A Nondestructive Indirect Approach to Long-Term Wood Moisture Monitoring Based on Electrical Methods

Abstract

1. Introduction

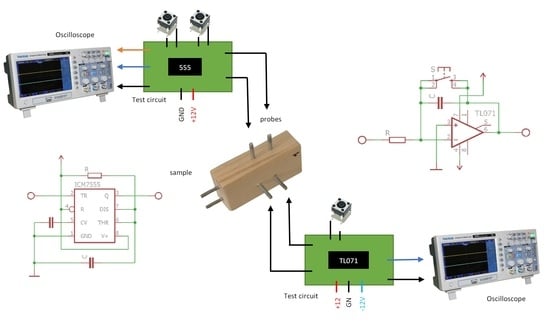

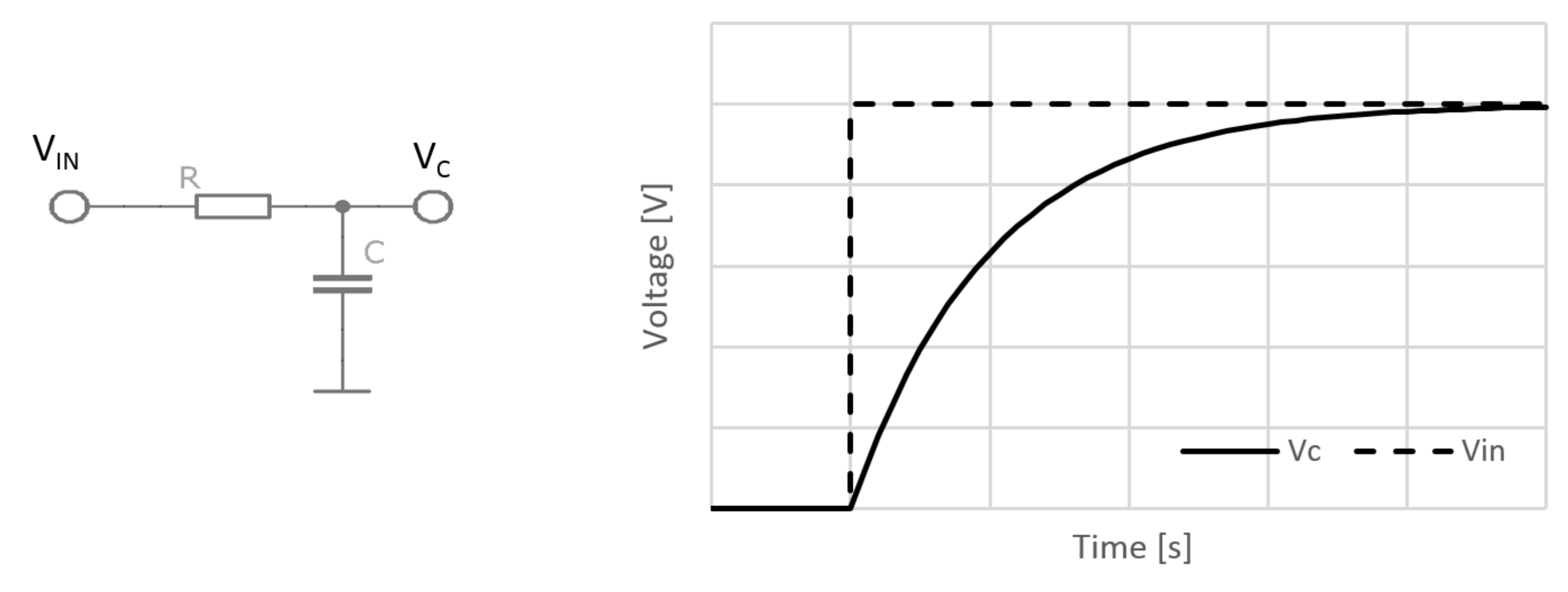

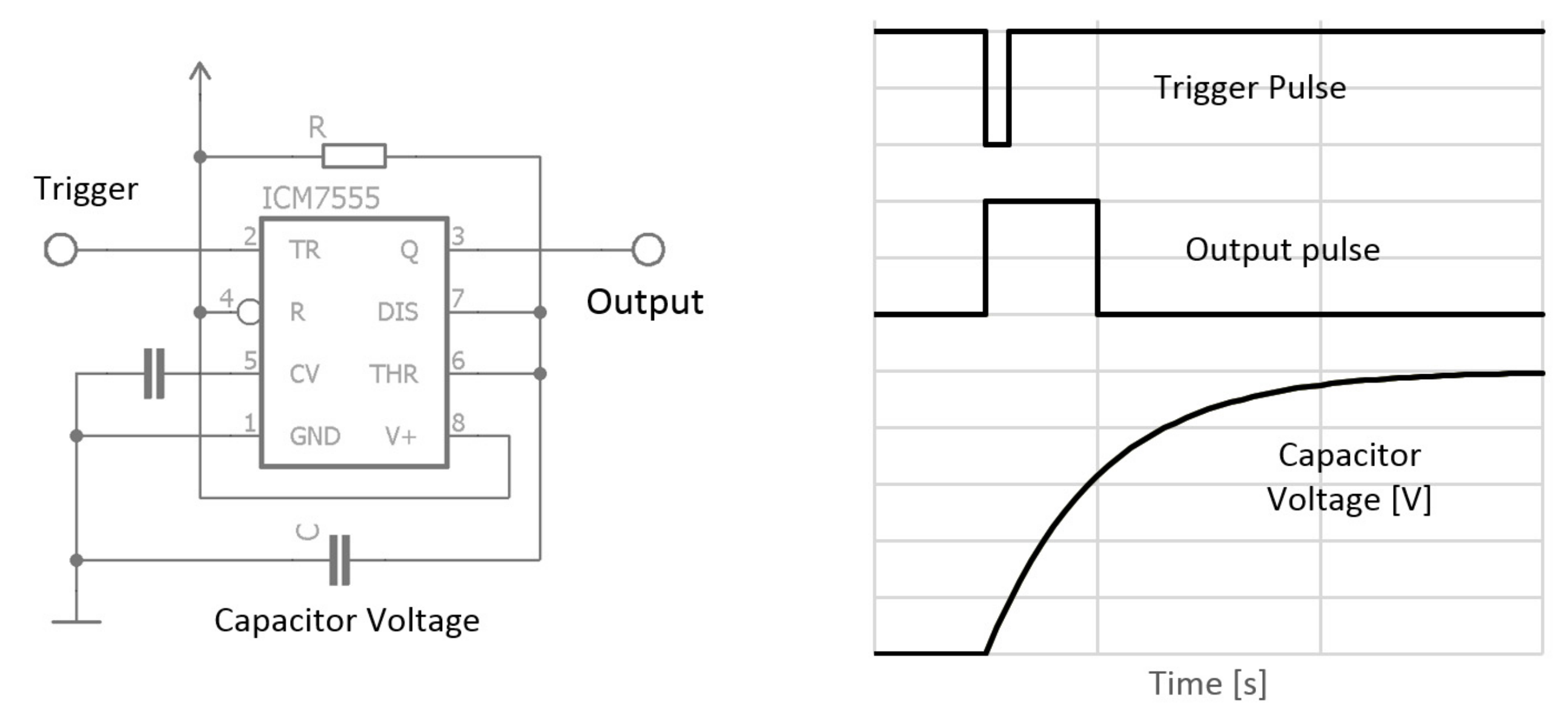

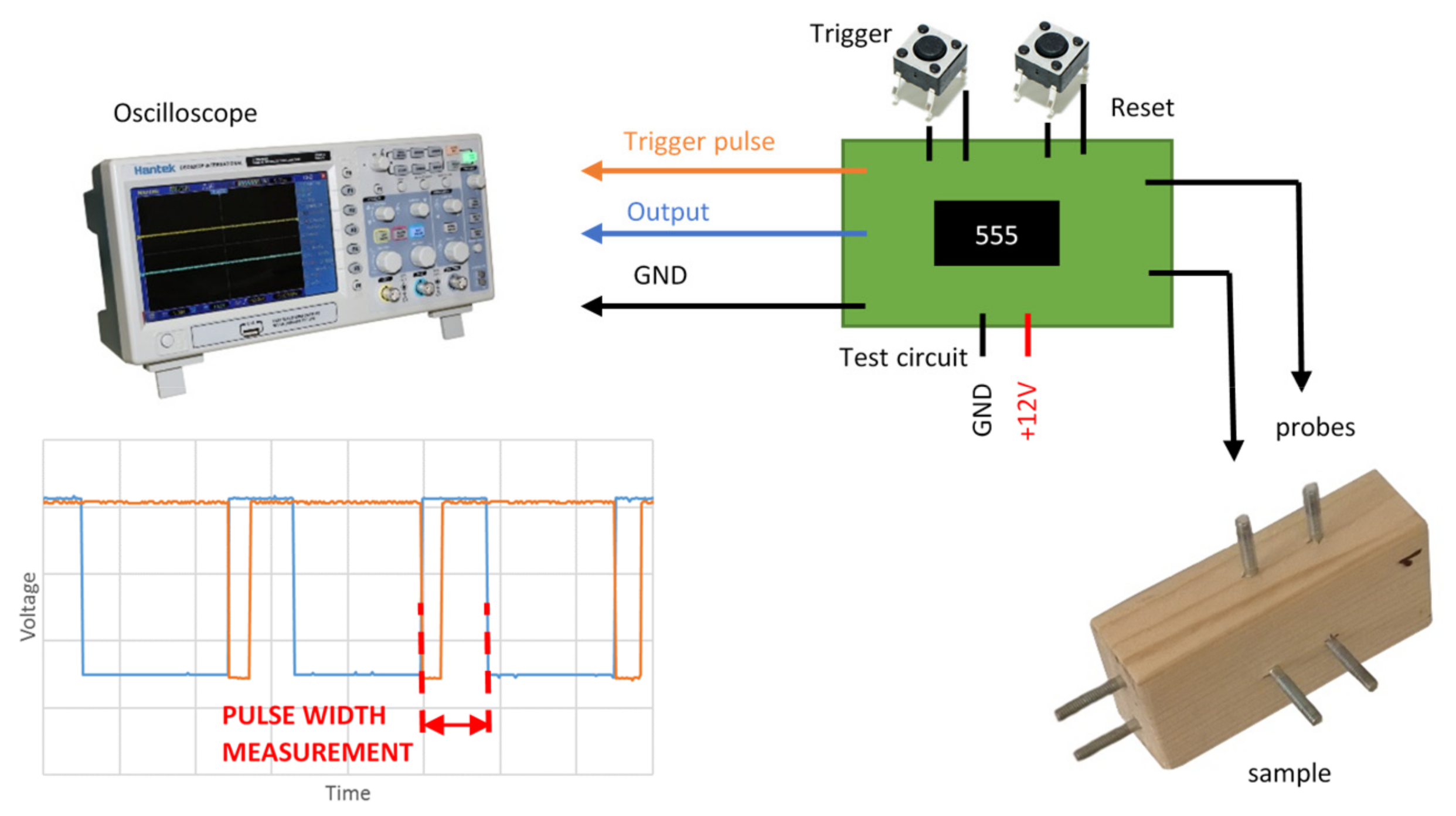

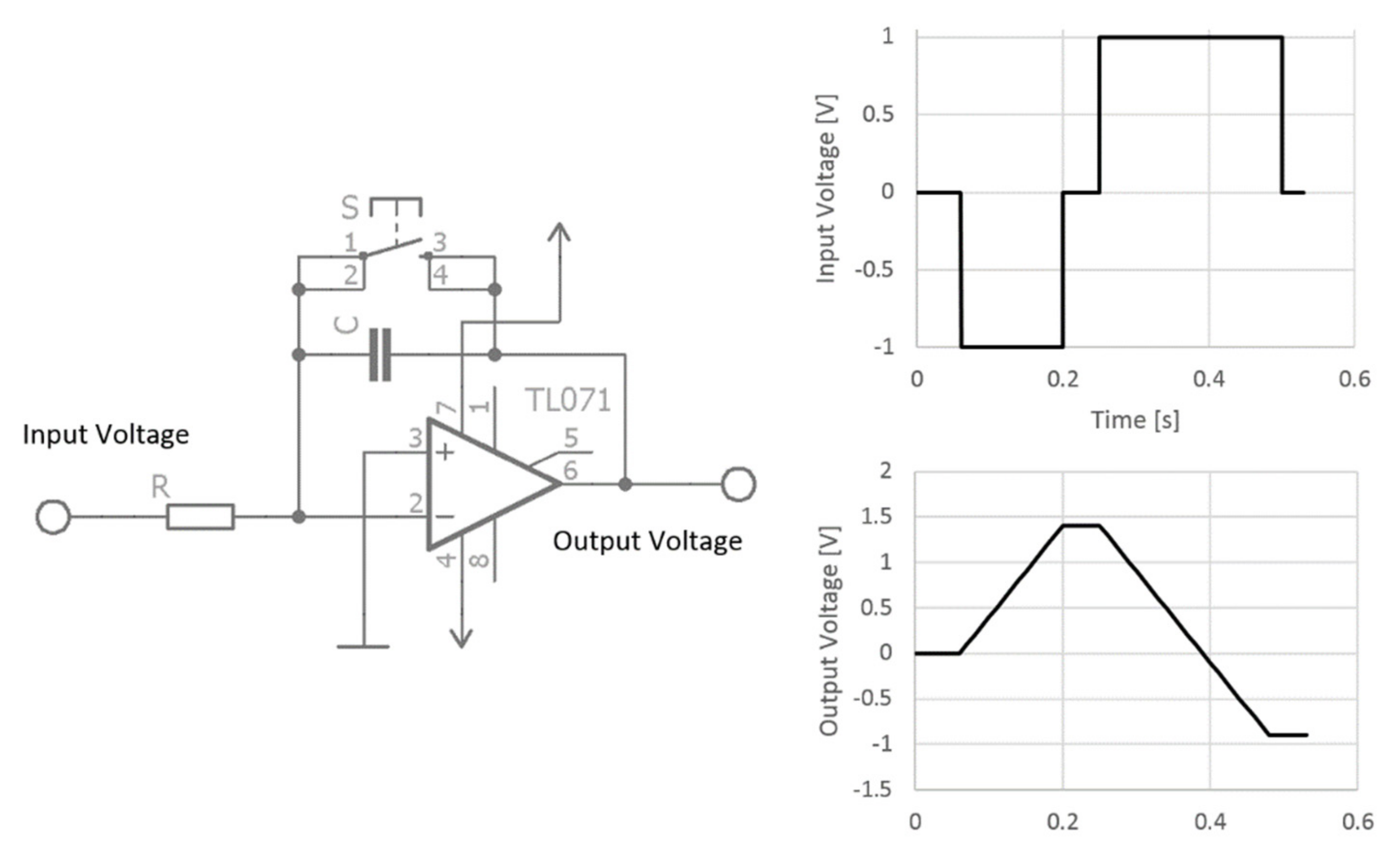

2. Description of the Circuits, Theoretical Principles, and Applications

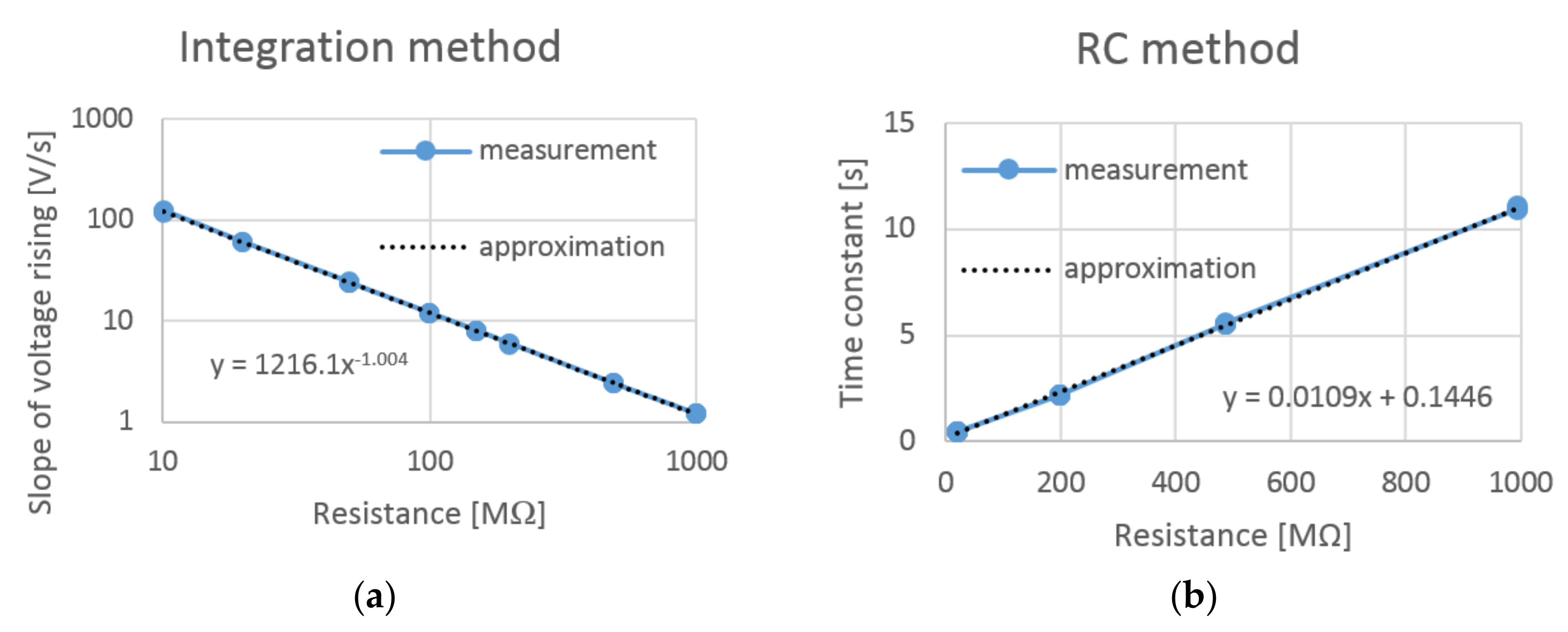

2.1. The RC Circuit Method

2.2. The Integration Method

