The Joining Behavior of Titanium and Q235 Steel Joined by Cold Metal Transfer Joining Technology

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Materials

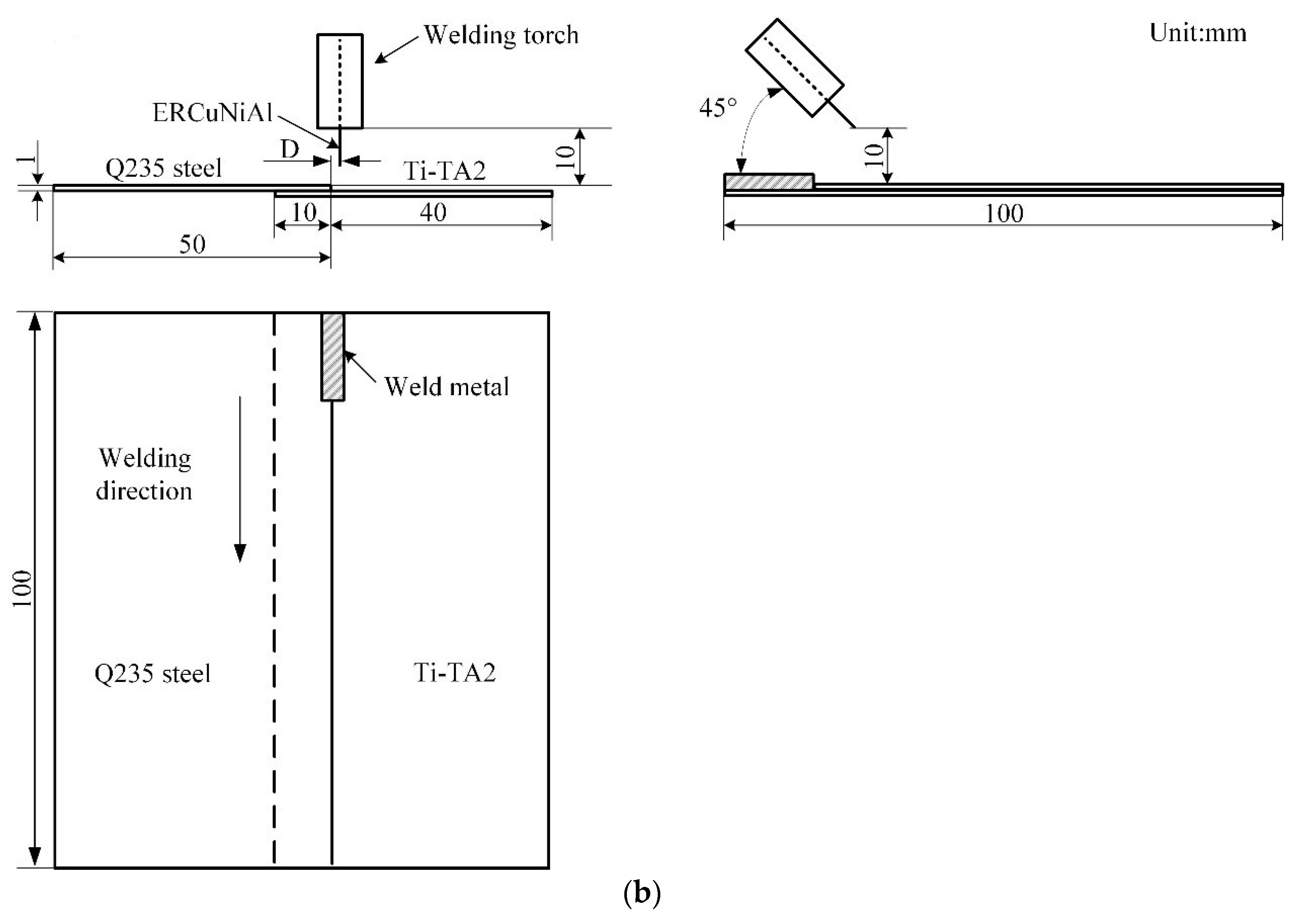

2.2. Welding Procedures

