Repair of Block Masonry Panels with CFRP Sheets

Abstract

:1. Introduction

2. Research Significance

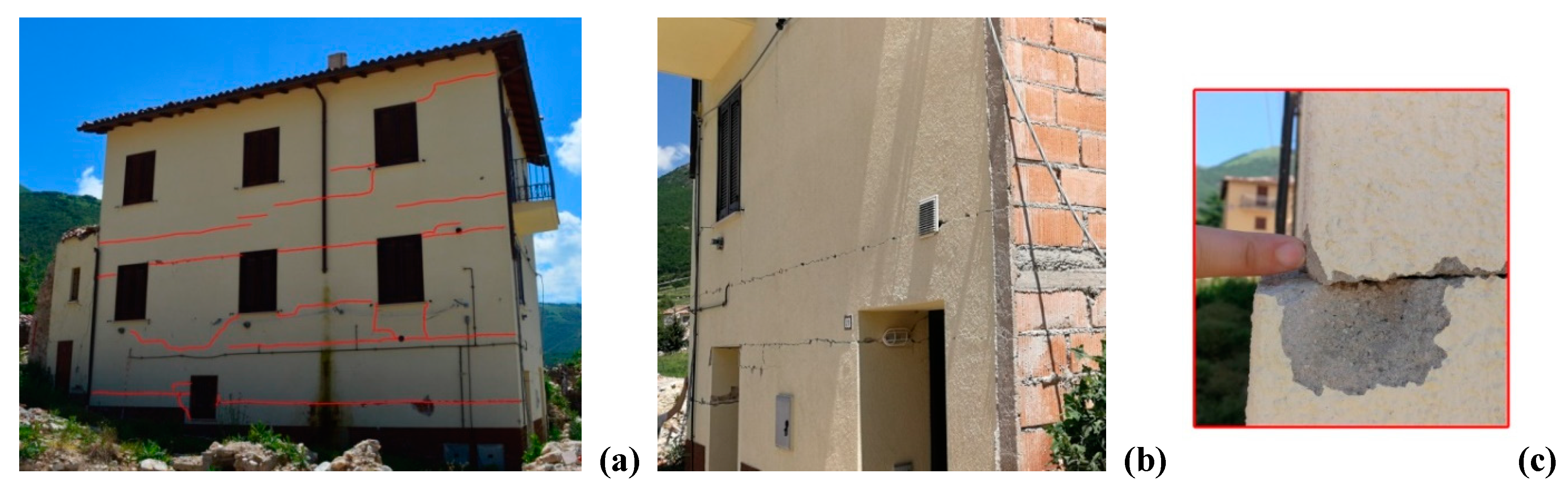

3. Survey of the Damage after the 2016 Umbrian Earthquake

3.1. Building No.1

3.2. Building No. 2

3.3. Building No. 3

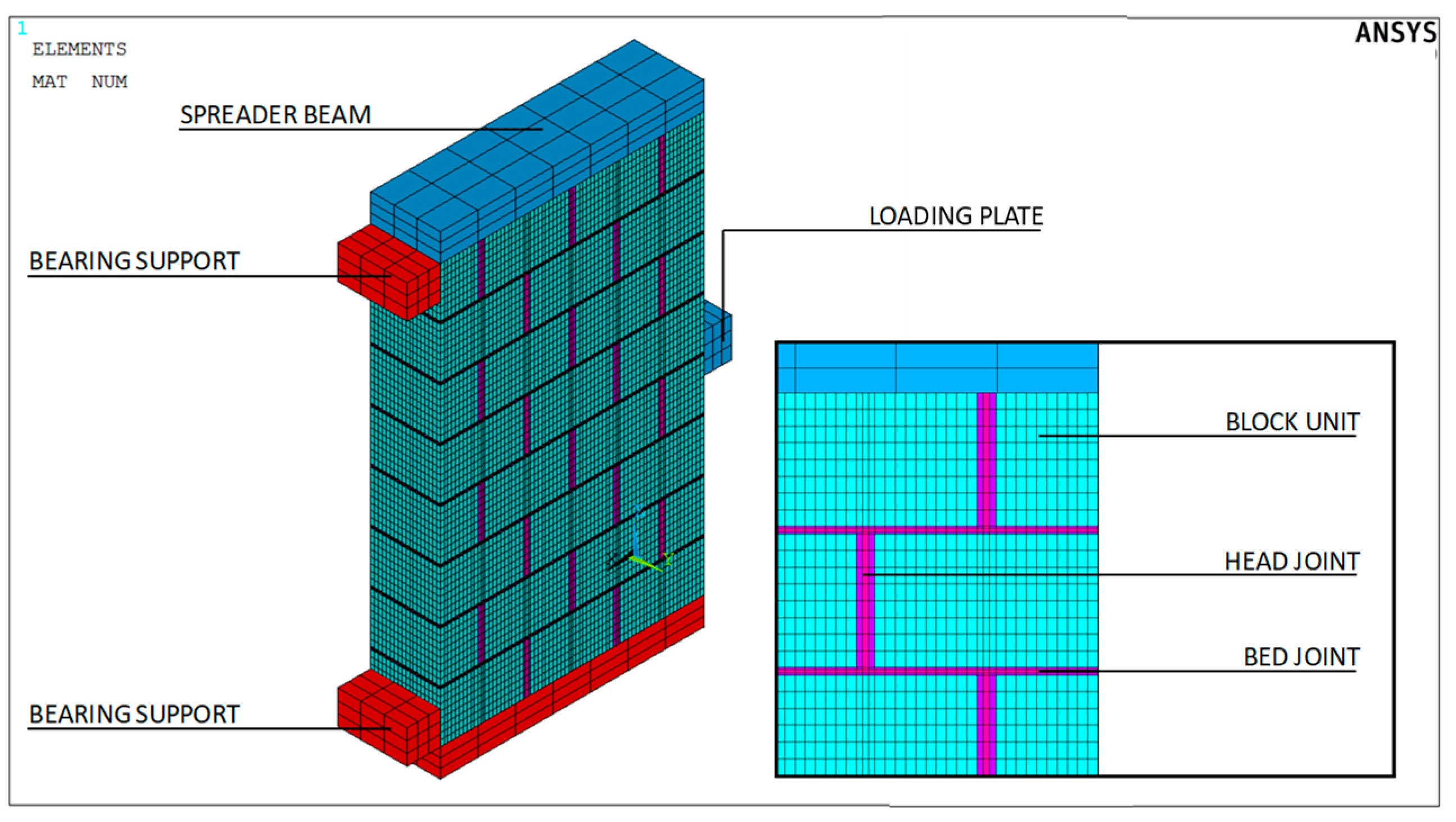

4. Numerical Analysis

5. Test Program

5.1. Specimen Description

5.2. Construction Materials

5.3. CFRP

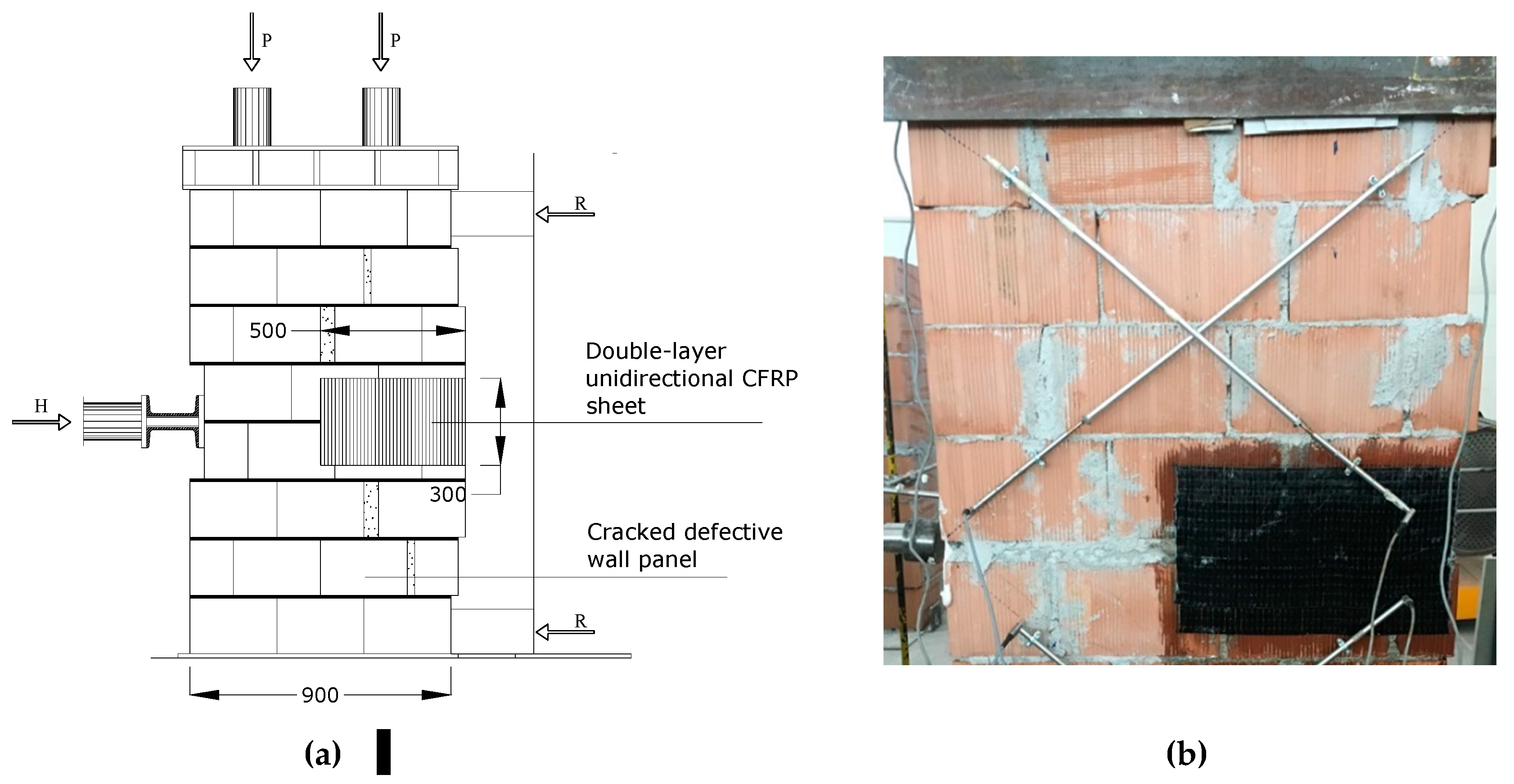

5.4. Test Arrangement

5.5. Test Results

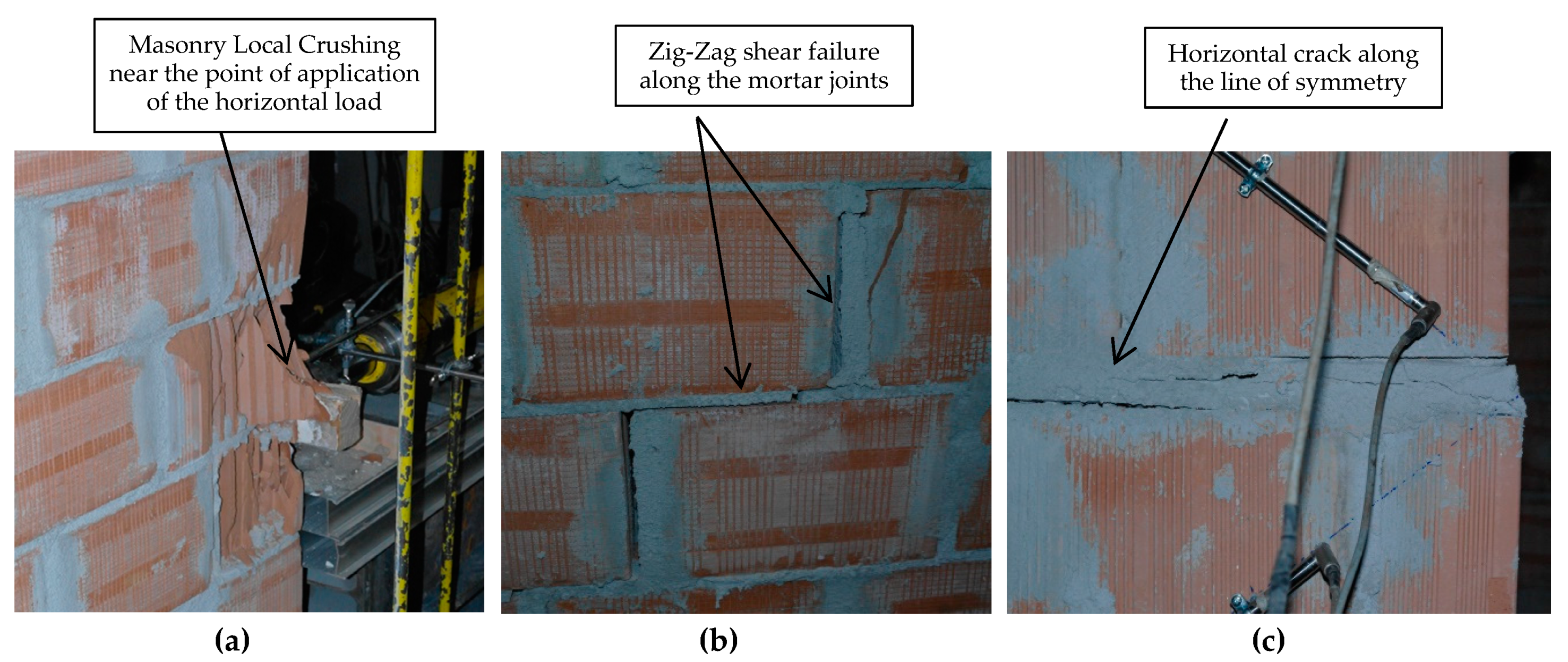

5.5.1. Control Non-Defective Walls

5.5.2. Control Defective Walls

5.5.3. Repaired Defective Walls

6. Conclusions

