Cross-Contamination Quantification in Powders for Additive Manufacturing: A Study on Ti-6Al-4V and Maraging Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- Two cross-contamination phenomena linked with the nature of the contaminant were observed and labelled, suggesting new perspectives for failure analysis procedures;

- By collecting EDS spectra on large areas of intentionally contaminated powder samples and comparing the elemental quantification with the nominal and pure powder compositions, the presence of the cross-contamination was detected;

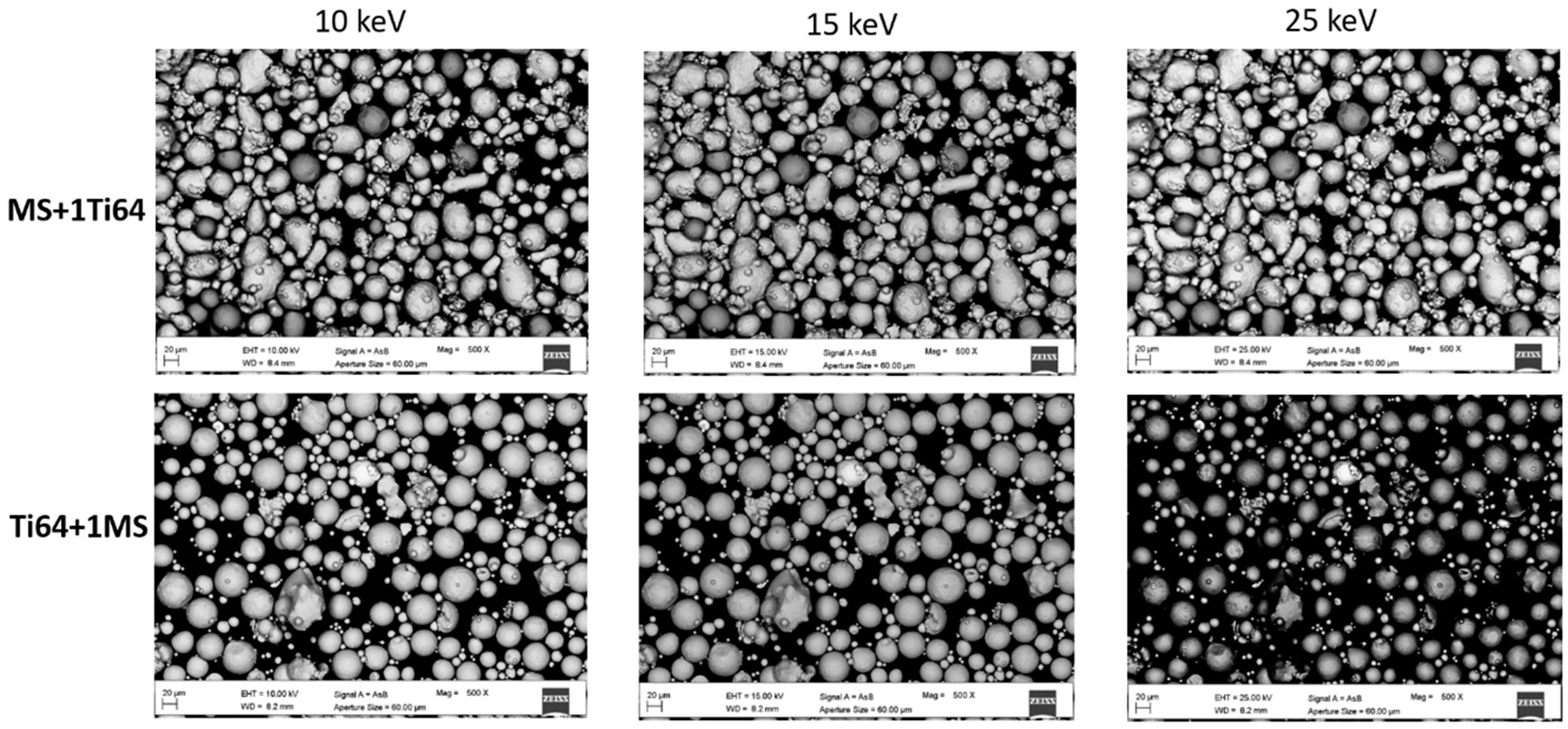

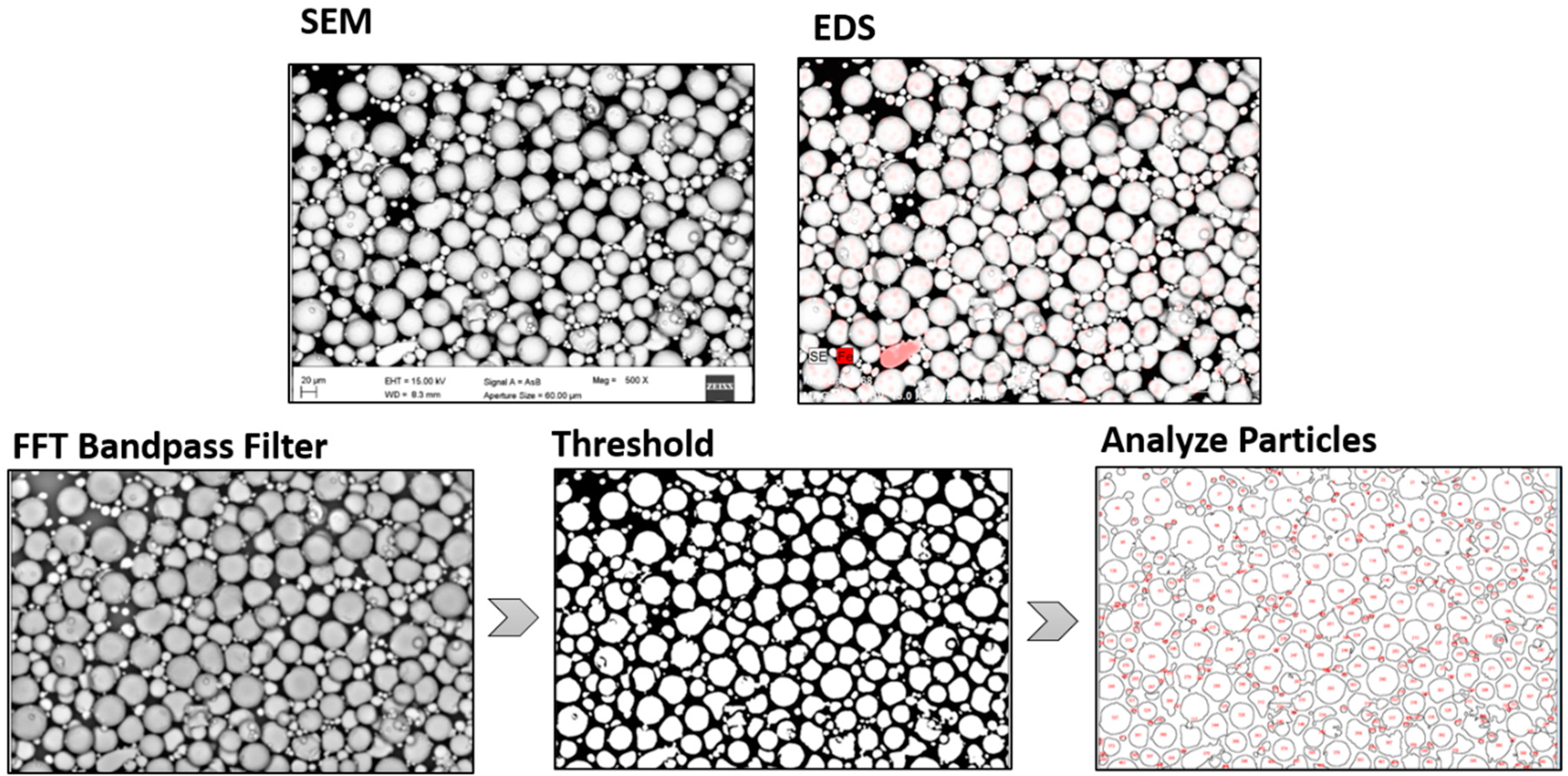

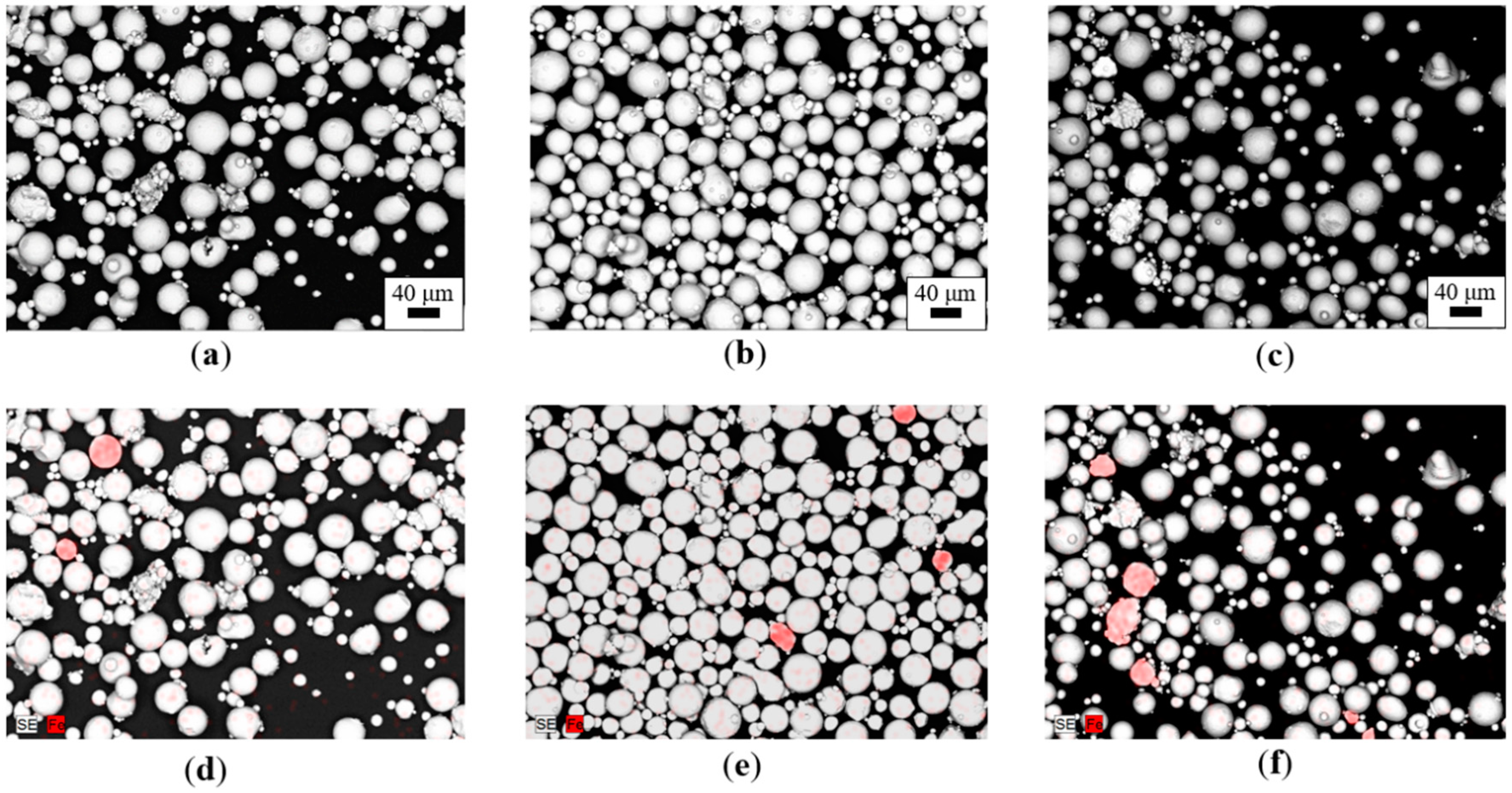

- A fine tuning of SEM parameters allows optimization of the contrast information of the BSE micrographs and aids in obtaining reliable results with the EDS elemental mapping;

