Abstract

YFeO3, YFe0.95Co0.05O3, Y0.95Gd0.05FeO3 and Y1−xGdxFe0.95Co0.05O3 (x = 0.0, 0.05, 0.10, 0.15 and 0.20) nanopowders were successfully fabricated via a low-temperature solid-state reaction technique. Results obtained using X-ray diffraction (XRD), scanning electron microscopy (SEM), and Raman spectra indicate that YFeO3 nanopowders with Gd3+ and Co3+ ions co-doping at Y and Fe-sites were fabricated at 800 °C in sizes below 50 nm, and a distorted structure was obtained. Magnetic hysteresis loop analyses illustrate that ferromagnetic behavior of YFeO3 nanopowders can be enhanced with the addition of Gd and Co. Whereas the maximum and remnant magnetization of the powders were found to be about 5.24 and 2.6 emu/g, respectively, the optical band gap was around 2.4 eV, proving that co-doped YFeO3 nanopowders have a strong capability to absorb visible light. Because both magnetic and optical properties of these materials are greatly improved with the addition of Gd and Co, one can expect the scope of their potential application in the magnetic and optical fields to increase.

1. Introduction

As one of the cutting edge multiferroic materials, AFeO3 (A = La, Y and Sc) materials have been the focus of industry research because of their couple orderings of ferroelectricity and anti-ferromagnetism. As a result, they have great potential application in data storage, information exchange, and 5G mobile phone systems [1]. YFeO3 is one of the most promising applications of rare earth AFeO3 materials [2]. YFeO3 has been reported to feature molecular ferroelectricity at low temperatures (10–40 K), good dielectric and magnetic properties [3,4,5,6], and is also becoming one of the most widely investigated multiferroic materials. Moreover, with a narrow optical gap (1.9–2.6 eV), its potential application as an optical material, especially decomposing organics should be considered for further study [7]. However, pristine YFeO3 is not easy to prepare as evident by problems such as the introduction of secondary phases and the hopping of charge between Fe2+ and Fe3+ [8,9,10], while its low magnetism characteristics [11] are possibly its main shortcoming. Studies show that an effective and efficient way [11,12,13] to overcome these problems, is by means of doping. Some scientists substituted Y by divalent and trivalent ions [14,15] and Fe by trivalent and high-valence ions [16]. While the use of Gd doping is rarely reported, one study showed that with Gd doping on the Y site, significant enhancement of magnetization was achieved. In addition, use of other-element doping on the Y site has the potential for improvement of the material’s optical properties [15]. For Fe-site ion doping, the main improvement focus was the reduction of leakage current and the enhancement of magnetic properties. It is known [17] that Y(Fe,Cr)O3 showed evidence of ferromagnetic property. Ma et al. [18] synthesized Mn doped YFeO3 by using a standard solid-state reaction method. Their findings showed that the leakage current was reduced so that ferroelectric properties are realized at room temperature.

Co doping may enhance the magnetic properties of RFeO3 material because it is magnetically active. While there is no report of co-doping of Co and Gd, the purpose of this paper is the study of co-doping of Co and Gd on YFeO3 with a particular emphasis on the microstructural, optical, and magnetic properties of the doped YFeO3 nanopowders.

