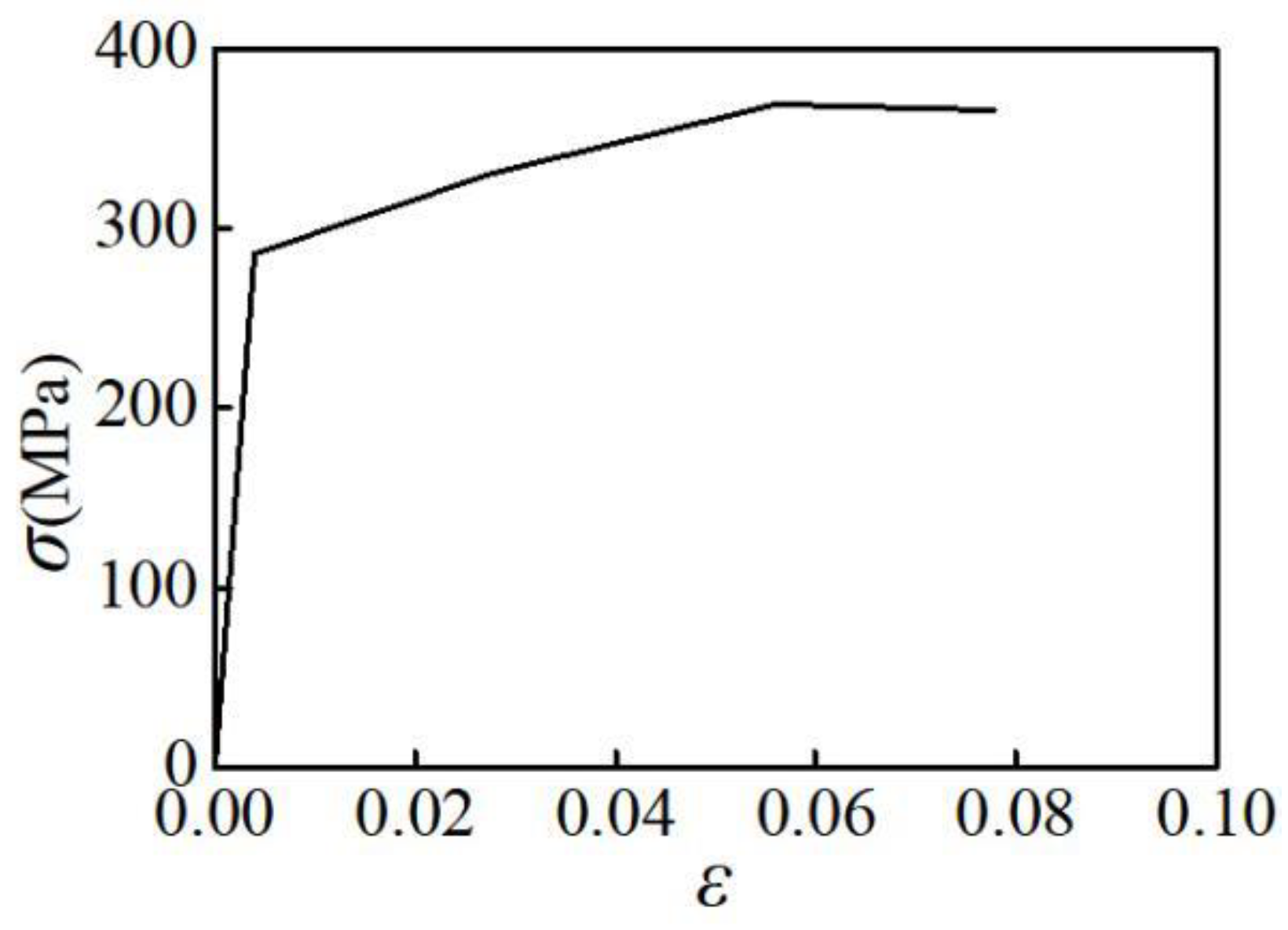

3.2. Stress-Strain Curves

3.2.1. Influence of Material Type

3.2.2. Influence of Loading Pattern

3.3. Stress Cycle Characteristics

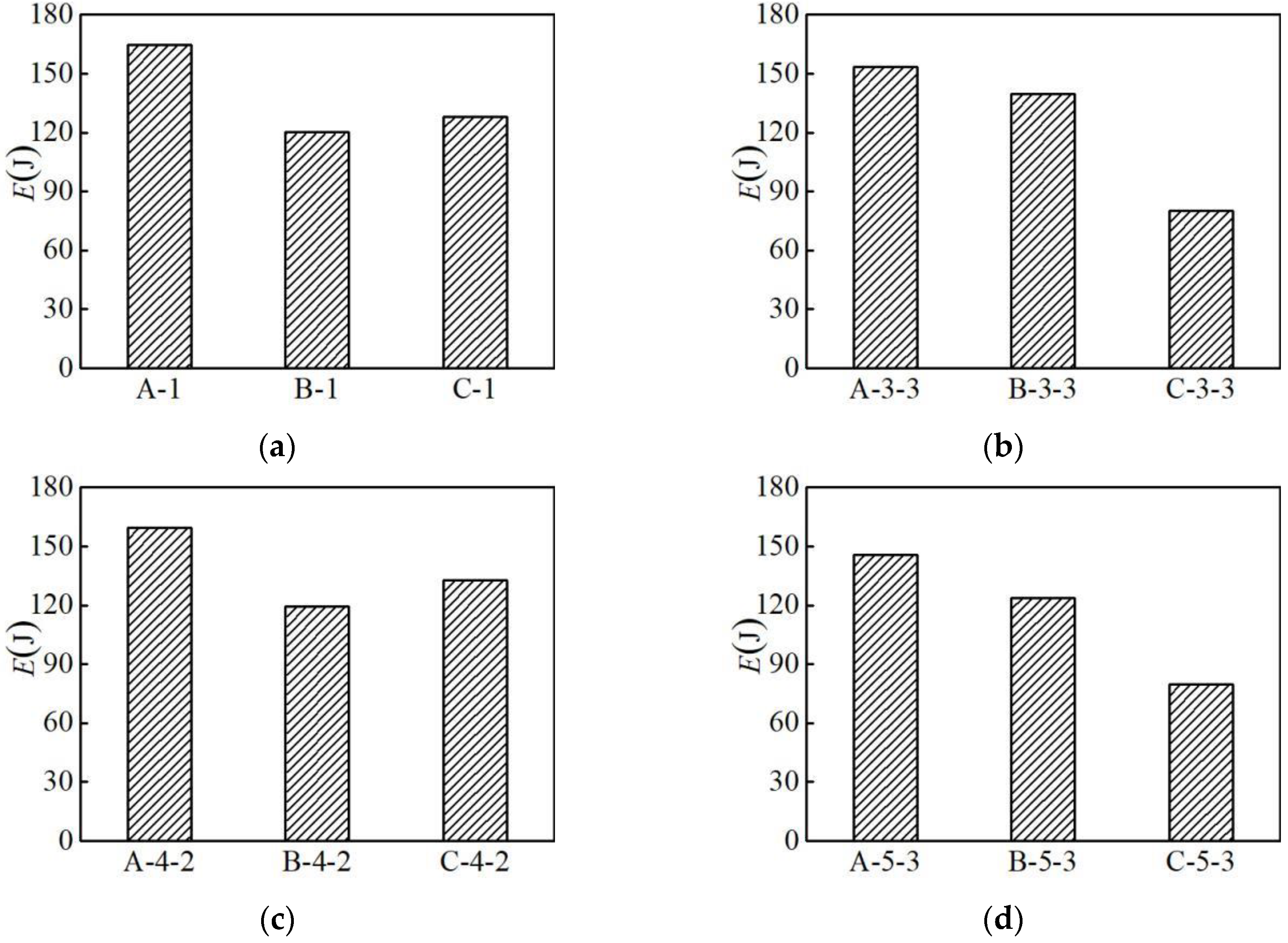

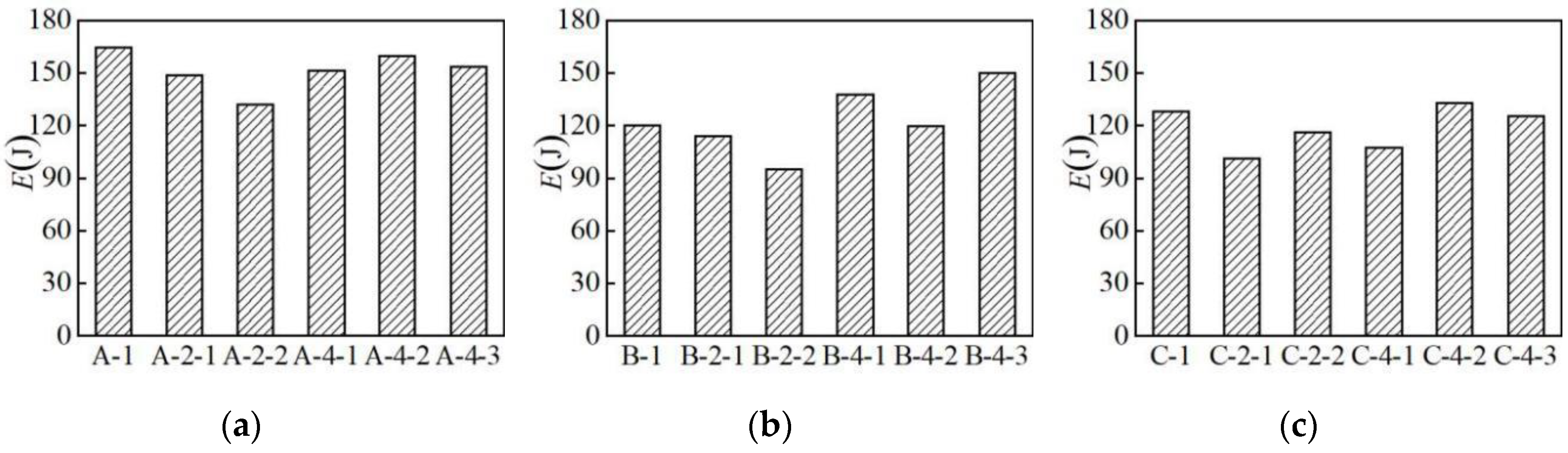

3.4. Hysteresis Energy

3.4.1. Influence of Material Type

3.4.2. Influence of Loading Pattern

4. Finite Element Model and Parameter Analysis

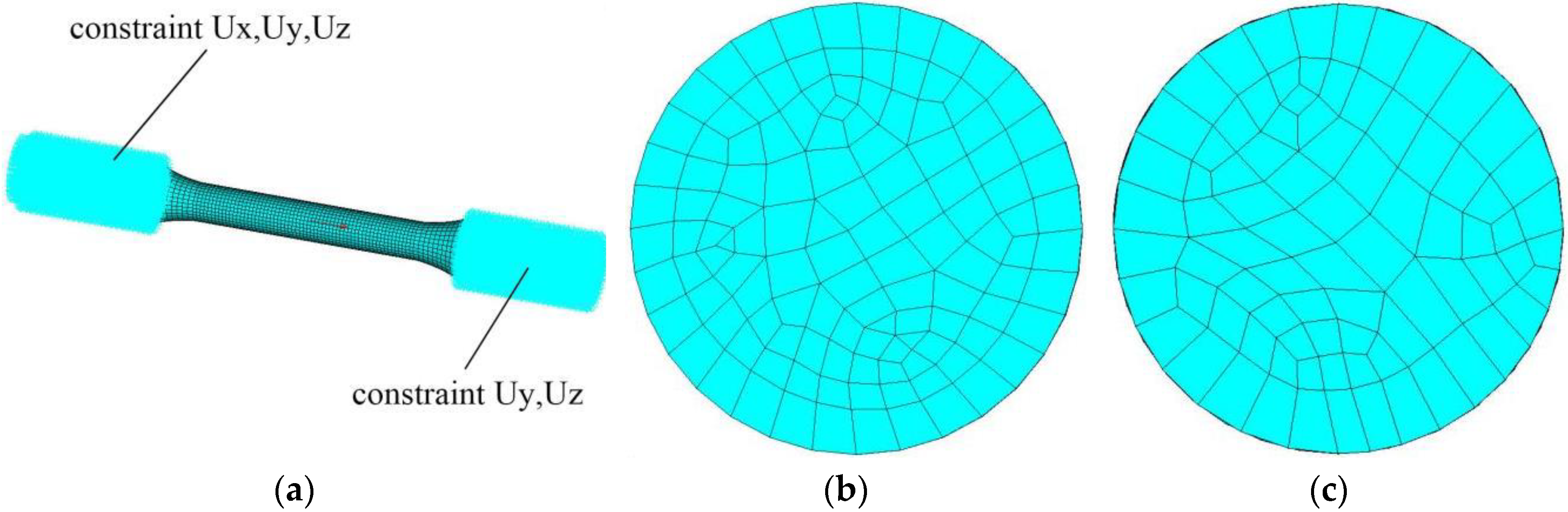

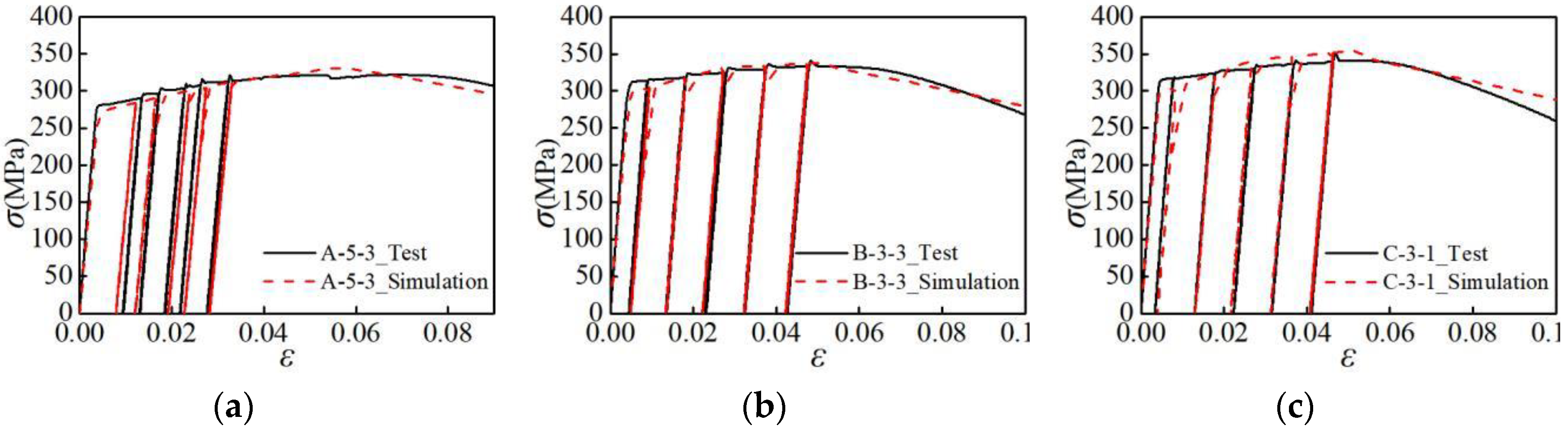

4.1. Finite Element Model and Verification

4.2. Numerical Analysis Specimens

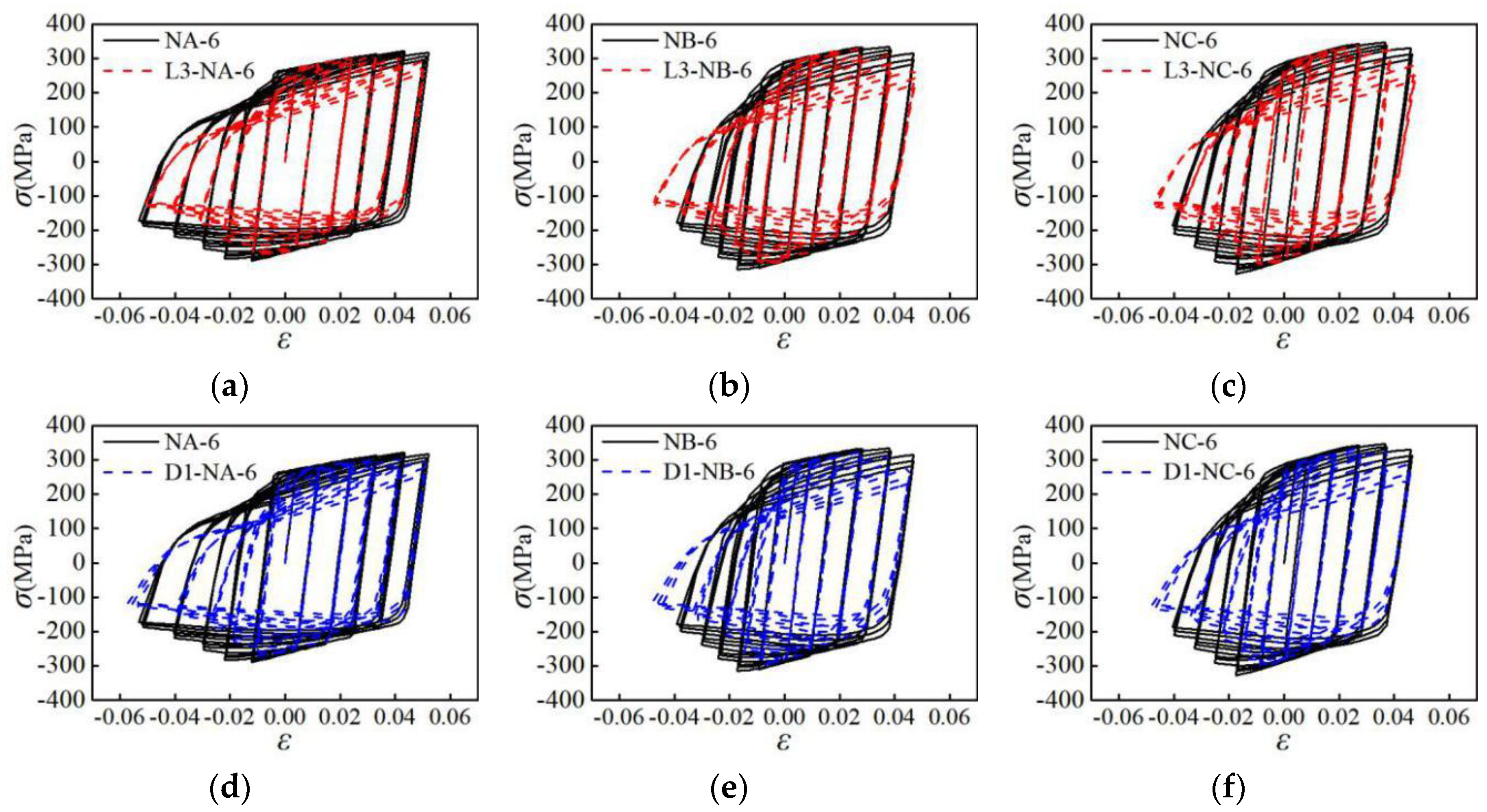

4.3. Hysteresis Curves

