Effective Design of the Graded Strut of BCC Lattice Structure for Improving Mechanical Properties

Abstract

:1. Introduction

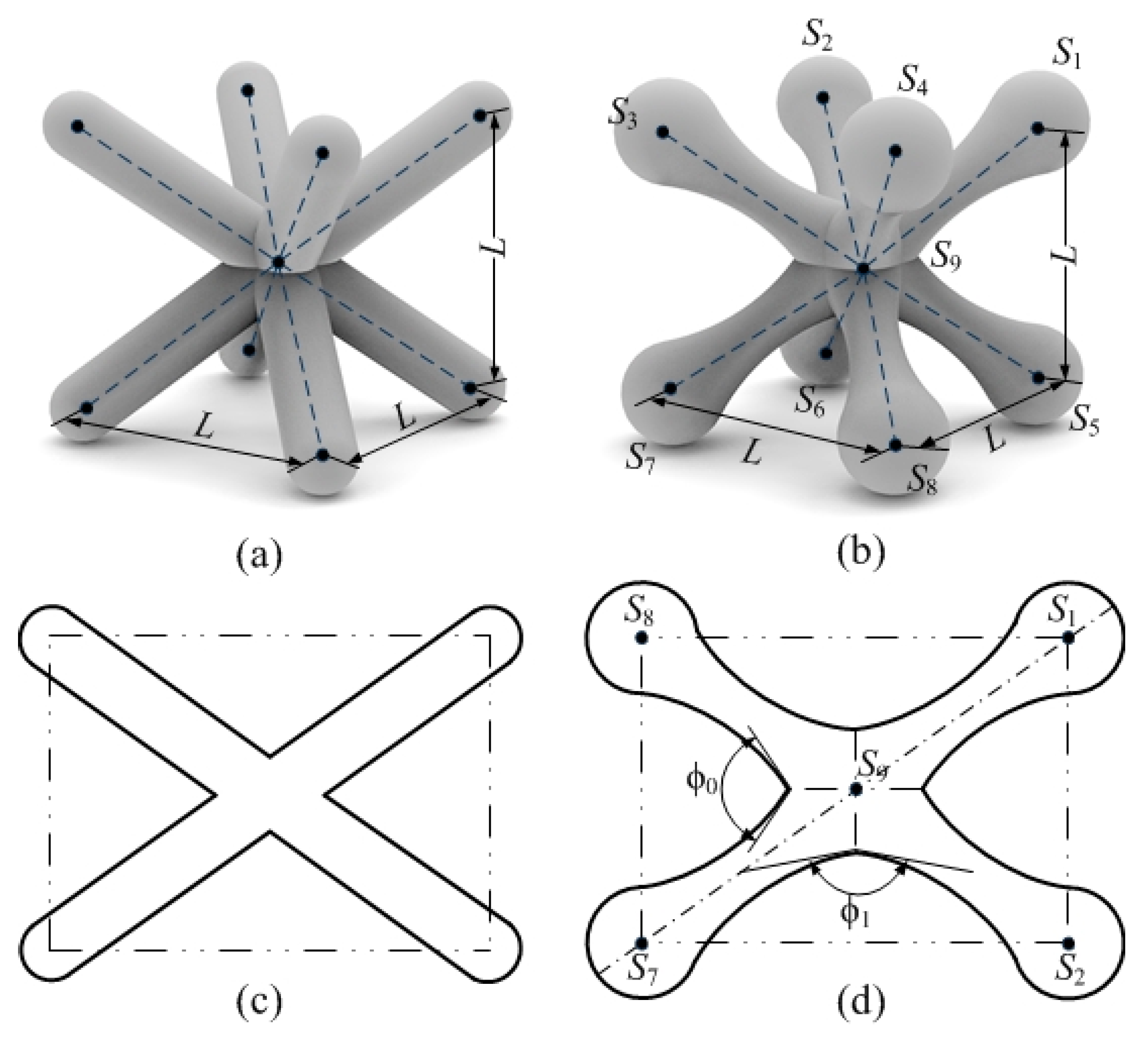

2. Design of the GBCC Unit Cell

2.1. Stress Analysis of the GBCC Unit Cell Node

2.2. Graded-density Strut Design

