Microstructure and Mechanical Properties of High Vacuum Die-Cast AlSiMgMn Alloys at as-Cast and T6-Treated Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. T6 Heat Treatment

2.3. Microstructure Analysis

2.4. Nanoindentation Test

2.5. Tensile Test

3. Results and Discussion

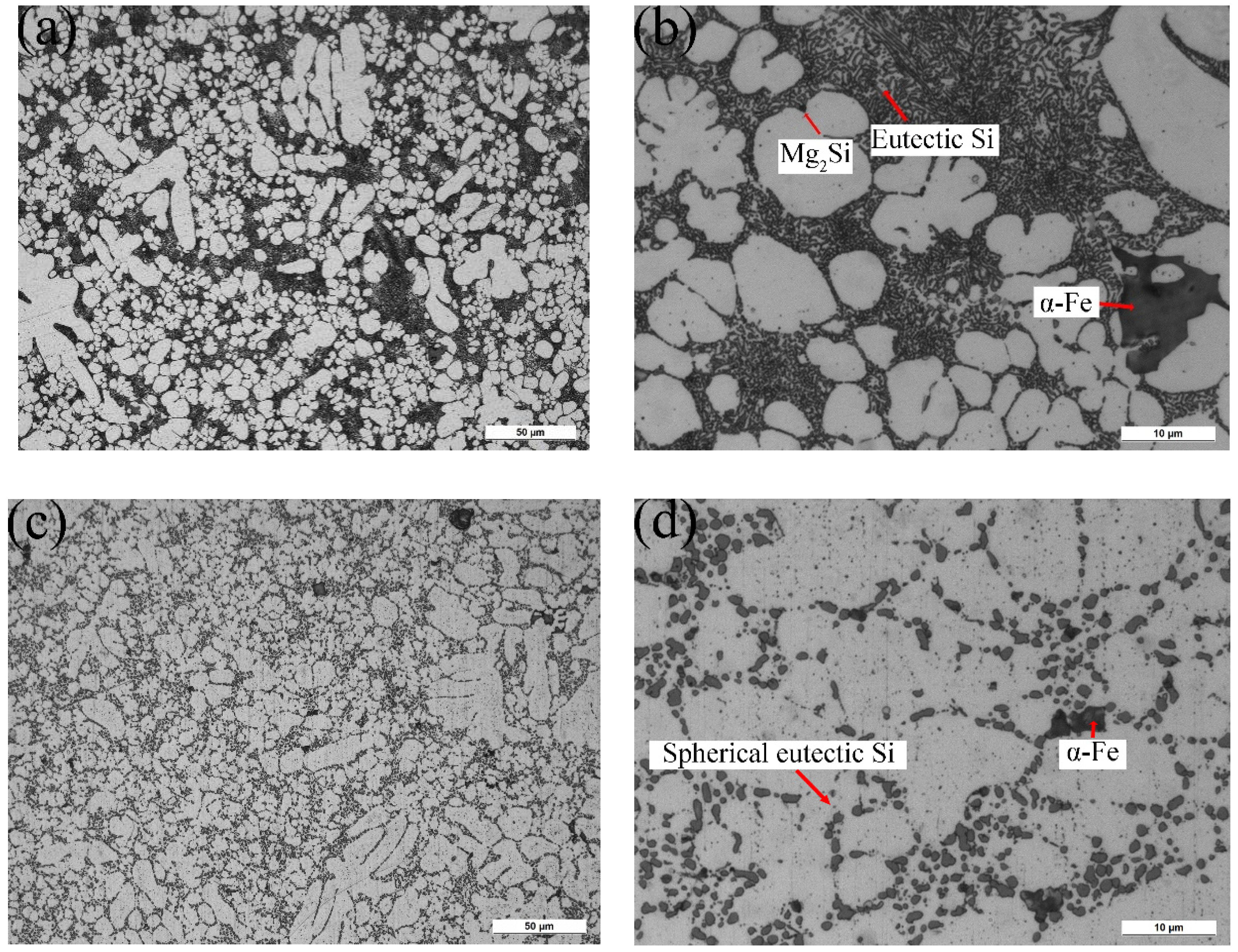

3.1. Microstructure

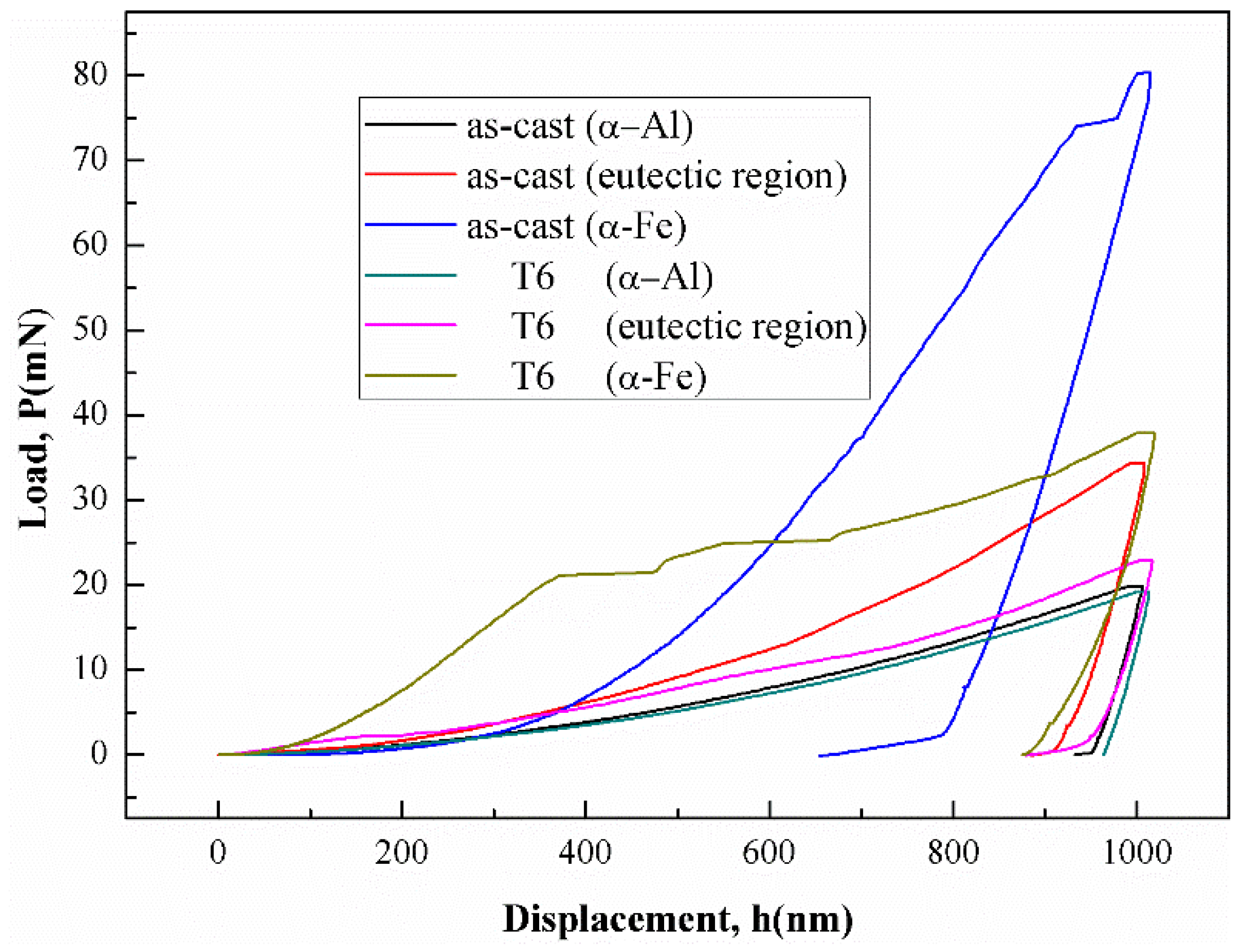

3.2. Nano-Indentation Hardness Test

3.3. Tensile Behavior

3.3.1. As-Cast Alloys

3.3.2. T6-Treated Alloy

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Niu, X.P.; Hu, B.H.; Pinwill, I.; Li, H. Vacuum assisted high pressure die casting of aluminium alloys. J. Mater. Process. Technol. 2000, 105, 119–127. [Google Scholar] [CrossRef]

- Aghion, E.; Moscovitch, N.; Arnon, A. The correlation between wall thickness and properties of HPDC Magnesium alloys. Mater. Sci. Eng. A 2007, 447, 341–346. [Google Scholar] [CrossRef]

- Dørum, C.; Laukli, H.I.; Hopperstad, O.S.; Langseth, M. Structural behaviour of Al–Si die-castings: Experiments and numerical simulations. Eur. J. Mech. A Solids 2009, 28, 1–13. [Google Scholar] [CrossRef]