2.3. Analysis of Joining Mechanism

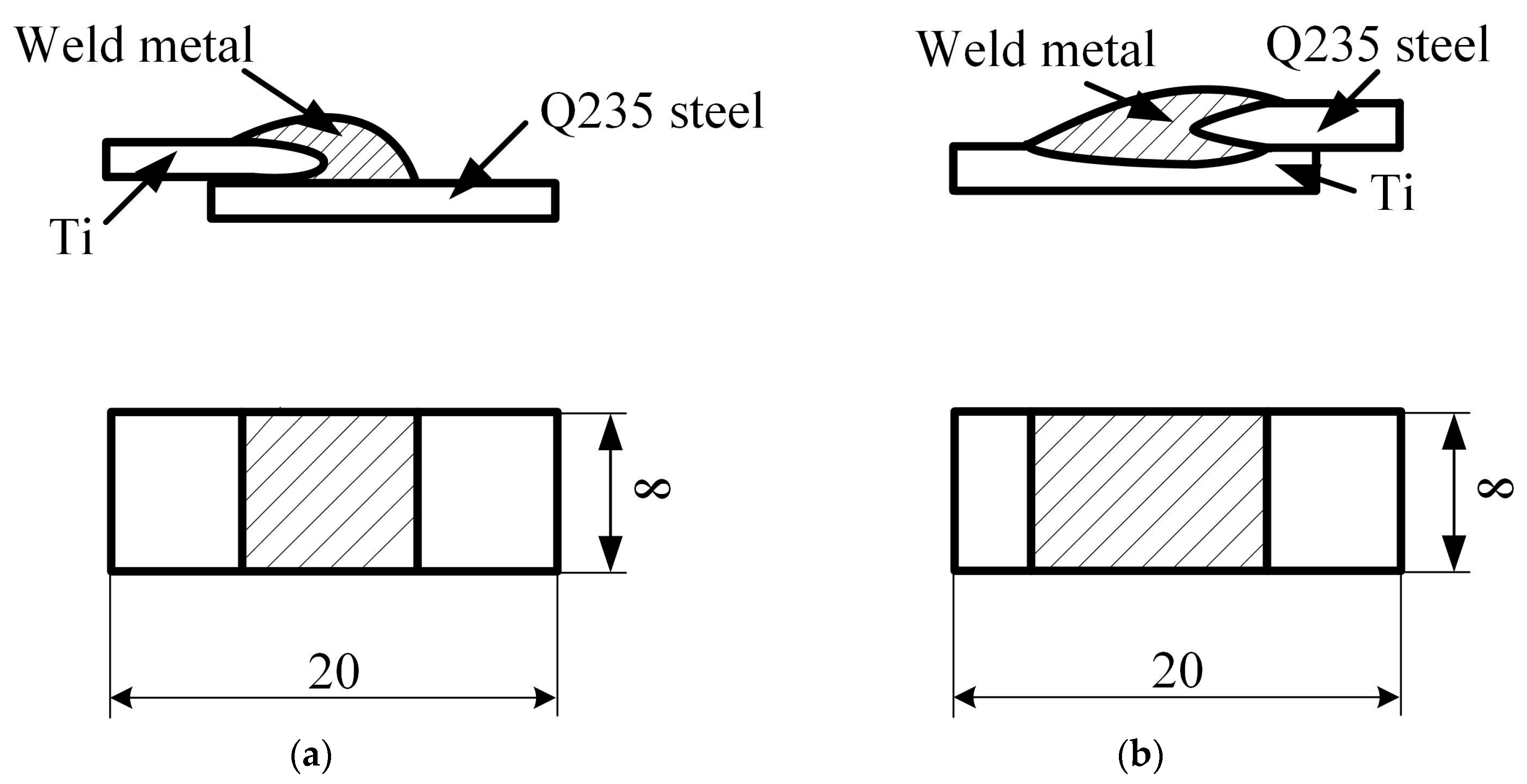

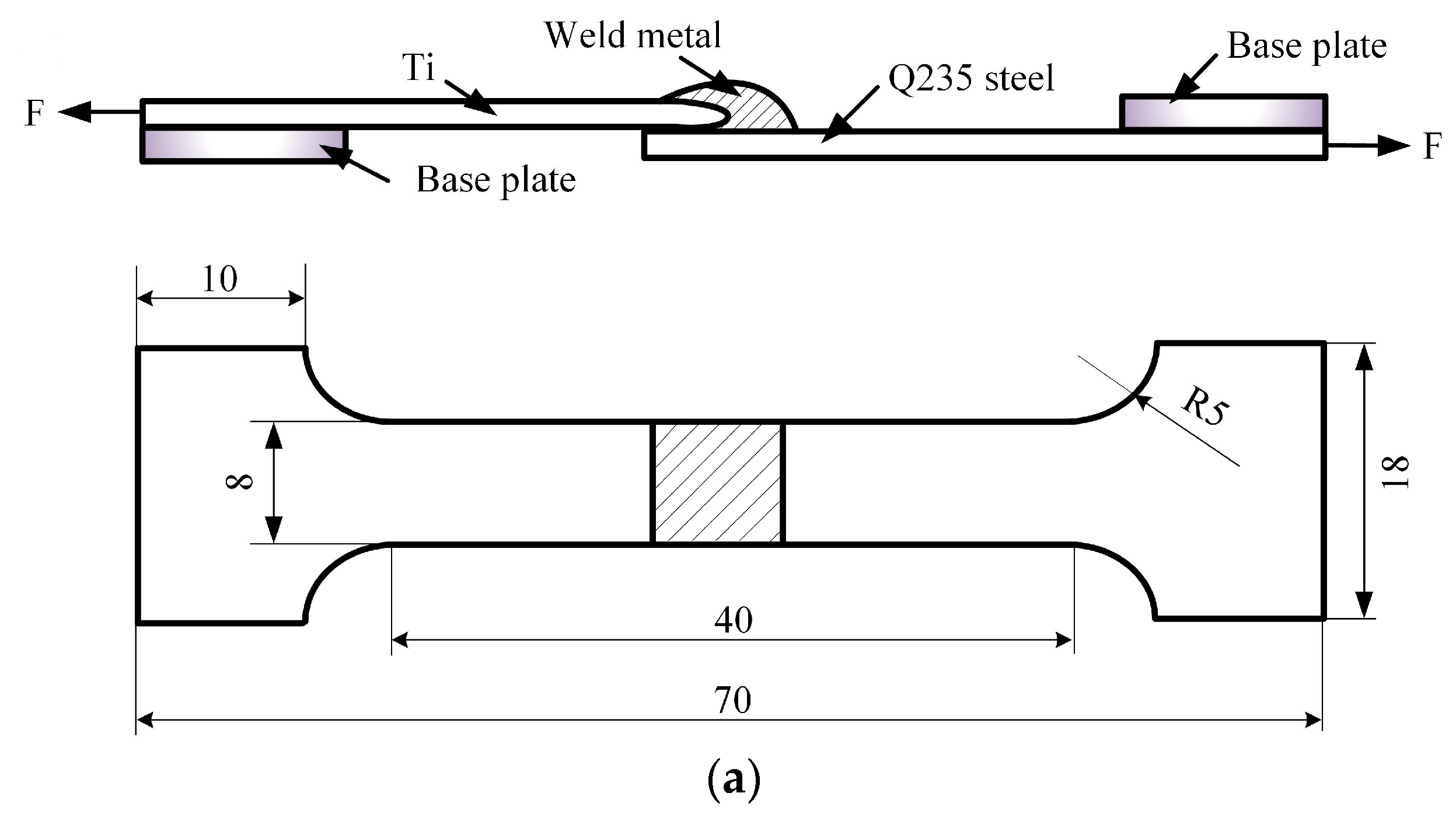

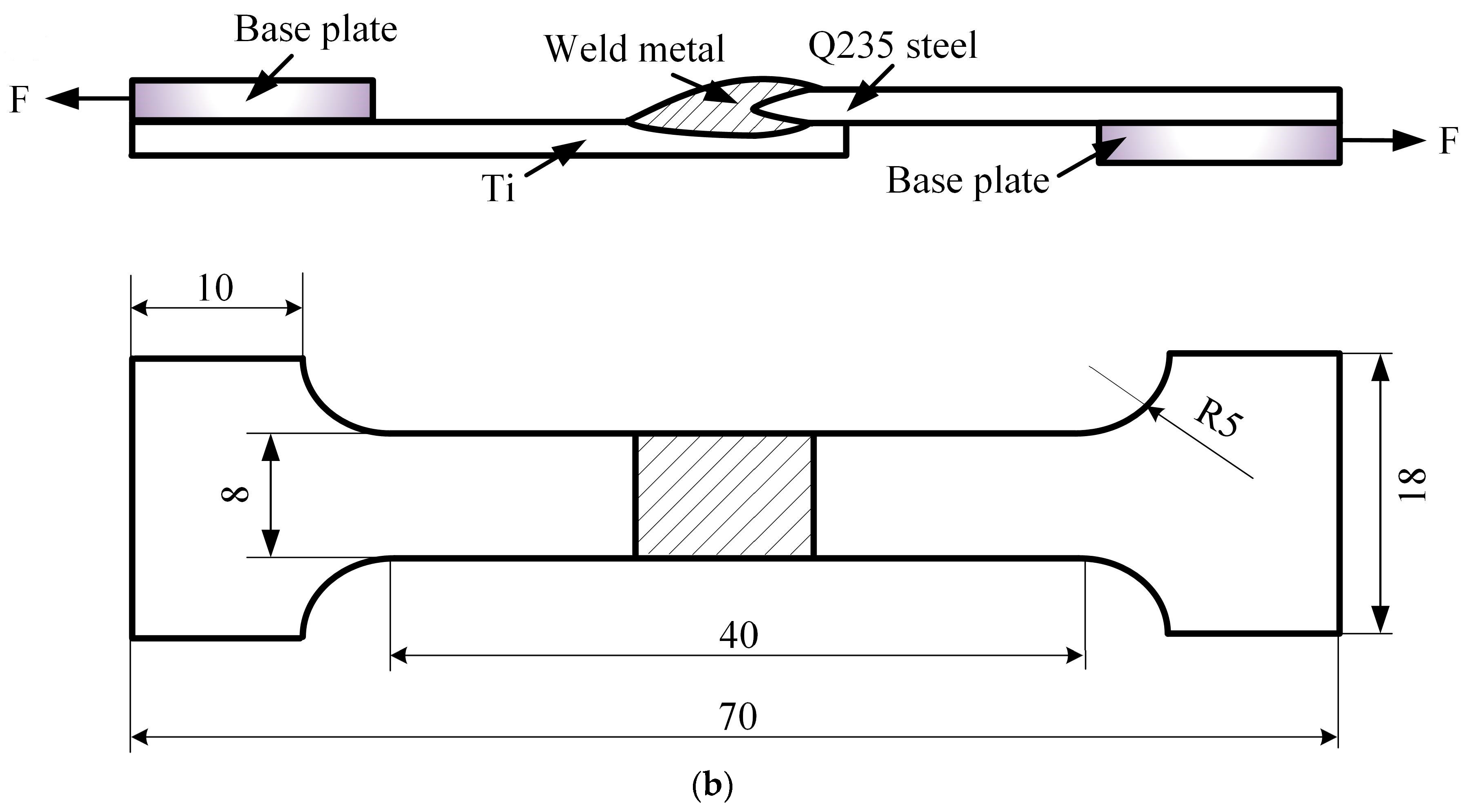

2.4. Mechanical Testing

3. Results

3.1. The Weld Appearance of Joints

3.2. Joining Mechanism of Joints