- When cross-contamination must be detected and measured, the density of the contaminant is the most relevant physical property;

- The use of the calculated area ratio between virgin powder particles and contaminants allowed numerical estimation of the cross-contamination. The experimental results showed a good agreement with the ratio of introduced cross-contamination amounts.

Author Contributions

Funding

Conflicts of Interest

References

- Sun, S.; Brandt, M.; Easton, M. Laser Additive Manufacturing Materials, Design, Technologies, and Applications, 1st ed.; Woodhead Publishing: Sawston, UK, 2017. [Google Scholar]

- Seifi, M.; Salem, A.; Beuth, J.; Harrysson, O.; Lewandowski, J.J. Overview of Materials Qualification Needs for Metal Additive Manufacturing. JOM 2016, 68, 747–764. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Materials issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Slotwinski, J.A.; Garboczi, E.J.; Stutzman, P.E.; Ferraris, C.F.; Watson, S.S.; Peltz, M.A. Characterization of Metal Powders Used for Additive Manufacturing. J. Res. Natl. Inst. Stand Technol. 2014, 119, 460–493. [Google Scholar] [CrossRef] [PubMed]

- Qian, M. Metal powder for additive manufacturing. JOM 2015, 67, 536–537. [Google Scholar] [CrossRef]

- Slotwinski, J.A.; Garboczi, E.J. Metrology needs for metal additive manufacturing powders. JOM 2015, 67, 538–543. [Google Scholar] [CrossRef]

- Denti, L.; Sola, A.; Defanti, S.; Sciancalepore, C.; Bondioli, F. Effect of powder recycling in laser-based powder bed fusion of Ti-6Al-4V. Manuf. Technol. 2019, 19, 190–196. [Google Scholar] [CrossRef]

- Hedberg, Y.; Norell, M.; Linhardt, P.; Bergqvist, H.; Odnevall Wallinder, I. Influence of surface oxide characteristics and speciation on corrosion, electrochemical properties and metal release of atomized 316L stainless steel powders. Int. J. Electrochem. Sci. 2012, 7, 11655–11677. [Google Scholar]

- Simchi, A. The role of particle size on the laser sintering of iron powder. Met. Mater. Trans. B 2004, 35, 937–948. [Google Scholar] [CrossRef]

- Brandão, A.D.; Gerard, R.; Gumpinger, J.; Beretta, S.; Makaya, A.; Pambaguian, L.; Ghidini, T. Challenges in Additive Manufacturing of Space Parts: Powder Feedstock Cross-Contamination and Its Impact on End Products. Materials 2017, 10, 522. [Google Scholar] [CrossRef]

- Gatto, A.; Bassoli, E.; Denti, L. Repercussions of powder contamination on the fatigue life of additive manufactured maraging steel. Addit. Manuf. 2018, 24, 13–19. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Sutton, A.T.; Kriewall, C.S.; Leu, M.C.; Newkirk, J.W. Powder characterisation techniques and effects of powder characteristics on part properties in powder-bed fusion processes. Virtual Phys. Prototyp. 2017, 12, 3–29. [Google Scholar] [CrossRef]

- Strondl, A.; Lyckfeldt, O.; Brodin, H.; Ackelid, U. Characterization and Control of Powder Properties for Additive Manufacturing. JOM 2015, 67, 549–554. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Sutton, A.T.; Kriewall, C.S.; Leu, M.C.; Newkirk, J.W. Powders for additive manufacturing processes: Characterization techniques and effects on part properties. In Solid Freeform Fabrication 2016, Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2015; University of Texas at Austin: Austin, TX, USA, 2015. [Google Scholar]