2. Experimental Procedures

YFeO3 (abbreviated as YFO), YFe0.95Co0.05O3 (Co5), Y0.95Gd0.05FeO3 (Gd5), Y0.95Gd0.05Fe0.95Co0.05O3 (Gd5Co5), Y0.9Gd0.1Fe0.95Co0.05O3 (Gd10Co5), Y0.85Gd0.15Fe0.95Co0.05O3 (Gd15Co5), and Y0.8Gd0.2Fe0.95Co0.05O3 (Gd20Co5) nanoparticles were synthesized using a low-temperature solid-state reaction technique as described in Ref. [19]. The raw reagents include Fe(NO3)3∙9H2O, Y(NO3)3∙6H2O, Co(NO3)2·6H2O, Gd(NO3)3·6H2O, and citric acid. Initially, Fe(NO3)3∙9H2O, Y(NO3)3∙6H2O and citric acid were weighed stoichiometrically and ground in an agate mortar for half an hour, respectively. The respective powders were then mixed and ground again in an agate mortar for half an hour. A light brown viscous substance was formed during the grinding process, implying that the complex was formed. The viscous substance was heated at 120 °C for 2 h to remove free water and then a powdery composite was harvested, serving as the precursor powders. The powders were ground and subsequently calcined for 1 h in air at 800 °C to provide the nanoparticles. The crystal structures and morphology of the calcined particles were examined using XRD (D/max-RB, Rigaku, Tokyo, Japan) and SEM (S-4700, Hitachi, Tokyo, Japan). Raman spectra (InVia Reflex, Renishaw, London, UK spectrometer) were measured at room temperature with a range of 100 cm−1 to 1500 cm−1. Magnetic hysteresis loops were measured using PPMS (Physical Property Measurement System, DynaCool-9T, Quantum Design, Leatherhead, Surrey, UK). Optical absorbance properties of the experimental nanopowders were examined using a UV-Visible spectrophotometer (Shimadzu, UV-2600, Kyoto, Japan).

3. Results and Discussions

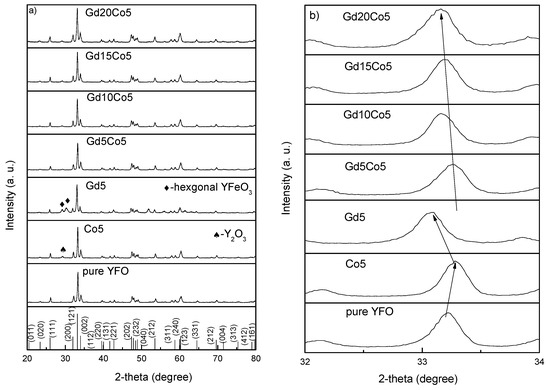

Figure 1a presents the XRD patterns of the tested (0 ≤ x ≤ 0.2) samples calcined at 800 °C. The pattern for the pristine YFeO3 nanopowders suggests the presence of the obvious orthorhombic YFeO3 pattern and that no minor impurity peaks were present. This outcome shows that the synthesis reaction for the orthorhombic structure was completed and the purity was high. The doped nanopowders indicate the same characteristic shape as that of the pristine YFeO3 patterns with a slight shift in the peak position and phase. For Gd5, some peaks for the hexagonal YFeO3 structure emerged. For Co5, peaks for Y2O3 appeared, showing that some minor impurity was introduced. This is a normal situation involving the case where instability of YFeO3 exists and which is due to the radius difference. However, this effect totally disappears for the Co-Gd co-doped sample. Figure 1b shows the YFeO3 peaks at 2θ ~33°, shifting toward a higher 2θ angle with substitution of Co into YFeO3. The figure also shows a shift towards a lower 2θ angle with further substitution of Gd into YFeO3, and while keeping almost the same position of Gd and Co-doped samples due to Gd3+ (Gd3+ 0.938 Å) possessed a larger ionic radii compared with Y3+ (Y3+ 0.9 Å), and Co3+ (Co3+ 0.61 Å) possessed a smaller one compared with Fe3+ (Fe3+ 0.645 Å) [15,20]. Thus, it is evident that Gd3+ and Co3+ replaced the Y3+ and Fe3+ ions in YFeO3, respectively. The XRD pattern shows the highest peak for the Co-doped particles and its 2θ angle location is nearly identical to that of pure YFO. The stress introduced by the change in radius was reduced so that impurities disappeared.

Figure 1.

(a) XRD patterns of as-prepared nanoparticles calcined at 800 °C; (b) the magnified patterns of peaks at 2θ ~32°.

Table 1 shows the lattice parameters with different Co and Gd concentrations. All these values increased with increase in Gd content and decreased with Co addition. This behavior demonstrates that the replacement of Y3+ with Gd3+ results in the increase of the lattice volume of YFeO3 (rGd3+ > rY3+), whereas the replacement of Fe3+ with Co3+ results in the decrease of YFeO3 volume (rCo3+ < rFe3+). The continuous evolution of lattice parameters with increasing Gd and Co concentrations also shows the presence of a successful substitution of Y3+ and Fe3+ ions by Gd3+ and Co3+ ions.