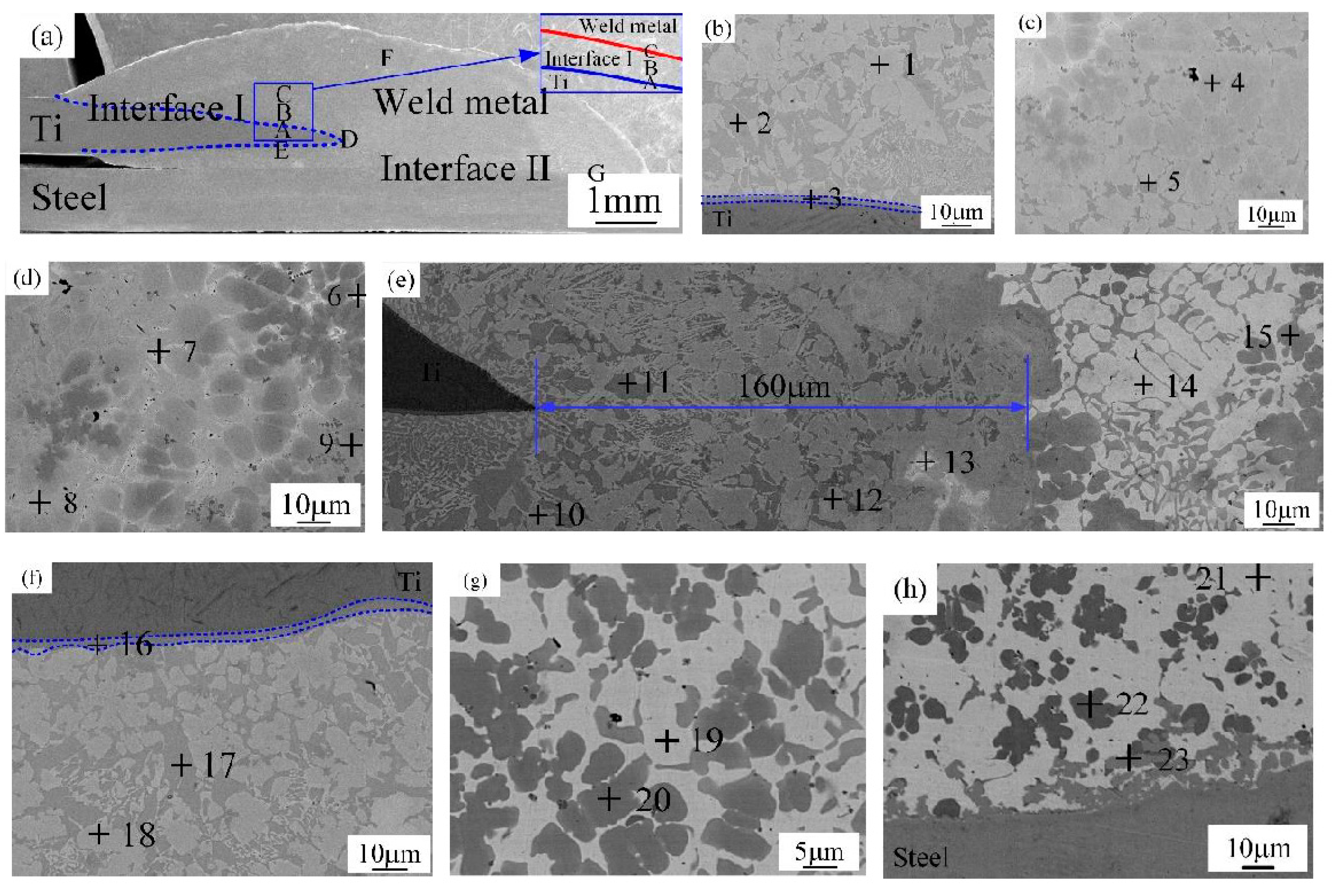

3.2.1. Joint I (Top Ti-TA2 to Bottom Q235 Steel Lapped Joint)

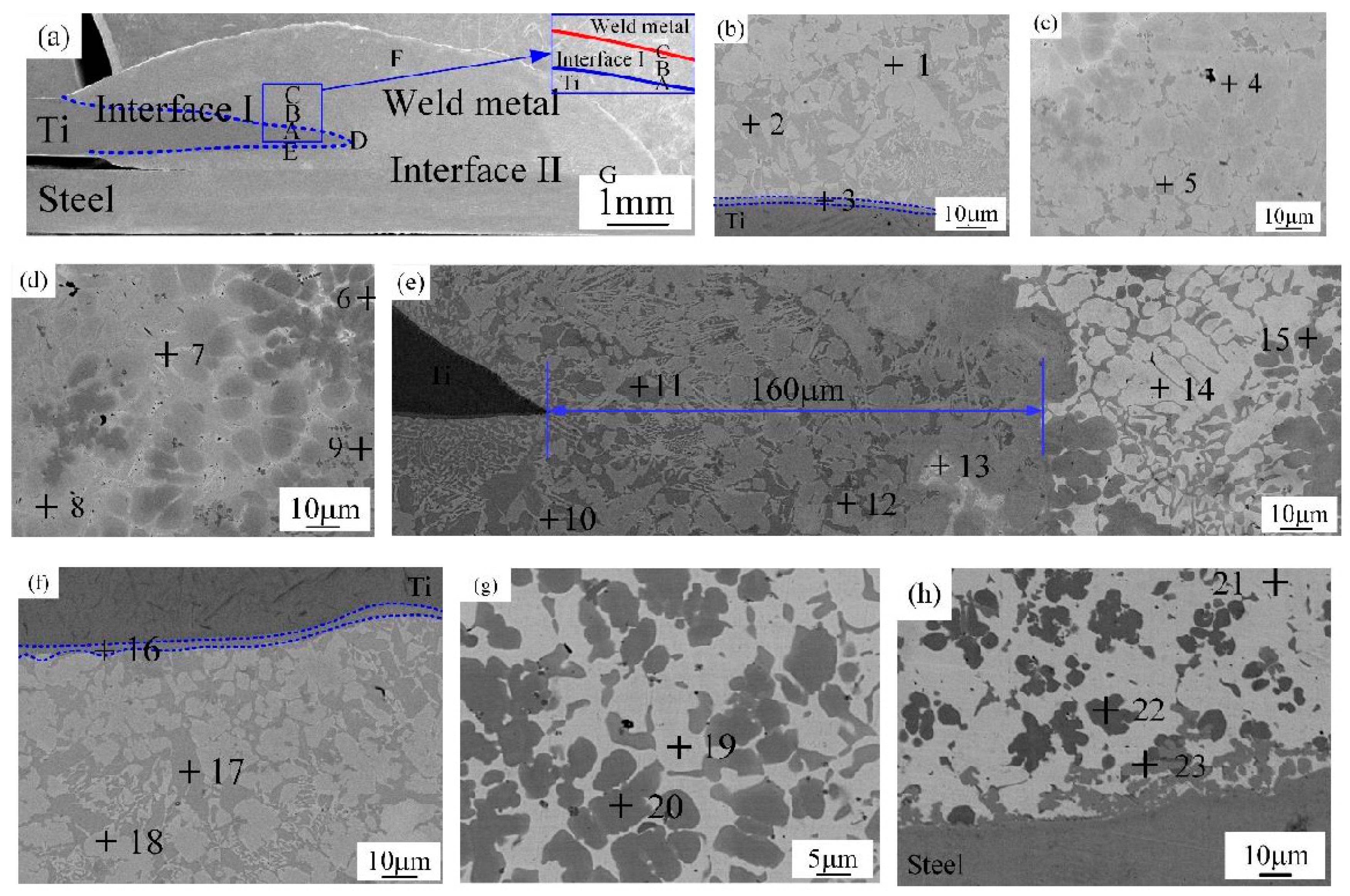

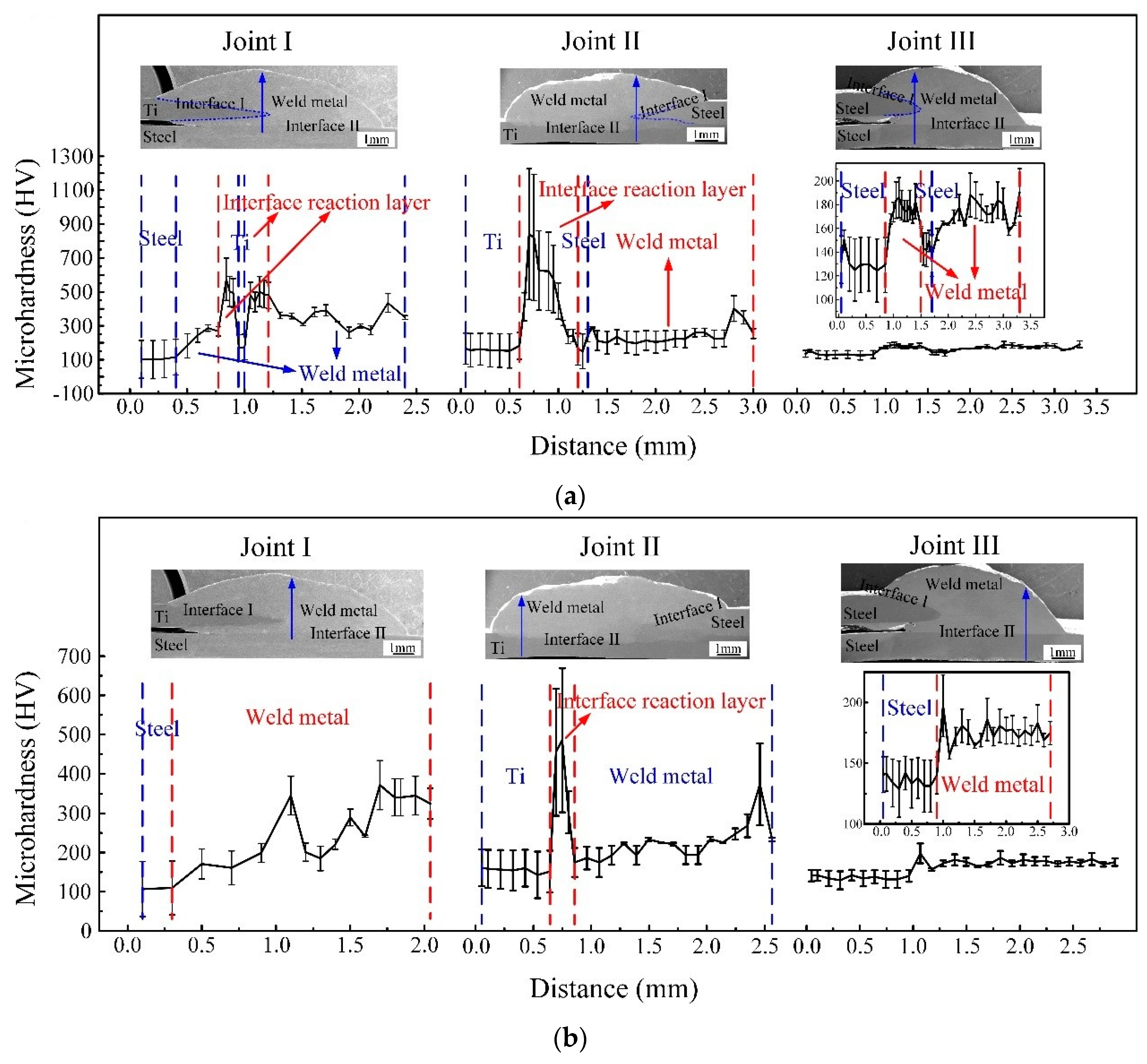

3.2.2. Joint II (Top Q235 Steel to Bottom Ti-TA2 Lapped Joint)