3. Establishment of GBCC Theoretical Model

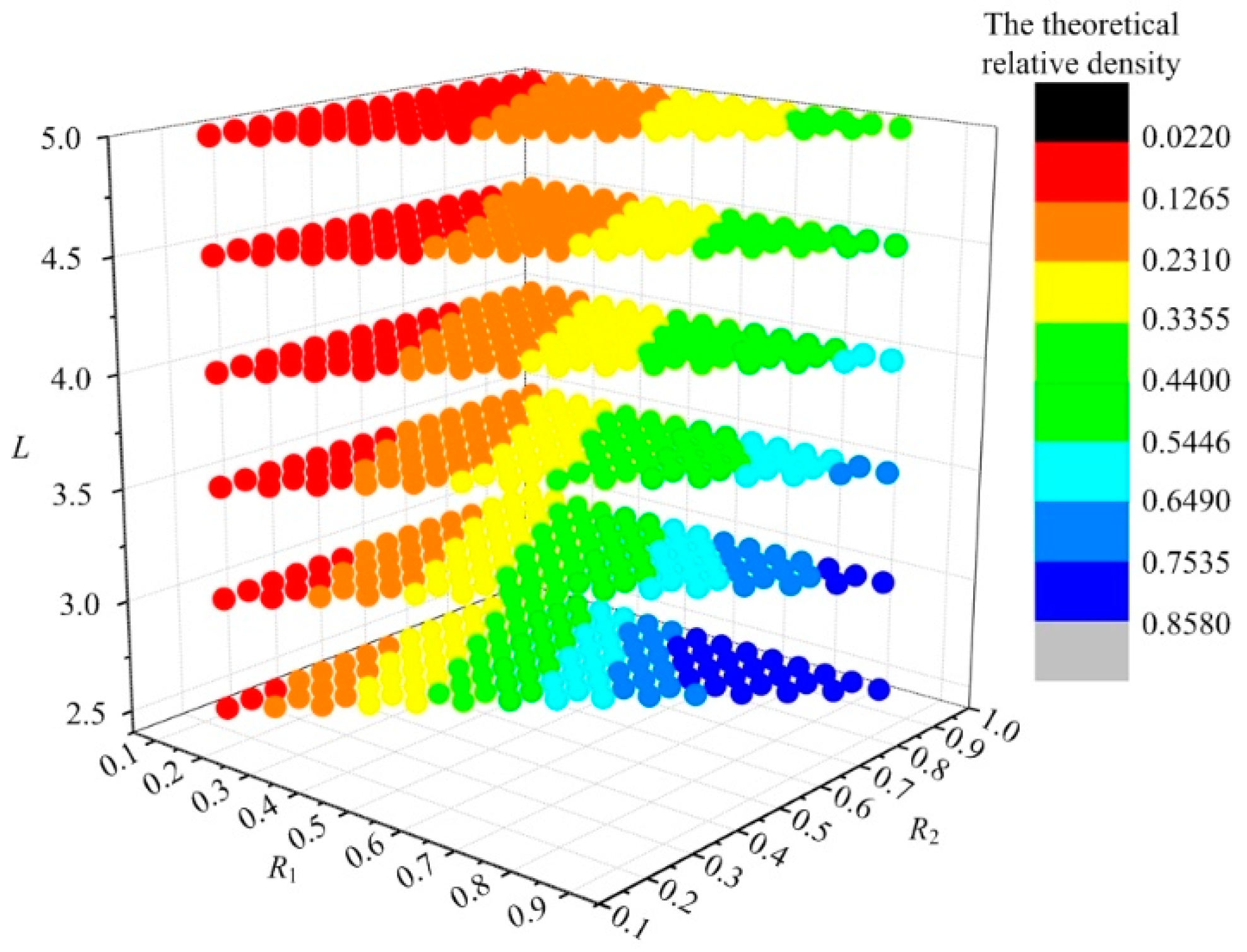

3.1. Analysis of the Relative Density of the GBCC Lattice Structure

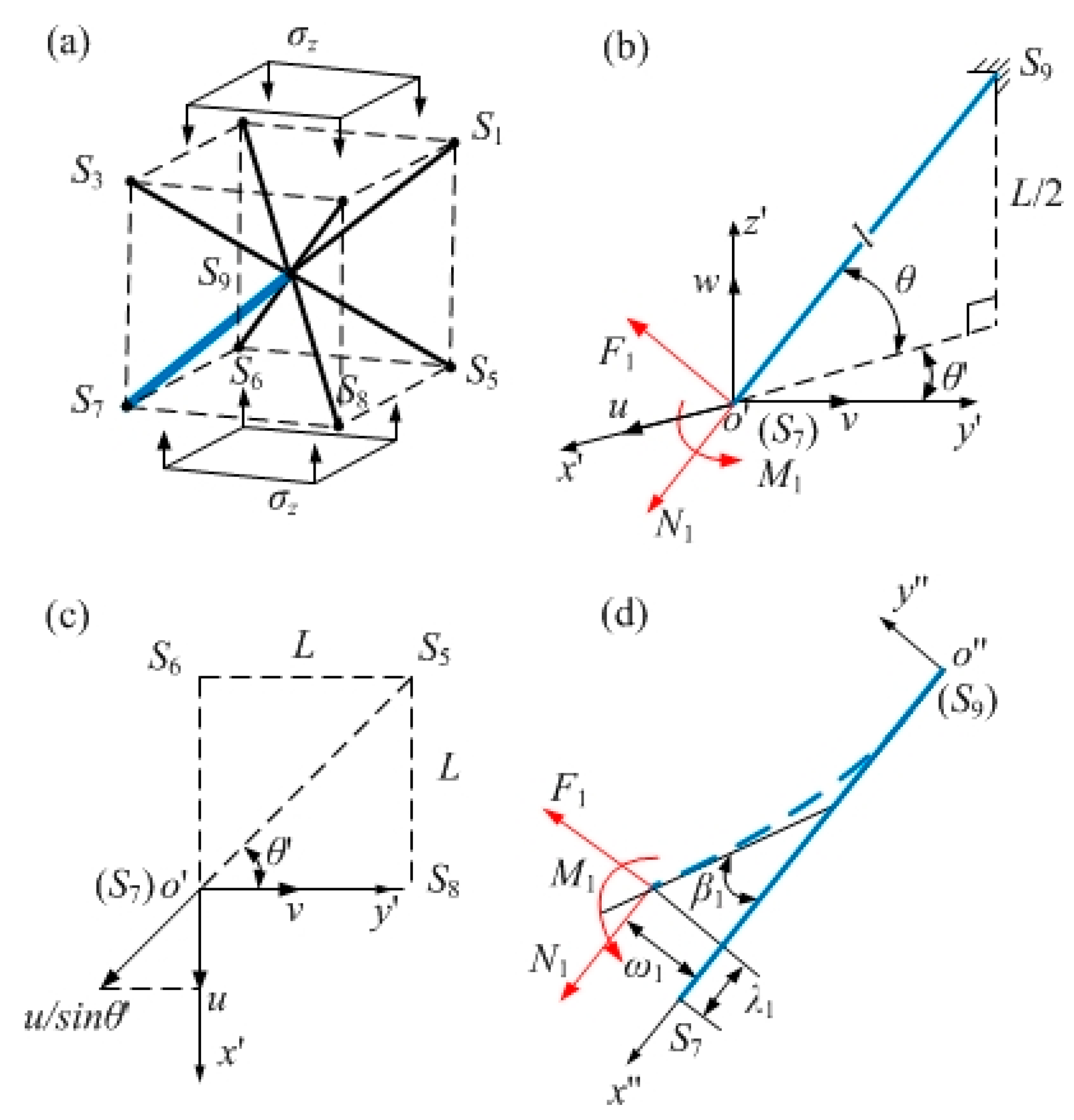

3.2. Force Analysis of the GBCC Lattice Structure

- All struts in a unit cell are slender struts, idealized as Euler-Bernoulli beams;

- The deformation of the strut is always on the diagonal surface of the unit cell with the strut axis. For example, the deformation of struts S1S7 and S3S5 is in the diagonal plane S1S3S7S5.