Table 1.

Lattice parameters and volume of the samples.

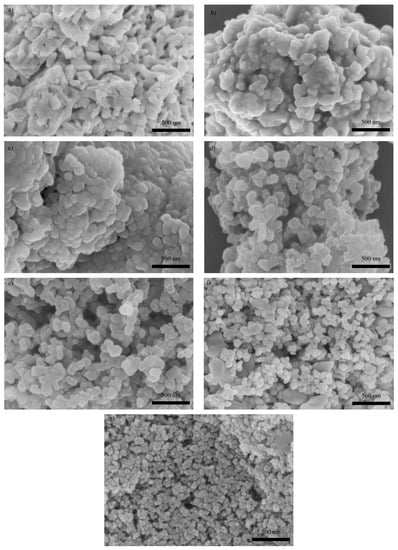

SEM images of YFeO3 nanopowders are shown in Figure 2. These demonstrate that the particle sizes of the test nanopowders were homogeneous with some minor agglomeration. The particle sizes of the test samples of YFO, Co5, Gd5, Co5Gd5, Co5Gd10, Co5Gd15 and Co5Gd20 were approximately 150, 120, 95, 80, 75, 45 and 40 nm, respectively. From the results obtained, it is apparent that the Co and Gd substitution decreased the grain size, while particle size decreased significantly with Co and Gd co-doping. As is well known, whenever the diffusion rate is low, rare earth ions can inhibit grain growth of RFeO3 [11]. In addition, Gd3+ ions (radius of 0.983 Å) are larger than Y3+ ions (radius of 0.9 Å). The mismatch of ion sizes introduces defects in the lattice, leading to particle refinement. In addition, Co3+ can suppress hopping of Fe2+ and Fe3+, depriving the oxygen vacancy and subsequently preventing growth of the grains [21]. Some agglomeration of particles appears in Co and Gd co-doping samples, and may be attributed to the large surface area to volume ratio of the nanoparticles. The latter is to be expected whenever the low-temperature solid-state reaction method is used. Similar effects of grain refinement induced by rare earth and magnetic element co-doping has been reported in other references [14,17,21,22].

Figure 2.

SEM micrographs of as-prepared nanoparticles: (a) YFO; (b) Co5; (c) Gd5; (d) Gd5Co5; (e) Gd10Co5; (f) Gd15Co5; (g) Gd20Co5.

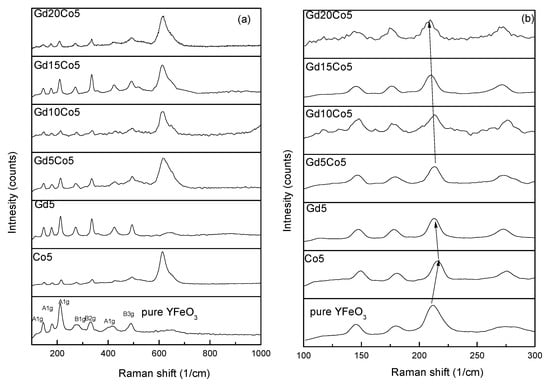

Figure 3 shows the Raman patterns obtained from the YFeO3 powders. As is well known, for the case involving the Pnma structure of YFeO3, only modes of A1g, B1g, B2g, and B3g are active. Furthermore, one can say with a high degree of certainty that the first and second A1g modes are associated with Y–O bonds, and the A1g and Bg modes are related to Fe-O bonds at higher frequencies [23]. The 221 cm−1 A1g mode is represented as an FeO6 octahedral structure [9,10,24]. The vibrating modes of Co5 were similar to those of pure YFO, while the intensity was reduced slightly and the peak at 610 cm−1 increased as expected owing to the minor change of Fe–O bonds resulting from the doping of the Co element. For the case involving substitution of Gd3+ for Y3+, the parameters of lattice (grain size) increased, leading to a shift in the Raman bands to a lower wave-number. Raman bands were found to broaden with increase of Gd3+ and Co3+ (in YFeO3) because of the disorder introduced by two different cations. The Gd–O and Y–O bonds, with their inherent different strengths, can influence their vibration frequencies. In general, one can state that these results are consistent with the XRD patterns. Thus, it can be concluded that Co and Gd co-doping has a substantial effect on the modification of the YFeO3 structure.

