The Use of Eutectic Fe-Si-B Alloy as a Phase Change Material in Thermal Energy Storage Systems

Abstract

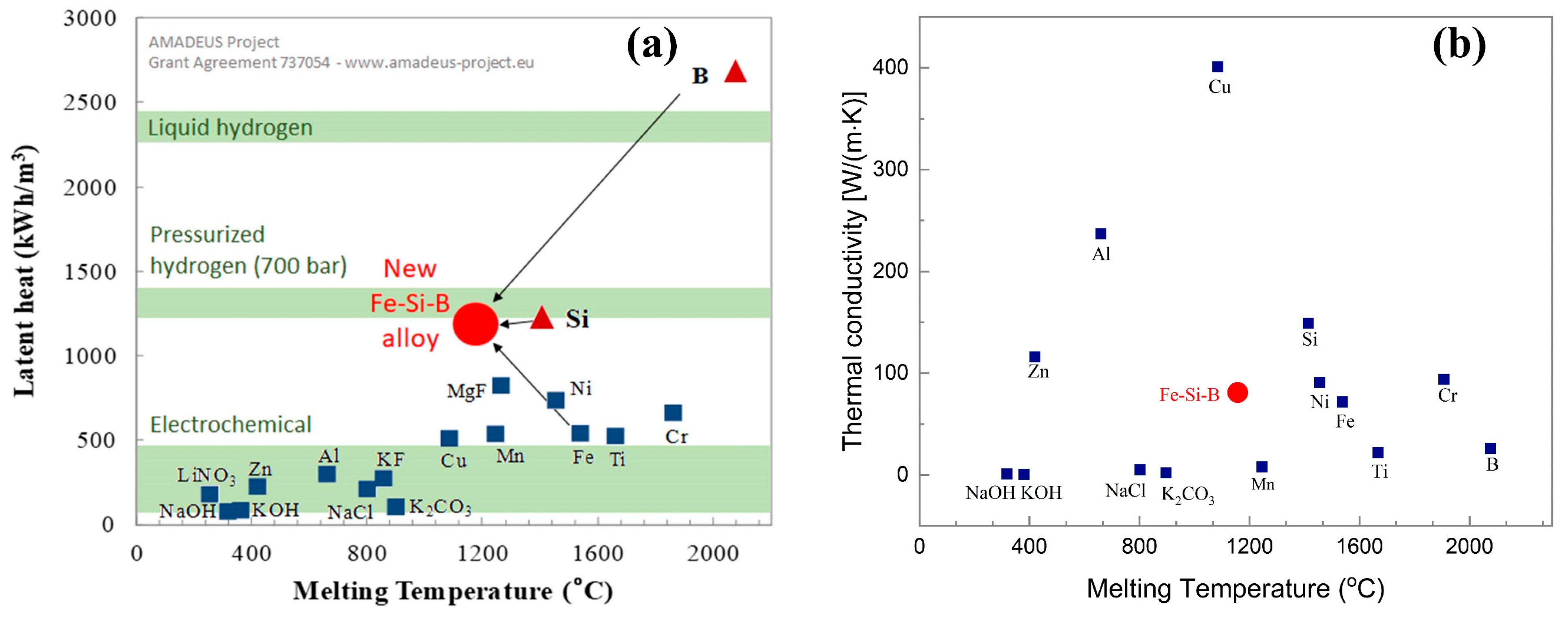

:1. Introduction

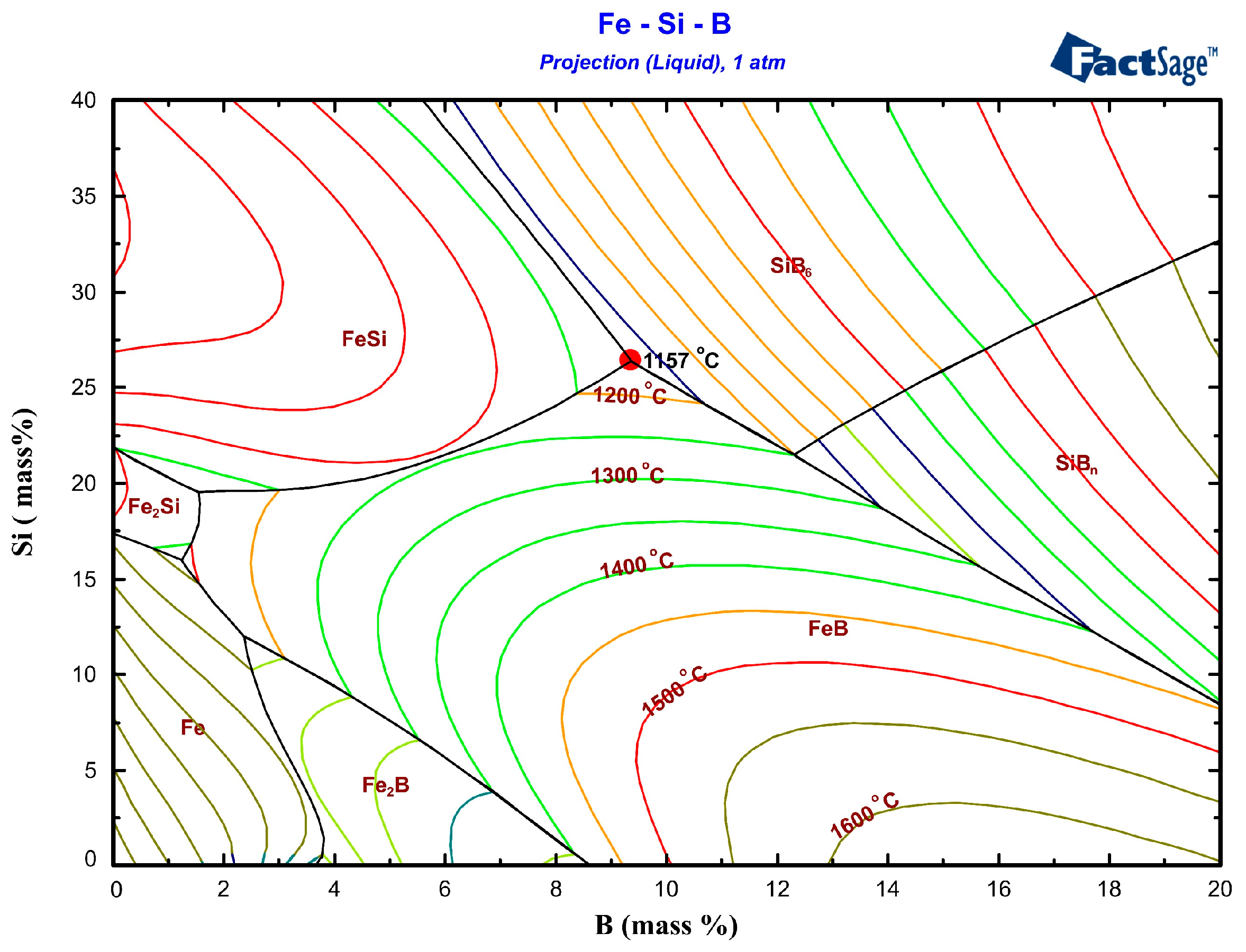