4. Experimental and Finite Element Simulation Details

4.1. Finite Element Analysis of the Lattice Structure

4.2. Sample Fabrication

5. Results and Discussion

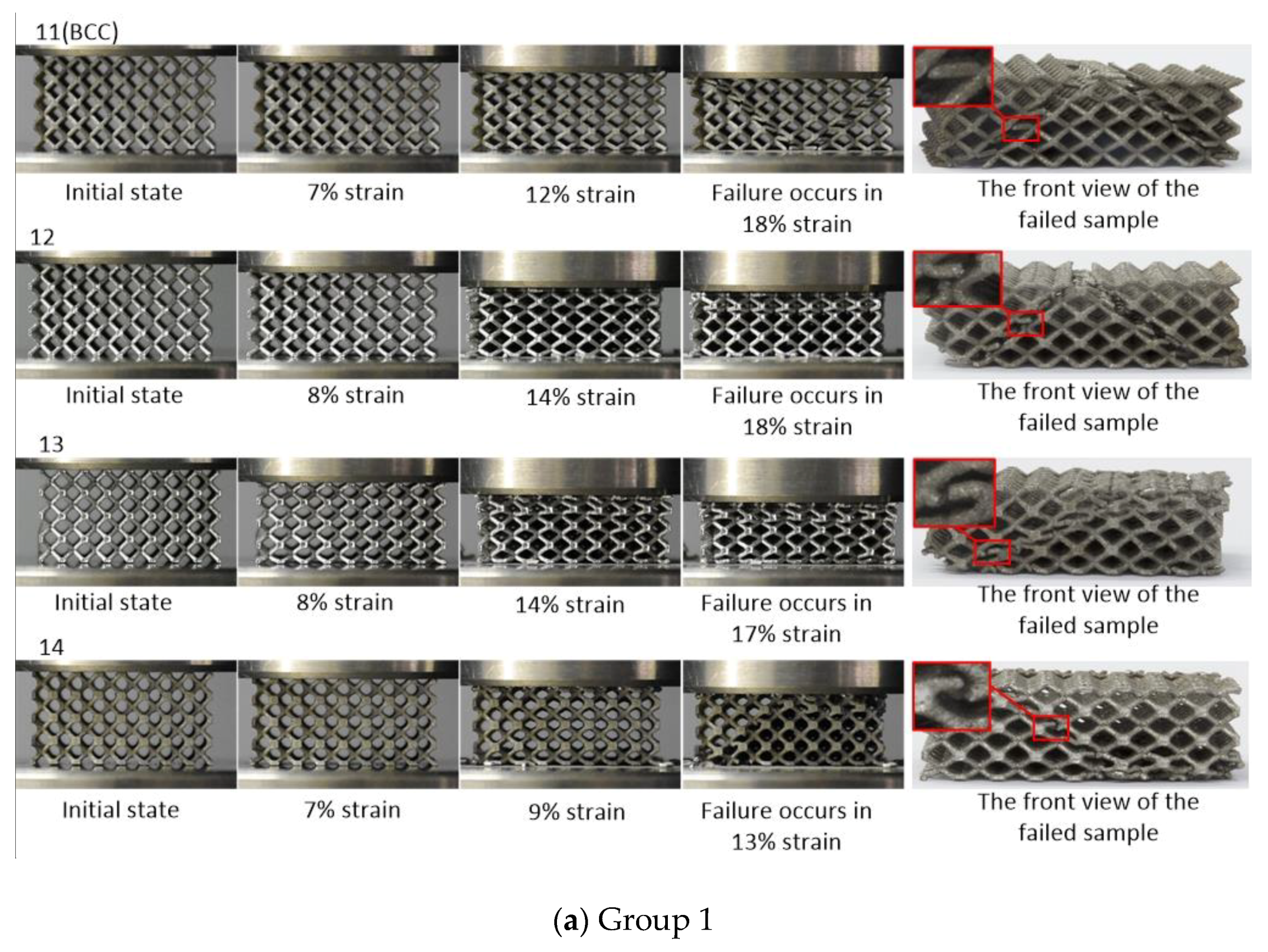

5.1. Deformation of GBCC Lattice Structures Subsection

5.2. Relative Density

5.3. Mechanical Properties of GBCC Lattice Structure

5.3.1. Mechanical Response of Experiments and Finite Element Simulation

5.3.2. Initial Stiffness and Plastic Failure Strength

5.3.3. Energy Analysis

6. Conclusions

- To relieve the stress concentration defects at the nodes of the BCC lattice structure and improve the mechanical properties, the radii corner of the BCC unit cell nodes should be increased. A lattice structure with graded struts (namely, the GBCC structure) is proposed accordingly.

- A general model of the GBCC lattice structure is established. By combining the classical beam theory with the energy conservation law, a specific mapping relationship between the GBCC unit cell size and the mechanical model of the lattice structure is proposed. The mathematical prediction models for the relative density of the GBCC lattice structure are also established. For all the GBCC and BCC samples, the theoretical prediction accuracy of the force model ξ1 is less than 16%, and the theoretical prediction accuracy of the relative density ξ is less than 9%, which proves the correctness of the theoretical calculation method for the force and the relative density analysis of the lattice structure.

- Under identical experimental conditions and density parameters, the finite element simulation, the fabrication and experimental tests of the new GBCC structure and BCC reference structure were completed. The Johnson-Cook (J-C) phenomenological constitutive model and the J-C ductile fracture model are added to the finite element simulation to simulate the stress distribution of the failed lattice sample node. As the radii corner at the intersection of two struts increases, for the same relative density, the stress concentration effect at the lattice structure node is improved, and the failure position of the strut will gradually move away from the node, thereby improving the mechanical properties (including compression and energy absorption properties).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cooper, D.E.; Stanford, M.; Kibble, K.A.; Gibbons, G.J. Additive manufacturing for product improvement at Red Bull Technology. Mater. Des. 2012, 41, 226–230. [Google Scholar] [CrossRef]

- Zhai, Y.; Lados, D.A.; LaGoy, J.L. Additive manufacturing: making imagination the major limitation. Jom 2014, 66, 808–816. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Drizo, A.; Pegna, J. Environmental impacts of rapid prototyping: an overview of research to date. Rapid Prototyp. J. 2006, 12, 64–71. [Google Scholar] [CrossRef]