- Kaufman, J.G.; Rooy, E.L. Aluminum Alloy Castings Properties, Processes, and Applications. Aluminum Alloy Cast. Prop. Process. Appl. 2007, 33, 243–255. [Google Scholar] [CrossRef]

- Medved, J.; Kores, S.; Vončina, M. Development of innovative Al-Si-Mn-Mg alloys with high mechanical properties. TMS Meet. Exhib. 2018, 373–380. [Google Scholar] [CrossRef]

- Franke, R.; Dragulin, D.; Zovi, A.; Casarotto, F. Progress in ductile aluminum high pressure die casting alloys for the automotive industry. Proc. SPIE Int. Soc. Opt. Eng. 2007, 8704, 1. [Google Scholar]

- Zovi, A.; Casarotto, F. Silafont-36, the low iron ductile die casting alloy development and applications. La Metallurgia Italiana. 2007, 99, 33. [Google Scholar]

- Zhao, H.D.; Wang, F.; Li, Y.Y.; Xia, W. Experimental and numerical analysis of gas entrapment defects in plate ADC12 die castings. J. Mater. Process. Technol. 2009, 209, 4537–4542. [Google Scholar] [CrossRef]

- Okayasu, M.; Takeuchi, S.; Aizawa, K. In Situ, Observation of Material Failure in Cast Aluminum Alloy During Monotonic Loading Observed by a High-Speed Camera. Exp. Mech. 2014, 54, 1479–1489. [Google Scholar] [CrossRef]

- Wang, L.; Turnley, P.; Savage, G. Gas content in high pressure die castings. J. Mater. Process. Technol. 2011, 211, 1510–1515. [Google Scholar] [CrossRef]

- Dong, X.; He, L.; Huang, X.; Li, P. Effect of electromagnetic transport process on the improvement of hydrogen porosity defect in A380 aluminum alloy. Int. J. Hydrogen Energy 2015, 40, 9287–9297. [Google Scholar] [CrossRef]

- Aziz, A.A.K.M. Influence of Casting Defects on Tensile Properties of ADC12 Aluminum Alloy Die-Castings. Mater. Trans. 2008, 49, 1621–1628. [Google Scholar] [CrossRef]

- Niklas, A.; Bakedano, A.; Orden, S.; Silva, M.; Nogués, E.; Fernández-Calvo, A.I. Effect of Microstructure and Casting Defects on the Mechanical Properties of Secondary AlSi10MnMg (Fe) Test Parts Manufactured by Vacuum Assisted high Pressure Die Casting Technology. Mater. Today Proc. 2015, 2, 4931–4938. [Google Scholar] [CrossRef]

- Li, X.; Xiong, S.M.; Guo, Z. Improved mechanical properties in vacuum-assist high-pressure die casting of AZ91D alloy. J. Mater Process Technol. 2016, 231, 1–7. [Google Scholar] [CrossRef]

- Wan, L.; Hu, Z.; Wu, S.; Liu, X. Mechanical properties and fatigue behavior of vacuum-assist die cast AlMgSiMn alloy. Mater. Sci. Eng. A 2013, 576, 252–258. [Google Scholar] [CrossRef]

- Niklas, A.; Orden, S.; Bakedano, A.; Silva, M.; Nogués, E.; Fernández-Calvo, A.I. Effect of solution heat treatment on gas porosity and mechanical properties in a die cast step test part manufactured with a new AlSi10MnMg (Fe) secondary alloy. Mater. Sci. Eng. A 2016, 667, 376–382. [Google Scholar] [CrossRef]

- Timelli, G.; Lohne, O.; Arnberg, L.; Hans, I.L. Effect of Solution Heat Treatments on the Microstructure and Mechanical Properties of a Die-Cast AlSi7MgMn. Metall. Mater. Trans. A 2008, 39, 1747–1758. [Google Scholar] [CrossRef]

- Srivastava, M.C.; Lohne, O. Effects of Heat Treatment on the Microstructure and Mechanical Properties of Ductile AlSi9MgMn Die Castings. Int. J. Metalcast. 2016, 10, 556–565. [Google Scholar] [CrossRef]

- Srivastava, M.C.; Lohne, O. Energy Absorption Characteristics of Ductile AlSi4MgMn and AlSi9MgMn Die-Castings Investigated by Shear Bolt Testing. Int. J. Metalcast. 2017, 11, 356–365. [Google Scholar] [CrossRef]

- Cato, D.; Hans, I.L.; Odd, S.H. Through-process numerical simulations of the structural behaviour of Al–Si die-castings. Comp. Mater. Sci. 2009, 46, 100–111. [Google Scholar] [CrossRef]