4.4. Skeleton Curves

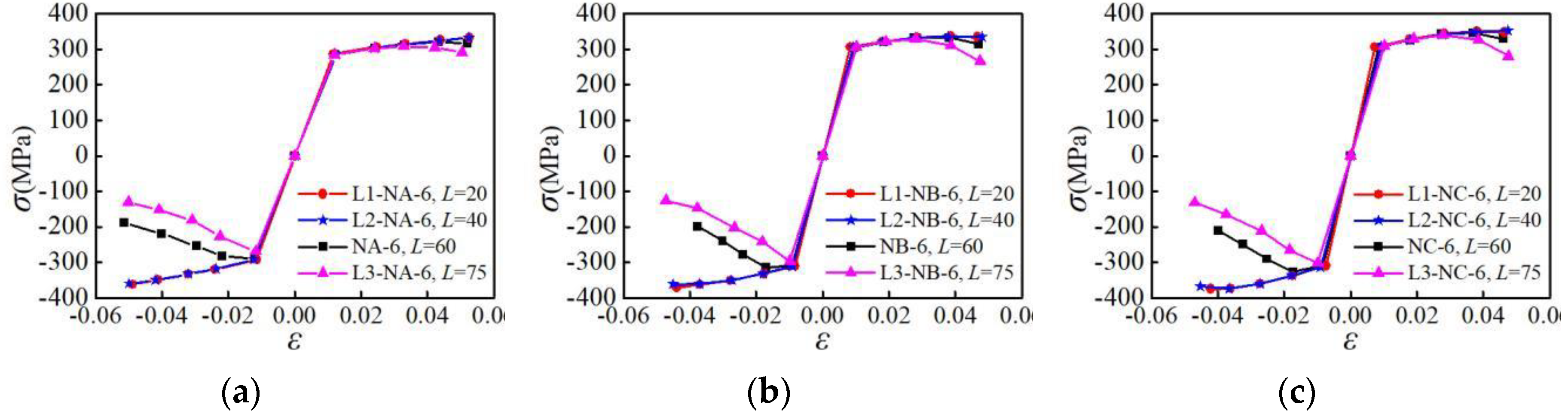

4.4.1. Influence of Parallel Section Length

4.4.2. Influence of Parallel Section Diameter

4.4.3. Influence of Loading Pattern

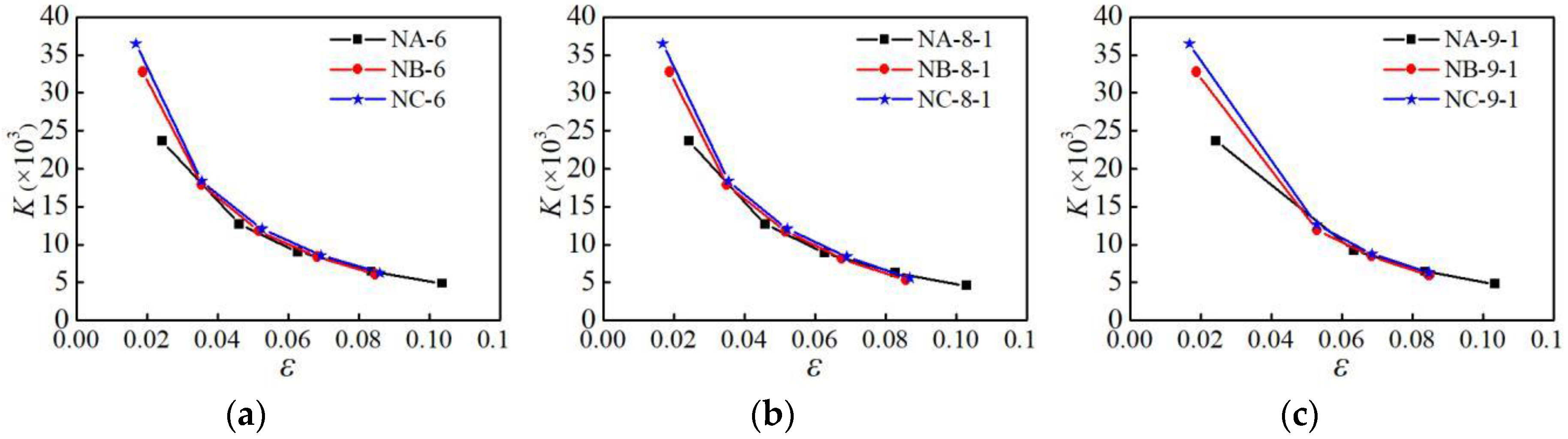

4.5. Stiffness Degradation

4.5.1. Influence of Material Type

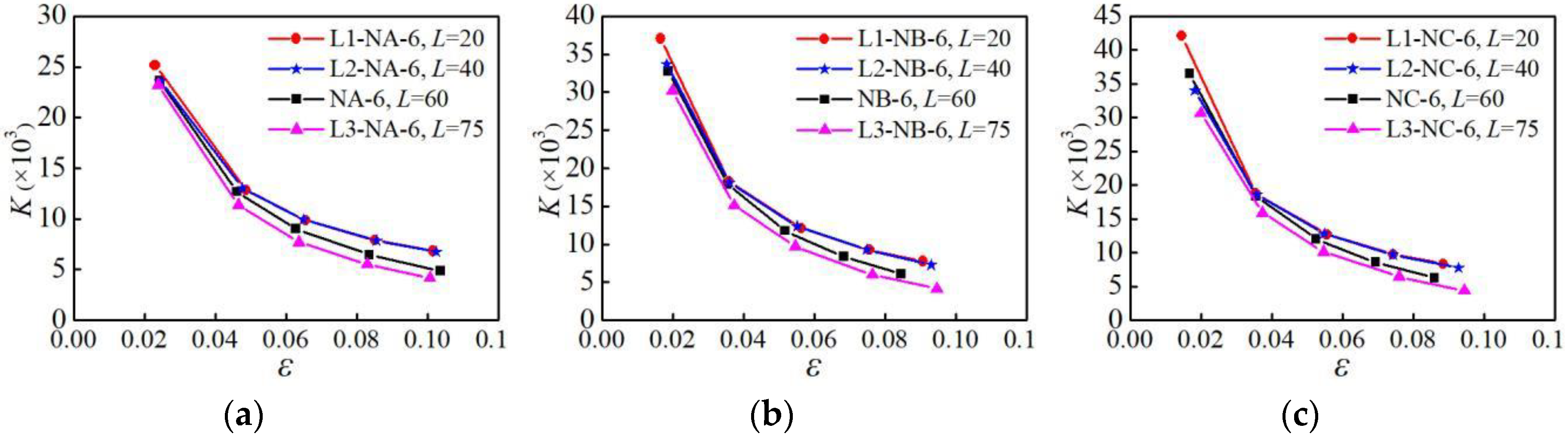

4.5.2. Influence of Parallel Section Length

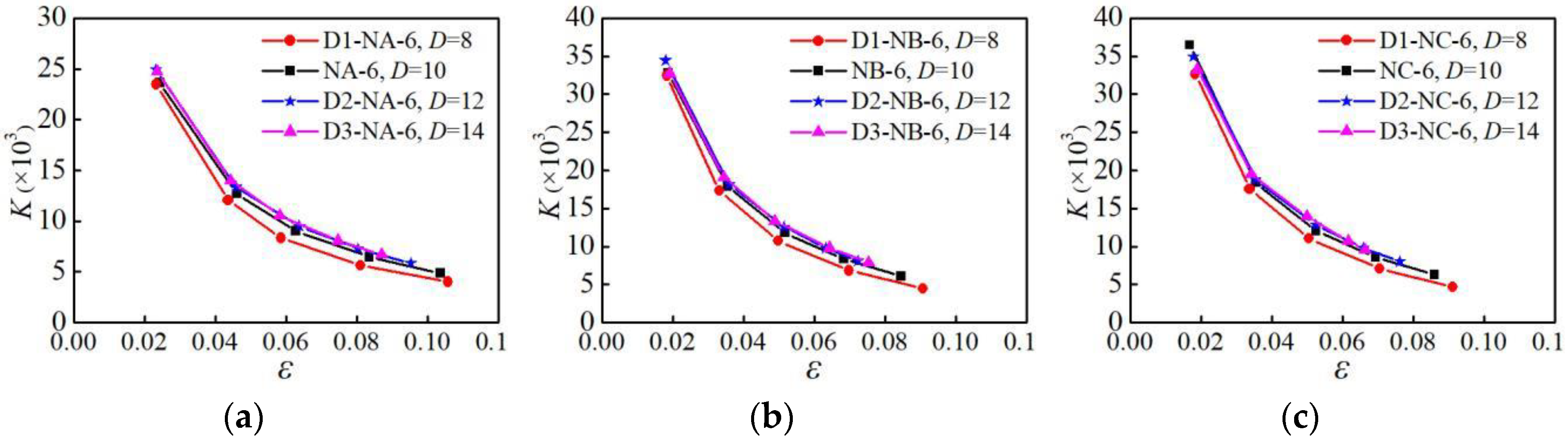

4.5.3. Influence of Parallel Section Diameter

5. Strength Design Formula

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Guo, X.; Xiong, Z.; Luo, Y.; Xu, H.; Liang, S. Block tearing and local buckling