Effect of Selected Luminescent Layers on CCT, CRI, and Response Times

Abstract

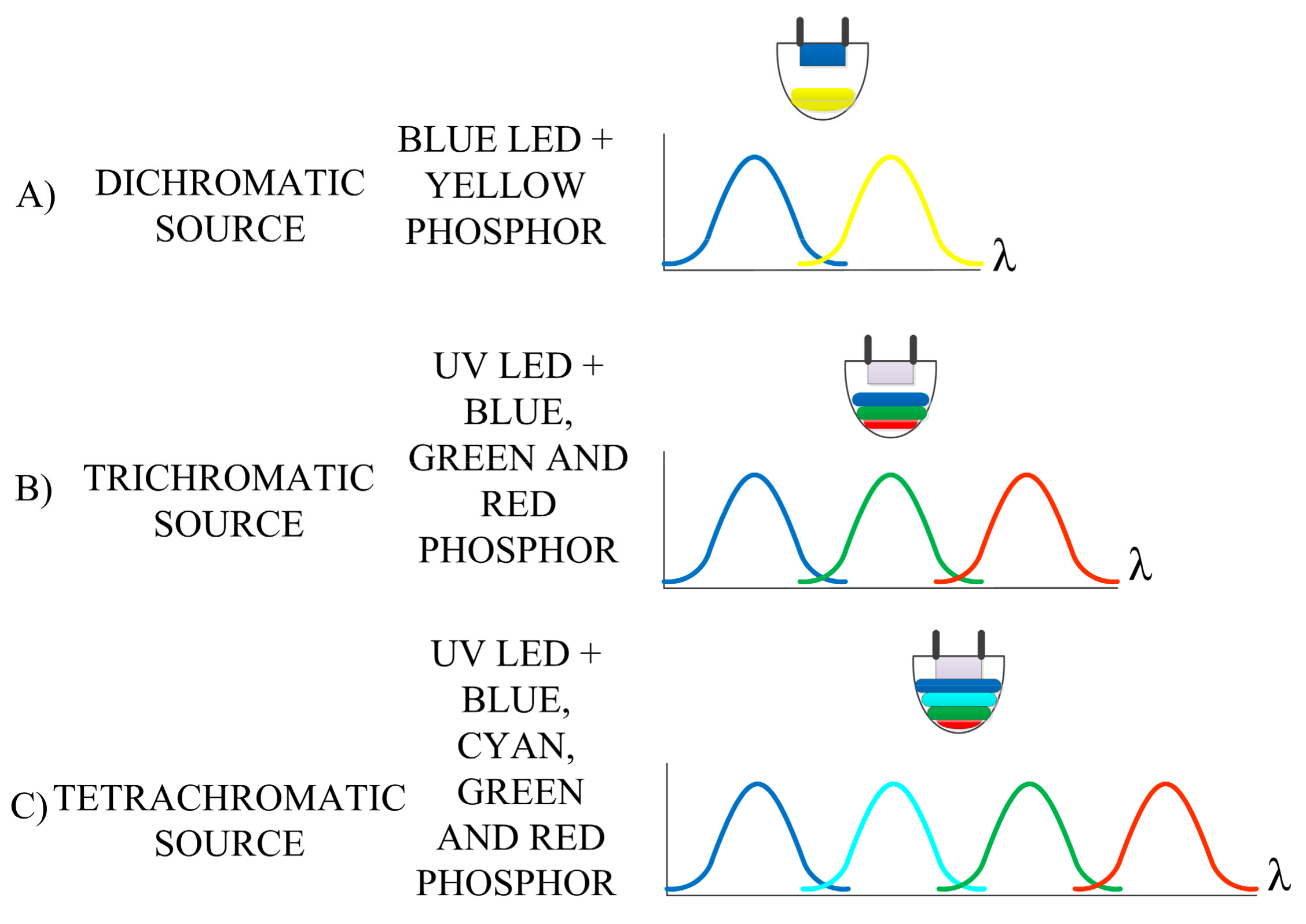

:1. Introduction

2. Materials and Methods

Preparation of Samples

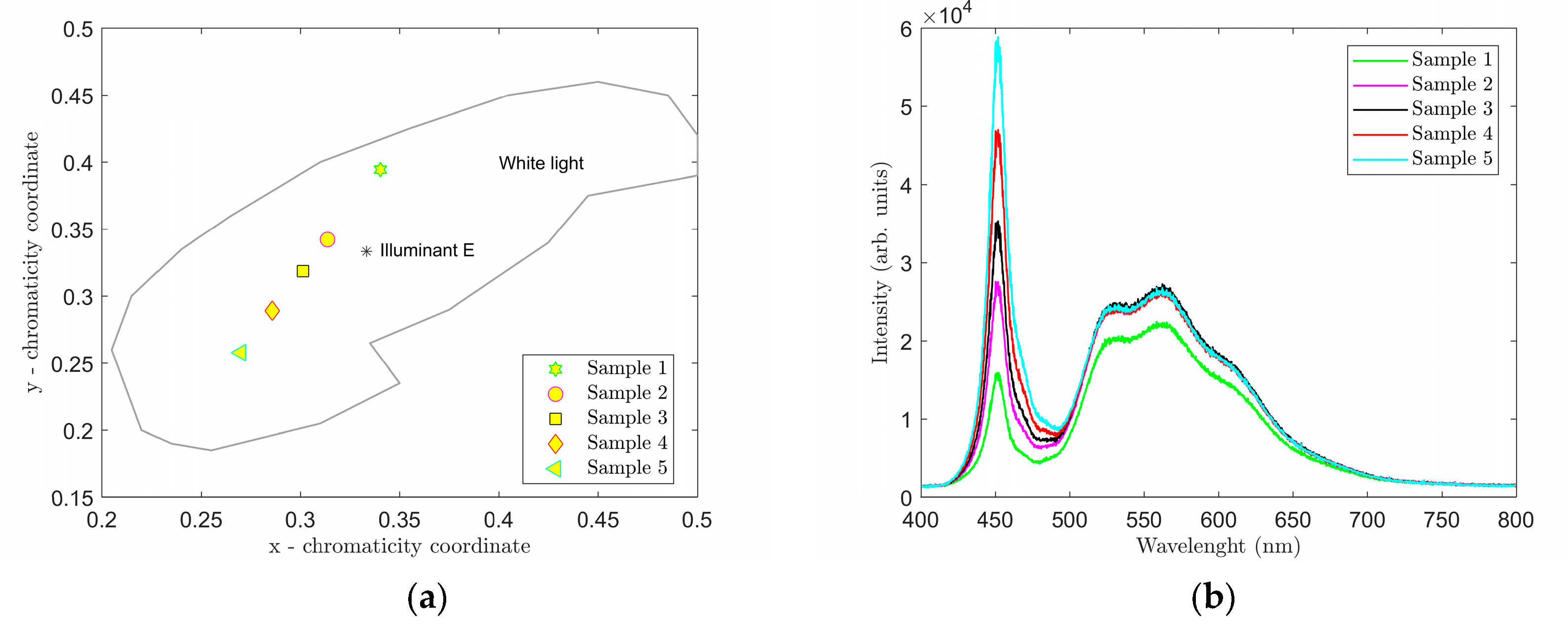

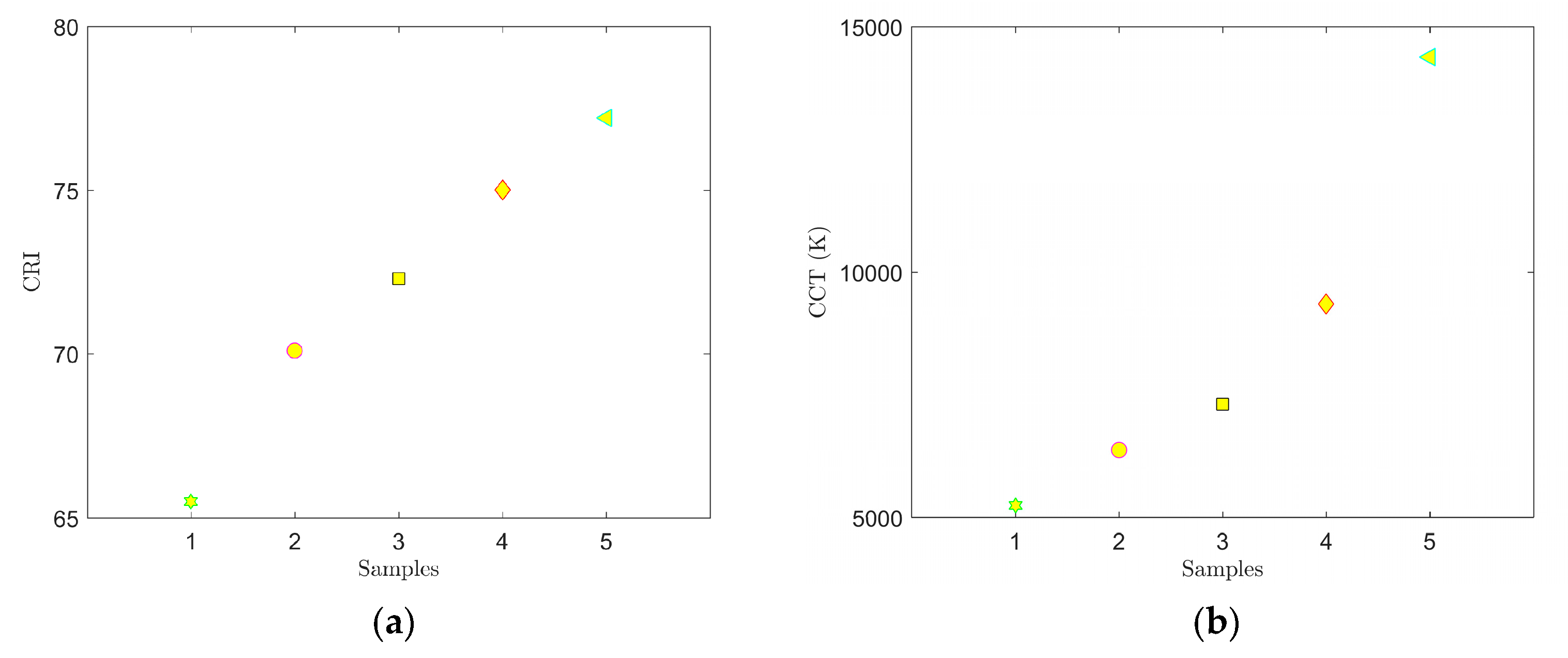

3. Measurements and Results

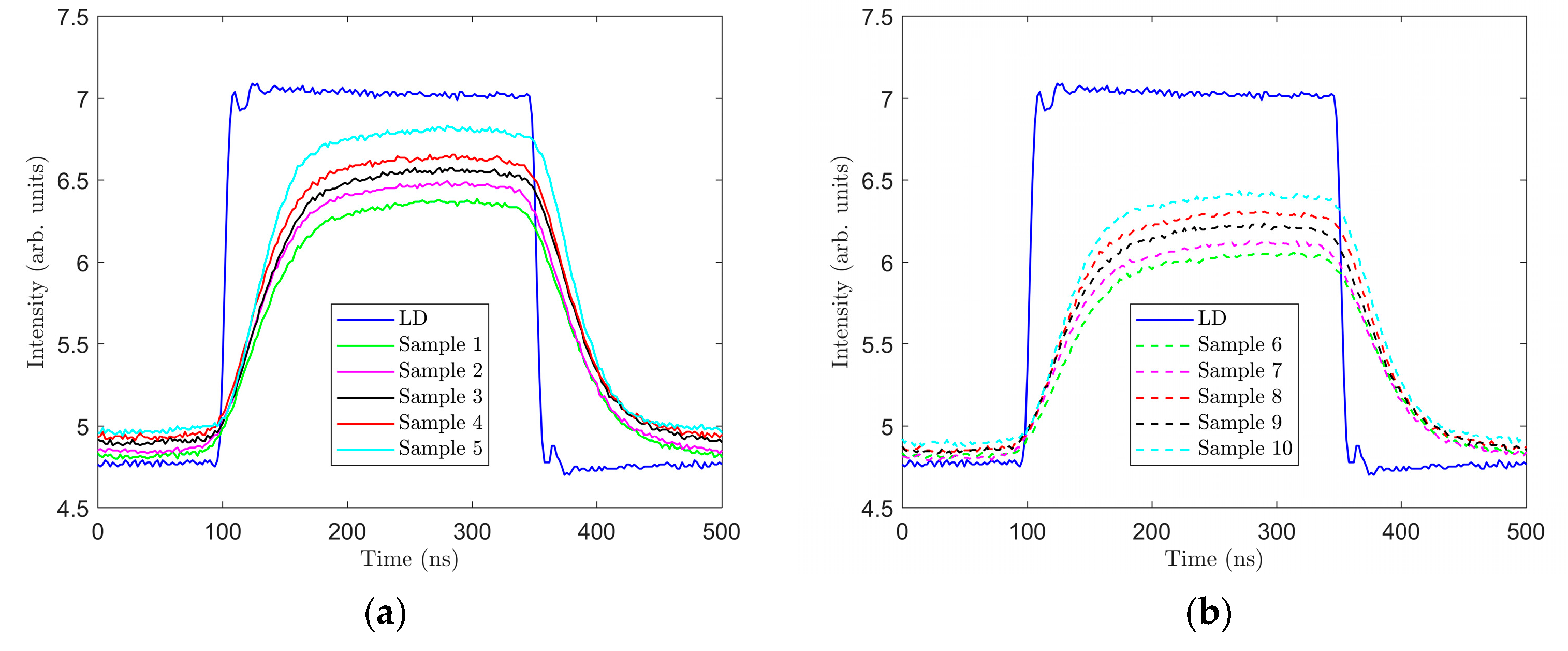

Measurement of Rising and Falling Edge Times

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Schubert, E.F. Light-Emitting Diodes, 2nd ed.; Cambridge University Press: New York, NY, USA, 2006; ISBN 10-0-521-86538-7. [Google Scholar]

- Liu, M.; Li, K.; Kong, F.-M.; Zhao, J.; Xu, C.-J. Using three-component hierarchical structures to improve the light extraction from white LEDs based on red-green-blue color mixing method. Prog. Electromagn. Res. C 2017, 75, 169–180. [Google Scholar] [CrossRef]