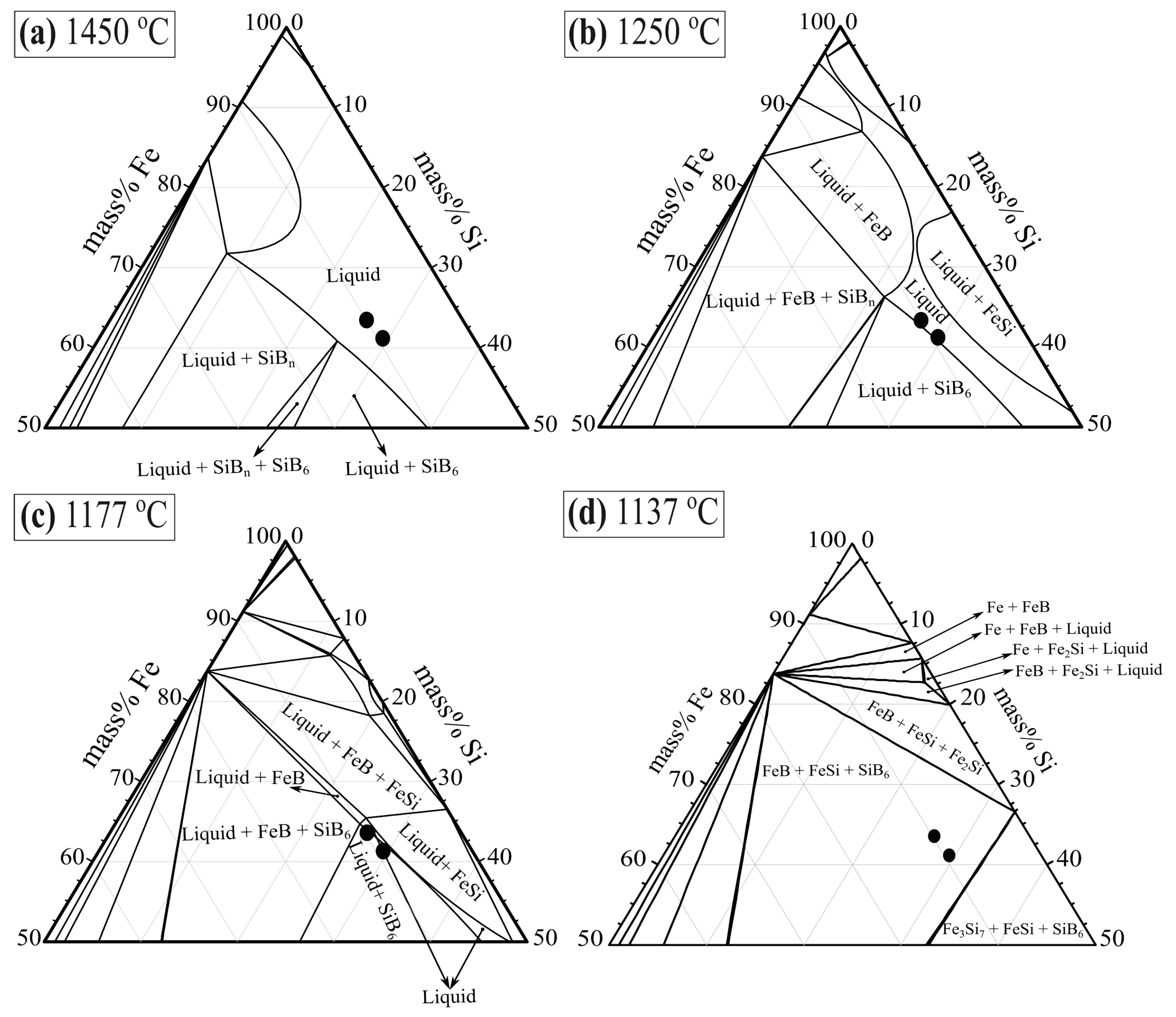

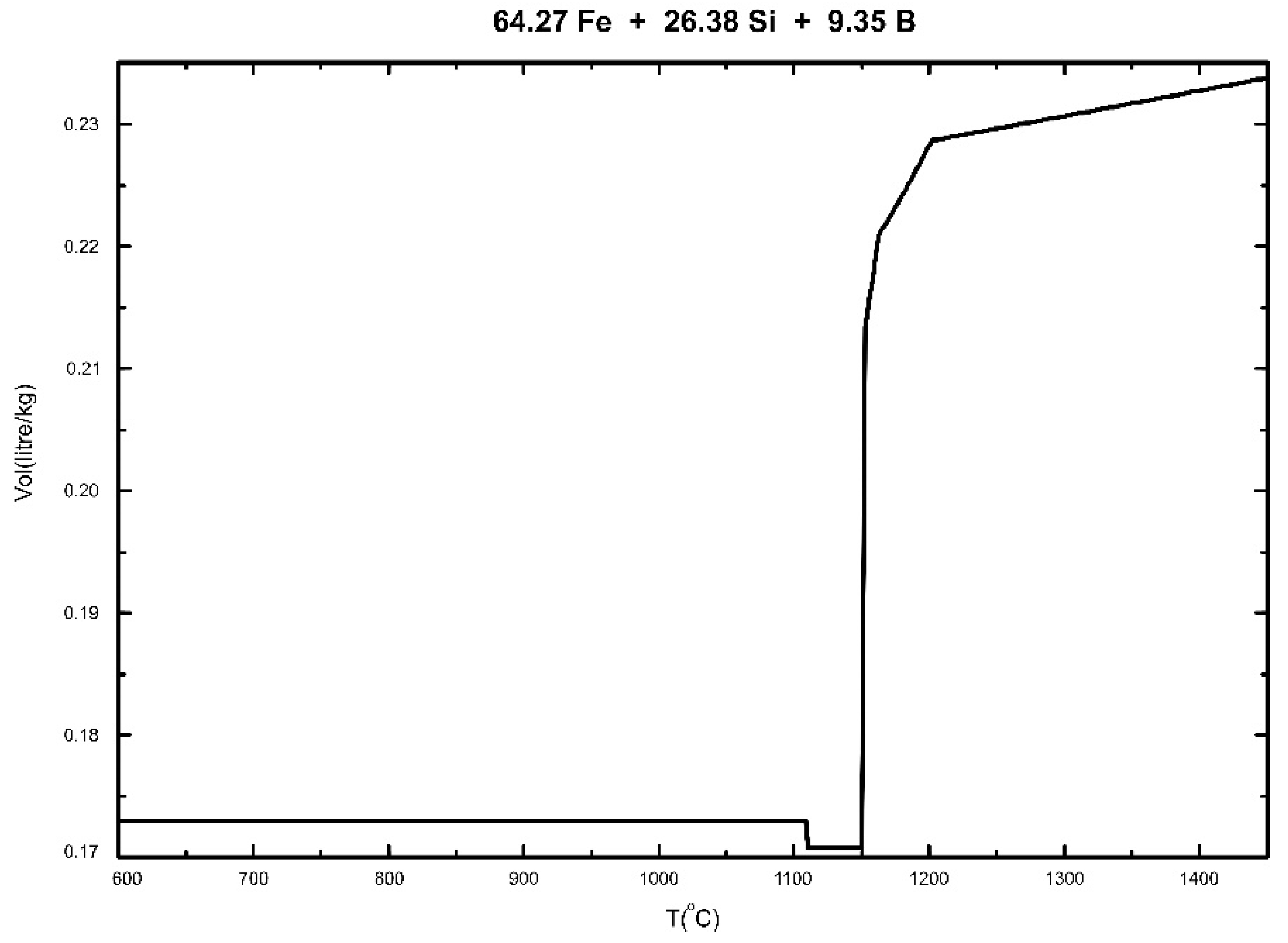

2. Thermodynamic Properties of Fe-Si-B System

3. Experimental Procedure and Materials

3.1. Materials

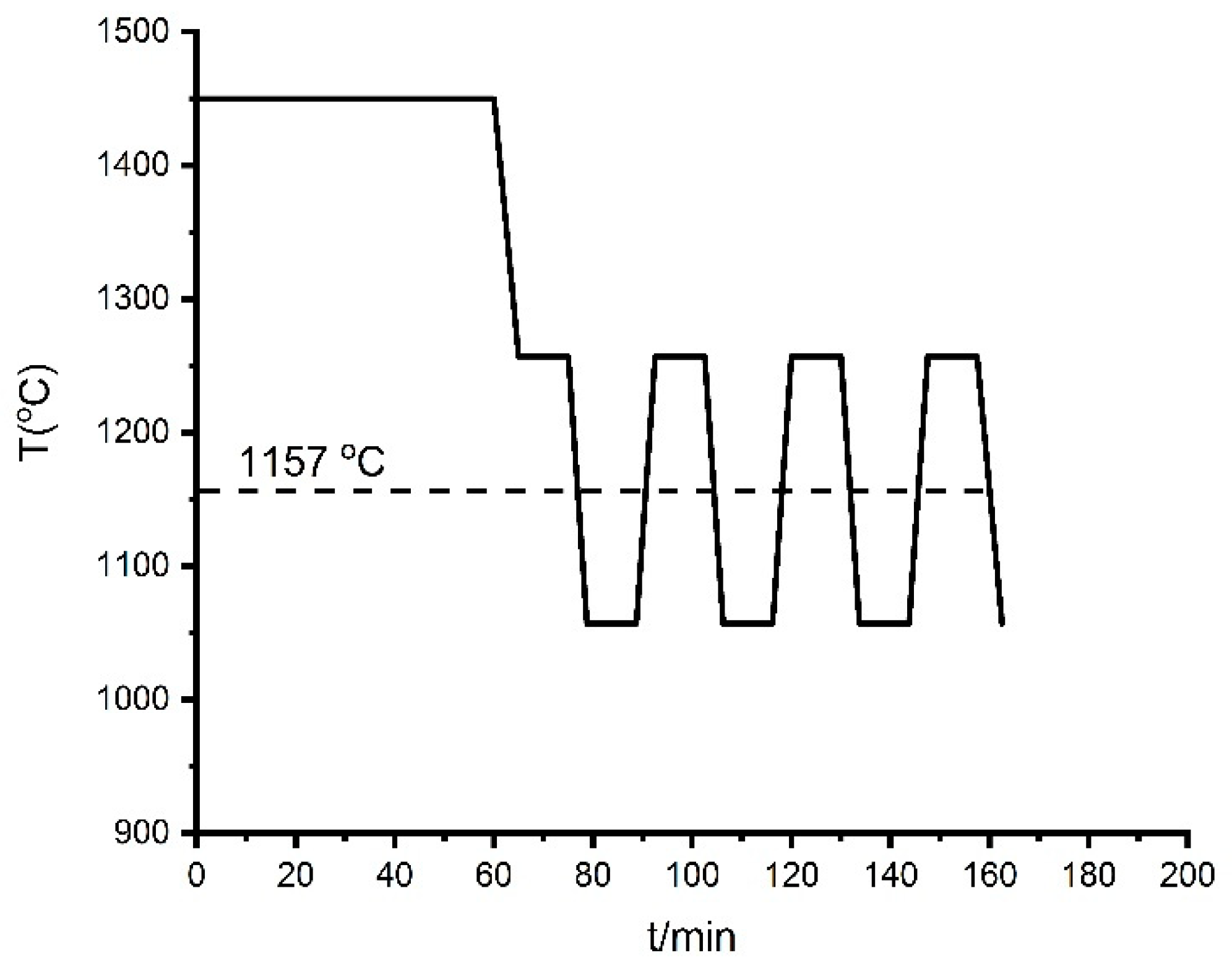