Figure 3.

(a) Raman spectra of as-prepared nanoparticles. (b) The magnified patterns of 221 cm−1.

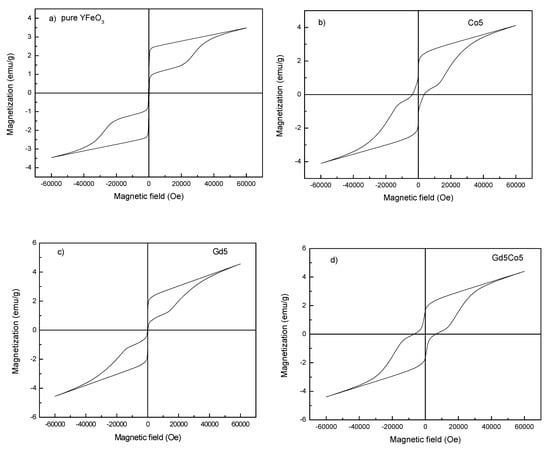

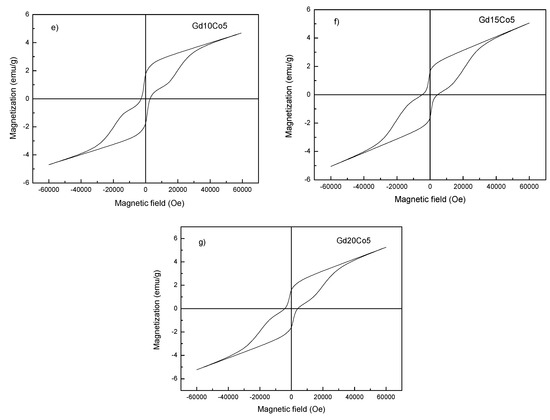

Figure 4 shows the magnetic properties of the nanopowders at room temperature. Values of maximum magnetization (Mm), remnant magnetization (Mr), and the coercive field (Hc) of the test samples are listed in Table 2. As is commonly known, YFeO3 is antiferromagnetic and features weak magnetic properties. In the case of pristine YFeO3, the hysteresis loop is typical weak magnetization in antiferromagnetic type. The magnetization parameters for the pristine YFeO3 sample Mm, Mr, and Hc had magnitudes of 3.50 emu/g, 0.89 emu/g, and 161 Oe. For the case involving the doped samples, a large open region was seen at the center of the hysteresis loops suggesting ferromagnetic behavior. Even when exposed to a 60 kOe outer magnetic field, the loops were not saturated. For Co5, Mm, Mr were slightly improved and Hc was reduced. Their corresponding values were about 4.56 emu/g, 0.95 emu/g and 120 Oe, respectively. For the case of co-doping of Co and Gd, the net magnetization decreased slightly at first, and then began to increase, reaching a high value of 5.24 emu/g for the Co5Gd20 particles. These values are summarized in Table 2. The value of Mr reached a maximum (Mr = 1.66 emu/g) for the Co5Gd5 nanoparticles. The reasons for observed improvement of the magnetization may be summarized as follows:

Figure 4.

Magnetic hysteresis loops of as-prepared nanoparticles: (a) YFO; (b) Co5; (c) Gd5; (d) Gd5Co5; (e) Gd10Co5; (f) Gd15Co5; (g) Gd20Co5.

Table 2.

List of the magnetic and optical parameters for YFeO3 powders.

(1) The effect of nanoparticles. Uncompensated surface spins of Fe3+ ions are created when particle size is small. This situation leads to a strong magnetic enhancement [25,26].