3.2.3. Joint III (Q235 Steel to Q235 Steel Lapped Joint)

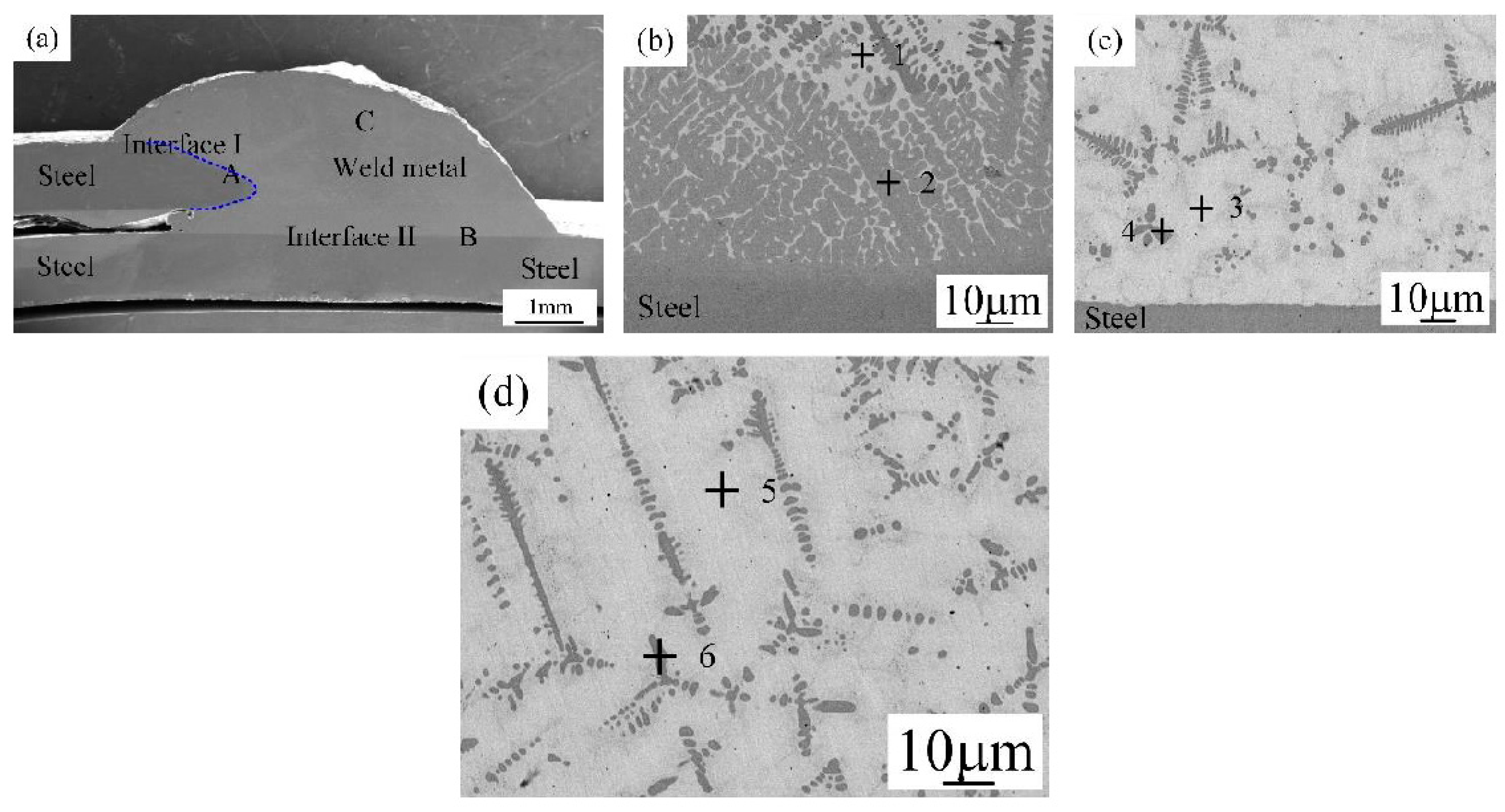

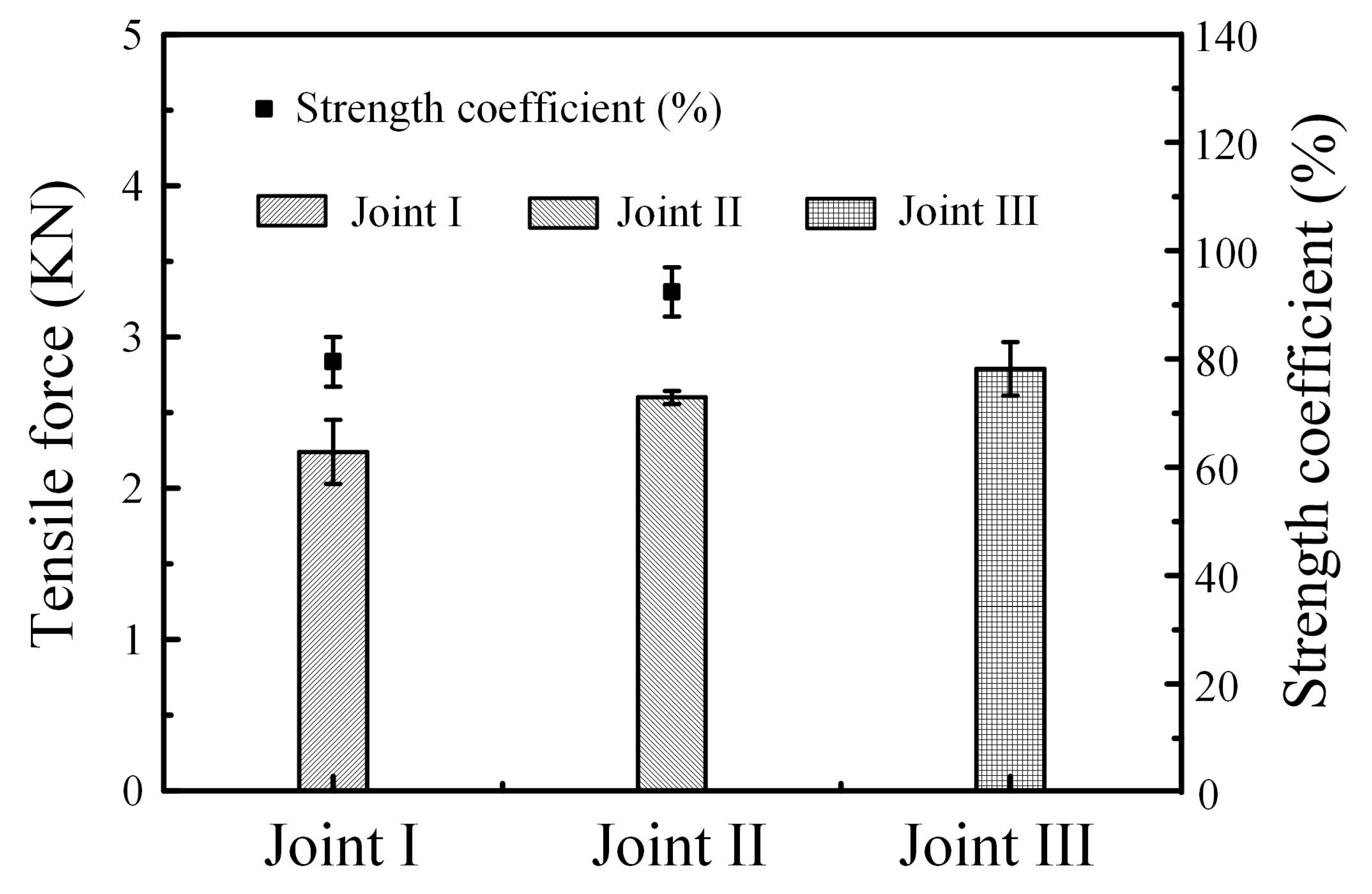

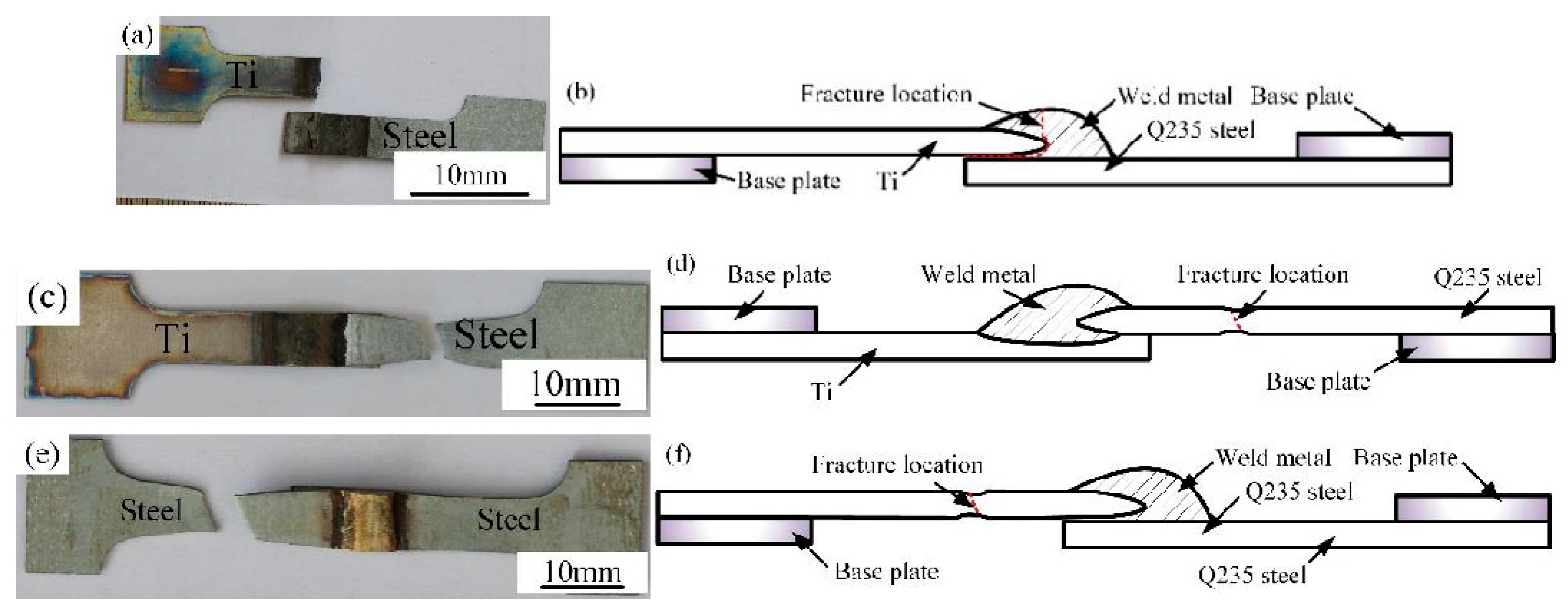

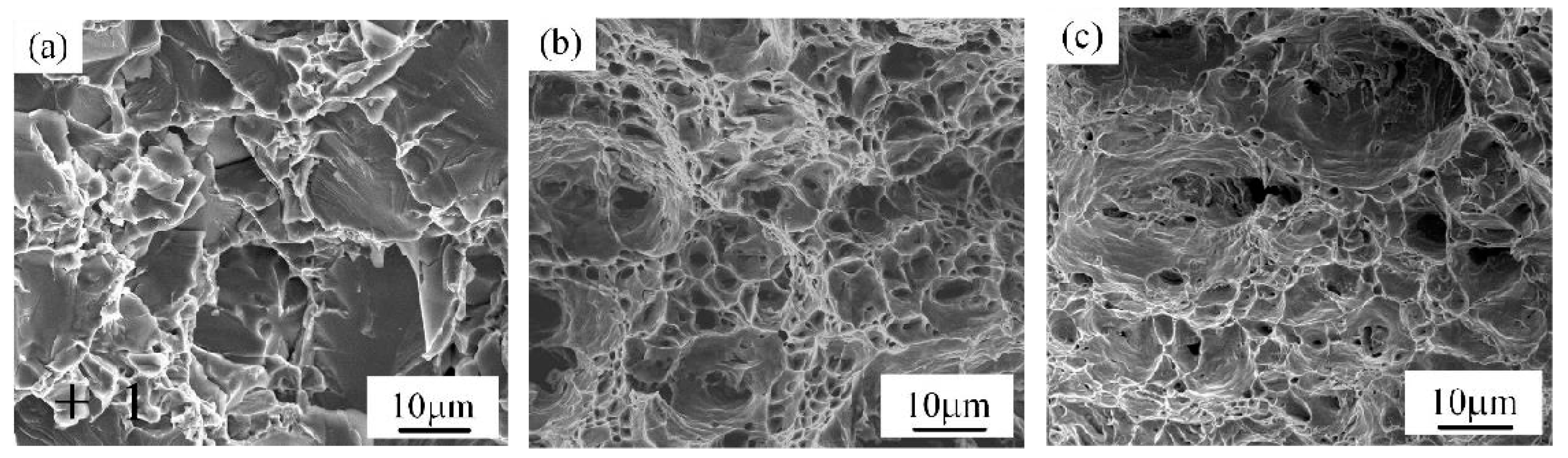

3.3. Mechanical Properties of Joints

4. Discussion

4.1. The Effect of the Stacking Order on the Joining Mechanism of the Ti-Steel Joints

4.2. The Effect of the Stacking Order on the Tensile Force of the Ti-Steel Joints

5. Conclusions

- (1)