3. Materials and Methods

3.1. Sample Preparation Procedure

3.2. Circuit Setup and Calibration Procedure

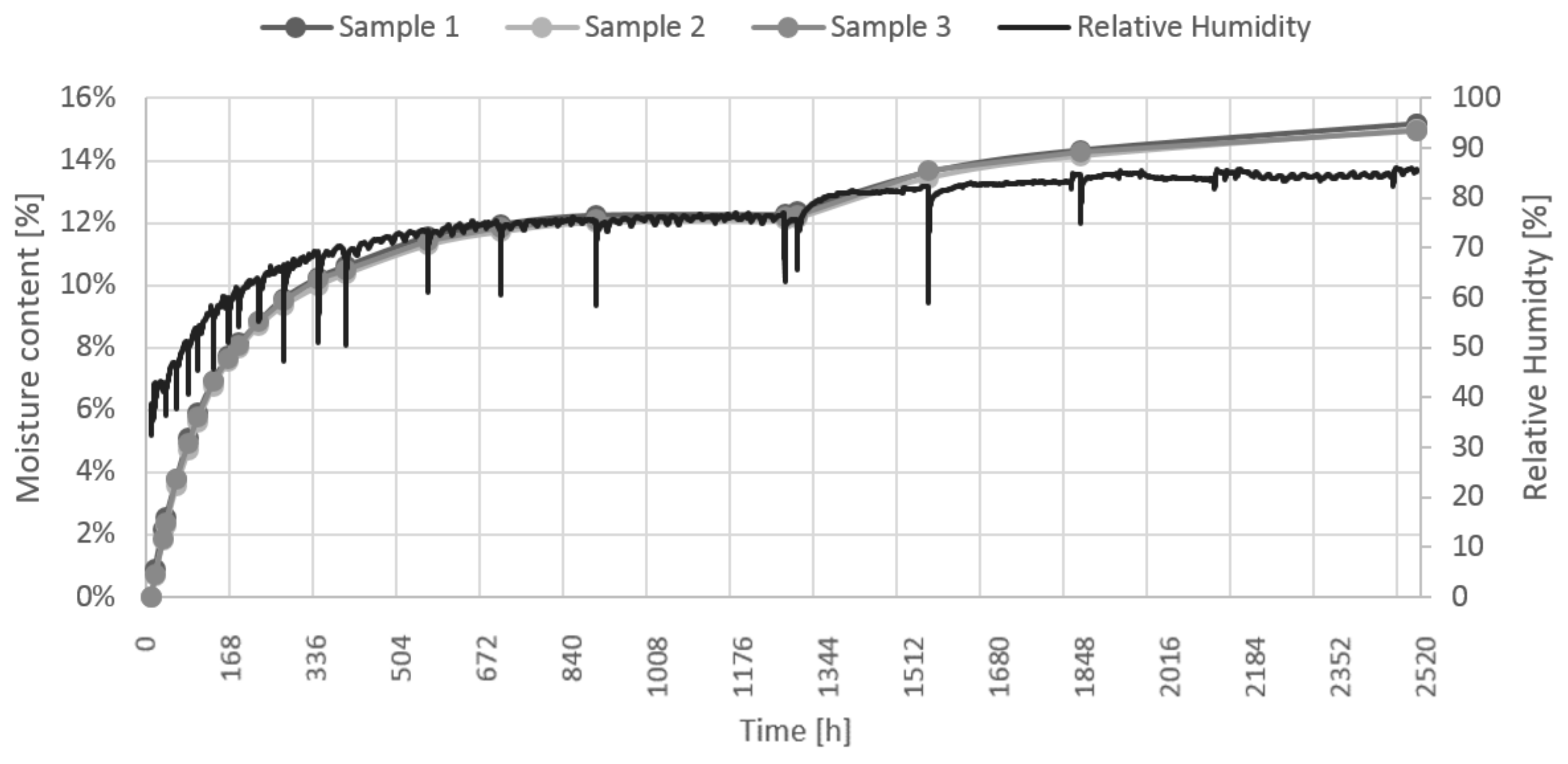

3.3. Sample Conditioning and Measurement Procedure

3.4. Statistical Analysis

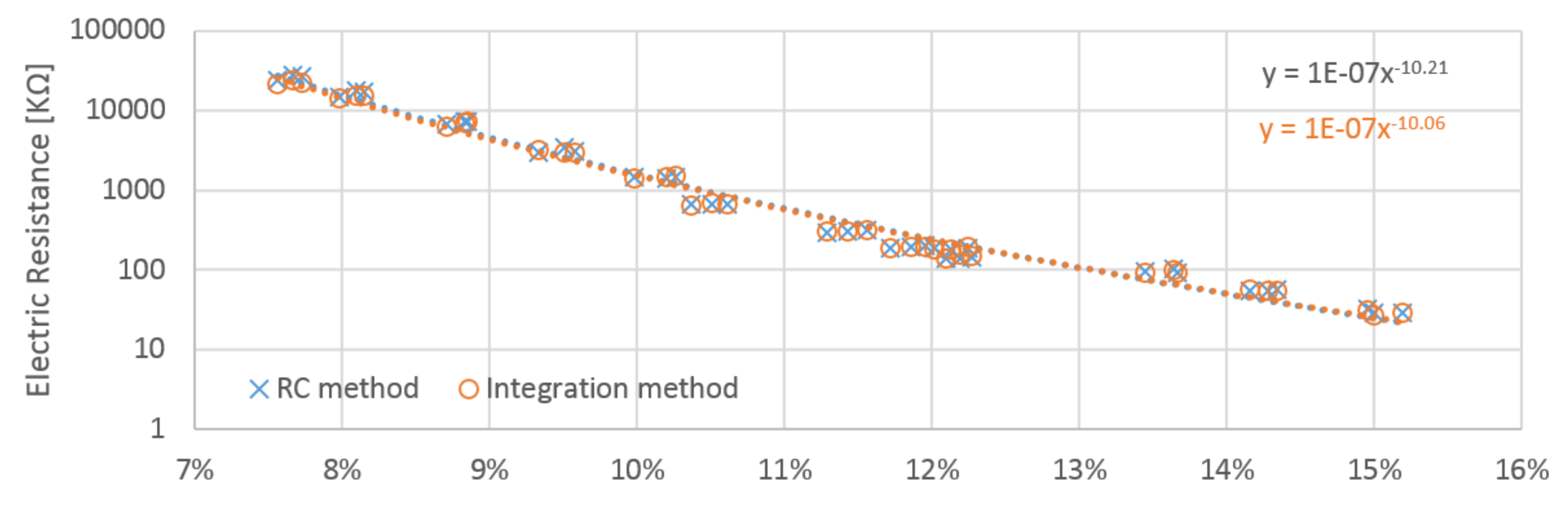

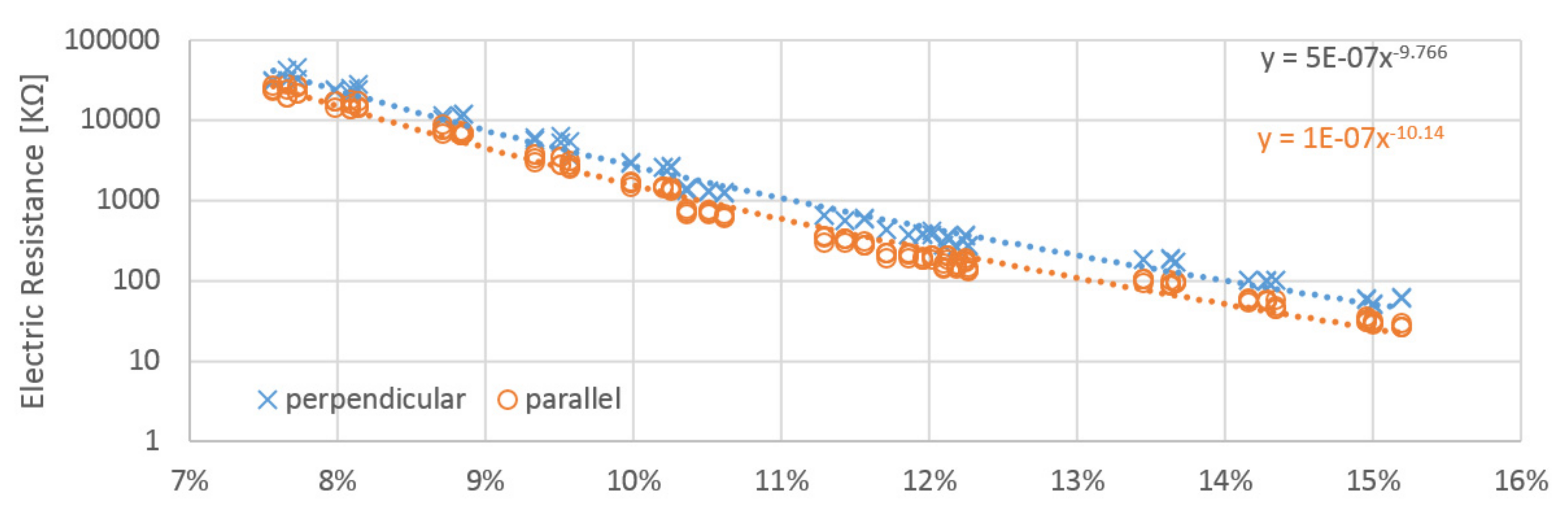

4. Results

5. Statistical Evaluation of Results

5.1. Construction of Bland-Altman Plots

5.2. Proportional Measurement Bias

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kosny, J.; Asiz, A.; Smith, I.; Shrestha, S.; Fallahi, A. A