Blends of rABS and SEBS: Influence of In-Situ Compatibilization on the Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Blend Preparation

2.3. Mechanical Testing

2.4. Scanning Electron Microscopy (SEM)

2.5. Fourier Transform Infrared (FT-IR) Spectroscopy

2.6. Rheological Characterization Measurements

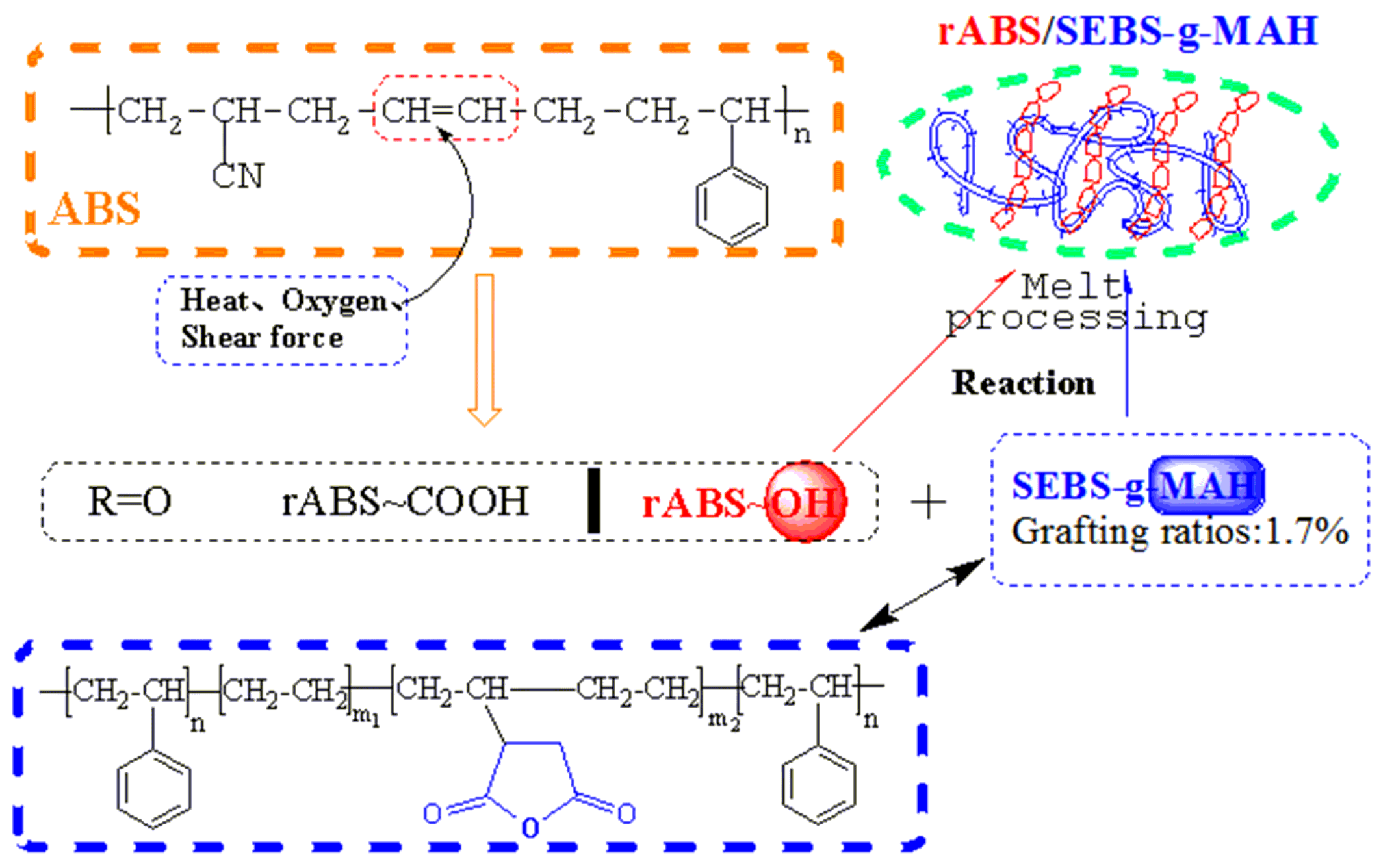

3. Results and Discussion