- Mei, J.; Liu, L. Research on white light color temperature deviation based on tricolor LEDs. Guangxue Xuebao Acta Opt. Sin. 2016, 36, 0833001. (In Chinese) [Google Scholar] [CrossRef]

- Muthu, S.; Gaines, J.R. Green and Blue LED-Based White Light Source: Implementation Challenges and Control Design. In Proceeding of the IEEE Industry Applications Society 38th Annual Meeting: Crossroads to Innovation, Salt Lake City, UT, USA, 12–16 October 2003; pp. 515–522. [Google Scholar]

- Withnall, R.; Silver, J. Luminescence of phosphors. In Handbook of Visual Display Technology; Chen, J., Cranton, W., Fihn, M., Eds.; Springer: Berlin, Germany, 2012. [Google Scholar]

- Feng, G.; Jiang, W.; Liu, J.; Li, C.; Zhang, Q.; Miao, L.; Wu, Q. Synthesis and luminescence properties of Al2O3@YAG: Ce core–shell yellow phosphor for white LED application. Ceram. Int. 2018, 44, 8435–8439. [Google Scholar] [CrossRef]

- Chen, L.-C.; Tseng, Z.-L.; Chang, W.-W.; Lin, Y.W. Warm white light-emitting diodes using organic–inorganic halide perovskite materials coated YAG:Ce3+ phosphors. Ceram. Int. 2018, 44, 3868–3872. [Google Scholar] [CrossRef]

- Wang, J.; Lee, S.W.R.; Zou, H. Investigation on the influence of phosphor particle size gradient on the optical performance of white light-emitting diodes. In Proceedings of the IEEE 18th Electronics Packaging Technology Conference, EPTC 2016, Singapore, 30 November–3 December 2016. [Google Scholar]