- Guan, G.; Hirsch, M.; Lu, Z.H.; Childs, D.T.; Matcher, S.J.; Goodridge, R.; Groom, K.M.; Clare, A.T. Evaluation of selective laser sintering processes by optical coherence tomography. Mater. Des. 2015, 88, 837–846. [Google Scholar] [CrossRef]

- Merkt, S.; Hinke, C.; Bültmann, J.; Brandt, M.; Xie, Y.M. Mechanical response of TiAl6V4 lattice structures manufactured by selective laser melting in quasistatic and dynamic compression tests. J. Laser Appl. 2015, 27, S17006. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, X.; Konovalov, S.V. Additive Manufacturing Based on Welding Arc: A low-Cost Method. J. Surf. Investig X-ray Synchrotron Neutron Tech. 2017, 11, 1317–1328. [Google Scholar] [CrossRef]

- Chen, X.; Su, C.; Wang, Y.; Siddiquee, A.N.; Sergey, K.; Jayalakshmi, S.; Singh, R.A. Cold Metal Transfer (CMT) Based Wire and Arc Additive Manufacture (WAAM) System. J. Surf. Investig X-ray Synchrotron Neutron Tech. 2018, 12, 1278–1284. [Google Scholar] [CrossRef]

- Evans, A.G.; Hutchinson, J.W.; Fleck, N.A.; Ashby, M.F.; Wadley, H.N.G. The topological design of multifunctional cellular metals. Prog. Mater. Sci. 2001, 46, 309–327. [Google Scholar] [CrossRef]

- Smith, M.; Guan, Z.; Cantwell, W.J. Finite element modelling of the compressive response of lattice structures manufactured using the selective laser melting technique. Int. J. Mech. Sci. 2013, 67, 28–41. [Google Scholar] [CrossRef]

- Ushijima, K.; Cantwell, W.J.; Mines, R.A.; Tsopanos, S.; Smith, M. An investigation into the compressive properties of stainless steel micro-lattice structures. J. Sandw. Struct. Mater. 2011, 13, 303–329. [Google Scholar] [CrossRef]

- Gümrük, R.; Mines, R.A.W. Compressive behaviour of stainless steel micro-lattice structures. Int. J. Mech. Sci. 2013, 68, 125–139. [Google Scholar] [CrossRef]

- Feng, Q.; Tang, Q.; Liu, Z.; Liu, Y.; Setchi, R. An investigation of the mechanical properties of metallic lattice structures fabricated using selective laser melting. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 1719–1730. [Google Scholar] [CrossRef]

- Ptochos, E.; Labeas, G. Shear modulus determination of cuboid metallic open-lattice cellular structures by analytical, numerical and homogenisation methods. Strain 2012, 48, 415–429. [Google Scholar] [CrossRef]

- Bai, L.; Zhang, J.; Chen, X.; Yi, C.; Chen, R.; Zhang, Z. Configuration optimization design of Ti6Al4V lattice structure formed by SLM. Materials 2018, 11, 1856. [Google Scholar] [CrossRef]

- Shen, Y.; McKown, S.; Tsopanos, S.; Sutcliffe, C.J.; Mines, R.A.; Cantwell, W.J. The mechanical properties of sandwich structures based on metal lattice architectures. J. Sandw. Struct. Mater. 2010, 2, 159–180. [Google Scholar] [CrossRef]

- Gümrük, R.; Mines, R.A.W.; Karadeniz, S. Static mechanical behaviours of stainless steel micro-lattice structures under different loading conditions. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2013, 586, 392–406. [Google Scholar] [CrossRef]

- McKown, S.; Shen, Y.; Brookes, W.K.; Sutcliffe, C.J.; Cantwell, W.J.; Langdon, G.S.; Nurick, G.N.; Theobald, M.D. The quasi-static and blast loading response of lattice structures. Int. J. Impact Eng. 2008, 35, 795–810. [Google Scholar] [CrossRef]

- Beharic, A.; Egui, R.R.; Yang, L. Drop-weight impact characteristics of additively manufactured sandwich structures with different cellular designs. Mater. Des. 2018, 145, 122–134. [Google Scholar] [CrossRef]

- Mines, R.A.; Tsopanos, S.; Shen, Y.; Hasan, R.; McKown, S.T. Drop weight impact behaviour of sandwich panels with metallic micro lattice cores. Int. J. Impact Eng. 2013, 60, 120–132. [Google Scholar] [CrossRef] [Green Version]

- Crupi, V.; Kara, E.; Epasto, G.; Guglielmino, E.; Aykul, H. Static behavior of lattice structures produced via direct metal laser sintering technology. Mater. Des. 2017, 135, 246–256. [Google Scholar] [CrossRef]