review of high-value wood framed and composite wood wall technologies using advanced insulation techniques. Energy Build. 2014, 72, 441–456. [Google Scholar] [CrossRef]

- Norberg, P. Monitoring wood moisture content using the WETCORR method Part 1: Background and theoretical considerations. Holz Als Roh Werkstoff 1999, 57, 448–453. [Google Scholar] [CrossRef]

- Isaksson, T.; Thelandersson, S. Experimental investigation on the effect of detail design on wood moisture content in outdoor above ground applications. Build. Environ. 2013, 59, 239–249. [Google Scholar] [CrossRef]

- Németh, R.; Tsalagkas, D.; Bak, M. Effect of soil contact on the modulus of elasticity of beeswax-impregnated wood. BioResources 2015, 10, 1574–1586. [Google Scholar] [CrossRef]

- Dietsch, P.; Franke, S.; Franke, B.; Gamper, A.; Winter, S. Methods to determine wood moisture content and their applicability in monitoring concepts. J. Civ. Struct. Health Monit. 2015, 5, 115–127. [Google Scholar] [CrossRef]

- Brischke, C.; Thelandersson, S. Modelling the outdoor performance of wood products—A review on existing approaches. Constr. Build. Mater. 2014, 66, 384–397. [Google Scholar] [CrossRef]

- Brischke, C.; Meyer, L.; Bornemann, T. The potential of moisture content measurements for testing the durability of timber products. Wood Sci. Technol. 2013, 43, 869–886. [Google Scholar] [CrossRef]

- Tanaka, T.; Avramidis, S.; Shida, S. Evaluation of moisture content distribution in wood by soft X-ray imaging. J Wood Sci. Modelling the outdoor performance of wood products—A review on existing approaches. Constr. Build. Mater. 2009, 55, 69–73. [Google Scholar]

- Tanaka, T.; Kawai, Y. A new method for nondestructive evaluation of solid wood moisture content based on dual-energy X-ray absorptiometry. Wood Sci. Technol. 2013, 47, 1213–1229. [Google Scholar] [CrossRef]

- Maeda, K.; Ohta, M.; Momohara, I. Relationship between the mass profile and the strength property profile of decayed wood. Wood Sci. Technol. 2015, 49, 331–344. [Google Scholar] [CrossRef]