- Kim, Y.; Shim, K.B.; Wu, M.; Jung, H.-K. Monodispersed spherical YAG:Ce3+ phosphor particles by one-pot synthesis. J. Alloy. Compd. 2017, 693, 40–47. [Google Scholar] [CrossRef]

- Gu, G.; Xiang, W.; Yang, C.; Fan, W.; Lv, Y.; Zhang, Z.; Liang, X. A novel single-component white-emitting Tb and Mn co-doped large-sized Y3Al5O12:Ce3+ single crystal for white LED. Sci. Adv. Mater. 2016, 8, 1354–1360. [Google Scholar] [CrossRef]

- Du, Y.; Shao, C.; Dong, Y.; Yang, Q. Electroluminescent Properties of WLEDs with the Structures of Ce:YAG Single Crystal/Blue Chip and Sr2Si5N8:Eu2+/Ce:YAG Single Crystal/Blue Chip. J. Disp. Technol. 2016, 12, 323–327. [Google Scholar] [CrossRef]

- Zhao, B.; Liang, X.; Chen, Z.; Xie, C.; Luo, L.; Zhang, Z.; Zhong, J.; Xiang, W. Studies on optical properties and Ce concentration of Ce: YAG single crystal for WLEDs. Gaodeng Xuexiao Huaxue Xuebao Chem. J. Chin. Univ. 2014, 35, 230–236. [Google Scholar]

- Zhou, H.; Zou, J.; Yang, B.; Wu, W.; Shi, M.; Wang, Z.; Liu, Y.; Li, M.; Zhao, G. Facile preparation and luminescence performance of transparent YAG:Ce phosphor-in-tellurate-glass inorganic color converter for white-light-emitting diodes. J. Non Cryst. Solids 2018, 481, 537–542. [Google Scholar] [CrossRef]

- Peng, Y.; Li, R.; Cheng, H.; Chen, Z.; Chen, M. High-power white LED packaging using phosphor-in-glass and its thermal reliability. In Proceedings of the 13th China International Forum on Solid State Lighting, SSLCHINA, Beijing, China, 15–17 November 2016. [Google Scholar]

- Gong, M.; Liang, X.; Wang, Y.; Xu, H.; Zhang, L.; Xiang, W. Novel synthesis and optical characterization of phosphor-converted WLED employing Ce:YAG-doped glas. J. Alloy. Compd. 2016, 664, 125–132. [Google Scholar] [CrossRef]

- Lin, H.-Y.; Tu, Z.-Y.; Ku, P.-C.; Lin, C.-C.; Kuo, H.-C. Large area lighting applications with organic dye embedded flexible film. In Proceedings of the Light-Emitting Diodes: Materials, Devices, and Applications for Solid State Lighting XIX; SPIE 9383, San Francisco, CA, USA, 7–12 February 2015. [Google Scholar]

- Chen, L.-C.; Lin, W.-W.; Chen, J.-W. Fabrication of GaN-based white light-emitting diodes on yttrium aluminum garnet-polydimethylsiloxane flexible substrates. Adv. Mater. Sci. Eng. 2015, 2015, 537163. [Google Scholar] [CrossRef]

- Jargus, J.; Nedoma, J.; Fajkus, M.; Novak, M.; Vasinek, V. Study combination of luminophore and polydimethylsiloxane for alternative option of passive energy lighting. In Proceedings of the Image Sensing Technologies: Materials, Devices, Systems, and Applications IV; SPIE 10209, Anaheim, CA, USA, 9–13 April 2017. [Google Scholar]

- Esteves, A.C.C.; Brokken-Zijp, J.; Laven, J.; de With, G. Light converter coatings from cross-linked PDMS/particles composite. Prog. Org. Coat. 2010, 68, 1–2. [Google Scholar] [CrossRef]

- Li, X.; Jiang, Y.; Li, J.; Shi, Z.; Zhu, G.; Wang, Y. Integrated photonics chip with InGaN/GaN light-emitting diode and bended waveguide for visible-light communications. Opt. Laser Technol. 2019, 114, 103–109. [Google Scholar] [CrossRef]

- Xie, E.; He, X.; Islim, M.S.; Purwita, A.A.; Mckendry, J.J.D.; Gu, E.; Haas, H.; Dawson, M.D. High-speed visible light communication based on a III-nitride series-biased micro-LED array. J. Lightwave Technol. 2019, 37, 1180–1186. [Google Scholar] [CrossRef]

- Wu, T.-C.; Chi, Y.-C.; Wang, H.-Y. White-lighting communication with a Lu3Al5O12:Ce3+/CaAlSiN3:Eu2+ Glass Covered 450-nm InGaN Laser Diode. J. Lightwave Technol. 2018, 36, 1634–1643. [Google Scholar] [CrossRef]

- Zafar, F.; Bakaul, M.; Parthiban, R. Laser-diode-based visible light communication: Toward gigabit class communication. IEEE Commun. Mag. 2017, 55, 144–151. [Google Scholar] [CrossRef]

- Devi, P.; Maddila, R.K. External modulation using MZM for visible wavelengths. In Optical and Wireless Technologies; Vijay, J., Singh, G., Tiwari, M., D’alessandro, A., Eds.; Springer: Singapore, 2020; pp. 37–41. [Google Scholar]

- Xu, Y.; Chen, Z.; Gong, Z.; Xia, Z.; Yuan, T.; Gu, Z.; Zhao, W.; Chen, J. Hybrid modulation scheme for visible light communication using CMOS camera. Opt. Commun. 2019, 440, 89–94. [Google Scholar] [CrossRef]