of aluminum alloy gusset joint plates. KSCE J. Civ. Eng. 2016, 20, 820–831. [Google Scholar] [CrossRef]

- Guo, X.; Xiong, Z.; Luo, Y.; Qiu, L.; Liu, J. Experimental investigation on the semi-rigid behaviour of aluminium alloy gusset joints. Thin Walled Struct. 2015, 87, 30–40. [Google Scholar] [CrossRef]

- Xue, L. A unified expression for low cycle fatigue and extremely low cycle fatigue and its implication for monotonic loading. Int. J. Fatigue 2008, 30, 1691–1698. [Google Scholar] [CrossRef]

- Libertiny, G.Z. Effect of Hydrostatic Pressure on the Short Life Fatigue Property of an Alloy Steel. Proc. Inst. Mech. Eng. 1967, 182, 58–64. [Google Scholar]

- Shaha, S.K.; Czerwinski, F.; Kasprzak, W.; Friedman, J.; Chen, D.L. Improving High-Temperature Tensile and Low-Cycle Fatigue Behavior of Al-Si-Cu-Mg Alloys Through Micro-additions of Ti, V, and Zr. Metall. Mater. Trans. A 2015, 46, 3063–3078. [Google Scholar] [CrossRef]

- Huang, H.; Dong, Y.; Xing, Y.; Jia, Z.; Liu, Q. Low cycle fatigue behaviour at 300 °C and microstructure of Al-Si-Mg casting alloys with Zr and Hf additions. J. Alloys Compd. 2018, 765, 1253–1262. [Google Scholar] [CrossRef]

- Liu, H.J.; Fujii, H.; Maeda, M.; Nogi, K. Tensile properties and fracture locations of friction-stir-welded joints of 2017-T351 aluminum alloy. J. Mater. Process. Technol. 