(2) The distorted structure is affected by the doping effect. A FeO6 octahedron structure consists of one Fe3+ ion and six O2− ions, while each Fe3+ magnetic moment is not precisely parallel to the neighboring ones, forming a small angle [25,26], which causes weak ferromagnetism in the antiferromagnetic YFeO3. Substituting an Fe3+ ion with a larger radius Co3+ ion will reduce the canted angle of the FeO6 octahedra and release the distortion, and combined with a refined powder size, a higher magnetization is achieved. [27].

(3) The Gd3+ ion with a large magnetic moment (μeff = 8.0 μB) is magnetically active. When Y3+ is replaced by Gd3+, Y–O–Gd chains instead of Gd–O–Gd chains are formed, further improving the magnetization of the Co and Gd co-doped nanopowders [15].

In summary, the three reasons noted above serve to bring about the enhancement of magnetization. Others who conducted similar research made similar findings. Khalifa et al. [16] reported that Mm and Mr were about 0.8 emu/g and 0.1 emu/g for Ti-doped YFeO3 nanoparticles prepared using an improved sol-gel technique. Shi et al. [17] synthesized YFe0.5Cr0.5O3 nanoparticles by the sol-gel method, and showed that Mm and Mr were approximately 2.0 and 0.5 emu/g, respectively. As reported by Shi, the maximum Mm and Mr values for Y0.95Ho0.05Fe0.5Cr0.5O3 nanoparticles prepared using a low-temperature citric acid assisted sol-gel technology were about 4.5 and 1.2 emu/g, respectively [17]. Yuan et al. [15] synthesized Y0.9Gd0.1FeO3 using a solid-state reaction method, and obtained values of Mm, Mr, and Hc of 2.5 emu/g, 1.0 emu/g and 30,000 Oe, respectively. Still, it is worth noting that the property values in the present study are comparable with, or better than the results reported by others.

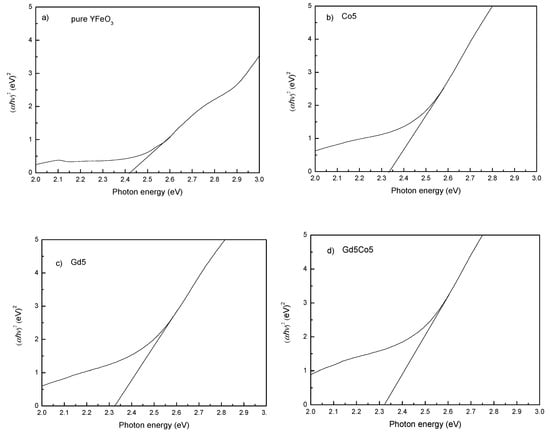

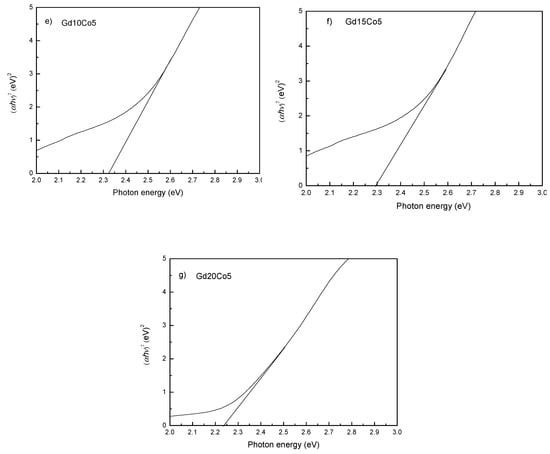

YFeO3 possesses a narrow optical band gap (1.6–2.4 eV) and has been used in light-electric energy conversion applications. From the UV-visible absorption spectra (Figure 5), the optical energy band gap (Eg) of the seven test samples can be calculated using a Tauc function expressed in Equation (1) [28]:

Figure 5.

(αhν)2 as a function of photon energy for as-prepared nanoparticles: (a) YFO; (b) Co5; (c) Gd5; (d) Gd5Co5; (e) Gd10Co5; (f) Gd15Co5; (g) Gd20Co5.