- Haigh, P.A.; Chvojka, P.; Ghassemlooy, Z.; Zvanovec, S.; Darwazeh, I. Visible light communications: Multi-band super-Nyquist CAP modulation. Opt. Express 2019, 27, 8912–8919. [Google Scholar] [CrossRef] [PubMed]

- Salmento, M.L.G.; Soares, G.M.; Alonso, J.M.; Braga, H.A.C. A Dimmable offline LED driver with OOK-M-FSK modulation for VLC applications. IEEE Trans. Ind. Electron. 2019, 66, 5220–5230. [Google Scholar] [CrossRef]

- Yan, D.; Mao, X.; Xie, S.; Cong, J.; Chen, H. Design Fully Integrated Driver Circuit for Phosphorescent White Light-Emitting-Diode High Speed Real-Time Wireless Communication. IEEE Photonics J. 2019, 11, 1–10. [Google Scholar] [CrossRef]

- Khadr, M.; Aziz, A.; Fayed, H.; Aly, M. Bandwidth and BER Improvement employing a pre-equalization circuit with white LED arrays in a MISO VLC system. Appl. Sci. 2019, 9, 986. [Google Scholar] [CrossRef]

- Salamandra, L.; Nia, N.Y.; Natali, M. Perovskite photo-detectors (PVSK-PDs) for visible light communication. Org. Electron. 2019, 69, 220–226. [Google Scholar] [CrossRef]

- Kosman, J.; Almer, O.; Abbas, T. 500Mb/s -46.1dBm CMOS SPAD Receiver for laser diode visible-light communications. In Proceedings of the IEEE International Solid-State Circuits Conference—(ISSCC) IEEE, San Francisco, CA, USA, 17–21 February 2019; pp. 468–470. [Google Scholar]

- Swain, K.P.; Palai, G.; Moharana, J.K. Design and implementation of opto-electro decoder using photonic structure: A new application of Li-fi vis-a-vis optical embedded system. Optik 2019, 178, 658–663. [Google Scholar] [CrossRef]

- Liu, X.; Lin, R.; Qian, Z. An InGaN micro-LED based photodetector array for high-speed parallel visible light communication. In Proceedings of the Asia Communications and Photonics Conference (ACP) IEEE, Hangzhou, China, 26–29 October 2018; pp. 1–3. [Google Scholar]

- Ma, S.; Dai, J.; Lu, S.; Li, H.; Zhang, H.; Du, C.; Li, S. Signal demodulation with machine learning methods for physical layer visible light communications: Prototype platform, open dataset, and algorithms. IEEE Access 2019, 7, 30588–30598. [Google Scholar] [CrossRef]

- Vitasek, J.; Jargus, J.; Stratil, T.; Latal, J.; Kolar, J. Illumination and communication characteristics of white light created by laser excitation of YAG: Ce phosphor powders. Opt. Mater. 2018, 83, 131–137. [Google Scholar] [CrossRef]

- Pokorny, M.; Paterek, J.; Nikl, M.; Sykorova, S.; Stehlik, A.; Polak, J.; Houzvivka, J. Concentration dependence of energy transfer Ce3+→Er3+ in YAG host. Opt. Mater. 2018, 86, 338–342. [Google Scholar] [CrossRef]

- Vitasek, J.; Jargus, J.; Hejduk, S.; Stratil, T.; Latal, J.; Vasinek, V. Phosphor decay measurement and its influence on communication properties. In Proceedings of the 19th International Conference on Transparent Optical Networks (ICTON) IEEE, Girona, Spain, 2–6 July 2017; pp. 1–4. [Google Scholar]

- Lisitsyn, V.M.; Ju, Y.; Stepanov, S.A.; Soschin, N.M. Complex study on photoluminescence properties of YAG:Ce,Gd phosphors. J. Phys. Conf. Ser. 2017, 830, 012160. [Google Scholar] [CrossRef] [Green Version]

- CIE Commission Internationale de l’Eclairage Proceedings; Cambridge University Press: Cambridge, UK, 1995.

- Bass, M. Handbook of Optics; R.R. Donnelly & Sons Company: Chicago, IL, USA, 1995; ISBN 0-07-047740-X. [Google Scholar]

- Janjua, B.; Ng, T.K.; Zhao, C.; Oubei, H.M.; Shen, C.; Prabaswara, A.; Alias, M.S.; Alhamoud, A.A.; Alatawi, A.A.; Albadri, A.M.; et al. Ultrabroad linewidth orange-emitting nanowires LED for high CRI laser-based white lighting and gigahertz communications. Opt. Express 2016, 24, 19228–19236. [Google Scholar] [CrossRef]

- He, M.; Cheng, Y.; Shen, L.; Zhang, H.; Shen, C.; Xiang, W.; Liang, X. Doping manganese into CsPb(Cl/Br)3 quantum dots glasses: Dual-color emission and super thermal stability. J. Am. Ceram. Soc. 2019, 102, 1090–1100. [Google Scholar] [CrossRef]

- Minh, T.H.Q.; Nhan, N.H.K.; Anh, N.D.Q.; Nam, T.T.; Lee, H.-Y. Improving color uniformity and color rending index of remote-phosphor packaging white leds by co-doping SiO2 and Sr2Si5N8:Eu2+ particles. Mater. Sci. Pol. 2018, 36, 370–374. [Google Scholar] [CrossRef]