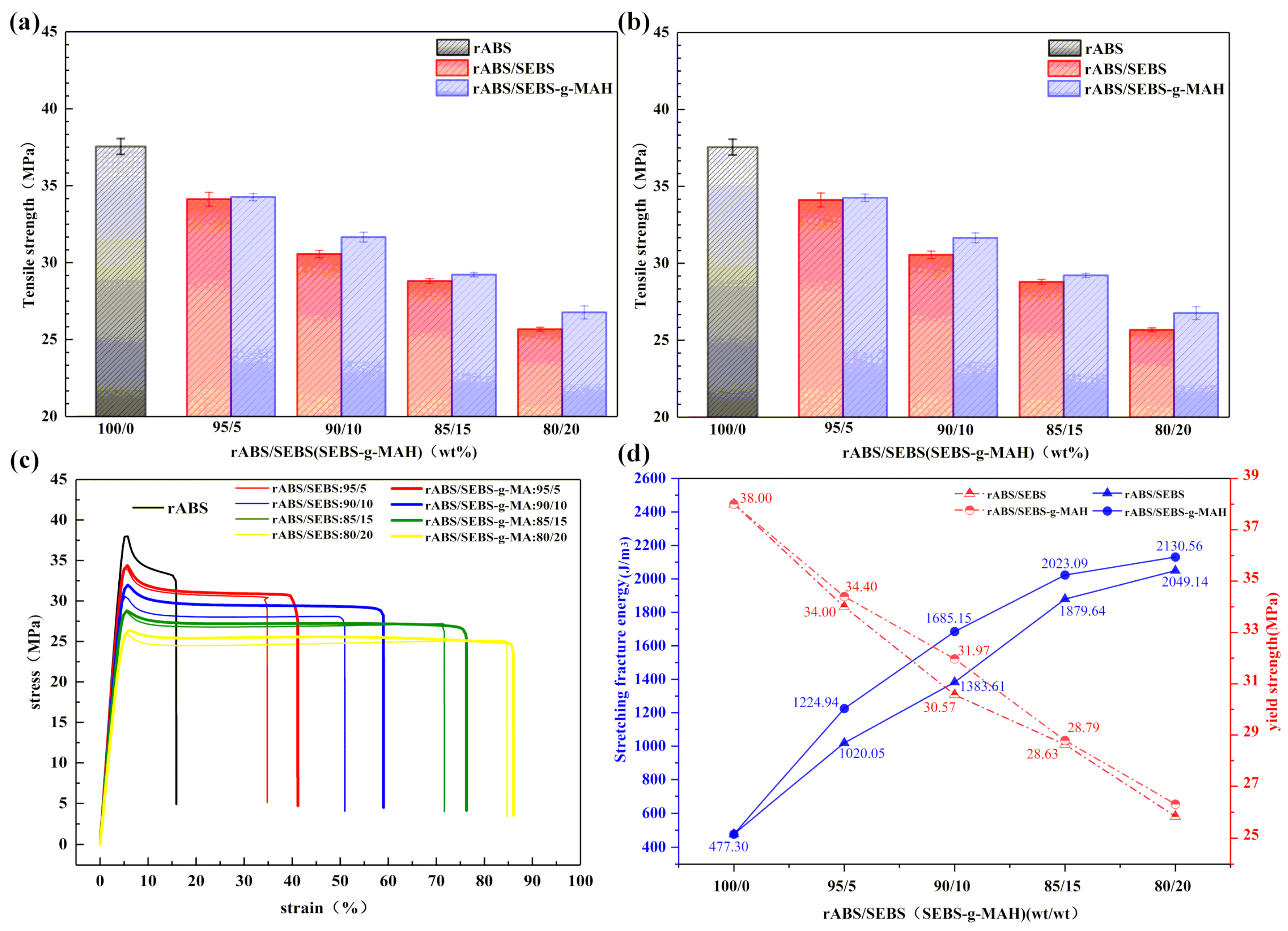

3.1. Mechanical Properties

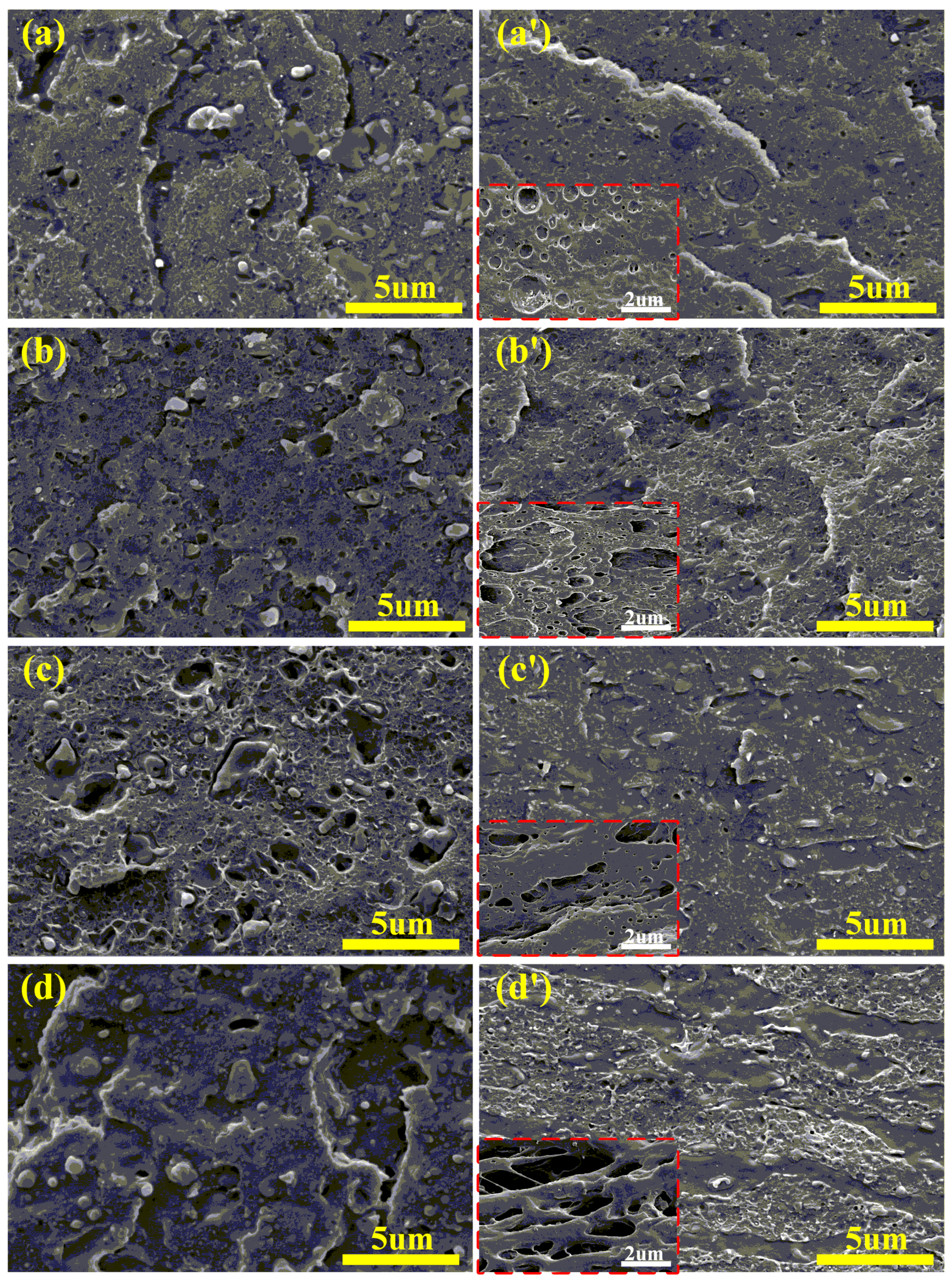

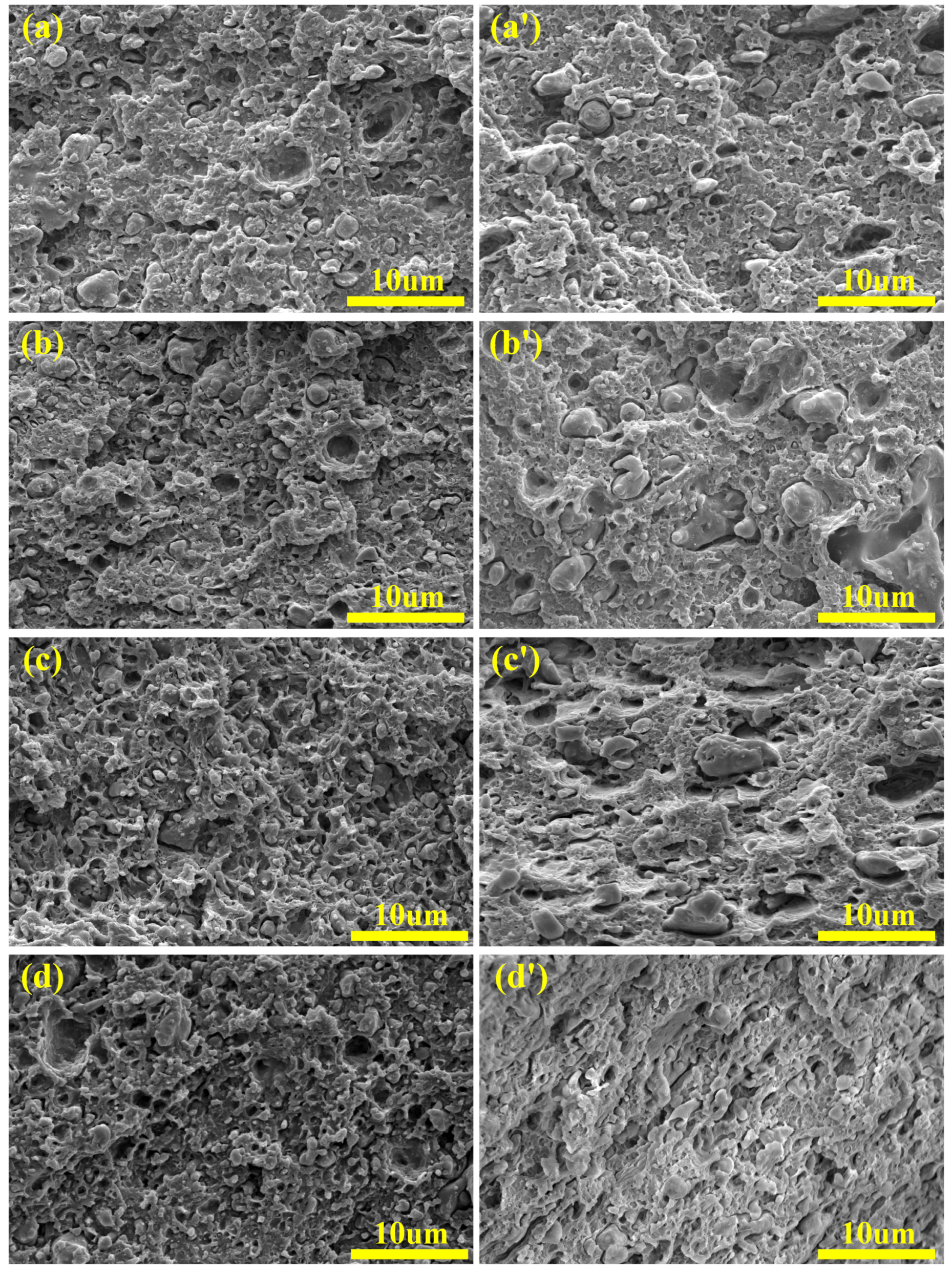

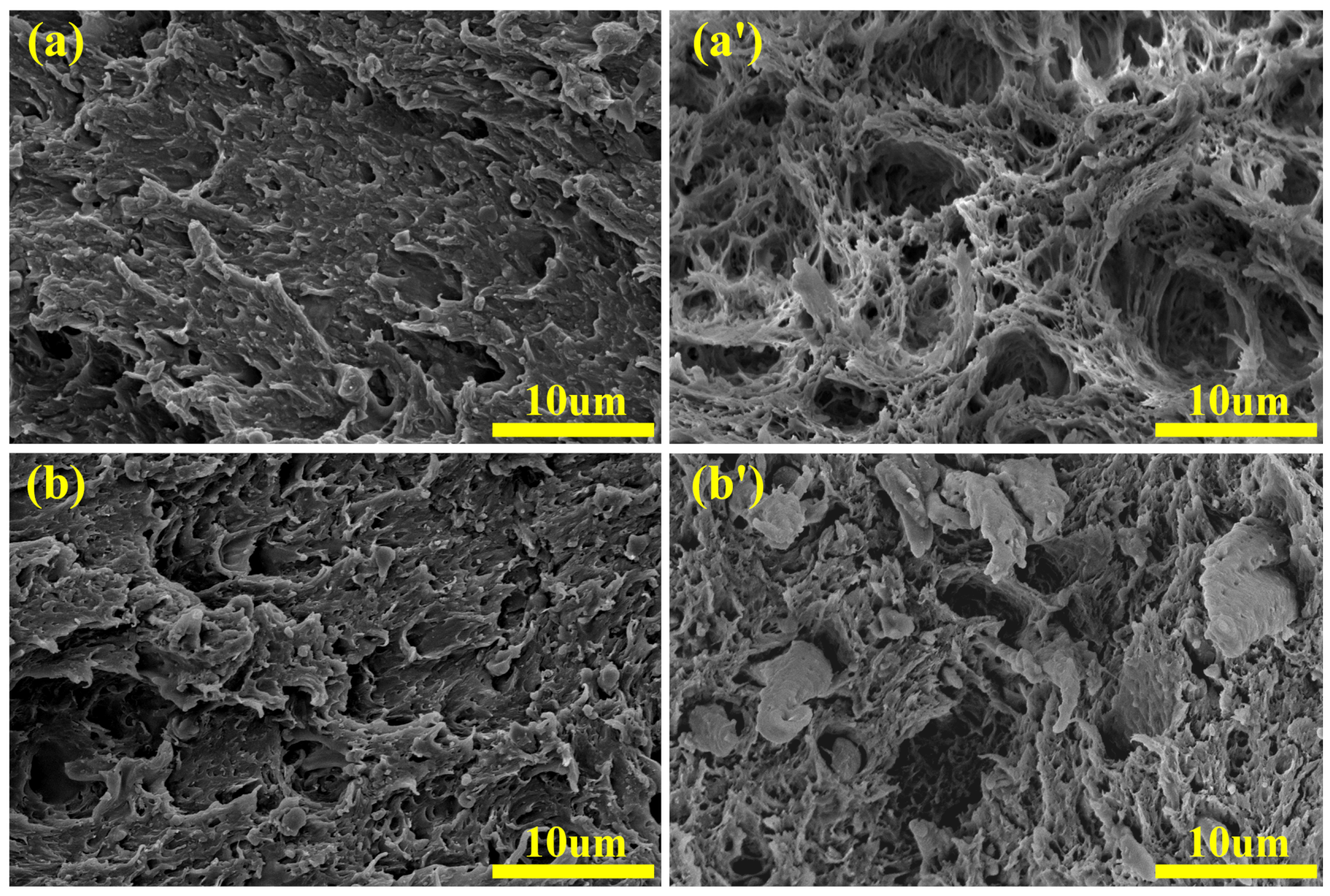