The Eg values shown in Figure 5 illustrate strong visible light absorption, indicating their promising decomposition application (See Table 2). YFO has the maximum Eg value (2.42 eV). It is decreased to 2.15 eV for Gd20Co5 nanoparticles. Clearly, the energy band gap becomes smaller with refined particle size of the YFeO3 powders. Thus, the reduction of the energy gap with co-doping is ascribed to the smaller particle size and lattice distortion reduction generated by the addition of Co and Gd. Further, according to Reference [23], reduced particle size leads to a narrow energy gap. Nonuniform microstrains caused by lattice distortions can impact energy levels, affecting the energy band gap [28,29]. YFeO3 possesses the band gap of 2p O, and 4d Y atoms. All these states are partially filled [28]. The Gd atom is with the 4f state which is also not fully filled orbits. Thus f-d hybridization of the 4d Y and 3d Fe atoms causes light absorption. In addition, the same d states of Fe and Co overlap with the 2p states O atom, causing a narrow energy gap [15,30]. Moreover, Gd3+ and Co3+ ions partially substituting Y3+ and Fe3+ ions refine the as-synthesized nanoparticles size and increase chemical pressure, thereby resulting in a smaller value of Eg [30]. Zhang et al. [28] obtained Eg values of 1.94, 2.43 and 2.30 eV, respectively, for the hexagonal, orthorhombic, and YFeO3 containing a mixture of the two phases. Shen et al. [31] reported that the Eg value obtained from a first-principles calculation for YFeO3 ceramics was 2.58 eV. Wu et al. [23] prepared YFeO3 in which, hexagonal and orthorhombic phases co-existed; this material had a band gap of 2.41 eV. For YFeO3 ceramics prepared by the conventional solid-state method, the energy band gap was found to be 2.58 eV [7]. Liu et al. [32] measured the optical properties of hexagonal-YFeO3/α-Fe2O3 heterojunction composite nanowire and obtained Eg values of approximately 2.15 eV. Once again, it is worth noting that our Eg values compare favorably with these results. Therefore, one can reasonably conclude that the YFeO3 nanopowders used in this study can be used in the decomposition of organic compounds.

4. Conclusions

Co and Gd co-doped YFeO3 nanopowders were fabricated using a low-temperature solid-state reaction method. Data obtained using XRD and Raman analyses show that, with Gd and Co substitution, YFeO3 nanoparticles exhibit a distortion refined structure. The particle size for pristine YFeO3 nanoparticles is about 100-200 nm, and those for Co5, Gd5, Co5Gd5, Co5Gd10, Co5Gd15 and Co5Gd20 are approximately 120, 95, 80, 75, 45 and 40 nm, respectively. The maximum magnetization and remnant magnetization for the co-doped YFeO3 powders are about 5.49 and 2.20 emu/g, respectively, when exposed to a magnetic field of 60 kOe. The energy band gap of YFeO3 nanopowders was reduced from 2.41 to 2.23 using the co-doping method, thereby indicating their potential in decomposition applications. Because the co-doping method used in the study was found to be easy to control for fabricating the YFeO3 nanopowder samples, it is proposed that the method be adopted for use in the applied magnetic and optical fields.

Author Contributions

M.W. and T.W. conceived and designed the experiments; M.W. performed the experiments; M.W. and T.W. analyzed the data; M.W. wrote the paper.

Funding

This research was funded by the Research Funding of Shenzhen Polytechnic (6019310005K).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dho, J.; Blamire, M. Competing functionality in multiferroic YMnO3. Appl. Phys. Lett. 2005, 87, 2504. [Google Scholar] [CrossRef]

- Wang, L.J.; Feng, S.M.; Zhu, J.L.; Yu, R.C.; Jin, C.Q.; Yu, W.; Wang, X.H.; Li, L.T. Ferroelectricity of multiferroic hexagonal TmMnO3 ceramics synthesized under high pressure. Appl. Phys. Lett. 2007, 91, 172502. [Google Scholar] [CrossRef]