2003, 142, 692–696. [Google Scholar] [CrossRef] [Green Version]

- Lee, W.B.; Yeon, Y.M.; Jung, S.B. The improvement of mechanical properties of friction-stir-welded A356 Al alloy. Mater. Sci. Eng. A 2003, 355, 154–159. [Google Scholar] [CrossRef]

- Srivatsan, T.S. The low-cycle fatigue and cyclic fracture behaviour of 7150 aluminium alloy. Int. J. Fatigue 1991, 13, 313–321. [Google Scholar] [CrossRef]

- Hao, H.; Ye, D.; Chen, C. Strain ratio effects on low-cycle fatigue behavior and deformation microstructure of 2124-T851 aluminum alloy. Mater. Sci. Eng. A 2014, 605, 151–159. [Google Scholar] [CrossRef]

- Arcari, A.; De Vita, R.; Dowling, N.E. Mean stress relaxation during cyclic straining of high strength aluminum alloys. Int. J. Fatigue 2009, 31, 1742–1750. [Google Scholar] [CrossRef]

- Arcari, A.; Dowling, N.E. Modeling mean stress relaxation in variable amplitude loading for 7075-T6511 and 7249-T76511 high strength aluminum alloys. Int. J. Fatigue 2012, 42, 238–247. [Google Scholar] [CrossRef]

- Kim, S.; Burns, J.T.; Gangloff, R.P. Fatigue crack formation and growth from localized corrosion in Al–Zn–Mg–Cu. Eng. Fract. Mech. 2009, 76, 651–667. [Google Scholar] [CrossRef]