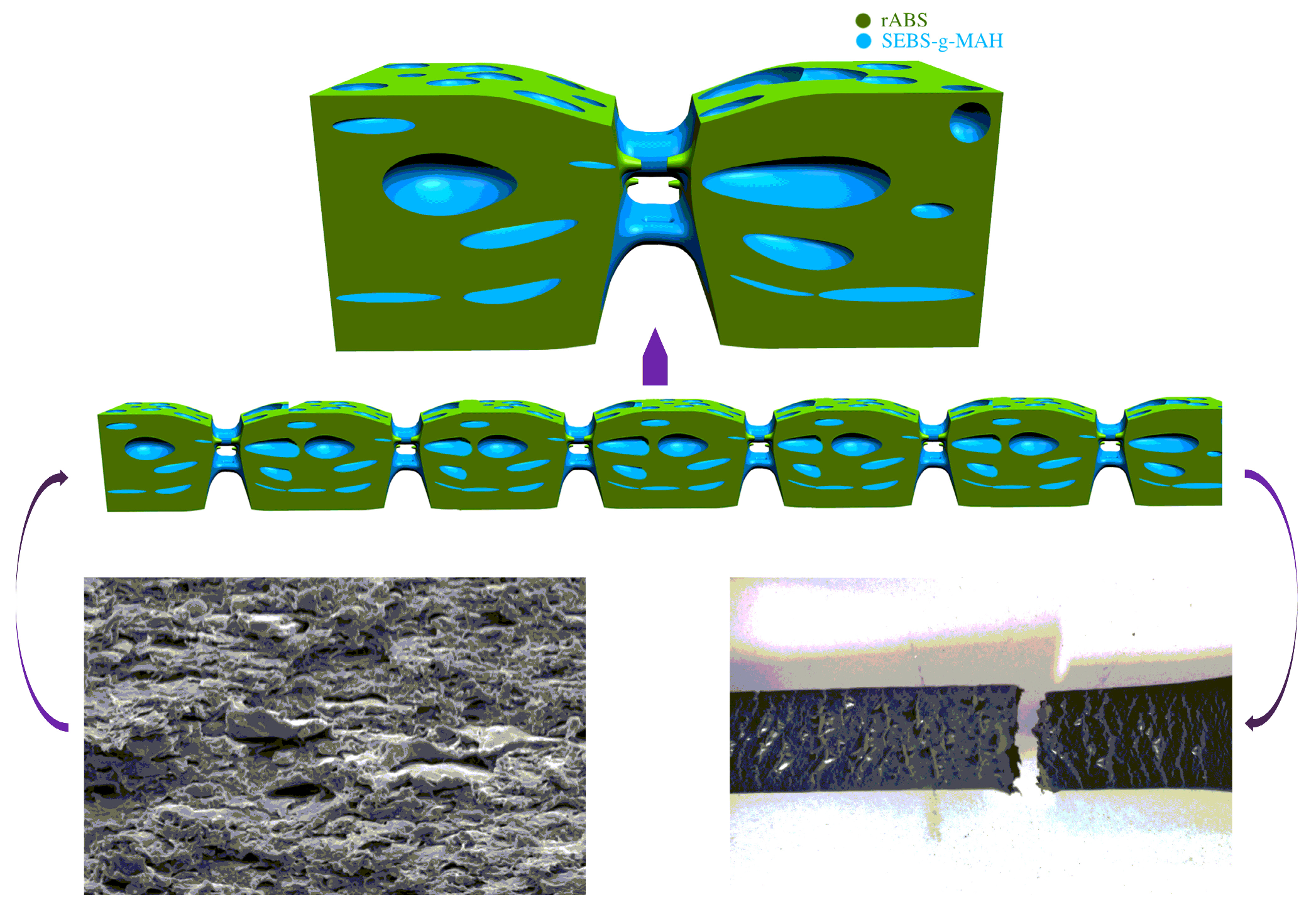

3.2. Morphological Analysis

3.3. The FTIR Analysis

3.4. Rheological Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hayeemasae, N.; Song, L.W.; Ismail, H. Sustainable use of eggshell powder in the composite based on recycled polystyrene and virgin polystyrene mixture. Int. J. Polym. Anal. Charact. 2019, 24, 266–275. [Google Scholar]