- Bernier, F.; Tahara, R.; Gendron, M. Additive manufacturing powder feedstock characterization using X-ray tomography. Met. Powder Rep. 2018, 73, 158–162. [Google Scholar] [CrossRef]

- Montazeri, M.; Yavari, R.; Rao, P.; Boulware, P. In-process monitoring of material cross-contamination defects in laser powder bed fusion. J. Manuf. Sci. Eng. 2018, 140, 111001. [Google Scholar] [CrossRef]

- Kennedy, S.; Dalley, A.M.; Kotyk, G.J. Additive manufacturing: Assessing metal powder quality through characterizing feedstock and contaminants. J. Mater. Eng. Perform. 2019, 28, 728–740. [Google Scholar] [CrossRef]

- Murphy, T.F.; Schade, C.T.; Zwiren, A. Using automated image analysis for characterization of additive manufacturing powders. Int. J. Powder Met. 2018, 54, 47–59. [Google Scholar]

- Gasper, A.N.D.; Hickman, D.; Ashcroft, I.; Sharma, S.; Wang, X.; Szost, B.; Johns, D.; Clare, A.T. Oxide and spatter powder formation during laser powder bed fusion of Hastelloy X. Powder Technol. 2019, 354, 333–337. [Google Scholar] [CrossRef]

- Ali, U.; Esmaeilizadeh, R.; Ahmed, F.; Sarker, D.; Muhammad, W.; Keshavarzkermani, A.; Mahmoodkhani, Y.; Marzbanrad, E.; Toyserkani, E. Identification and characterization of spatter particles and their effect on surface roughness, density and mechanical response of 17-4 PH stainless steel laser powder-bed fusion parts. Mater. Sci. Eng. A 2019, 756, 98–107. [Google Scholar] [CrossRef]

- Esmaeilizadeh, R.; Ali, U.; Keshavarzkermani, A.; Mahmoodkhani, Y.; Marzbanrad, E.; Toyserkani, E. On the effect of spatter particles distribution on the quality of Hastelloy X parts made by laser powder-bed fusion additive manufacturing. J. Manuf. Process 2019, 37, 11–20. [Google Scholar] [CrossRef]

- Material Data Sheet for EOS MS1 for EOSINT M270. Available online: https://www.eos.info/eos_binaries0/eos/04f875d5141d28f7/8ecee6ee388d/MS-MS1-M270-M280_200W_Material_data_sheet_05-14_en.pdf (accessed on 10 February 2019).

- Material Data Sheet for EOS Ti64 for EOSINT M290. Available online: https://www.eos.info/eos_binaries0/eos/a4eeb73865d54434/5926811b3739/Ti-Ti64_9011-0014_9011-0039_M290_Material_data_sheet_11-17_en.pdf (accessed on 11 February 2019).

- Goldstein, J.I.; Newbury, D.E.; Joy, D.C.; Lyman, C.E.; Echlin, P.; Lifshin, E.; Sawyer, L.; Michael, J.R. Scanning Electron Microscopy and X-Ray Microanalysis, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Rasband, W.S. Image J; National Institutes of Health: Bethesda, MD, USA, 2016. Available online: http://imagej.nih.gov/ij/ (accessed on 1 March 2019).

- Mengucci, P.; Gatto, A.; Bassoli, E.; Denti, L.; Fiori, F.; Girardin, E.; Bastianoni, P.; Rutkowski, B.; Czyrska-Filemonowicz, A.; Barucca, G. Effects of build orientation and element partitioning on microstructure and mechanical properties of biomedical Ti-6Al-4V alloy produced by laser sintering. J. Mech. Behav. Biomed. Mater. 2017, 71, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Barucca, G.; Santecchia, E.; Majni, G.; Girardin, E.; Bassoli, E.; Denti, L.; Gatto, A.; Iuliano, L.; Moskalewicz, T.; Mengucci, P. Structural characterization of biomedical Co–Cr–Mo components produced by direct metal laser sintering. Mater. Sci. Eng. C 2015, 48, 263–269. [Google Scholar] [CrossRef] [PubMed]