- Khaidukov, N.M.; Hongbin, L. Extended broadband luminescence of dodecahedral multisite Ce3+ ions in garnets {Y3}[MgA](BAlSi)O12 (A = Sc, Ga, Al; B = Ga, Al). Dyes Pigments 2017, 142, 524–529. [Google Scholar] [CrossRef]

- Park, K.; Kim, H.; Shinde, K.N.; Dhoble, S.J. Luminescence Properties of Ces3+ Doped Y3Al5O12 Phosphors Synthesized by Solution Combustion Method for White LEDs. Adv. Mater. Res. 2013, 679, 63–67. [Google Scholar] [CrossRef]

- Okada, G.; Akatsuka, M.; Yanagida, T. Characterizations of Ce-doped Y4Al2O9 crystals for scintillator Applications. Sens. Mater. 2018, 30, 1547–1554. [Google Scholar] [CrossRef]

- Jinsheng, L.; Xiumei, H.; Lei, W.; Xudong, S.; Xiwei, Q. Photoluminescence properties of (Y1−xCex)3Al5O12 (x = 0.005–0.03) nanophosphors and transparent ceramic by a homogeneous co-precipitation method. J. Lumin. 2019, 206, 364–369. [Google Scholar]

- Osipov, V.V.; Ishchenko, A.V.; Shitov, L.A. Fabrication, optical and scintillation properties of transparent YAG:Ce ceramics. Opt. Mater. 2017, 71, 98–102. [Google Scholar] [CrossRef]

| Sample | Speed of Rotation to Prepare the Layer (rpm) | Layer Thickness (μm) | Weight Ratio YAG:Ce and PDMS | Weight Ratio CaS:Eu and PDMS |