- Maskery, I.; Aremu, A.O.; Simonelli, M.; Tuck, C.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J. Mechanical properties of Ti-6Al-4V selectively laser melted parts with body-centred-cubic lattices of varying cell size. Exp. Mech. 2015, 55, 1261–1272. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; McMillan, M.; Sun, S.; Shidid, D.; Brandt, M. Mechanical properties of Ti6Al4V and AlSi12Mg lattice structures manufactured by Selective Laser Melting (SLM). Laser Addit. Manuf. 2017, 5, 119–161. [Google Scholar]

- Ataee, A.; Li, Y.; Brandt, M.; Wen, C. Ultrahigh-strength titanium gyroid scaffolds manufactured by selective laser melting (SLM) for bone implant applications. Acta Mater. 2018, 158, 354–368. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Fang, G.; Xing, L.L.; Liu, W.; Zhou, J. Effect of porosity variation strategy on the performance of functionally graded Ti-6Al-4V scaffolds for bone tissue engineering. Mater. Des. 2018, 157, 523–538. [Google Scholar] [CrossRef]

- Ataee, A.; Li, Y.; Fraser, D.; Song, G.; Wen, C. Anisotropic Ti-6Al-4V gyroid scaffolds manufactured by electron beam melting (EBM) for bone implant applications. Mater. Des. 2018, 137, 345–354. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Elambasseril, J.; McMillan, M.; Chirent, T.; Sun, Y.; Qian, M.; Easton, M.; Brandt, M. Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater. Des. 2016, 98, 344–357. [Google Scholar] [CrossRef]

- Gorny, B.; Niendorf, T.; Lackmann, J.; Thoene, M.; Troester, T.; Maier, H.J. In situ characterization of the deformation and failure behavior of non-stochastic porous structures processed by selective laser melting. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2011, 528, 7962–7967. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, D.; Zhang, P.; Zhao, M.; Jafar, S. Mechanical properties of optimized diamond lattice structure for bone scaffolds fabricated via selective laser melting. Materials 2018, 11, 374. [Google Scholar] [CrossRef]

- Li, P. Constitutive and failure behaviour in selective laser melted stainless steel for microlattice structures. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2015, 622, 114–120. [Google Scholar] [CrossRef]

- Montazerian, H.; Davoodi, E.; Asadi-Eydivand, M.; Kadkhodapour, J.; Solati-Hashjin, M. Porous scaffold internal architecture design based on minimal surfaces: a compromise between permeability and elastic properties. Mater. Des. 2017, 126, 98–114. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Young, P. Ti–6Al–4V triply periodic minimal surface structures for bone implants fabricated via selective laser melting. J. Mech. Behav. Biomed. Mater. 2015, 51, 61–73. [Google Scholar] [CrossRef] [PubMed]

- Dalaq, A.S.; Abueidda, D.W.; Al-Rub, R.K.A. Mechanical properties of 3D printed interpenetrating phase composites with novel architectured 3D solid-sheet reinforcements. Compos. Pt. A Appl. Sci. Manuf. 2016, 84, 266–280. [Google Scholar] [CrossRef]

- Yang, L.; Yan, C.; Han, C.; Chen, P.; Yang, S.; Shi, Y. Mechanical response of a triply periodic minimal surface cellular structures manufactured by selective laser melting. Int. J. Mech. Sci. 2018, 148, 149–157. [Google Scholar] [CrossRef]

- Yang, L.; Yan, C.; Fan, H.; Li, Z.; Cai, C.; Chen, P.; Shi, Y.; Yang, S. Investigation on the orientation dependence of elastic response in Gyroid cellular structures. J. Mech. Behav. Biomed. Mater. 2019, 90, 73–85. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Mertens, R.; Ferrucci, M.; Yan, C.; Shi, Y.; Yang, S. Continuous graded Gyroid cellular structures fabricated by selective laser melting: Design, manufacturing and mechanical properties. Mater. Des. 2019, 162, 394–404. [Google Scholar] [CrossRef]

- Liu, F.; Mao, Z.; Zhang, P.; Zhang, D.Z.; Jiang, J.; Ma, Z. Functionally graded porous scaffolds in multiple patterns: New design method, physical and mechanical properties. Mater. Des. 2018, 160, 849–860. [Google Scholar] [CrossRef]

- Maskery, I.; Aremu, A.O.; Parry, L.; Wildman, R.D.; Tuck, C.J.; Ashcroft, I.A. Effective design and simulation of surface-based lattice structures featuring volume fraction and cell type grading. Mater. Des. 2018, 155, 220–232. [Google Scholar] [CrossRef]