- Thompson, R.C.; Moore, C.J.; Vom Saal, F.S.V.; Swan, S.H. Plastics, the environment and human health: Current consensus and future trends. Philos. Trans. R. Soc. B Boil. Sci. 2009, 364, 2153–2166. [Google Scholar]

- Zhong, S.; Pearce, J.M. Tightening the loop on the circular economy: Coupled distributed recycling and manufacturing with recyclebot and RepRap 3-D printing. Resour. Conserv. Recycl. 2018, 128, 48–58. [Google Scholar]

- Li, Y.; Shimizu, H. Improvement in toughness of poly(l-lactide) (PLLA) through reactive blending with acrylonitrile–butadiene–styrene copolymer (ABS): Morphology and properties. Eur. Polym. J. 2009, 45, 738–746. [Google Scholar]

- Chen, T.; Zhang, J. Compatibilization of acrylonitrile-butadiene-styrene terpolymer/poly(ethylene glycol-co-1,4-cyclohexanedimethanol terephthalate) blend: Effect on morphology, interface, mechanical properties and hydrophilicity. Appl. Surf. Sci. 2018, 437, 62–69. [Google Scholar]

- Tang, L.; Wang, L.; Chen, P.; Fu, J.; Xiao, P.; Ye, N.; Zhang, M. Toughness of ABS/PBT blends: The relationship between composition, morphology, and fracture behavior. J. Appl. Polym. Sci. 2018, 135, 46051–46059. [Google Scholar]

- Boldizar, A.; Möller, K. Degradation of ABS during repeated processing and accelerated ageing. Polym. Degrad. Stab. 2003, 81, 359–366. [Google Scholar]

- Duh, Y.S.; Ho, T.C.; Chen, J.R.; Kao, C.S. Study on Exothermic Oxidation of Acrylonitrile-butadiene-styrene (ABS) Resin Powder with Application to ABS Processing Safety. Polymers 2010, 2, 174–187. [Google Scholar] [Green Version]

- Li, Y.; Wu, X.; Song, J.; Li, J.; Shao, Q.; Cao, N.; Lu, N.; Guo, Z. Reparation of recycled acrylonitrile- butadiene-styrene by pyromellitic dianhydride: Reparation performance evaluation and property analysis. Polymers 2017, 124, 41–47. [Google Scholar]

- Hamad, K.; Kaseem, M.; Deri, F. Recycling of waste from polymer materials: An overview of the recent works. Polym. Degrad. Stab. 2013, 98, 2801–2812. [Google Scholar]

- Liu, N.C.; Baker, W.E. The separate roles of phase structure and interfacial adhesion in toughening a brittle polymer. Polym. Eng. Sci. 1992, 32, 1695–1702. [Google Scholar]

- Ojijo, V.; Ray, S.S. Super toughened biodegradable polylactide blends with non-linear copolymer interfacial architecture obtained via facile in-situ reactive compatibilization. Polymers 2015, 80, 1–17. [Google Scholar]

- Li, H.; Sundararaj, U. Morphology Development of Polymer Blends in Extruder: The Effects of Compatibilization and Rotation Rate. Macromol. Chem. Phys. 2009, 210, 852–863. [Google Scholar]

- Horiuchi, S.; Matchariyakul, N.; Yase, K.; Kitano, T. Morphology Development through an Interfacial Reaction in Ternary Immiscible Polymer Blends. Macromolecules 1997, 30, 3664–3670. [Google Scholar]

- González-Montiel, A.; Keskkula, H.; Paul, D. Impact-modified nylon 6/polypropylene blends: 2. Effect of reactive functionality on morphology and mechanical properties. Polymers 1995, 36, 4605–4620. [Google Scholar]

- Tanrattanakul, V.; Hiltner, A.; Baer, E.; Perkins, W.; Massey, F.; Moet, A. Effect of elastomer functionality on toughened PET. Polymers 1997, 38, 4117–4125. [Google Scholar]

- Mazidi, M.M.; Edalat, A.; Berahman, R.; Hosseini, F.S. Highly-Toughened Polylactide- (PLA-) Based Ternary Blends with Significantly Enhanced Glass Transition and Melt Strength: Tailoring the Interfacial Interactions, Phase Morphology, and Performance. Macromolecules 2018, 51, 4298–4314. [Google Scholar]

- Zhang, K.; Nagarajan, V.; Misra, M.; Mohanty, A.K. Supertoughened Renewable PLA Reactive Multiphase Blends System: Phase Morphology and Performance. ACS Appl. Mater. Interfaces 2014, 6, 12436–12448. [Google Scholar]

- Liu, X.; Boldizar, A.; Rigdahl, M.; Bertilsson, H. Recycling of blends of acrylonitrile-butadiene-styrene (ABS) and polyamide. J. Appl. Polym. Sci. 2002, 86, 2535–2543. [Google Scholar]