- Lin, C.; Yang, S. Corrosion fatigue behavior of 7050 aluminum alloys in different tempers. Eng. Fract. Mech. 1998, 59, 779–795. [Google Scholar] [CrossRef]

- Burns, J.T.; Gupta, V.K.; Agnew, S.R.; Gangloff, R.P. Effect of low temperature on fatigue crack formation and microstructure-scale propagation in legacy and modern Al–Zn–Mg–Cu alloys. Int. J. Fatigue 2013, 55, 268–275. [Google Scholar] [CrossRef]

- Gasquères, C.; Sarrazin-Baudoux, C.; Petit, J.; Dumont, D. Fatigue crack propagation in an aluminium alloy at 223K. Scr. Mater. 2005, 53, 1333–1337. [Google Scholar] [CrossRef]

- Conley, J.G.; Huang, J.; Asada, J.; Akiba, K. Modeling the effects of cooling rate, hydrogen content, grain refiner and modifier on microporosity formation in Al A356 alloys. Mater. Sci. Eng. A 2000, 285, 49–55. [Google Scholar] [CrossRef]

- Wang, Q.G.; Apelian, D.; Lados, D.A. Fatigue behavior of A356-T6 aluminum cast alloys. Part I. Effect of casting defects. J. Light Met. 2001, 1, 73–84. [Google Scholar] [CrossRef]

- Azadi, M.; Shirazabad, M.M. Heat treatment effect on thermo-mechanical fatigue and low cycle fatigue behaviors of A356.0 aluminum alloy. Mater. Des. 2013, 45, 279–285. [Google Scholar] [CrossRef] [Green Version]

- Zhu, M.; Jian, Z.; Yang, G.; Zhou, Y. Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys. Mater. Des. 2012, 36, 243–249. [Google Scholar] [CrossRef]

- Wang, C.; Usami, T.; Funayama, J.; Imase, F. Low-cycle fatigue testing of extruded aluminium alloy buckling-restrained braces. Eng. Struct. 2013, 46, 294–301. [Google Scholar] [CrossRef]

- Underhill, P.R.; DuQuesnay, D.L. Effect of small cycles and load spectrum truncation on the fatigue life scatter in 7050 Al alloy. Int. J. Fatigue 2009, 31, 538–543. [Google Scholar] [CrossRef]

- DuQuesnay, D.L.; Underhill, P.R. Fatigue life scatter in 7xxx series aluminum alloys. Int. J. Fatigue 2010, 32, 398–402. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, G.; Cheng, J.; Jiang, L. Investigation of the low-cycle fatigue life under multi-axial non-proportional loading. Mater. Sci. Eng. A 2003, 355, 18–23. [Google Scholar] [CrossRef]

- ISO 6892-1: 2016 Metallic materials—Tensile testing—Part 1: Method of test at room temperature; International Organization for Standardization (ISO): Geneva, Switzerland, 2016.

| Specimen Label | Material Type | Loading Patterns | Specimen Label | Material Type | Loading Patterns |

|---|---|---|---|---|---|

| A-1 | AA6061 | NM1 | B-4-1 | AA7075 | NM4-1 |

| A-2-1 | AA6061 | NM2-1 | B-4-2 | AA7075 | NM4-2 |

| A-2-2 | AA6061 | NM2-2 | B-4-3 | AA7075 | NM4-3 |

| A-3-1 | AA6061 | NM3-1 | B-5-1 | AA7075 | NM5-1 |

| A-3-2 | AA6061 | NM3-2 | B-5-2 | AA7075 | NM5-2 |

| A-3-3 | AA6061 | NM3-3 | B-5-3 | AA7075 | NM5-3 |

| A-4-1 | AA6061 | NM4-1 | C-1 | AA6063 | NM1 |

| A-4-2 | AA6061 | NM4-2 | C-2-1 | AA6063 | NM2-1 |

| A-4-3 | AA6061 | NM4-3 | C-2-2 | AA6063 | NM2-2 |

| A-5-1 | AA6061 | NM5-1 | C-3-1 | AA6063 | NM3-1 |

| A-5-2 | AA6061 | NM5-2 | C-3-2 | AA6063 | NM3-2 |

| A-5-3 | AA6061 | NM5-3 | C-3-3 | AA6063 | NM3-3 |

| B-1 | AA7075 | NM1 | C-4-1 | AA6063 | NM4-1 |

| B-2-1 | AA7075 | NM2-1 | C-4-2 | AA6063 | NM4-2 |

| Specimen Label | fu (MPa) | εu (%) | E (J) | δ (%) | Specimen Label | fu (MPa) | εu (%) | E (J) | δ (%) |