- Abueidda, D.W.; Dalaq, A.S.; Al-Rub, R.K.; Younes, H.A. Finite element predictions of effective multifunctional properties of interpenetrating phase composites with novel triply periodic solid shell architectured reinforcements. Int. J. Mech. Sci. 2015, 92, 80–89. [Google Scholar] [CrossRef]

- Daynes, S.; Feih, S.; Lu, W.F.; Wei, J. Optimisation of functionally graded lattice structures using isostatic lines. Mater. Des. 2017, 127, 215–223. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.T.; Aremu, A.O.; Tuck, C.J.; Ashcroft, I.A.; Wildman, R.D.; Hague, R.J. A mechanical property evaluation of graded density Al-Si10-Mg lattice structures manufactured by selective laser melting. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2016, 70, 264–274. [Google Scholar] [CrossRef]

- Maskery, I.; Hussey, A.; Panesar, A.; Aremu, A.; Tuck, C.; Ashcroft, I.; Hague, R. An investigation into reinforced and functionally graded lattice structures. J. Cell. Plast. 2017, 53, 151–165. [Google Scholar] [CrossRef]

- Al-Saedi, D.S.; Masood, S.H.; Faizan-Ur-Rab, M.; Alomarah, A.; Ponnusamy, P. Mechanical properties and energy absorption capability of functionally graded F2BCC lattice fabricated by SLM. Mater. Des. 2018, 144, 32–44. [Google Scholar] [CrossRef]

- du Plessis, A.; Yadroitsava, I.; Yadroitsev, I. Ti6Al4V lightweight lattice structures manufactured by laser powder bed fusion for load-bearing applications. Opt. Laser Technol. 2018, 108, 521–528. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Williams, H.; Yang, E.; Alghamdi, A.; Lozanovski, B.; Zhang, X.; Shidid, D.; Farahbod-Sternahl, L.; Witt, G.; et al. Inconel 625 lattice structures manufactured by selective laser melting (SLM): Mechanical properties, deformation and failure modes. Mater. Des. 2018, 157, 179–199. [Google Scholar] [CrossRef]

- Feng, Q.; Tang, Q.; Liu, Y.; Setchi, R.; Soe, S.; Ma, S.; Bai, L. Quasi-static analysis of mechanical properties of Ti6Al4V lattice structures manufactured using selective laser melting. Int. J. Adv. Manuf. Technol. 2018, 94, 2301–2313. [Google Scholar] [CrossRef]

- Zhang, Y.; Outeiro, J.C.; Mabrouki, T. On the selection of Johnson-Cook constitutive model parameters for Ti-6Al-4 V using three types of numerical models of orthogonal cutting. Procedia Cirp 2015, 31, 112–117. [Google Scholar] [CrossRef]

- Habib, F.N.; Iovenitti, P.; Masood, S.H.; Nikzad, M. Fabrication of polymeric lattice structures for optimum energy absorption using Multi Jet Fusion technology. Mater. Des. 2018, 155, 86–98. [Google Scholar] [CrossRef]

- Yan, C.; Hao, L.; Hussein, A.; Young, P.; Raymont, D. Advanced lightweight 316L stainless steel cellular lattice structures fabricated via selective laser melting. Mater. Des. 2014, 55, 533–541. [Google Scholar] [CrossRef] [Green Version]

- Qiu, C.; Yue, S.; Adkins, N.J.; Ward, M.; Hassanin, H.; Lee, P.D.; Withers, P.J.; Attallah, M.M. Influence of processing conditions on strut structure and compressive properties of cellular lattice structures fabricated by selective laser melting. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2015, 628, 188–197. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Fang, G.; Leeflang, S.; Zadpoor, A.A.; Zhou, J. Topological design, permeability and mechanical behavior of additively manufactured functionally graded porous metallic biomaterials. Acta Biomater. 2019, 84, 437–452. [Google Scholar] [CrossRef] [PubMed]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Ashby, M.F. The properties of foams and lattices. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2005, 364, 15–30. [Google Scholar] [CrossRef] [PubMed]

| L (mm) | R1 (mm) | R2 (mm) | σz (MPa) | M1 (Theory) (N·mm) | M1 (FEA) (N·mm) | ξ1 (%) |