- Hultnas, M.; Fernandez-Cano, V. Determination of the moisture content in wood chips of Scots pine and Norway spruce using Mantex desktop scanner based on dual energy X-ray absorptiometry. J. Wood Sci. 2012, 58, 309–314. [Google Scholar] [CrossRef]

- Meyer, L.; Brischke, C. Fungal decay at different moisture levels of selected European-grown wood species. Int. Biodeter. Biodeger. 2015, 103, 23–29. [Google Scholar] [CrossRef]

- Brischke, C.; Rapp, O.A. Influence of wood moisture content and wood temperature on fungal decay in the field: Observations in different micro-climates. Wood Sci. Technol. 2008, 42, 663–677. [Google Scholar] [CrossRef]

- Van den Bulcke, J.; Van Acker, J.; De Smet, J. An experimental set-up for real-time continuous moisture measurements of plywood exposed to outdoor climate. Build. Environ. 2009, 44, 2368–2377. [Google Scholar] [CrossRef][Green Version]

- Otten, K.A.; Brischke, C.; Meyer, C. Material moisture content of wood and cement mortars—Electrical resistance-based measurements in the high ohmic range. Constr. Build. Mater. 2017, 153, 640–646. [Google Scholar] [CrossRef]

- Dunlap, M.E. Electrical Moisture Meters for Wood; United States Department of Agriculture, Forest Service, Forest Product Laboratory: Madison, WI, USA, 1944. [Google Scholar]

- Wood Handbook—Wood as an Engineering Material; General Technical Report FPL-GTR-190; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010; p. 508.

- James, W.L. Electric Moisture Meters for Wood; General Technical Report FPL-GTR-6; United States Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1988; Available online: http://www.fpl.fs.fed.us/documnts/fplgtr/fplgtr06.pdf (accessed on 1 March 2019).

- Casans, S.; Iakymchuk, T.; Rosado-Muñoz, A. High resistance measurement circuit for fiber materials: Application to moisture content estimation. Measurement 2018, 119, 167–174. [Google Scholar] [CrossRef]

- Brischke, C.; Rapp, O.A.; Bayerbach, R. Measurement system for long-term recording of wood moisture content with internal conductively glued electrodes. Build. Environ. 2008, 43, 1566–1574. [Google Scholar] [CrossRef]

- Gao, S.; Bao, Z.; Wang, L.; Yue, X. Comparison of voltammetry and digital bridge methods for electrical resistance measurements in wood. Comput. Electron. Agr. 2018, 145, 161–168. [Google Scholar] [CrossRef]

- Chetpattananondh, P.; Thongpull, K.; Chetpattananondh, K. Interdigital capacitance sensing of moisture content in rubber wood. Comput. Electron. Agric. 2017, 142, 545–551. [Google Scholar] [CrossRef]

- Bland, J.M.; Altman, D.G. Statistical methods for assessing agreement between two methods of clinical measurement. Lancet 1986, 327, 307–310. [Google Scholar] [CrossRef]

- Hanneman, S.K. Design, analysis and interpretation of method-comparison studies. AACN Adv. Critic. Care 2009, 19, 19–234. [Google Scholar]

- Vodicka, A. Increased Moisture Detection and Early Warning System for Buildings. Ph.D. Thesis, Czech Technical University, Praha, Czech Republic, 2015. Available online: https://dspace.cvut.cz/ (accessed on 1 April 2019).

- Mlejnek, P.; Vodička, A.; Včelák, J. Zařízení pro detekci vlhkosti dřeva. Available online: https://stavba.tzb-info.cz/drevene-konstrukce/12437-zarizeni-pro-detekci-vlhkosti-dreva (accessed on 19 September 2018).

- Aguilar, H.M.; Landín, R.O. A simple technique for high resistance measurement. Phys. Edu. 2012, 47, 599–602. [Google Scholar] [CrossRef]

- Bland, J.M.; Altman, D.G. Measuring agreement in method comparison studies. Stat. Methods Med. Res. 1999, 8, 135–160. [Google Scholar] [CrossRef] [PubMed]

- Papez, J.; Kic, P. Wood moisture of rural timber construction. Agron. Res. 2013, 11, 505–512. [Google Scholar]

- Fernandez-Golfin, J.I.; Conde, M.; Calvo, R.; Baonza, M.V.; De Palacios, A.P.; Palacios, Y. Curves for the estimation of the moisture content of ten hardwoods by means of electrical resistance measurements. Forest Syst. 2012, 21, 121–127. [Google Scholar] [CrossRef]