- Santecchia, E.; Mengucci, P.; Gatto, A.; Bassoli, E.; Denti, L.; Bondioli, F.; Barucca, G. Development of a reliable method for contamination detection in raw metal powders for additive manufacturing. In Proceedings of the EuroPM18, Bilbao, Spain, 14–18 October 2018; EPMA: Shrewsbury, UK, 2018. [Google Scholar]

| Powders | Ni | Co | Mo | Ti | Al |

|---|---|---|---|---|---|

| MS (nominal) | 17–19 | 8.5–9.5 | 4.5–5.2 | 0.6–0.8 | 0.05–0.15 |

| MS pure | 16.0 ± 0.3 | 10.7 ± 0.1 | 3.7 ± 0.2 | 0.9 ± 0.1 | 0.02 ± 0.01 |

| MS + 0.5Ti64 | 15.4 ± 0.3 | 10.8 ± 0.1 | 3.5 ± 0.2 | 1.5 ± 0.2 | 0.05 ± 0.01 |

| MS + 1Ti64 | 16.1 ± 0.2 | 10.4 ± 0.1 | 4.7 ± 0.5 | 4.0 ± 0.1 | 0.6 ± 0.3 |

| MS + 2.5Ti64 | 15.6 ± 0.1 | 11.2 ± 0.1 | 4.9 ± 0.2 | 6 ± 1 | 0.7 ± 0.2 |

| Powders | Al | V | Fe |

|---|---|---|---|

| Ti64 (nominal) | 5.50–6.75 | 3.5–4.5 | <0.30 |

| Ti64 pure | 5.9 ± 0.2 | 2.72 ± 0.03 | ND 1 |

| Ti64 + 0.5MS | 5.4 ± 0.1 | 3.0 ± 0.1 | ND 1 |

| Ti64 + 1MS | 5.9 ± 0.1 | 2.6 ± 0.1 | 0.8 ± 0.1 |

| Ti64 + 2.5MS | 5.3 ± 0.4 | 3.4 ± 0.1 | 1.3 ± 0.1 |

| Sample Name | Area Ratio (%) |

|---|---|

| MS + 0.5Ti64 | 2.0 ± 0.2 |

| MS + 1Ti64 | 3.6 ± 0.3 |

| MS + 2.5Ti64 | 9.7 ± 0.6 |

| Ti64 + 0.5MS | 1.1 ± 0.4 |

| Ti64 + 1MS | 2.0 ± 0.2 |

| Ti64 + 2.5MS | 5.2 ± 0.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santecchia, E.; Mengucci, P.; Gatto, A.; Bassoli, E.; Defanti, S.; Barucca, G. Cross-Contamination Quantification in Powders for Additive Manufacturing: A Study on Ti-6Al-4V and Maraging Steel. Materials 2019, 12, 2342. https://doi.org/10.3390/ma12152342

Santecchia E, Mengucci P, Gatto A, Bassoli E, Defanti S, Barucca G. Cross-Contamination Quantification in Powders for Additive Manufacturing: A Study on Ti-6Al-4V and Maraging Steel. Materials. 2019; 12(15):2342. https://doi.org/10.3390/ma12152342

Chicago/Turabian StyleSantecchia, Eleonora, Paolo Mengucci, Andrea Gatto, Elena Bassoli, Silvio Defanti, and Gianni Barucca. 2019. "Cross-Contamination Quantification in Powders for Additive Manufacturing: A Study on Ti-6Al-4V and Maraging Steel" Materials 12, no. 15: 2342. https://doi.org/10.3390/ma12152342

APA StyleSantecchia, E., Mengucci, P., Gatto, A., Bassoli, E., Defanti, S., & Barucca, G. (2019). Cross-Contamination Quantification in Powders for Additive Manufacturing: A Study on Ti-6Al-4V and Maraging Steel. Materials, 12(15), 2342. https://doi.org/10.3390/ma12152342