- A large number of Ti-Cu IMCs are formed at the Ti-Cu weld metal interface in top Ti-TA2 to bottom Q235 steel lapped joint, causing a significant increase in the micro-hardness of interface reaction layers than weld metal.

- (2)

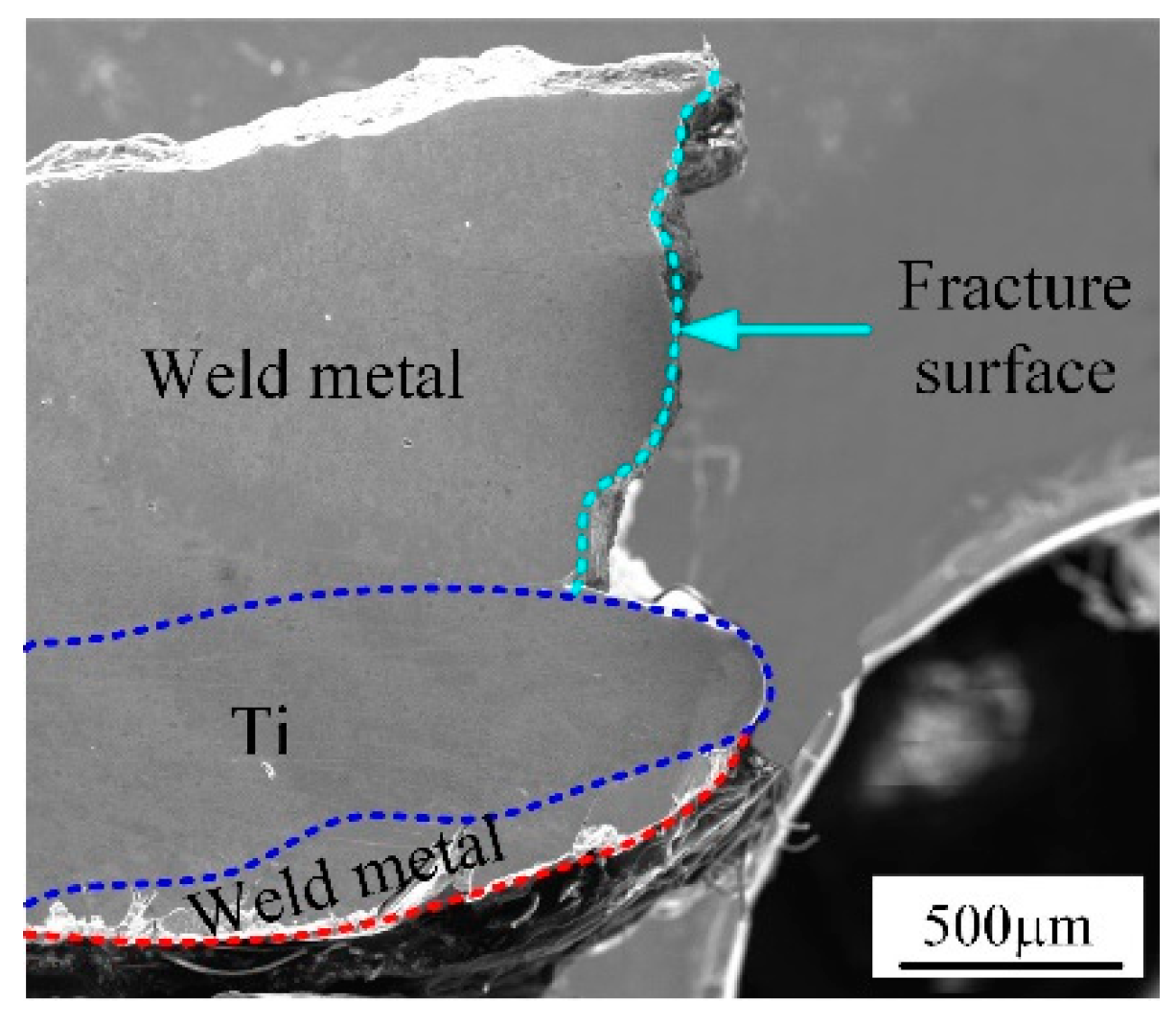

- The strength of the top Ti-TA2 to bottom Q235 steel lapped joint has the reduction due to the increasing volume fraction of Ti-Cu IMCs and an interface reaction layer with the thickness of 160 µm interface reaction layer. Additionally, the fracture is initiated at the Ti-Cu weld metal interface between the weld metal and Ti base metal, then propagated to weld metal, and finally fractured.

- (3)

- The difference in microstructure of joints is responsible for the variation of tensile force. Maximum tensile force of 2.6 KN could be obtained in top Q235 steel to bottom Ti-TA2 lapped joint, which could reach up to 93% that of steel-steel joint. It was attributed to the dispersed TiFe2 IMCs strengthening the interface.

- (4)

- The fracture of top Q235 steel to bottom Ti-TA2 lapped joint has a distinct dimple pattern. However, the fracture of top Ti-TA2 to bottom Q235 steel lapped joint exhibits a cleavage fracture mode containing AlCu2Ti IMCs.

Author Contributions

Funding

Conflicts of Interest

References

- Guo, S.; Zhou, Q.; Peng, Y.; Xu, X.; Diao, C.; Kong, J.; Luo, T.; Wang, K.; Zhu, J. Study on strengthening mechanism of Ti/Cu electron beam welding. Mater. Des. 2015, 67, 606–614. [Google Scholar] [CrossRef]

- Balasubramanian, M. Application of Box–Behnken design for fabrication of titanium alloy and 304 stainless steel joints with silver interlayer by diffusion bonding. Mater. Des. 2015, 77, 161–169. [Google Scholar] [CrossRef]

- Vigraman, T.; Ravindran, D.; Narayanasamy, R. Effect of phase transformation and intermetallic compounds on the microstructure and tensile strength properties of diffusion-bonded joints between Ti–6Al–4V and AISI 304L. Mater. Des. 2012, 36, 714–727. [Google Scholar] [CrossRef]

- Balasubramanian, M.; Jayabalan, V.; Balasubramanian, V. Developing mathematical models to predict tensile properties of pulsed current gas tungsten arc welded Ti-6Al-4V alloy. Mater. Des. 2008, 29, 92–97. [Google Scholar] [CrossRef]

- Li, X.; Li, J.; Liao, Z.; Jin, F.; Zhang, F.; Xiong, J. Microstructure evolution and mechanical properties of rotary friction welded TC4/SUS321 joints at various rotation speeds. Mater. Des. 2016, 99, 26–36. [Google Scholar] [CrossRef]

- Cao, R.; Huang, Q.; Chen, J.H.; Wang, P.C. Cold metal transfer spot plug welding of AA6061-T6-to-galvanized steel for automotive applications. J. Alloys Compd. 2014, 585, 622–632. [Google Scholar] [CrossRef]