|---|---|---|---|---|---|---|

| 4.00 | 0.330 | 0.430 | 17.4 | 194.4 | 174.2 | 11.6 |

| 4.00 | 0.275 | 0.385 | 11.9 | 132.8 | 134.7 | 1.4 |

| 4.00 | 0.180 | 0.265 | 3.1 | 34.7 | 34.3 | 1.0 |

| 3.25 | 0.180 | 0.265 | 5.1 | 30.7 | 34.1 | 9.9 |

| 2.50 | 0.180 | 0.265 | 5.5 | 15.0 | 17.7 | 15.3 |

| Group | Samples | L (mm) | R1 (mm) | R2 (mm) | ρ′ |

|---|---|---|---|---|---|

| 1 | 11 (BCC) | 4.0 | 0.35 | 0.35 | 0.140 |

| 12 | 4.0 | 0.33 | 0.43 | 0.140 | |

| 13 | 4.0 | 0.30 | 0.53 | 0.139 | |

| 14 | 4.0 | 0.27 | 0.65 | 0.142 | |

| 2 | 21 (BCC) | 4.0 | 0.40 | 0.40 | 0.178 |

| 22 | 4.0 | 0.375 | 0.50 | 0.177 | |

| 23 | 4.0 | 0.35 | 0.60 | 0.177 | |

| 24 | 4.0 | 0.325 | 0.70 | 0.179 | |

| 3 | 31 (BCC) | 4.0 | 0.30 | 0.30 | 0.106 |

| 32 | 4.0 | 0.275 | 0.385 | 0.105 | |

| 33 | 4.0 | 0.25 | 0.475 | 0.106 | |

| 34 | 4.0 | 0.225 | 0.55 | 0.106 |

| d1 | d2 | d3 | d4 | d5 | Melting Temperature | Transition Temperature | A | B | n | m | C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| −0.09 | 0.25 | −0.5 | 0.014 | 3.87 | 1630 | 995 | 862 | 331 | 0.34 | 0.8 | 0.012 |

| Power (W) | Spot Diameter (mm) | Scan Space (mm) | Layer Thickness (μm) | Density (%) |

|---|---|---|---|---|

| 200 | 0.1 | 0.15 | 50 | 99 |

| Group | Samples | Sample Mass (g) | Relative Density |

|---|---|---|---|

| 1 | 11 (BCC) | 10.8 | 0.149 |

| 12 | 11.0 | 0.152 | |

| 13 | 11.0 | 0.152 | |

| 14 | 11.3 | 0.156 | |

| 2 | 21 (BCC) | 13.6 | 0.187 |

| 22 | 14.0 | 0.193 | |

| 23 | 13.8 | 0.190 | |

| 24 | 14.1 | 0.194 | |

| 3 | 31 (BCC) | 8.3 | 0.114 |

| 32 | 8.6 | 0.118 | |

| 33 | 8.8 | 0.121 | |

| 34 | 8.8 | 0.121 |

| Group | Samples | ϕ1 (°) | ρ’ | σ’ (MPa) | E (MPa) |

|---|---|---|---|---|---|

| 1 | 11 (BCC) | 106.65 | 0.140 | 30.3 | 385.4 |

| 12 | 91.62 | 0.140 | 28.3 | 356.4 | |

| 13 | 79.94 | 0.139 | 26.1 | 325.2 | |

| 14 | 70.53 | 0.142 | 21.3 | 271.5 | |

| 2 | 21 (BCC) | 105.41 | 0.178 | 45.6 | 570.5 |

| 22 | 93.17 | 0.177 | 43.9 | 547.0 | |

| 23 | 81.44 | 0.177 | 40.3 | 476.3 | |

| 24 | 70.53 | 0.179 | 34.0 | 412.8 | |

| 3 | 31 (BCC) | 102.8 | 0.106 | 17.4 | 215.4 |

| 32 | 93.72 | 0.105 | 16.9 | 208.2 | |

| 33 | 81.38 | 0.106 | 16.1 | 185.6 | |

| 34 | 70.53 | 0.106 | 12.3 | 145.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, L.; Yi, C.; Chen, X.; Sun, Y.; Zhang, J. Effective Design of the Graded Strut of BCC Lattice Structure for Improving Mechanical Properties. Materials 2019, 12, 2192. https://doi.org/10.3390/ma12132192

Bai L, Yi C, Chen X, Sun Y, Zhang J. Effective Design of the Graded Strut of BCC Lattice Structure for Improving Mechanical Properties. Materials. 2019; 12(13):2192. https://doi.org/10.3390/ma12132192

Chicago/Turabian StyleBai, Long, Changyan Yi, Xiaohong Chen, Yuanxi Sun, and Junfang Zhang. 2019. "Effective Design of the Graded Strut of BCC Lattice Structure for Improving Mechanical Properties" Materials 12, no. 13: 2192. https://doi.org/10.3390/ma12132192

APA StyleBai, L., Yi, C., Chen, X., Sun, Y., & Zhang, J. (2019). Effective Design of the Graded Strut of BCC Lattice Structure for Improving Mechanical Properties. Materials, 12(13), 2192. https://doi.org/10.3390/ma12132192