3.2. Thermal Cycle Experiments of Fe-26.38Si-9.35B PCM

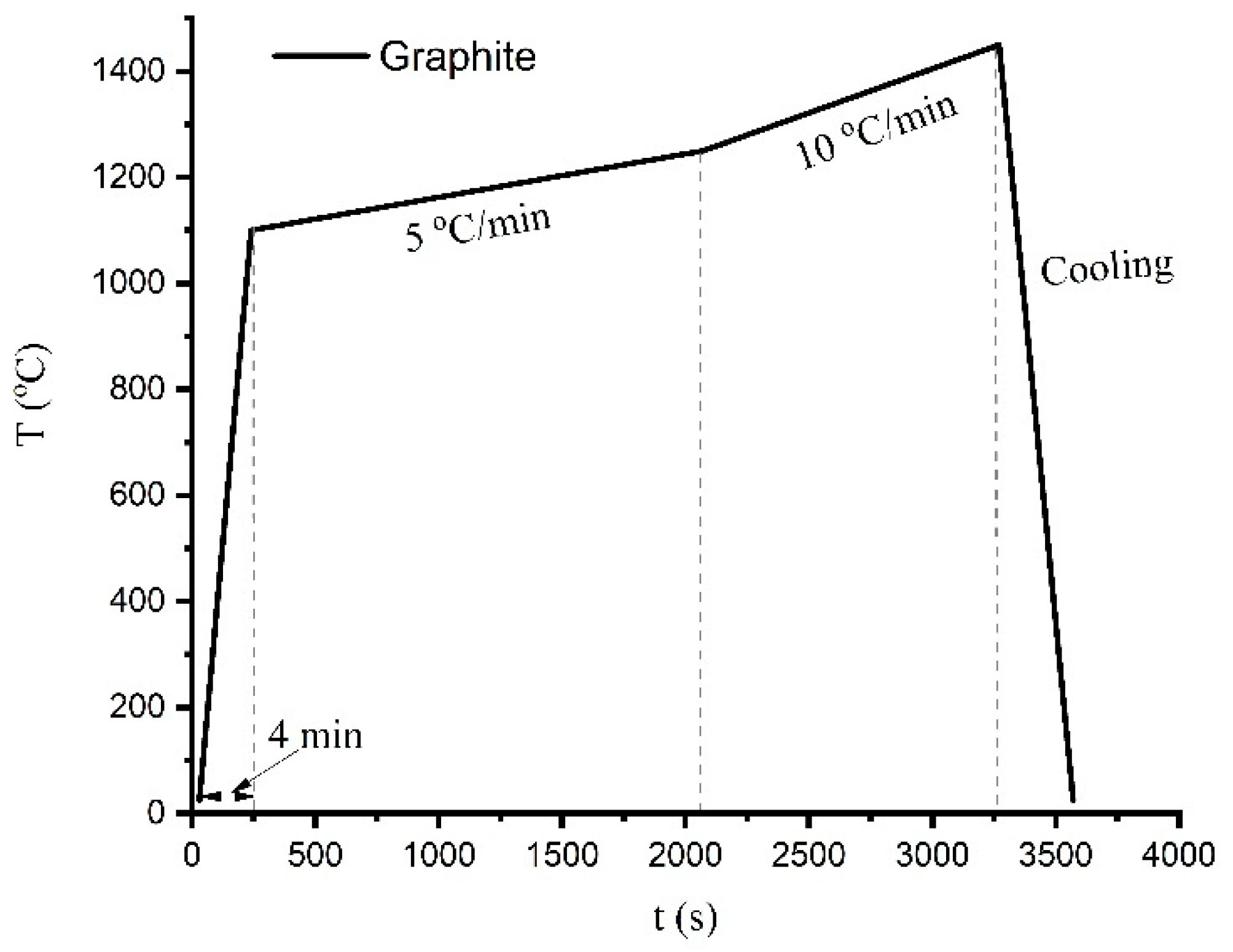

3.3. Wetting Experiment

3.4. Structural Characterization

4. Results and Discussion

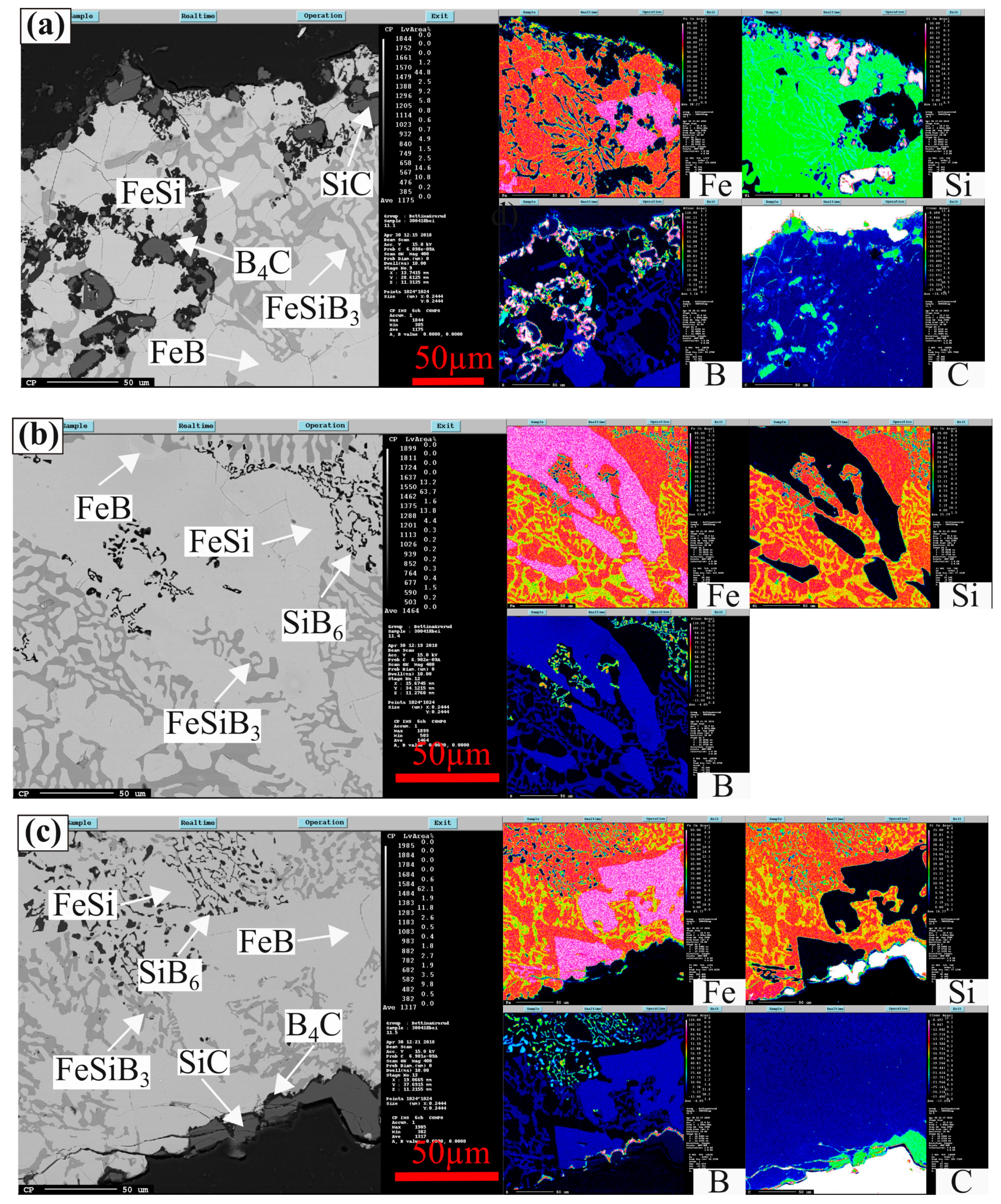