- Liu, J.G.; Cai, W.C.; Liu, L.; Han, J.T.; Liu, J. Investigation of interfacial structure and mechanical properties of titanium clad steel sheets prepared by a brazing-rolling process. Mater. Sci. Eng. A 2017, 703, 386–398. [Google Scholar] [CrossRef]

- Li, C.; Shi, Y.; Gu, Y.; Yuan, P. Monitoring weld pool oscillation using reflected laser pattern in gas tungsten arc welding. Mater. Des. 2018, 255, 876–885. [Google Scholar] [CrossRef]

- Liu, K.; Li, Y.; Wang, J. Improving the Interfacial Microstructure Evolution of Ti/Stainless Steel GTA Welding Joint by Employing Cu Filler Metal. Mater. Manuf. Process. 2016, 31, 2165–2173. [Google Scholar] [CrossRef]

- Li, P.; Li, J.; Salman, M.; Liang, L.; Xiong, J.; Zhang, F. Effect of friction time on mechanical and metallurgical properties of continuous drive friction welded Ti6Al4V/SUS321 joints. Mater. Des. 2014, 56, 649–656. [Google Scholar] [CrossRef]

- Akbarimousavi, S.A.A.; GohariKia, M. Investigations on the mechanical properties and microstructure of dissimilar cp-titanium and AISI 316L austenitic stainless steel continuous friction welds. Mater. Des. 2011, 32, 3066–3075. [Google Scholar] [CrossRef]

- Kundu, S.; Roy, D.; Chatterjee, S.; Olson, D.; Mishra, B. Influence of interface microstructure on the mechanical properties of titanium/17-4 PH stainless steel solid state diffusion bonded joints. Mater. Des. 2012, 37, 560–568. [Google Scholar] [CrossRef]

- Velmurugan, C.; Senthilkumar, V.; Sarala, S.; Arivarasan, J. Low temperature diffusion bonding of Ti-6Al-4V and duplex stainless steel. J. Mater. Process. Technol. 2016, 234, 272–279. [Google Scholar] [CrossRef]

- Kundu, S.; Mishra, B.; Olson, D.L.; Chatterjee, S. Interfacial reactions and strength properties of diffusion bonded joints of Ti64 alloy and 17-4PH stainless steel using nickel alloy interlayer. Mater. Des. 2013, 51, 714–722. [Google Scholar] [CrossRef]

- Cherepanov, A.N.; Mali, V.I.; Maliutina, I.N.; Orishich, A.M.; Malikov, A.G.; Drozdov, V.O. Laser welding of stainless steel to titanium using explosively welded composite inserts. Int. J. Adv. Manuf. Technol. 2016, 90, 3037–3043. [Google Scholar] [CrossRef]

- Lee, J.G.; Lee, M.K. Microstructure and mechanical behavior of a titanium-to-stainless steel dissimilar joint brazed with Ag-Cu alloy filler and an Ag interlayer. Mater. Charact. 2017, 129, 98–103. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, B.; Wang, H.; Feng, J. Microstructures and Mechanical Properties of Electron Beam-Welded Titanium-Steel Joints with Vanadium, Nickel, Copper and Silver Filler Metals. J. Mater. Eng. Perform. 2014, 23, 1498–1504. [Google Scholar] [CrossRef]

- Reichardt, A.; Dillon, R.P.; Borgonia, J.P.; Shapiro, A.A.; McEnerney, B.W.; Momose, T.; Hosemann, P. Development and characterization of Ti-6Al-4V to 304L stainless steel gradient components fabricated with laser deposition additive manufacturing. Mater. Des. 2016, 104, 404–413. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Grevey, D.; Sallamand, P. Dissimilar laser welding of AISI 316L stainless steel to Ti6-Al4-6V alloy via pure vanadium interlayer. Mater. Sci. Eng. A 2015, 622, 37–45. [Google Scholar] [CrossRef]

- Jing, Y.; Yang, Q.; Xiong, W.; Huang, B.; Li, B.; Zhang, M. Microstructure and shear strength of brazed joints between Ti(C, N)-based cermet and steel with Cu-Ag-Ti filler metal. J. Alloys Compd. 2016, 682, 525–530. [Google Scholar] [CrossRef]

- Cao, R.; Feng, Z.; Chen, J.H. Microstructures and properties of titanium–copper lap welded joints by cold metal transfer technology. Mater. Des. 2014, 53, 192–201. [Google Scholar] [CrossRef]

- Cao, R.; Wen, B.F.; Chen, J.H.; Wang, P.C. Cold Metal Transfer joining of magnesium AZ31B-to-aluminum A6061-T6. Mater. Sci. Eng. A 2013, 560, 256–266. [Google Scholar] [CrossRef]

- Cao, R.; Yu, G.; Chen, J.H.; Wang, P.C. Cold metal transfer joining aluminum alloys-to-galvanized mild steel. J. Mater. Process. Technol. 2013, 213, 1753–1763. [Google Scholar] [CrossRef]

- Cao, R.; Chang, J.H.; Zhu, H.X.; Mao, G.J.; Xu, Q.W.; Shi, Y.; Chen, J.H.; Wang, P.C. Investigation of wire selection for CMT plug joining Mg AZ31-to-galvanized steel. J. Manuf. Process. 2018, 32, 65–76. [Google Scholar] [CrossRef]

- Cao, R.; Chang, J.H.; Huang, Q.; Zhang, X.B.; Yan, Y.J.; Chen, J.H. Behaviors and effects of Zn coating on welding-brazing process of Al-Steel and Mg-steel dissimilar metals. J. Manuf. Process. 2018, 31, 674–688. [Google Scholar] [CrossRef]

- BS EN ISO 6507–1 (2005); Metallic Materials—Vickers Hardness Test—Part 1: Test Method; Br Stand 20; BSI: London, UK, 2005.

- Massalski, T.B. Binary Alloy Phase Diagrams; Materials Park, ASM International: Novelty, OH, USA, 1990. [Google Scholar]

- Prince, A.; Villars, P.; Okamoto, H. Handbook of Ternary Phase Alloys; Materials Park, ASM International: Novelty, OH, USA, 1995. [Google Scholar]

- Cao, R.; Feng, Z.; Lin, Q.; Chen, J.H. Study on cold metal transfer welding–brazing of titanium to copper. Mater. Des. 2014, 56, 65–173. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, Q.; Liu, J.; Wang, S.; Feng, J. Effect of axial external magnetic field on cold metal transfer welds of aluminum alloy and stainless steel. Mater. Lett. 2015, 152, 29–31. [Google Scholar] [CrossRef]

- Chen, R.; Wang, C.; Jiang, P.; Shao, X.; Zhao, Z.; Gao, Z.; Yue, C. Effect of axial magnetic field in the laser beam welding of stainless steel to aluminum alloy. Mater. Des. 2016, 109, 146–152. [Google Scholar] [CrossRef]

- Shen, Q.; Xiang, H.; Luo, G.; Wang, C.; Li, M.; Zhang, L. Microstructure and mechanical properties of TC4/oxygen-free copper joint with silver interlayer prepared by diffusion bonding. Mater. Sci. Eng. A 2014, 596, 45–51. [Google Scholar] [CrossRef]