- Cherry, M.; Islam, M.S.; Catlow, C.R.A. Oxygen ion migration in perovskite-type oxides. J. Solid State Chem. 1995, 118, 125–132. [Google Scholar] [CrossRef]

- Minh, N.Q. Ceramic fuel cells. J. Am. Ceram. Soc. 1993, 76, 563–588. [Google Scholar] [CrossRef]

- Sharon, M.; Prasad, B.M. Preparation and photocharacterization of YFeO3 semiconductor. Electrochim. Acta 1985, 30, 331–334. [Google Scholar] [CrossRef]

- Traversa, E.; Nunziante, P.; Sangaletti, L.; Allieri, B.; Depero, L.E.; Aono, H.; Sadaoka, Y. Synthesis and structural characterization of trimetallic perovskite-type rare-earth orthoferrites, LaxSm1-xFeO3. J. Am. Ceram. Soc. 2000, 83, 1087–1092. [Google Scholar] [CrossRef]

- Butler, M.A.; Ginley, D.S.; Eibschutz, M. Photoelectrolysis with YFeO3 electrodes. J. Appl. Phys. 1977, 48, 3070–3072. [Google Scholar] [CrossRef]

- Mathur, S.; Veith, M.; Rapalaviciute, R.; Shen, H.; Goya, G.F.; Filho, W.L.M.; Berquo, T.S. Molecule derived synthesis of nanocrystalline YFeO3 and investigations on its weak ferromagnetic behavior. Chem. Mater. 2004, 16, 1906–1913. [Google Scholar] [CrossRef]

- Schmool, D.S.; Keller, N.; Guyot, M.; Krishnan, R.; Tessier, M. Magnetic and magneto-optic properties of orthoferrite thin films grown by pulsed-laser deposition. J. Appl. Phys. 1999, 86, 5712–5717. [Google Scholar] [CrossRef]

- Shang, M.; Wang, C.; Chen, Y.; Sun, F.; Yuan, H. The multiferroic epitaxial thin film YFeO3. Mater. Lett. 2016, 175, 23–26. [Google Scholar] [CrossRef]

- Akbashev, A.; Semisalova, A.; Perov, N.; Kaul, A. Weak ferromagnetism in hexagonal orthoferrites RFeO3 (R = Lu, Er-Tb). Appl. Phys. Lett. 2011, 99, 122502. [Google Scholar] [CrossRef]

- Hemberger, J.; Schrettle, F.; Pimenov, A.; Lunkenheimer, P.; Ivanov, V.Y.; Mukhin, A.A.; Balbashov, A.M.; Loidl, A. Multiferroic phases of Eu1-xYxMnO3. Phys. Rev. B Condens. Matter 2007, 75, 5118. [Google Scholar] [CrossRef]

- Zhang, W.; Fang, C.; Yin, W.; Zeng, Y. One-step synthesis of yttrium orthoferrite nanocrystals via sol-gel auto-combustion and their structural and magnetic characteristics. Mater. Chem. Phys. 2013, 137, 877–883. [Google Scholar] [CrossRef]

- Van Tac, D.; Mittova, V.; Mittova, I.Y. Influence of lanthanum content and annealing temperature on the size and magnetic properties of sol–gel derived Y1−xLaxFeO3 nanocrystals. Inorg. Mater. 2011, 47, 521–526. [Google Scholar] [CrossRef]

- Yuan, X.; Sun, Y.; Xu, M. Effect of Gd substitution on the structure and magnetic properties of YFeO3 ceramics. J. Solid State Chem. 2012, 196, 362–366. [Google Scholar] [CrossRef]

- Khalifa, N.O.; Widatallah, H.M.; Gismelseed, A.M. Magnetic and Mössbauer studies of pure and Ti-doped YFeO3 nanocrystalline particles prepared by mechanical milling and subsequent sintering. Hyperfine Interact. 2016, 237, 1–11. [Google Scholar] [CrossRef]

- Shi, L.R.; Xia, Z.C.; Huang, S.; Xiao, G.L.; Jin, Z.; Wei, M.; Chen, B.R.; Shang, C.; Cheng, H.; Ouyang, Z.W. The magnetization reversal and high temperature dielectric response in Y1−xHxFe0.5Cr0.5O3. Ceram. Int. 2016, 42, 10808–10812. [Google Scholar] [CrossRef]