4.1. Phase Formation in the Fe-26.38Si-9.35B Alloy

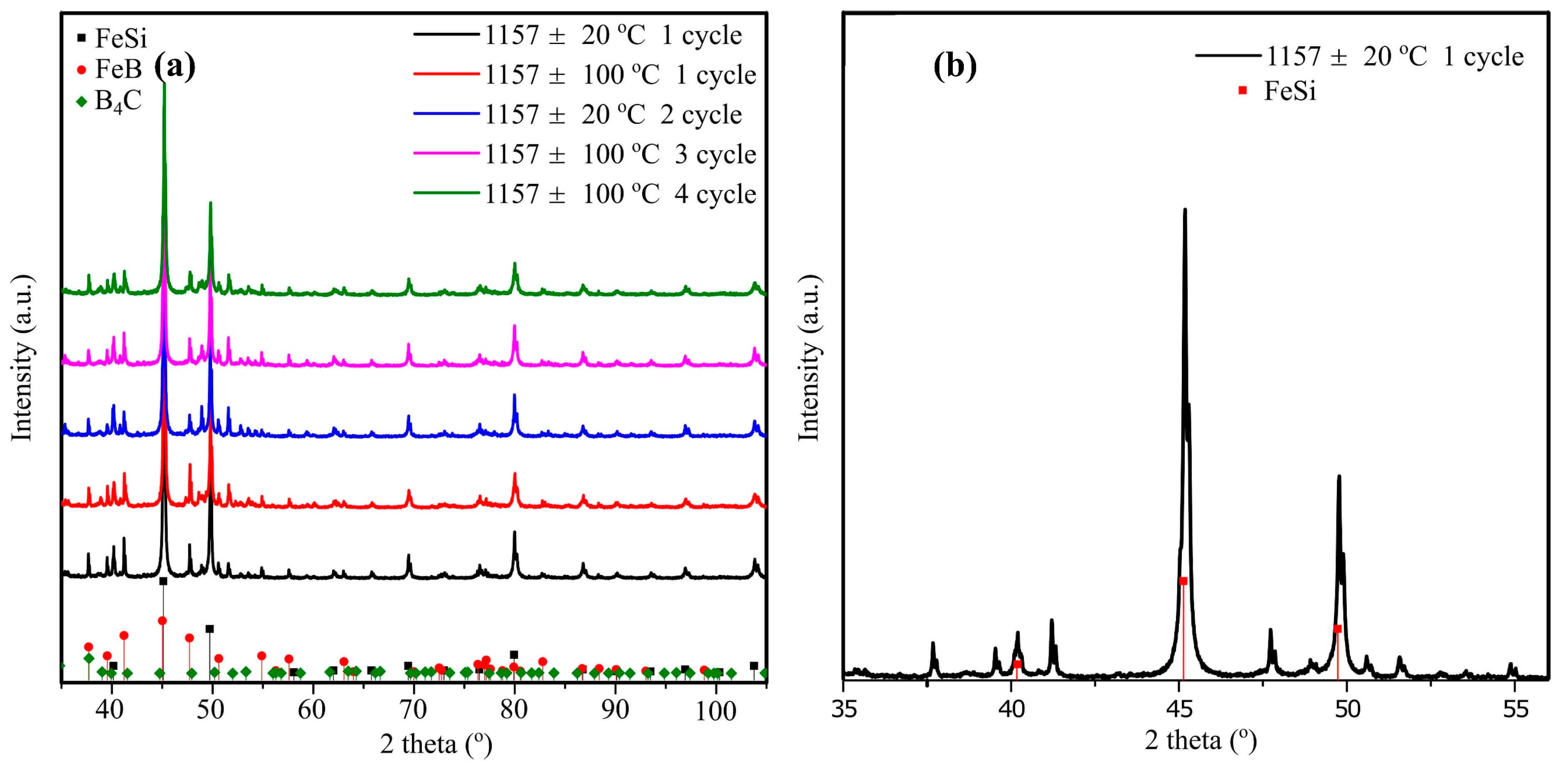

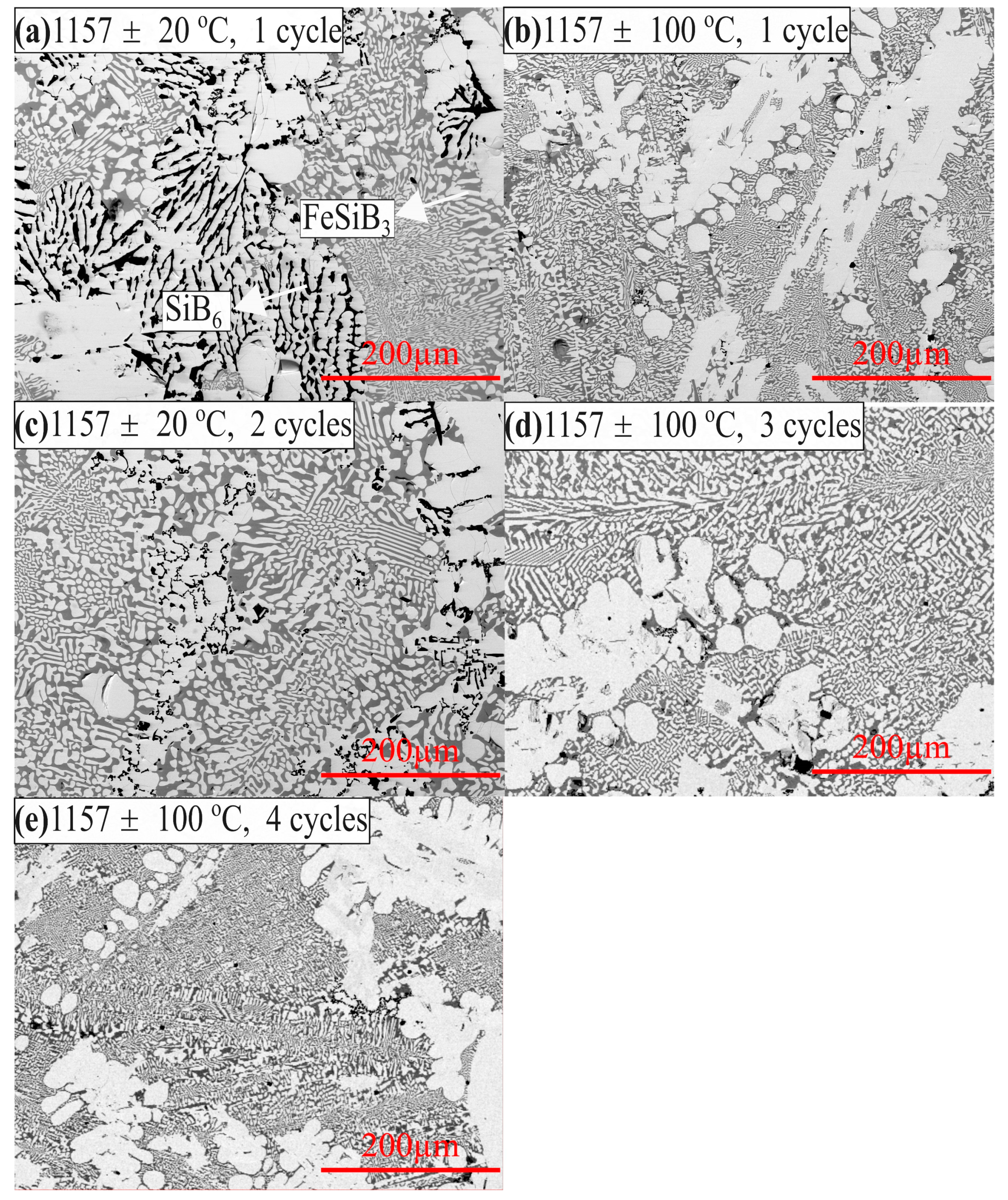

4.2. Effect of Thermal Cycling

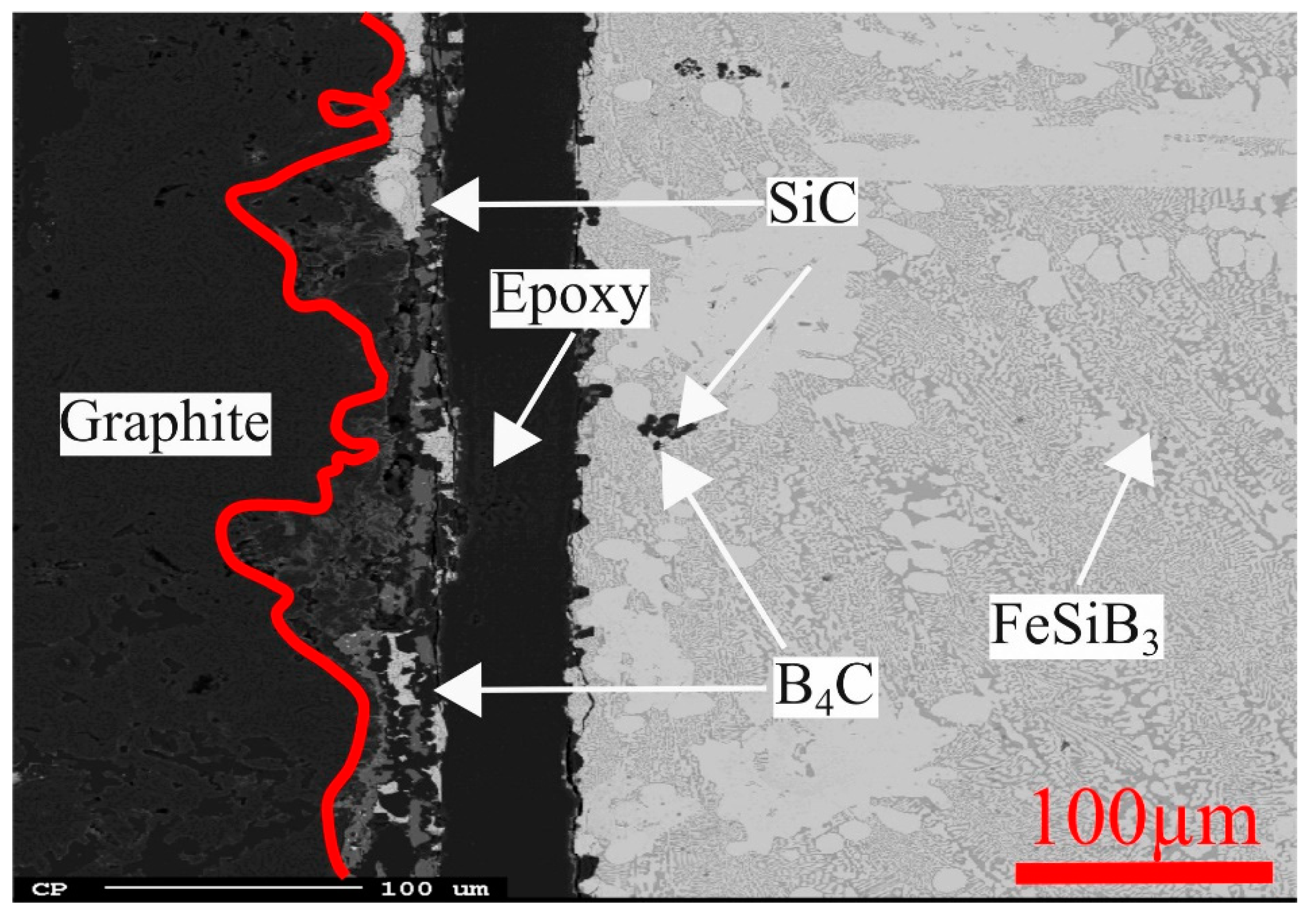