|---|---|---|---|---|

| 1 | 400 | 96 | 1:2 | 0 |

| 2 | 450 | 90 | 1:2 | 0 |

| 3 | 500 | 86 | 1:2 | 0 |

| 4 | 550 | 80 | 1:2 | 0 |

| 5 | 600 | 75 | 1:2 | 0 |

| 6 | 400 | 94 | 1:2 | 1:20 |

| 7 | 450 | 90 | 1:2 | 1:20 |

| 8 | 500 | 84 | 1:2 | 1:20 |

| 9 | 550 | 80 | 1:2 | 1:20 |

| 10 | 600 | 74 | 1:2 | 1:20 |

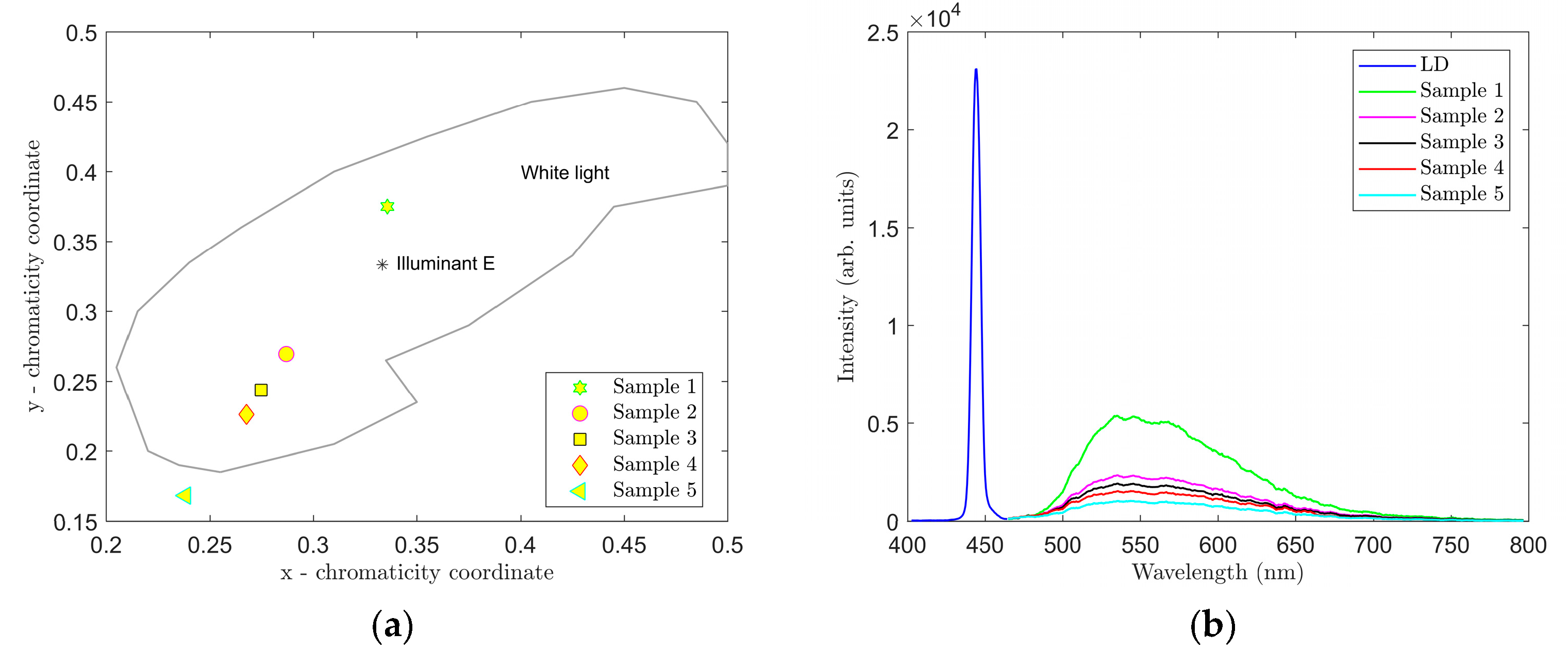

| Sample | CCT (K) | CRI (-) | x | y |

|---|---|---|---|---|

| 1 | 5250 | 65.5 | 0.3403 | 0.3943 |

| 2 | 6375 | 70.1 | 0.3136 | 0.3421 |

| 3 | 7307 | 72.3 | 0.3012 | 0.3186 |

| 4 | 9350 | 75.0 | 0.2857 | 0.2892 |

| 5 | 14377 | 77.2 | 0.2699 | 0.2579 |

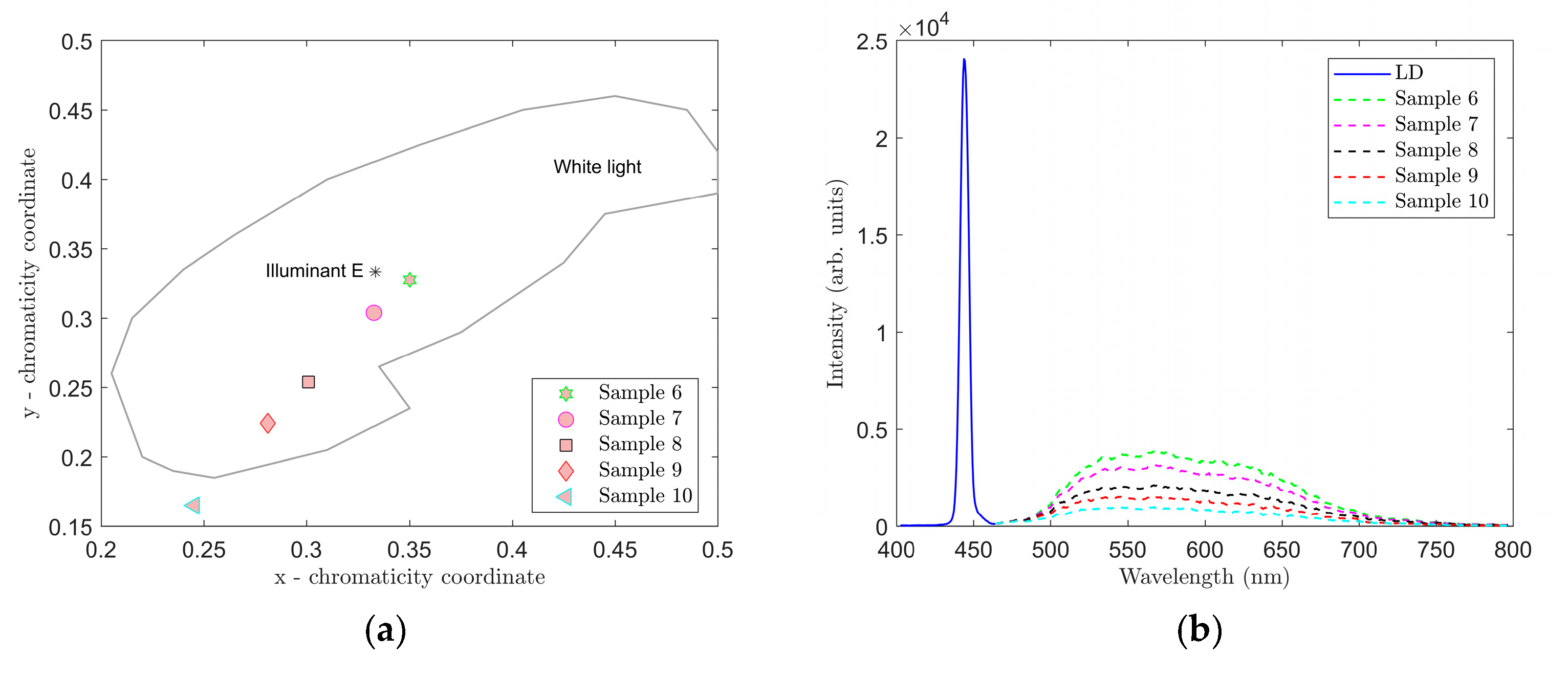

| Sample | CCT (K) | CRI (-) | x | y |

|---|---|---|---|---|

| 6 | 3317 | 83.9 | 0.4207 | 0.4070 |

| 7 | 4548 | 85.8 | 0.3551 | 0.3364 |

| 8 | 5724 | 85.3 | 0.3284 | 0.3072 |

| 9 | 8293 | 83.0 | 0.3026 | 0.2720 |

| 10 | 12286 | 79.9 | 0.2875 | 0.2490 |

| Sample | Rise Time tr (ns) | Fall Time tf (ns) |

|---|---|---|

| 1 | 75.89 | 76.58 |

| 2 | 72.48 | 73.35 |

| 3 | 70.38 | 71.29 |

| 4 | 64.82 | 66.44 |

| 5 | 58.05 | 58.53 |

| 6 | 80.22 | 80.79 |

| 7 | 77.77 | 78.84 |

| 8 | 74.15 | 75.22 |

| 9 | 69.20 | 70.02 |

| 10 | 65.16 | 65.71 |

| Sample | CCT (K) | CRI (-) | x | y |

|---|---|---|---|---|

| 1 | 5384 | 61.54 | 0.3357 | 0.3751 |