- Jianmin, S.; Helge, P.; Elisabeth, S.; Klaus, D. Chemical pretreatment and adhesive bonding properties of high-pressure die cast aluminum alloy: AlSi10MnMg. Int. J. Adhes. 2015, 61, 112–121. [Google Scholar] [CrossRef]

- Georgatis, E.; Lekatou, A.; Karantzalis, A.E.; Petropoulos, H.; Katsamakis, S.; Poulia, A. Development of a cast Al-Mg2Si-Si in situ composite: Microstructure, heat Treatment, and mechanical properties. J. Mater. Eng. Perform. 2013, 22, 729–741. [Google Scholar] [CrossRef]

- Zhang, J.; Fan, Z.; Wang, Y.Q.; Zhou, B.L. Microstructural evolution of the in situ Al-15wt.%Mg2Si composite with extra Si contents. Scr. Mater. 2000, 42, 1101–1106. [Google Scholar] [CrossRef]

- Abdul-Baqi, A.; Giessen, E.V.D. Indentation-induced interface delamination of a strong film on a ductile substrate. Thin Solid Films 2001, 381, 143–154. [Google Scholar] [CrossRef] [Green Version]

- Dominik, B.; Stefan, P.; Marc, H.; Werner, F.; Peter, J.; Mathias, G.; Heinz, W.H. Secondary Al-Si-Mg high-pressure die casting alloys with enhanced ductility. Metall. Mater. Trans A 2015, 46, 1035–1045. [Google Scholar] [CrossRef]

- Liu, F.; Zhao, H.D.; Yang, R.S.; Sun, F.Z. Crack propagation behavior of die-cast AlSiMgMn alloys with in-situ SEM observation and finite element simulation. Mater. Today Commun. 2019, 19, 114–123. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C. Nanoindentation Testing. Mater. Today 2003, 6, 21–37. [Google Scholar] [CrossRef]

- Malekan, A.; Emamy, M.; Rassizadehghani, J.; Emami, A.R. The effect of solution temperature on the microstructure and tensile properties of Al–15%Mg2Si composite. Mater. Des. 2011, 32, 2701–2709. [Google Scholar] [CrossRef]

- Emamy, M.; Emami, A.R.; Tavighi, K. The effect of Cu addition and solution heat treatment on the microstructure, hardness and tensile properties of Al–15%Mg2Si–0.15%Li composite. Mater. Sci. Eng. A 2013, 576, 36–44. [Google Scholar] [CrossRef]

- Eisaabadi, G.B.; Davami, P.; Varahrama, N.; Kim, S.K. On the effect of hydrogen and Fe on reproducibility of tensile properties in cast Al–Si–Mg alloys. Mater. Sci. Eng. A 2013, 565, 278–284. [Google Scholar] [CrossRef]

| Si | Mg | Mn | Fe | Cu | Zn | Ti | Sr | Al |

|---|---|---|---|---|---|---|---|---|

| 11.37 | 0.20 | 0.58 | 0.10 | 0.009 | 0.012 | 0.075 | 0.017 | Bal |

| Phase | Hardness (As-Cast) (HV) | Hardness (T6) (HV) | Young’s Modulus (As-cast) (GPa) | Young’s Modulus (T6) (GPa) |

|---|---|---|---|---|

| α-Al | 86.8 | 77.2 | 81.2 | 85.1 |

| Eutectic | 145.2 | 98.1 | 87.4 | 79.9 |

| α-Fe | 429.6 | 167.2 | 87.2 | 102.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Zhao, H.; Yang, R.; Sun, F. Microstructure and Mechanical Properties of High Vacuum Die-Cast AlSiMgMn Alloys at as-Cast and T6-Treated Conditions. Materials 2019, 12, 2065. https://doi.org/10.3390/ma12132065

Liu F, Zhao H, Yang R, Sun F. Microstructure and Mechanical Properties of High Vacuum Die-Cast AlSiMgMn Alloys at as-Cast and T6-Treated Conditions. Materials. 2019; 12(13):2065. https://doi.org/10.3390/ma12132065

Chicago/Turabian StyleLiu, Fei, Haidong Zhao, Runsheng Yang, and Fengzhen Sun. 2019. "Microstructure and Mechanical Properties of High Vacuum Die-Cast AlSiMgMn Alloys at as-Cast and T6-Treated Conditions" Materials 12, no. 13: 2065. https://doi.org/10.3390/ma12132065