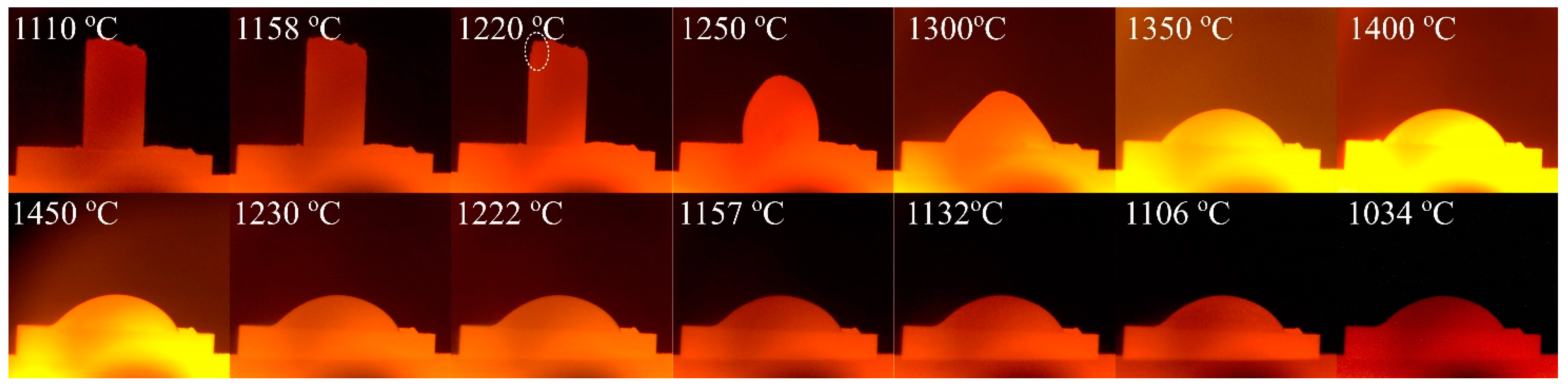

4.3. Wettability of Graphite Substrate by the Molten Fe-26.38Si-9.35B

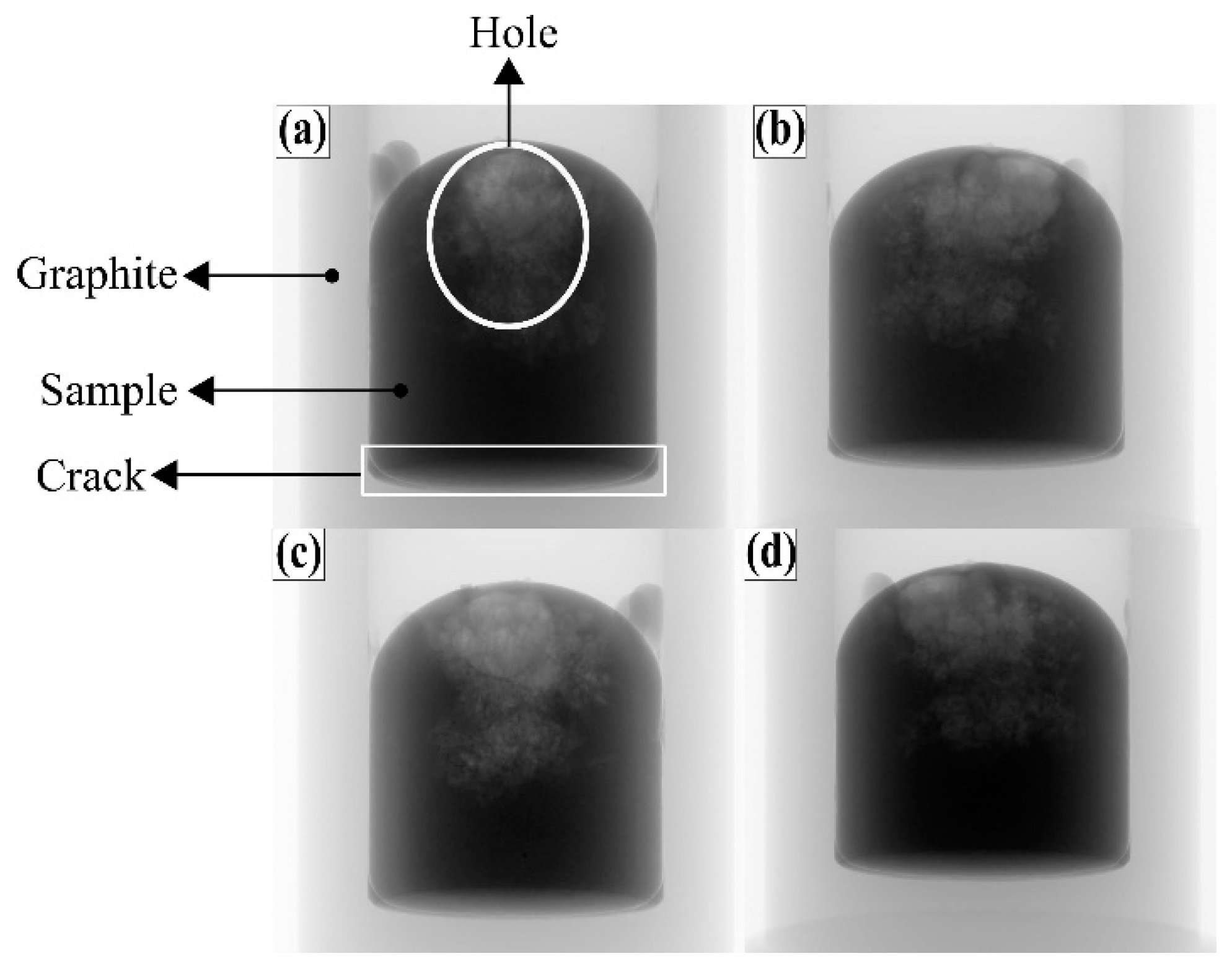

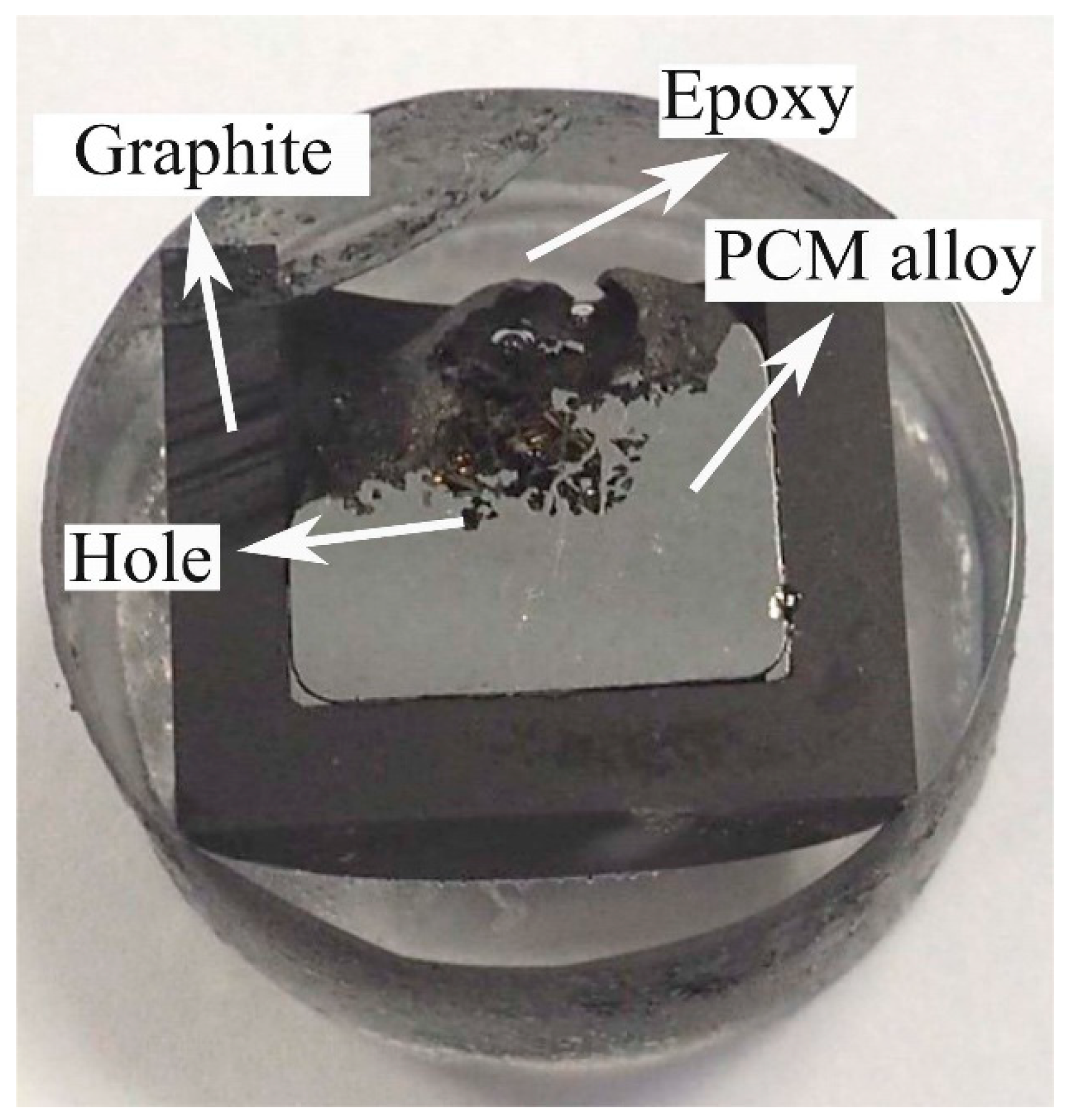

4.4. Pore Formation in the Solidified Fe-26.38Si-9.35B Alloy

5. Conclusions

- The fusion enthalpy of the eutectic Fe-26.38Si-9.35B alloy is calculated to be 1250 kWh/m3. This value is higher than other possible PCMs candidates in the literature.