- Yeh, S.-K.; Agarwal, S.; Gupta, R.K. Wood–plastic composites formulated with virgin and recycled ABS. Compos. Sci. Technol. 2009, 69, 2225–2230. [Google Scholar]

- Fu, Y.; Song, H.; Zhou, C.; Sun, S.; Zhang, H. Influence of core-shell particles structure on the morphology and brittle-ductile transition of PBT/ABS-g-GMA blends. Polym. Compos. 2013, 34, 15–21. [Google Scholar]

- Shimade, J. The mechanism of oxidative degradation of ABS resin. part I. The mechanism of thermooxidative degradation. J. Appl. Polym. Sci. 1968, 12, 655–669. [Google Scholar]

- Adeniyi, J.B. Clarification and discussion of chemical conversion in thermal and photooxidative degradation of ABS. Euro. Polym. J. 1983, 20, 291–299. [Google Scholar]

- Tiganisa, B.E.; Burna, L.S.; Davisa, P.; Hillb, A.J. Thermal degradation of acrylonitrile–butadiene–styrene (ABS) blends. Polym. Degrad. Stabil. 2002, 76, 425–434. [Google Scholar]

- Hutchinson, J.W. Fundamentals of the Phenomenological Theory of Nonlinear Fracture Mechanics. J. Appl. Mech. 1983, 50, 1042–1051. [Google Scholar]

- Voraruth, V.; Caldera, A.; Soares, J.B.P.; Anantawaraskul, S. Polyolefins Made with Dual Metallocene Catalysts: How Microstructure Affects Polymer Properties. Macromol. Chem. Phys. 2018, 219, 1700551. [Google Scholar]

- Yoo, Y.; Cui, L.; Yoon, P.J.; Paul, D.R. Morphology and Mechanical Properties of Rubber Toughened Amorphous Polyamide/MMT Nanocomposites. Macromolecules 2010, 43, 615–624. [Google Scholar]

- Liu, X.B.; Miao, X.P.; Guo, M.F.; Song, W.H.; Shao, J.B. Influence of the HDPE molecular weicght and content on the morphology and properties of the impact polypropylene copolymer/HDPE blends. RSC Adv. 2015, 5, 80297–80306. [Google Scholar]

- Anderson, K.S.; Hillmyer, M.A. The influence of block copolymer microstructure on the toughness of compatibilized polylactide/polyethylene blends. Polymers 2004, 45, 8809–8823. [Google Scholar]

- Heino, M.; Kirjava, J.; Hietaoja, P.; A Seppala, J. Compatibilization of polyethylene terephthalate/polypropylene blends with styrene-ethylene/butylene-styrene (SEBS) block copolymers. J. Appl. Polym. Sci. 1997, 65, 241–249. [Google Scholar]

- Matos, M.; Favis, B.; Lomellini, P. Interfacial modification of polymer blends—The emulsification curve: 1. Influence of molecular weight and chemical composition of the interfacial modifier. Polymers 1995, 36, 3899–3907. [Google Scholar]

- Bose, S.; Bhattacharyya, A.R.; Bondre, A.P.; Kulkarni, A.R.; Pötschke, P. Rheology, electrical conductivity, and the phase behavior of cocontinuous PA6/ABS blends with MWNT: Correlating the aspect ratio of MWNT with the percolation threshold. J. Polym. Sci. Part B Polym. Phys. 2010, 46, 1619–1631. [Google Scholar]

- Riaz, U.; Ashraf, S.M. Characterization of Polymer Blends with FTIR Spectroscopy; Wiley Blackwell: Hoboken, NJ, USA, 2015; pp. 625–678. [Google Scholar]

- Holland-Moritz, K.; Siesler, H.W. Infrared Spectroscopy of Polymers. Appl. Spectrosc. Rev. 2011, 52, 113–129. [Google Scholar]

- Filippi, S.; Yordanov, H.; Minkova, L.; Polacco, G.; Talarico, M. Reactive compatibilizer precursors for LDPE/PA6 blends, 4(a)—Maleic anhydride and glycidyl methacrylate grafted SEBS. Macromol. Mater. A Eng. 2004, 289, 512–523. [Google Scholar]

- Utracki, L.A.; Sammut, P. Rheological evaluation of polystyrene/polyethylene blends. Polym. Eng. Sci. 1988, 28, 1405–1415. [Google Scholar]

- Utracki, L.A.; Kanial, M.R. Melt rheology of polymer blends. Polym. Eng. Sci. 1982, 22, 96–114. [Google Scholar]

- Oommen, Z.; Zachariah, S.R.; Thomas, S.; Groeninckx, G.; Moldenaers, P.; Mewis, J. Melt rheology and morphology of uncompatibilized and in situ compatibilized nylon-6/ethylene propylene rubber blends. J. Appl. Polym. Sci. 2010, 92, 252–264. [Google Scholar]