- The tests reported herein provide some relevant data on the seismic response of hollow load-bearing block masonry. The test results are of interest because they seem to confirm the on-site evidence of the seismic damage produced by sliding phenomena between the block masonry and the RC beams.

- The application of a double layer of CFRP sheets was effective in repairing defective cracked panels. The CFRP repair was able to bring the lateral load capacity to the level of the control non-defective panels. It was demonstrated that a CFRP sheet height of 300 mm (150 mm bonding lengths on both semi-panels) is sufficient to prevent detachment or peeling phenomena during the shear test.

- The use of an epoxy adhesive seems to be critical and fundamental in order to prevent the opening of any further horizontal cracks in the defective panels. The stress concentration in the CFRP is very high, and only a strong bonding agent can be successful in transferring the tensile forces from the masonry material to the carbon fibers.

- The long-term behavior of the epoxy and the CFRP needs to be further investigated and controlled. Chemical and mechanical degradation of the resin could be a problem in the long run, as well as exposure to high temperatures during the hot summer days. However, degradation could be considered tolerable given the very high initial mechanical properties of both carbon fibers and epoxies.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Watt, K. ‘Making drain tiles a “home manufacture”’: Agricultural Consumers and the Social Construction of Clayworking Technology in the 1840s. Rural. Hist. 2002, 13, 39–60. [Google Scholar] [CrossRef]

- Jäger, A.; Lu, S.; Degée, H.; Mordant, C.; Chioccariello, A.; Rakicevic, Z.T.; Sendova, V.; Mendes, L.; Candeias, P.; Costa, A.C.; et al. Full-scale Testing of Modern Unreinforced Thermal Insulation Clay Block Masonry Houses. Pract. Soil Dyn. 2015, 35, 229–246. [Google Scholar]

- Lourenço, P.B.; Vasconcelos, G.; Medeiros, P.; Gouveia, J. Vertically perforated clay brick masonry for loadbearing and non-loadbearing masonry walls. Constr. Build. Mater. 2010, 24, 2317–2330. [Google Scholar] [CrossRef]

- Bennett, R.M.; Boyd, K.A.; Flanagan, R.D. Compressive Properties of Structural Clay Tile Prisms. J. Struct. Eng. 1997, 123, 920–926. [Google Scholar] [CrossRef]