- Six different phases are found in the PCM alloy after solidification. FeSi, FeB, SiB6, and FeSiB3 are the main phases appeared in the sample. SiC and B4C particles are located at the edge of the treated alloy in graphite crucible. The new ternary phase, FeSiB3, is identified by wavelength dispersive X-ray spectroscopy analysis.

- Under conditions of this study, the penetration of molten PCM alloy into the graphite crucible is negligible and the alloy has no degradation effect on graphite container.

- Wetting experiment shows that the molten PCM alloy wets well with graphite substrate, for the low contact angle of 31°.The shrinkage of the Fe-26.38Si-9.35B alloy creates small amounts of pores at the top and center position of the solidified sample. No expansion upon solidification is promising for further use of this PCM alloy.

- Further study will focus on investigating the stability of Fe-26.38Si-9.35B alloy in other refractory materials (e.g. Si3N4, BN, and Al2O3) in the melting/solidification process. Other investigations, such as the fusion enthalpy of the Fe-26.38Si-9.35B alloy and the confirmation of the new FeSiB3 phase will be considered in subsequent works.

Author Contributions

Funding

Conflicts of Interest

References

- Kenisarin, M.M. High-temperature phase change materials for thermal energy storage. Renew. Sustain. Energy Rev. 2010, 14, 955–970. [Google Scholar] [CrossRef]

- Kumar, N.; Banerjee, D. Phase Change Materials. In Handbook of Thermal Science and Engineering; Springer International Publishing: Cham, Switzerland, 2018; pp. 2213–2275. ISBN 978-3-319-26695-4. [Google Scholar]

- Fernández, A.I.; Barreneche, C.; Belusko, M.; Segarra, M.; Bruno, F.; Cabeza, L.F. Considerations for the use of metal alloys as phase change materials for high temperature applications. Sol. Energy Mater. Sol. Cells 2017, 171, 275–281. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Saman, W.; Bruno, F. Review on storage materials and thermal performance enhancement techniques for high temperature phase change thermal storage systems. Renew. Sustain. Energy Rev. 2012, 16, 2118–2132. [Google Scholar] [CrossRef]

- Kenisarin, M.; Mahkamov, K. Solar energy storage using phase change materials. Renew. Sustain. Energy Rev. 2007, 11, 1913–1965. [Google Scholar] [CrossRef]

- Magomedov, A.M. Netraditsionnye Istochniki Energii (Non-Traditional Sources of Energy); AOZT “Pamiatniki Otechestva”: Moscow, Russia, 1996. [Google Scholar]

- Khare, S.; Dell’Amico, M.; Knight, C.; McGarry, S. Selection of materials for high temperature sensible energy storage. Sol. Energy Mater. Sol. Cells 2013, 115, 114–122. [Google Scholar] [CrossRef]

- Kotzé, J.P.; von Backström, T.W.; Erens, P.J. Simulation and Testing of a Latent Heat Thermal Energy Storage Unit with Metallic Phase Change Material. Energy Procedia 2014, 49, 860–869. [Google Scholar] [CrossRef] [Green Version]

- He, Q.; Zhang, W. A study on latent heat storage exchangers with the high-temperature phase-change material. Int. J. Energy Res. 2001, 25, 331–341. [Google Scholar] [CrossRef]

- Akiyama, T.Y. Ashizawa, J.Y. Storage and release of heat in a single spherical capsule containing phase change material of high melting point. Heat Transf. Jpn. Res. 1992, 21, 199–217. [Google Scholar]

- Li, F.; Hu, Y.J.; Zhang, R.Y. The Influence of Heating-Cooling Cycles on the Thermal Storage Performances of Al-17 Wt.% Si Alloy. Adv. Mater. Res. 2011, 239–242, 2248–2251. [Google Scholar] [CrossRef]

- Kotzé, J.P.; von Backström, T.W.; Erens, P.J. High Temperature Thermal Energy Storage Utilizing Metallic Phase Change Materials and Metallic Heat Transfer Fluids. J. Sol. Energy Eng. 2013, 135, 035001. [Google Scholar] [CrossRef] [Green Version]

- Khare, S.; Dell’Amico, M.; Knight, C.; McGarry, S. Selection of materials for high temperature latent heat energy storage. Sol. Energy Mater. Sol. Cells 2012, 107, 20–27. [Google Scholar] [CrossRef]

- Cárdenas, B.; León, N. High temperature latent heat thermal energy storage: Phase change materials, design considerations and performance enhancement techniques. Renew. Sustain. Energy Rev. 2013, 27, 724–737. [Google Scholar] [CrossRef]

- Farkas, D.; Birchenall, C.E. New eutectic alloys and their heats of transformation. Metall. Trans. A 1985, 16, 323–328. [Google Scholar] [CrossRef]

- Gasanaliev, A.M.; Gamataeva, B.Y. Heat-accumulating properties of melts. Russ. Chem. Rev. 2000, 69, 179–186. [Google Scholar] [CrossRef]

- Gilpin, M.R. High Temperature Latent Heat Thermal Energy Storage to Augment Solar Thermal Propulsion for Microsatellites. Ph.D. Thesis, Viterbi School of Engineering, Los Angeles, CA, USA, April 2015. [Google Scholar]

- Rhim, W.K.; Ohsaka, K. Thermophysical properties measurement of molten silicon by high-temperature electrostatic levitator: Density, volume expansion, specific heat capacity, emissivity, surface tension and viscosity. J. Cryst. Growth 2000, 208, 313–321. [Google Scholar] [CrossRef]

- Datas, A.; Ramos, A.; Martí, A.; del Cañizo, C.; Luque, A. Ultra high temperature latent heat energy storage and thermophotovoltaic energy conversion. Energy 2016, 107, 542–549. [Google Scholar] [CrossRef] [Green Version]

- Olesinski, R.W.; Abbaschian, G.J. The B-Si (Boron-Silicon) system. Bull. Alloy Phase Diagr. 1984, 5, 478–484. [Google Scholar] [CrossRef]

- Zaitsev, A.I.; Kodentsov, A.A. Thermodynamic properties and phase equilibria in the Si-B system. J. Phase Equilibria. 2001, 22, 126–135. [Google Scholar] [CrossRef]

- Homa, M.; Sobczak, N.; Hodor, K.; Gezgin, S. Simultaneous TGA-DTA thermal analysis of Si-30B alloy. In Proceedings of the 73th Word Foundry Congress, Krakow, Poland, 23–27 September 2018. [Google Scholar]

- Grorud, B. Interaction of Eutectic Fe-Si-B Alloy with Graphite Crucibles. Master’s Thesis, NTNU, Trondheim, Norway, June 2018. [Google Scholar]

- Shanks, H.R.; Maycock, P.D.; Sidles, P.H.; Danielson, G.C. Thermal conductivity of silicon from 300 to 1400 K. Phys. Rev. 1963, 130, 1743–1748. [Google Scholar] [CrossRef]

- Powell, R.W. Further measurements of the thermal and electrical conductivity of iron at high temperatures. Proc. Phys. Soc. 1939, 51, 407–418. [Google Scholar] [CrossRef]

- Slack, G.A.; Oliver, D.W.; Horn, F.H. Thermal conductivity of boron and some boron compounds. Phys. Rev. B 1971, 4, 1714–1720. [Google Scholar] [CrossRef]

- Poletti, M.G.; Battezzati, L. Assessment of the ternary Fe-Si-B phase diagram. Calphad Comput. Coupling Phase Diagr. Thermochem. 2013, 43, 40–47. [Google Scholar] [CrossRef]

- Lacaze, J.; Sundman, B. An assessment of the Fe-C-Si system. Metall. Trans. A 1991, 22, 2211–2223. [Google Scholar] [CrossRef]

- Ho, C.Y.; Powell, R.W.; Liley, P.E. Thermal Conductivity of the Elements. J. Phys. Chem. Ref. Data 1972, 1, 279–421. [Google Scholar] [CrossRef] [Green Version]