| 2 | 10328 | 69.96 | 0.2869 | 0.2695 |

| 3 | 16283 | 69.41 | 0.2747 | 0.2436 |

| 4 | 27460 | 66.62 | 0.2676 | 0.2261 |

| 5 | 5048 | 78.02 | 0.2381 | 0.1682 |

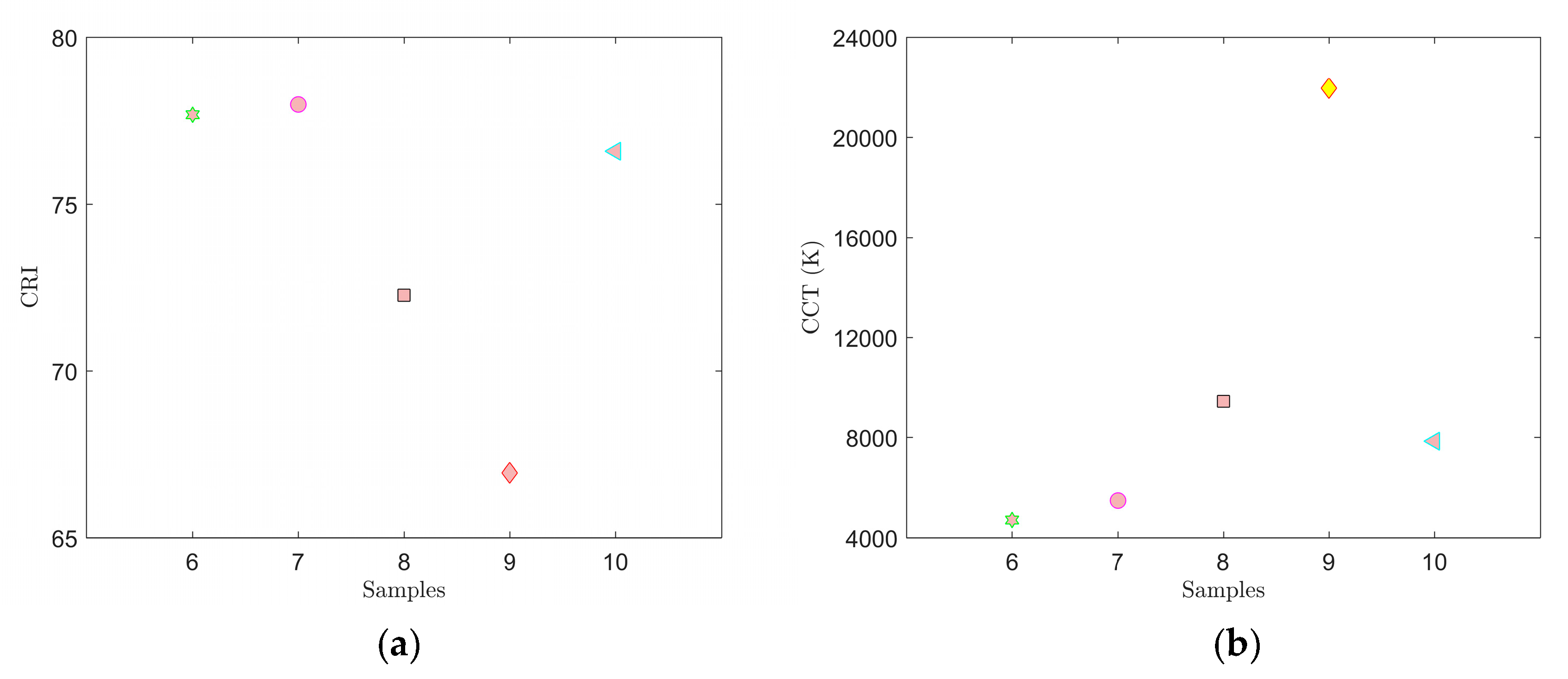

| Sample | CCT (K) | CRI (-) | x | y |

|---|---|---|---|---|

| 6 | 4703 | 77.67 | 0.3500 | 0.3276 |

| 7 | 5482 | 77.98 | 0.3326 | 0.3039 |

| 8 | 9450 | 72.26 | 0.3009 | 0.2538 |

| 9 | 21956 | 66.94 | 0.2811 | 0.2242 |

| 10 | 7848 | 76.58 | 0.2453 | 0.1652 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jargus, J.; Vitasek, J.; Nedoma, J.; Vasinek, V.; Martinek, R. Effect of Selected Luminescent Layers on CCT, CRI, and Response Times. Materials 2019, 12, 2095. https://doi.org/10.3390/ma12132095

Jargus J, Vitasek J, Nedoma J, Vasinek V, Martinek R. Effect of Selected Luminescent Layers on CCT, CRI, and Response Times. Materials. 2019; 12(13):2095. https://doi.org/10.3390/ma12132095

Chicago/Turabian StyleJargus, Jan, Jan Vitasek, Jan Nedoma, Vladimir Vasinek, and Radek Martinek. 2019. "Effect of Selected Luminescent Layers on CCT, CRI, and Response Times" Materials 12, no. 13: 2095. https://doi.org/10.3390/ma12132095

APA StyleJargus, J., Vitasek, J., Nedoma, J., Vasinek, V., & Martinek, R. (2019). Effect of Selected Luminescent Layers on CCT, CRI, and Response Times. Materials, 12(13), 2095. https://doi.org/10.3390/ma12132095