- Nagy, B.; Tóth, E. Hygrothermal behaviour of hollow and filled ceramic masonry blocks. RILEM Proc. PRO 2016, 112, 279–288. [Google Scholar]

- Brozovsky, J.; Zach, J. Evaluation of technical condition of masonry structures. In Proceedings of the 15th International Brick and Block Masonry Conference, Florianópolis, Brazil, 3–6 June 2012. [Google Scholar]

- Nagy, B.; Orosz, M. Optimized thermal performance design of filled ceramic masonry blocks. Appl. Mech. Mater. 2015, 797, 174–181. [Google Scholar] [CrossRef]

- Magenes, G.; Calvi, G.M. In-plane seismic response of brick masonry walls. Earthq. Eng. Struct. Dyn. 1997, 26, 1091–1112. [Google Scholar] [CrossRef]

- Lu, S.; Kasa, M. Seismic test program of special designed clay blocks due to earthquake resistance by Wienerberger consisting real scale shaking table, cyclic shear, diagonal tension and compression tests. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008. [Google Scholar]

- Mendes, L.; Candeias, P.; Correia, A.; Campos Costa, A.; Coelho, E.; Jäger, A.; Lu, S.; Degée, H.; Mordant, C. Full-Scale Seismic Testing of modern unreinforced thermal insulation clay block masonry houses. In Proceedings of the 9th International Masonry Conference, Guimarães, Portugal, 7–9 July 2014. [Google Scholar]

- Tomaževič, M. Earthquake-Resistant Design of Masonry Buildings; World Scientific Pub Co Pte Ltd.: Singapore, 1999. [Google Scholar]

- Italian Building Code. Norme Tecniche per la Progettazione, Esecuzione e Collaudo degli Edifici in Muratura e per il loro Consolidamento; Italian Goverment: Rome, Italy, 1987.

- Magenes, G. Masonry Building Design in Seismic areas: Recent experiences and prospects from a European Standpoint. In Proceedings of the 13th European Conference on Earthquake Engineering, Geneva, Switzerland, 3–8 September 2006. [Google Scholar]

- Sullivan, T.J.; Calvi, G.M.; Priestley, M.J.N. Initial Stiffness vs. secant Stiffness in displacement based design. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Da Porto, F.; Guidi, G.; Garbin, E.; Modena, C. In-Plane Behavior of Clay Masonry Walls: Experimental Testing and Finite-Element Modeling. J. Struct. Eng. 2010, 136, 1379–1392. [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M. Architectural Heritage: A Discussion on Conservation and Safety. Heritage 2019, 2, 631–647. [Google Scholar] [CrossRef] [Green Version]

- Borri, A.; Corradi, M.; Castori, G.; Sisti, R.; De Maria, A. Analysis of the collapse mechanisms of medieval churches struck by the 2016 Umbrian earthquake. Int. J. Archit. Herit. 2019, 13, 215–228. [Google Scholar] [CrossRef]

- Sorrentino, L.; Cattari, S.; Da Porto, F.; Magenes, G.; Penna, A. Seismic behaviour of ordinary masonry buildings during the 2016 central Italy earthquakes. Bull. Earthq. Eng. 2018, 1–25. [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M.; Vignoli, A. Seismic upgrading of masonry structures with FRP. In Proceedings of the 7th International Conference on inspection appraisal repairs and maintenance of buildings and structures, Nottingham, UK, 11–13 September 2001. [Google Scholar]

- Corradi, M.; Borri, A.; Vignoli, A. Strengthening techniques tested on masonry structures struck by the Umbria–Marche earthquake of 1997–1998. Constr. Build. Mater. 2002, 16, 229–239. [Google Scholar] [CrossRef]

- Capozucca, R. Experimental analysis of historic masonry walls reinforced by CFRP under in-plane cyclic loading. Compos. Struct. 2011, 94, 277–289. [Google Scholar] [CrossRef]

- Valluzzi, M.; Tinazzi, D.; Modena, C. Shear behavior of masonry panels strengthened by FRP laminates. Constr. Build. Mater. 2002, 16, 409–416. [Google Scholar] [CrossRef]