- Tashi, R.S.; Mousavi, S.; Atabaki, M.M. Diffusion brazing of Ti-6Al-4V and austenitic stainless steel using silver-based interlayer. Mater. Des. 2014, 54, 161–167. [Google Scholar] [CrossRef]

| Materials | Tm/°C | α/K−1 | λ/W(m·K)−1 | ρ/g∙cm−3 | Crystal Lattice | σb/MPa |

|---|---|---|---|---|---|---|

| TA2 | 1668 | 8.2 × 10−6 | 13.8 | 4.5 | bcc/hcp | 495 |

| Q235 | 1535 | 11.5 × 10−6 | 66.7 | 7.86 | bcc/fcc | 235 |

| Materials | Element (wt. %) | ||||||

|---|---|---|---|---|---|---|---|

| TA2 | Fe | C | N | H | O | Ti | |

| 0.3 | 0.1 | 0.05 | 0.0015 | 0.25 | Bal. | ||

| Hot dipped galvanized mild Q235 steel | C | Si | Mn | P | S | Fe | Hot dipping Zn-coating (g∙m−2) |

| 0.01 | 0.01 | 0.39 | 0.30 | 0.025 | Bal. | 60 | |

| ERCuNiAl | Al | Ni | Fe | Pb | Mn | Cu | |

| 8.0 | 6.0 | 3.0 | 0.038 | 1.0 | Bal. | ||

| Sample No. | Wire-Feeder Speed (m∙min−1) | Weld Speed (mm∙s−1) | Heat Input (KJ∙mm−1) | Lap Jointing Type | Filler Metal |

|---|---|---|---|---|---|

| #1 | 6 | 8.53 | 0.170 | type I | ERCuNiAl |

| #2 | 6 | 8.53 | 0.170 | type II | ERCuNiAl |

| #3 | 6 | 8.53 | 0.170 | – | ERCuNiAl |

| #4 | 6 | 8.53 | 0.170 | – | ERCuNiAl |

| Point. | Al | Si | Ti | Fe | Cu | Zn | Ni | Possible Phase |

|---|---|---|---|---|---|---|---|---|

| 1 | 6.68 | 0.34 | 47.15 | 8.58 | 34.55 | 1.24 | 3.47 | CuTi2 and AlTi3 |

| 2 | 7.49 | 0.43 | 59.91 | 0.71 | 30.89 | – | 1.57 | CuTi2 |

| 3 | 1.87 | 1.13 | 83.48 | 1.63 | 10.77 | – | 1.12 | CuTi2 and α-Ti |

| 4 | 21.50 | 0.21 | 26.09 | 5.24 | 45.44 | 0.88 | 0.65 | AlCu2Ti |

| 5 | 7.15 | 0.92 | 58.31 | 0.69 | 31.78 | 0.57 | 0.59 | CuTi2 |

| 6 | 3.26 | 0.87 | 7.5 | 1.17 | 83.02 | 0.92 | 3.25 | Cu solid solution |

| 7 | 1.99 | 0.23 | 28.26 | 1.07 | 64.39 | 2.41 | 1.65 | Ti2Cu3 and βTiCu4 |

| 8 | 1.28 | 0.67 | 37.16 | 2.82 | 53.08 | 1.53 | 3.46 | Ti2Cu3 and Ti3Cu4 |

| 9 | 20.86 | 0.71 | 26.31 | 4.26 | 47.14 | – | 0.72 | AlCu2Ti |

| 10 | 7.84 | – | 44.54 | 7.58 | 34.49 | 1.21 | 4.35 | CuTi2 and AlTi3 |

| 11 | 6.37 | – | 59.14 | 1.18 | 32.37 | – | 0.95 | CuTi2 |

| 12 | 22.52 | – | 26.38 | 1.87 | 47.18 | – | 2.05 | AlCu2Ti |

| 13 | 1.76 | – | 33.62 | 1.12 | 62.25 | – | 1.25 | Ti2Cu3 and βTiCu4 |

| 14 | 10.29 | – | 2.25 | 1.19 | 84.87 | – | 1.40 | (Cu) and Al3Ti |

| 15 | 22.91 | – | 24.85 | 17.70 | 22.48 | 0.95 | 11.12 | Al-Ti-Cu-Fe-Ni phase |

| 16 | 2.80 | 0.77 | 82.02 | 1.76 | 11.06 | 0.83 | 0.76 | CuTi2 and α-Ti |

| 17 | 8.61 | – | 56.06 | 1.51 | 29.87 | 1.53 | 2.42 | CuTi2 |

| 18 | 7.82 | – | 45.23 | 8.27 | 34.09 | 0.88 | 3.70 | CuTi2 and AlTi3 |

| 19 | 11.30 | – | 2.69 | 1.02 | 81.64 | 2.21 | 1.15 | (Cu) and Al3Ti |

| 20 | 24.95 | – | 23.84 | 18.25 | 22.19 | 0.58 | 10.19 | Al-Ti-Cu-Fe-Ni phase |

| 21 | 13.73 | 0.49 | 1.03 | 1.75 | 78.63 | 2.57 | 1.69 | (Cu) and Al3Ti |

| 22 | 23.86 | 0.42 | 23.39 | 20.40 | 17.49 | 0.68 | 13.75 | Al-Ti-Cu-Fe-Ni phase |

| 23 | 7.25 | 1.50 | 24.06 | 51.33 | 12.16 | 1.30 | 2.40 | Fe-Ti-Cu IMCs |

| Point. | Al | Si | Ti | Fe | Cu | Zn | Ni | Possible Phase |

|---|---|---|---|---|---|---|---|---|

| 1 | 17.36 | 1.27 | 1.29 | 6.37 | 70.53 | 0.55 | 2.62 | (Cu) and Al3Ti |

| 2 | 12.01 | 0.54 | 6.87 | 64.87 | 11.31 | 1.21 | 3.19 | Fe-Al-Cu IMCs |

| 3 | 2.35 | – | 30.64 | 62.46 | 2.24 | 2.30 | – | TiFe2 |

| 4 | 15.34 | – | 1.75 | 4.50 | 75.77 | – | 2.65 | (Cu) and Al3Ti |

| 5 | 15.32 | – | 7.58 | 60.60 | 13.09 | – | 3.41 | Fe-Al-Cu IMCs |

| 6 | 28.88 | – | 21.65 | 20.24 | 14.23 | – | 15.00 | Al-Ti-Cu-Fe-Ni phase |

| 7 | 16.87 | – | 1.43 | 2.26 | 77.27 | 0.48 | 1.69 | (Cu) and Al3Ti |

| 8 | 11.21 | 0.88 | 62.92 | 4.61 | 16.88 | 1.41 | 2.10 | (Ti)(HT) |

| 9 | 7.14 | 0.77 | 56.79 | 1.71 | 29.38 | 1.72 | 2.49 | CuTi2 |

| 10 | 7.64 | 1.78 | 51.44 | 11.77 | 24.50 | 0.52 | 2.35 | Fe-Ti-Cu IMCs |

| 11 | 2.10 | 1.64 | 80.45 | 1.24 | 11.97 | – | 1.43 | CuTi2 and α-Ti |

| Point. | Al | Fe | Cu | Zn | Ni | Possible Phase |

|---|---|---|---|---|---|---|

| 1 | 15.00 | 9.63 | 68.54 | 3.42 | 3.42 | (Cu) and Al3Ti |

| 2 | 8.18 | 76.60 | 11.55 | 1.71 | 1.95 | Fe-Al-Cu IMCs |

| 3 | 18.47 | 4.20 | 69.04 | 3.62 | 4.67 | (Cu) and Al3Ti |

| 4 | 18.07 | 59.73 | 13.43 | 2.59 | 6.19 | Fe-Al-Cu IMCs |

| 5 | 16.72 | 3.92 | 72.21 | 3.20 | 3.95 | (Cu) and Al3Ti |

| 6 | 19.35 | 60.74 | 15.38 | – | 4.53 | Fe-Al-Cu IMCs |

| Point. | Al | Si | Ti | Fe | Cu | Zn | Ni | Possible Phase |

|---|---|---|---|---|---|---|---|---|

| 1 | 19.5 | 0.5 | 27.6 | 5.9 | 40.2 | – | 6.3 | AlCu2Ti |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, J.; Cao, R.; Yan, Y. The Joining Behavior of Titanium and Q235 Steel Joined by Cold Metal Transfer Joining Technology. Materials 2019, 12, 2413. https://doi.org/10.3390/ma12152413

Chang J, Cao R, Yan Y. The Joining Behavior of Titanium and Q235 Steel Joined by Cold Metal Transfer Joining Technology. Materials. 2019; 12(15):2413. https://doi.org/10.3390/ma12152413

Chicago/Turabian StyleChang, Jinghuan, Rui Cao, and Yingjie Yan. 2019. "The Joining Behavior of Titanium and Q235 Steel Joined by Cold Metal Transfer Joining Technology" Materials 12, no. 15: 2413. https://doi.org/10.3390/ma12152413