- Ma, Y.; Wu, Y.J.; Lin, Y.Q.; Chen, X.M. Microstructures and multiferroic properties of YFe1-xMnxO3 ceramics prepared by spark plasma sintering. J. Mater. Sci. Mater. Electron. 2010, 21, 838–843. [Google Scholar] [CrossRef]

- Wang, M.; Wang, T.; Song, S.; Tan, M. Structure-controllable synthesis of multiferroic YFeo3 nanopowders and their optical and magnetic properties. Materials 2017, 10, 626. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. A 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Chakrabarti, K.; Das, K.; Sarkar, B.; Ghosh, S.; De, S.K.; Sinha, G.; Lahtinen, J. Enhanced magnetic and dielectric properties of Eu and Co co-doped BiFeO3 nanoparticles. Appl. Phys. Lett. 2012, 101, 759. [Google Scholar] [CrossRef]

- Yang, L.P.; Zhang, A.M.; Dai, Y.; Wu, X.S. The effect of Dy–Fe co-doping on the structural and magnetic properties of h-YMnO3. J. Mater. Sci. Mater. Electron. 2017, 28, 8872–8877. [Google Scholar] [CrossRef]

- Wu, L.; Yu, J.C.; Zhang, L.; Wang, X.; Li, S. Selective self-propagating combustion synthesis of hexagonal and orthorhombic nanocrystalline yttrium iron oxide. J. Solid State Chem. 2004, 177, 3666–3674. [Google Scholar] [CrossRef]

- Ma, Y.; Chen, X.M.; Lin, Y.Q. Relaxorlike dielectric behavior and weak ferromagnetism in YFeO3 ceramics. J. Appl. Phys. 2008, 103, 124111. [Google Scholar] [CrossRef]

- Moriya, T. New mechanism of anisotropic superexchange interaction. Phys. Rev. Lett. 1960, 4, 228–230. [Google Scholar] [CrossRef]

- Dzyaloshinsky, I. A thermodynamic theory of weak ferromagnetism of antiferromagnetics. J. Phys. Chem. Solids 1958, 4, 241–255. [Google Scholar] [CrossRef]

- Arlt, G.; Hennings, D.; With, G.D. Dielectric properties of fine-grained barium titanate ceramics. J. Appl. Phys. 1985, 58, 1619–1625. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, J.; Xu, J.; Gao, Q.; Hong, Z. Controllable synthesis of hexagonal and orthorhombic YFeO3 and their visible-light photocatalytic activities. Mater. Lett. 2012, 81, 1–4. [Google Scholar] [CrossRef]

- Mocherla, P.S.V.; Karthik, C.; Ubic, R.; Rao, M.S.R.; Sudakar, C. Tunable bandgap in BiFeO3 nanoparticles: The role of microstrain and oxygen defects. Appl. Phys. Lett. 2013, 103, 2463–2485. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhu, X.; Xu, Y.; Gao, H.; Xiao, Y.; Liang, D.; Zhu, J.; Zhu, J.; Xiao, D. Effect of La3+ substitution on the phase transitions, microstructure and electrical properties of Bi1-xLaxFeO3 ceramics. J. Alloys Compd. 2013, 546, 57–62. [Google Scholar] [CrossRef]

- Shen, T.; Hu, C.; Yang, W.L.; Liu, H.C.; Wei, X.L. Theoretical investigation of magnetic, electronic and optical properties of orthorhombic YFeO3: A first-principle study. Mater. Sci. Semicond. Process. 2015, 34, 114–120. [Google Scholar] [CrossRef]

- Liu, J.; He, F.; Chen, L.; Qin, X.; Zhao, N.; Huang, Y.; Peng, Y. Novel hexagonal-YFeO3/α-Fe2O3 heterojunction composite nanowires with enhanced visible light photocatalytic activity. Mater. Lett. 2016, 165, 263–266. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).