- Micelli, F.; Ombres, L. Natural masonry strengthened with CFRP: Experiments and modelling on wall panels. In Proceeding of the International Conference Composite in Constructions (CCC2003), Cosenza, Italy, 16–19 September 2003. [Google Scholar]

- Corradi, M.; Sisti, R.; Borri, A. Effect of thin cement-based renders on the structural response of masonry wall panels. Appl. Sci. 2018, 8, 98. [Google Scholar] [CrossRef]

- Wei, C.-Q.; Zhou, X.-G.; Ye, L.-P. Experimental study of masonry walls strengthened with CFRP. Struct. Eng. Mech. 2007, 25, 675–690. [Google Scholar] [CrossRef]

- Triantafillou, T.C. Strengthening of Masonry Structures Using Epoxy-Bonded FRP Laminates. J. Compos. Constr. 1998, 2, 96–104. [Google Scholar] [CrossRef]

- Mahmood, H.; Ingham, J.M. Diagonal Compression Testing of FRP-Retrofitted Unreinforced Clay Brick Masonry Wallettes. J. Compos. Constr. 2011, 15, 810–820. [Google Scholar] [CrossRef] [Green Version]

- Borri, A.; Corradi, M.; Sisti, R.; Castori, G. Typical failure modes of hollow load-bearing block walls. In Proceedings of the 13th North American Masonry conference, Salt Lake City, UT, USA, 16–19 June 2019. [Google Scholar]

- Willis, C.; Seracino, R.; Griffith, M. Out-of-plane strength of brick masonry retrofitted with horizontal NSM CFRP strips. Eng. Struct. 2010, 32, 547–555. [Google Scholar] [CrossRef]

- Sisti, R.; Di Ludovico, M.; Borri, A.; Prota, A. Damage assessment and the effectiveness of prevention: The response of ordinary unreinforced masonry buildings in Norcia during the Central Italy 2016–2017 seismic sequence. Bull. Earthq. Eng. 2018, 1–21. [Google Scholar] [CrossRef]

- Gabor, A.; Ferrier, E.; Jacquelin, E.; Hamelin, P. Analysis and modelling of the in-plane shear behaviour of hollow brick masonry panels. Constr. Build. Mater. 2006, 20, 308–321. [Google Scholar] [CrossRef]

- Italian Building Code. Norme Tecniche per il Calcolo, L’esecuzione ed il Collaudo delle Strutture in Cemento Armato, Normale e Precompresso e per le Strutture Metalliche; Italian Goverment: Rome, Italy, 1996.

- Italian Building Code. Aggiornamento delle «Norme Tecniche per le Costruzioni»; Italian Goverment: Rome, Italy, 2018.

- Baggio, C.; Bernardini, A.; Colozza, R.; Coppari, S.; Corazza, L.; Della Bella, M.; Di Pasquale, G.; Dolce, M.; Goretti, A.; Martinelli, A.; et al. Field Manual for Post-Earthquake Damage and Safety Assessment and Short Term Countermeasures (AeDES); European Commission, Joint Research Centre Institute for the Protection and Security of the Citizen, EUR: Luxembourg, 2007; p. 22868. [Google Scholar]

- ANSYS 15.0, Ansys User Manual; Ansys Inc.: Canonsburg, PA, USA, 2013.

- Fornaci Briziarelli Marsciano. Available online: http://www.fbm.it/ (accessed on 17 May 2019).

- EN 1015-11:2007 Methods of Test for Mortar for Masonry. Part 11—Determination of Flexural and Compressive Strength of Hardened Mortars; CEN (European Committee for Standardization): Bruxelles, Belgium, 1999.

- ASTM International. ASTM D638-14, Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Corradi, M.; Borri, A. A database of the structural behavior of masonry in shear. Bull. Earthq. Eng. 2018, 16, 3905–3930. [Google Scholar] [CrossRef]

- Boschi, S.; Galano, L.; Vignoli, A. Mechanical characterisation of Tuscany masonry typologies by in situ tests. Bull. Earthq. Eng. 2019, 17, 413–438. [Google Scholar] [CrossRef]

- Turnšek, V.; Cacovic, F. Some experimental results on the strength of brick masonry walls. In Proceedings of the 2nd International Brick Masonry Conference, Stoke-on-Trent, UK, 12–15 April 1970. [Google Scholar]

- Italian Building Code. Guidelines. Istruzioni per l’applicazione dell’«Aggiornamento delle "Norme Tecniche per le Costruzioni"» di cui al Decreto Ministeriale 17 Gennaio 2018; Italian Goverment: Rome, Italy, 2019.