- Zalba, B.; Marı́n, J.M.; Cabeza, L.F.; Mehling, H. Review on thermal energy storage with phase change: materials, heat transfer analysis and applications. Appl. Therm. Eng. 2003, 23, 251–283. [Google Scholar] [CrossRef]

- Bjørnstad, E.L.; Tranell, G. Mass Transfer of Al and Ca Between Silicon and Synthetic SiO2-CaO-Al2O3 Slags. In Materials Processing Fundamentals; Allanore, A., Lambotte, G., Lee, J., Eds.; Springer: Boston, MA, USA, 2017; pp. 85–96. [Google Scholar] [CrossRef]

- Neamţu, B.V.; Marinca, T.F.; Chicinaş, I.; Isnard, O.; Popa, F.; Păşcuţă, P. Preparation and soft magnetic properties of spark plasma sintered compacts based on Fe–Si–B glassy powder. J. Alloys Compd. 2014, 600, 1–7. [Google Scholar] [CrossRef]

- Tong, H.Y.; Wang, J.T.; Ding, B.Z.; Jiang, H.G.; Lu, K. The structure and properties of nanocrystalline Fe78B13Si9 alloy. J. Non. Cryst. Solids 1992, 150, 444–447. [Google Scholar] [CrossRef]

- Aronsson, B.; Engström, I. X-Ray Investigations on M-Si-B Systems (M = Mn, Fe, Co). II. Some Features of the Fe-Si-B and Mn-Si-B Systems. Acta Chem. Scand. 1960, 14, 1403–1413. [Google Scholar] [CrossRef]

- Tang, K.; Oslash, E.J.; Tranell, G.; Tangstad, M. A Thermochemical Database for the Solar Cell Silicon Materials. Mater. Trans. 2009, 50, 1978–1984. [Google Scholar] [CrossRef] [Green Version]

- Seifert, H.J.; Peng, J.; Golczewski, J.; Aldinger, F. Phase equilibria of precursor-derived Si-(B-)C-N ceramics. Appl. Organomet. Chem. 2001, 15, 794–808. [Google Scholar] [CrossRef]

- Gao, H.; Dong, B.S.; Zhong, J.; Li, Z.Z.; Xu, M.; Zhou, S.X. The influence of substrate and atmosphere on the properties of FeSiB(Cu,Nb) alloy melts. Sci. China Technol. Sci. 2016, 59, 1892–1898. [Google Scholar] [CrossRef]

- Humenik, M.; Kingery, W. Metal-Ceramic Interactions: III, Surface Tension and Wettability of Metal-Ceramic Systems. J. Am. Ceram. Soc. 1954, 37, 18–23. [Google Scholar] [CrossRef]

- Sun, H.; Mori, K.; Sahajwalla, V.; Pehlke, R.D. Carbon Solution in Liquid Iron and Iron Alloys. High Temp. Mater. Process. 1998, 17, 257–270. [Google Scholar] [CrossRef]

- Wu, C.; Sahajwalla, V. Influence of melt carbon and sulfur on the wetting of solid graphite by Fe-C-S melts. Metall. Mater. Trans. B 1998, 29, 471–477. [Google Scholar] [CrossRef]

- Zhao, L.; Sahajwalla, V. Interfacial phenomena during wetting of graphite/alumina mixtures by liquid iron. ISIJ Int. 2003, 43, 1–6. [Google Scholar] [CrossRef]

- Rubio, P.J.Y.; Hong, L.; Saha-Chaudhury, N.; Bush, R.; Sahajwalla, V. Dynamic Wetting of Graphite and SiC by Ferrosilicon Alloys and Silicon at 1550 C. ISIJ Int. 2006, 46, 1570–1576. [Google Scholar] [CrossRef]

- Coble, R.L.; Flemings, M.C. On the removal of pores from castings by sintering. Metall. Trans. 1971, 2, 409–415. [Google Scholar] [CrossRef]

- Brinkman, J.A. On the mechanism of pore formation during diffusion. Acta Metall. 1955, 3, 606–607. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. Metal matrix composites: production by the stir casting method. J. Mater. Process. Technol. 1999, 92–93, 1–7. [Google Scholar] [CrossRef]

| Metal | Thermal Conductivity, λ (W/(m∙K)) | ||||||

|---|---|---|---|---|---|---|---|

| 30 °C | 100 °C | 300 °C | 500 °C | 700 °C | 900 °C | 1100 °C | |

| Si[24] | 142.2 | 97.4 | 57.7 | 40 | 29.8 | 28.9 | 28.7 |

| Fe[25] | 71.7 | 65.4 | 52.8 | 41.9 | 35.5 | 34.7 | 35.6 |

| B[26] | 26 | – | – | – | – | – | – |

| Fe-26Si-9B | 81 | 64.9 | 47.3 | 37.1 | 31.3 | 30.3 | 30.6 |

| Sample | Boron |

|---|---|

| Fe | 211 |

| Cr | 11 |

| Si | 16 |

| Al | 51 |

| Zr | 29 |

| Mn | 1 |

| Crucible | Property | Value | Unit |

|---|---|---|---|

| Graphite | Bulk | 1.9 | mg/m3 |

| Cumulative pore volume | 0.052 | m3/g | |

| Open porosity | 10 | vol % | |

| Radius of average open pores | 1.4 | µm | |

| Thermal conductivity | 140 | W/(m∙K) | |

| Al2O3 | Purity | 99.8 | % |

| Operating temperature range | <1750 | °C | |

| Permeability | Gas tight | - | |

| Water absorption | None | - |

| Sample | Si | Fe | B | Al | Mn | |

|---|---|---|---|---|---|---|

| Fe-Si-B-1 | Detected | 26.68 | 56.47 | 8.11 | 0.067 | 0.21 |

| Normalized | 29.15 | 61.69 | 8.86 | 0.073 | 0.23 | |

| Fe-Si-B-2 | Detected | 27.87 | 66.45 | 9.54 | 0.18 | 0.23 |

| Normalized | 26.73 | 63.72 | 9.15 | 0.17 | 0.22 | |

| Nominal composition | 26.38 | 64.27 | 9.35 |

| Phase | Fe | Std. Dev. | Si | Std. Dev. | B | Std. Dev. |

|---|---|---|---|---|---|---|

| FeSi | 45.5 | ±1.2 | 43.2 | ±1.1 | 11.3 | ±1.7 |

| FeSiB3 | 22.0 | ±1.0 | 20.6 | ±1.4 | 57.3 | ±0.4 |

| FeB | 47.7 | ±0.9 | 0.23 | ±0.9 | 52.0 | ±0.1 |

| SiB6 | 0.31 | ± 0.1 | 10.6 | ± 0.2 | 89.3 | ± 0.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, J.; Grorud, B.; Sindland, C.; Safarian, J.; Tang, K.; Sellevoll, K.; Tangstad, M. The Use of Eutectic Fe-Si-B Alloy as a Phase Change Material in Thermal Energy Storage Systems. Materials 2019, 12, 2312. https://doi.org/10.3390/ma12142312

Jiao J, Grorud B, Sindland C, Safarian J, Tang K, Sellevoll K, Tangstad M. The Use of Eutectic Fe-Si-B Alloy as a Phase Change Material in Thermal Energy Storage Systems. Materials. 2019; 12(14):2312. https://doi.org/10.3390/ma12142312

Chicago/Turabian StyleJiao, Jianmeng, Bettina Grorud, Caroline Sindland, Jafar Safarian, Kai Tang, Kathrine Sellevoll, and Merete Tangstad. 2019. "The Use of Eutectic Fe-Si-B Alloy as a Phase Change Material in Thermal Energy Storage Systems" Materials 12, no. 14: 2312. https://doi.org/10.3390/ma12142312

APA StyleJiao, J., Grorud, B., Sindland, C., Safarian, J., Tang, K., Sellevoll, K., & Tangstad, M. (2019). The Use of Eutectic Fe-Si-B Alloy as a Phase Change Material in Thermal Energy Storage Systems. Materials, 12(14), 2312. https://doi.org/10.3390/ma12142312