- Tol, R.; Groeninckx, G.; Vinckier, I.; Moldenaers, P.; Mewis, J. Phase morphology and stability of co-continuous (PPE/PS)/PA6 and PS/PA6 blends: Effect of rheology and reactive compatibilization. Polymers 2004, 45, 2587–2601. [Google Scholar]

- Thornton, B.A.; Villasenor, R.G.; Maxwell, B. The melt elasticity of polymer blends: Polystyrene/poly(methyl methacrylate). J. Appl. Polym. Sci. 2010, 25, 653–663. [Google Scholar]

- Song, Y.; Zheng, Q. Application of two phase model to linear viscoelasticity of reinforced rubbers. Polymers 2011, 52, 593–596. [Google Scholar]

- Hong, B.; Jo, W. Effects of molecular weight of SEBS triblock copolymer on the morphology, impact strength, and rheological property of syndiotactic polystyrene/ethylene–propylene rubber blends. Polymers 2000, 41, 2069–2079. [Google Scholar]

- Han, C.D.; Kim, J.; Kim, J.K. Determination of the order-disorder transition temperature of block copolymers. Macromolecules 1989, 22, 383–394. [Google Scholar]

- Friedrich, C.; Braun, H. Generalized Cole-Cole behavior and its rheological relevance. Rheol. Acta 1992, 31, 309–322. [Google Scholar]

- Hao, M.; Wu, H.; Zhu, Z. In situ reactive interfacial compatibilization of polylactide/sisal fiber biocomposites via melt-blending with an epoxy-functionalized terpolymer elastomer. RSC Adv. 2017, 7, 32399–32412. [Google Scholar] [Green Version]

| Sample | Tensile Strength (MPa) | Modulus of Tensile (MPa) | Elongation at Break (%) | Impact Strength (kJ/m2) | Fracture Energy (J/m3) |

|---|---|---|---|---|---|

| rABS | 37.5 ± 0.5 | 845.1 ± 25.9 | 15.8 ± 2.6 | 11.3 ± 0.9 | 477.3 |

| rABS/SEBS:95/5 | 34.1 ± 0.5 | 807.6 ± 11.7 | 34.0 ± 5.3 | 8.1 ± 0.4 | 1020.1 |

| rABS/SEBS:90/10 | 30.6 ± 0.2 | 748.0 ± 8.7 | 49.6 ± 10.8 | 8.1 ± 0.4 | 1383.0 |

| rABS/SEBS:85/15 | 28.8 ± 0.2 | 679.3 ± 18.7 | 71.9 ± 8.7 | 8.0 ± 0.5 | 1880.6 |

| rABS/SEBS:80/20 | 25.7 ± 0.1 | 625.2 ± 5.7 | 84.4 ± 5.0 | 8.1 ± 0.6 | 2049.1 |

| rABS/SEBS-g-MAH:95/5 | 34.3 ± 0.3 | 805.2 ± 6.7 | 41.4 ± 4.3 | 9.5 ± 0.5 | 1225.9 |

| rABS/SEBS-g-MAH:90/10 | 31.7 ± 0.3 | 736.8 ± 8.8 | 57.6 ± 6.7 | 10.0 ± 0.1 | 1685.2 |

| rABS/SEBS-g-MAH:85/15 | 29.2 ± 0.1 | 681.9 ± 5.6 | 76.2 ± 2.8 | 11.8 ± 0.7 | 2023.1 |

| rABS/SEBS-g-MAH:80/20 | 26.8 ± 0.4 | 608.9 ± 7.1 | 85.8 ± 4.5 | 15.2 ± 0.8 | 2131.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, Z.; He, H.; Zhu, Z.; Xue, B.; Wang, G.; Chen, M.; Xiong, C. Blends of rABS and SEBS: Influence of In-Situ Compatibilization on the Mechanical Properties. Materials 2019, 12, 2352. https://doi.org/10.3390/ma12152352

Zhan Z, He H, Zhu Z, Xue B, Wang G, Chen M, Xiong C. Blends of rABS and SEBS: Influence of In-Situ Compatibilization on the Mechanical Properties. Materials. 2019; 12(15):2352. https://doi.org/10.3390/ma12152352

Chicago/Turabian StyleZhan, Zhiming, Hezhi He, Zhiwen Zhu, Bin Xue, Guozhen Wang, Ming Chen, and Chengtian Xiong. 2019. "Blends of rABS and SEBS: Influence of In-Situ Compatibilization on the Mechanical Properties" Materials 12, no. 15: 2352. https://doi.org/10.3390/ma12152352

APA StyleZhan, Z., He, H., Zhu, Z., Xue, B., Wang, G., Chen, M., & Xiong, C. (2019). Blends of rABS and SEBS: Influence of In-Situ Compatibilization on the Mechanical Properties. Materials, 12(15), 2352. https://doi.org/10.3390/ma12152352