- Jasinski, R. Research of Influence of the Shape of Unreinforced Masonry Shear Walls Made of Calcium Silicate Masonry Units. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 022009. [Google Scholar] [CrossRef]

| Property | Fired Clay Hollow Blocks | Mortar |

|---|---|---|

| Number of Tested Samples | 6 | 12 |

| Sample Dimensions (mm) | 300 × 250 × 180 * | 40 × 40 × 80 ** |

| Weight Single Unit (kg) | 12.511 | 0.525 |

| Voids (%) | 45 + | - |

| Failure Load (kN) | 475.7 | 24.65 |

| Compressive Strength (MPa) | 6.58 ++ | 15.7 |

| CoV Compressive Strength (%) | 11.2 | 5.79 |

| Number of Tested Samples | - | 6 |

| Sample Dimensions (mm) | - | 40 × 40 × 160 |

| Bending Strength (MPa) | - | 3.75 |

| CoV Bending Strength (%) | - | 8.53 |

| Type of Fibres | Carbon |

|---|---|

| Number of Tested Samples | 10 |

| Dry Fiber Thickness (mm) | 0.165 |

| Fiber Density (g/m2) | 300 |

| Matrix Type | epoxy |

| Tensile Strength (MPa) and (CoV) (%) | 3324 (18.1) |

| Young’s modulus (GPa) and (CoV) (%) | 312.2 (19.2) |

| Test No. | Vertical Compressive Stress σ0 (MPa) | Horizontal Cracking Load (kN) | Shear Failure Load H (kN) | Shear Strength τ0 (MPa) | Failure Mode |

|---|---|---|---|---|---|

| P1-ND-30 | 0.3 | - | >150.55 | 0.137 | Local crushing |

| P2-DE-20 | 0.2 | 61.71 | 152.89 | 0.167 | Diagonal cracking |

| P3-ND-20 | 0.2 | - | 158.68 | 0.175 | Diagonal cracking |

| P4-DE-30 | 0.3 | 134.07 | 182.98 | 0.179 | Diagonal cracking |

| P4-RE-30 | 0.3 | - | 211.28 | 0.219 | Diagonal cracking |

| P5-DE-20 | 0.2 | 78.47 | - | - | Horizontal cracking |

| P6-DE-20 | 0.2 | 116.97 | - | - | Horizontal cracking |

| P6-RE-20 | 0.2 | - | 167.32 | 0.182 | Diagonal cracking |

| mean ND-20 | 0.2 | - | 158.68 | 0.156 | |

| mean ND-30 | 0.3 | - | >150.55 | ||

| mean DE-20 | 0.2 | 85.71 | 152.89 | 0.173 | |

| mean DE-30 | 0.3 | 134.07 | 182.98 | ||

| mean RE-20 | 0.2 | - | 167.32 | 0.182 | |

| mean RE-30 | 0.3 | - | 211.28 | 0.219 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corradi, M.; Castori, G.; Sisti, R.; Borri, A.; Pesce, G.L. Repair of Block Masonry Panels with CFRP Sheets. Materials 2019, 12, 2363. https://doi.org/10.3390/ma12152363

Corradi M, Castori G, Sisti R, Borri A, Pesce GL. Repair of Block Masonry Panels with CFRP Sheets. Materials. 2019; 12(15):2363. https://doi.org/10.3390/ma12152363

Chicago/Turabian StyleCorradi, Marco, Giulio Castori, Romina Sisti, Antonio Borri, and Giovanni Luca Pesce. 2019. "Repair of Block Masonry Panels with CFRP Sheets" Materials 12, no. 15: 2363. https://doi.org/10.3390/ma12152363

APA StyleCorradi, M., Castori, G., Sisti, R., Borri, A., & Pesce, G. L. (2019). Repair of Block Masonry Panels with CFRP Sheets. Materials, 12(15), 2363. https://doi.org/10.3390/ma12152363