- Moron, C.; Garcia-Fuentevilla, L.; Garcia, A.; Moron, A. Measurement of moisture in wood for application in the restoration of old buildings. Sensors 2016, 16, 697. [Google Scholar] [CrossRef]

| Sample 1 | |||||||||||||

| 7.73% | 8.14% | 8.85% | 9.57% | 10.26% | 10.61% | 11.56% | 11.96% | 12.25% | 12.27% | 13.63% | 14.34% | 15.19% | |

| A | 26,550 | 14,936 | 6835 | 2775 | 1326 | 612 | 282 | 186 | 170 | 130 | 89 | 49 | 27 |

| B | 27,101 | 17,174 | 7220 | 3083 | 1461 | 665 | 313 | 201 | 191 | 147 | 102 | 58 | 29 |

| C | 46,009 | 28,257 | 12,046 | 5502 | 2601 | 1253 | 599 | 379 | 355 | 268 | 188 | 101 | 61 |

| Sample 2 | |||||||||||||

| 7.56% | 7.98% | 8.71% | 9.33% | 9.98% | 10.36% | 11.29% | 11.71% | 12.02% | 12.10% | 13.45% | 14.15% | 15.00% | |

| A | 27,009 | 17,358 | 8752 | 3372 | 1735 | 777 | 345 | 224 | 209 | 162 | 105 | 61 | 32 |

| B | 23,725 | 14,569 | 6716 | 2989 | 1462 | 672 | 299 | 191 | 185 | 140 | 95 | 54 | 29 |

| C | 30,183 | 24,550 | 11,514 | 5754 | 3009 | 1454 | 650 | 428 | 415 | 282 | 183 | 102 | 52 |

| Sample 3 | |||||||||||||

| 7.66% | 8.09% | 8.83% | 9.50% | 10.20% | 10.51% | 11.43% | 11.86% | 12.13% | 12.19% | 13.66% | 14.28% | 14.95% | |

| A | 24,349 | 16,239 | 6550 | 3453 | 1473 | 697 | 331 | 222 | 207 | 147 | 95 | 55 | 36 |

| B | 27,853 | 17,780 | 7321 | 3428 | 1427 | 669 | 302 | 193 | 183 | 140 | 94 | 55 | 33 |

| C | 42,294 | 24,936 | 10,945 | 6396 | 2599 | 1286 | 561 | 369 | 346 | 261 | 173 | 102 | 61 |

| Sample 1 | |||||||||||||

| 7.73% | 8.14% | 8.85% | 9.57% | 10.26% | 10.61% | 11.56% | 11.96% | 12.25% | 12.27% | 13.63% | 14.34% | 15.19% | |

| A | 21,565 | 14,593 | 6723 | 2622 | 1371 | 621 | 281 | 183 | 174 | 135 | 86 | 45 | 26 |

| B | 22,452 | 15,499 | 7151 | 2918 | 1496 | 673 | 312 | 198 | 196 | 148 | 101 | 56 | 29 |

| C | 33,257 | 24,589 | 11,950 | 5109 | 2687 | 1299 | 575 | 385 | 367 | 279 | 184 | 99 | 60 |

| Sample 2 | |||||||||||||

| 7.56% | 7.98% | 8.71% | 9.33% | 9.98% | 10.36% | 11.29% | 11.71% | 12.02% | 12.10% | 13.45% | 14.15% | 15.00% | |

| A | 24,570 | 17,251 | 7513 | 3756 | 1675 | 728 | 353 | 225 | 203 | 149 | 103 | 58 | 30 |

| B | 21,639 | 14,227 | 6246 | 3183 | 1419 | 645 | 308 | 186 | 180 | 137 | 94 | 58 | 27 |

| C | 31,784 | 23,127 | 10,383 | 6034 | 2853 | 1339 | 654 | 430 | 366 | 276 | 184 | 100 | 50 |

| Sample 3 | |||||||||||||

| 7.66% | 8.09% | 8.83% | 9.50% | 10.20% | 10.51% | 11.43% | 11.86% | 12.13% | 12.19% | 13.66% | 14.28% | 14.95% | |

| A | 19,681 | 13,700 | 6558 | 2833 | 1496 | 747 | 340 | 213 | 209 | 156 | 97 | 57 | 30 |

| B | 23,737 | 15,293 | 6945 | 3019 | 1437 | 695 | 304 | 194 | 184 | 156 | 92 | 54 | 31 |

| C | 30,981 | 21,213 | 11,066 | 5170 | 2612 | 1328 | 559 | 379 | 359 | 271 | 171 | 99 | 58 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slávik, R.; Čekon, M.; Štefaňák, J. A Nondestructive Indirect Approach to Long-Term Wood Moisture Monitoring Based on Electrical Methods. Materials 2019, 12, 2373. https://doi.org/10.3390/ma12152373

Slávik R, Čekon M, Štefaňák J. A Nondestructive Indirect Approach to Long-Term Wood Moisture Monitoring Based on Electrical Methods. Materials. 2019; 12(15):2373. https://doi.org/10.3390/ma12152373

Chicago/Turabian StyleSlávik, Richard, Miroslav Čekon, and Jan Štefaňák. 2019. "A Nondestructive Indirect Approach to Long-Term Wood Moisture Monitoring Based on Electrical Methods" Materials 12, no. 15: 2373. https://doi.org/10.3390/ma12152373

APA StyleSlávik, R., Čekon, M., & Štefaňák, J. (2019). A Nondestructive Indirect Approach to Long-Term Wood Moisture Monitoring Based on Electrical Methods. Materials, 12(15), 2373. https://doi.org/10.3390/ma12152373