|---|---|---|---|---|---|---|---|---|---|

| A-1 | 369.32 | 6.59% | 164.55 | 11.98% | B-4-1 | 336.93 | 4.29% | 137.80 | 10.90% |

| A-2-1 | 343.27 | 8.55% | 148.75 | 11.78% | B-4-2 | 341.20 | 4.64% | 119.55 | 9.36% |

| A-2-2 | 358.23 | 5.77% | 132.23 | 10.62% | B-4-3 | 340.74 | 3.99% | 150.23 | 11.68% |

| A-3-1 | 355.47 | 5.03% | 128.81 | 9.68% | B-5-1 | 332.17 | 2.89% | 135.43 | 10.80% |

| A-3-2 | 338.69 | 5.48% | 122.95 | 9.60% | B-5-2 | 332.25 | 5.56% | 136.22 | 10.70% |

| A-3-3 | 361.55 | 4.80% | 153.34 | 10.74% | B-5-3 | 331.11 | 2.63% | 123.83 | 9.72% |

| A-4-1 | 355.55 | 5.03% | 151.32 | 11.98% | C-1 | 347.66 | 5.10% | 128.17 | 9.78% |

| A-4-2 | 350.78 | 4.29% | 159.51 | 12.04% | C-2-1 | 346.77 | 2.66% | 101.17 | 7.78% |

| A-4-3 | 365.82 | 5.04% | 153.48 | 10.94% | C-2-2 | 353.24 | 5.41% | 116.34 | 8.96% |

| A-5-1 | 332.05 | 4.16% | 123.36 | 9.74% | C-3-1 | 350.63 | 4.68% | 134.82 | 10.46% |

| A-5-2 | 349.25 | 8.55% | 164.78 | 11.44% | C-3-2 | 360.08 | 5.14% | 141.15 | 10.72% |

| A-5-3 | 322.06 | 6.95% | 145.67 | 12.00% | C-3-3 | 351.39 | 4.87% | 80.08 | 6.22% |

| B-1 | 330.34 | 4.97% | 120.08 | 9.80% | C-4-1 | 355.92 | 4.75% | 107.59 | 8.76% |

| B-2-1 | 328.58 | 4.78% | 114.15 | 9.16% | C-4-2 | 354.80 | 4.57% | 132.77 | 10.44% |

| B-2-2 | 312.84 | 5.02% | 95.22 | 8.66% | C-4-3 | 343.58 | 4.72% | 125.53 | 9.74% |

| B-3-1 | 337.03 | 4.82% | 105.88 | 8.44% | C-5-1 | 351.66 | 3.18% | 101.90 | 7.96% |

| B-3-2 | 341.66 | 4.88% | 122.85 | 9.64% | C-5-2 | 354.61 | 3.03% | 84.08 | 6.74% |

| B-3-3 | 340.86 | 4.85% | 139.84 | 11.06% | C-5-3 | 348.83 | 2.83% | 79.74 | 6.70% |

| Parallel Section Length LC (mm) | Parallel Section Diameter (mm) | Loading Patterns | Specimen Label (Material Type) | Specimen Label (Material Type) | Specimen Label (Material Type) |

|---|---|---|---|---|---|

| 60 | 10 | NM6 | NA-6 (AA6061) | NB-6 (AA7075) | NC-6 (AA6063) |

| 20 | 10 | NM6 | L1-NA-6 (AA6061) | L1-NB-6 (AA7075) | L1-NC-6 (AA6063) |

| 40 | 10 | NM6 | L2-NA-6 (AA6061) | L2-NB-6 (AA7075) | L2-NC-6 (AA6063) |

| 75 | 10 | NM6 | L3-NA-6 (AA6061) | L3-NB-6 (AA7075) | L3-NC-6 (AA6063) |

| 60 | 8 | NM6 | D1-NA-6 (AA6061) | D1-NB-6 (AA7075) | D1-NC-6 (AA6063) |

| 60 | 12 | NM6 | D2-NA-6 (AA6061) | D2-NB-6 (AA7075) | D2-NC-6 (AA6063) |

| 60 | 14 | NM6 | D3-NA-6 (AA6061) | D3-NB-6 (AA7075) | D3-NC-6 (AA6063) |

| 60 | 10 | NM7-1 | NA-7-1 (AA6061) | NB-7-1 (AA7075) | NC-7-1 (AA6063) |

| 60 | 10 | NM7-2 | NA-7-2 (AA6061) | NB-7-2 (AA7075) | NC-7-2 (AA6063) |

| 60 | 10 | NM7-3 | NA-7-3 AA(6061) | NB-7-3 (AA7075) | NC-7-3 (AA6063) |

| 60 | 10 | NM8-1 | NA-8-1 (AA6061) | NB-8-1 (AA7075) | NC-8-1 (AA6063) |

| 60 | 10 | NM8-2 | NA-8-2 (AA6061) | NB-8-2 (AA7075) | NC-8-2 (AA6063) |

| 60 | 10 | NM9-1 | NA-9-1 (AA6061) | NB-9-1 (AA7075) | NC-9-1 (AA6063) |

| 60 | 10 | NM9-2 | NA-9-2 AA(6061) | NB-9-2 (AA7075) | NC-9-2 (AA6063) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Li, H.; Chen, T.; Cao, B.; Li, X. Mechanical Properties of Aluminum Alloys under Low-Cycle Fatigue Loading. Materials 2019, 12, 2064. https://doi.org/10.3390/ma12132064

Zhao X, Li H, Chen T, Cao B, Li X. Mechanical Properties of Aluminum Alloys under Low-Cycle Fatigue Loading. Materials. 2019; 12(13):2064. https://doi.org/10.3390/ma12132064

Chicago/Turabian StyleZhao, Xuehang, Haifeng Li, Tong Chen, Bao’an Cao, and Xia Li. 2019. "Mechanical Properties of Aluminum Alloys under Low-Cycle Fatigue Loading" Materials 12, no. 13: 2064. https://doi.org/10.3390/ma12132064