The δ Phase Precipitation of an Inconel 718 Superalloy Fabricated by Electromagnetic Stirring Assisted Laser Solid Forming

Abstract

:1. Introduction

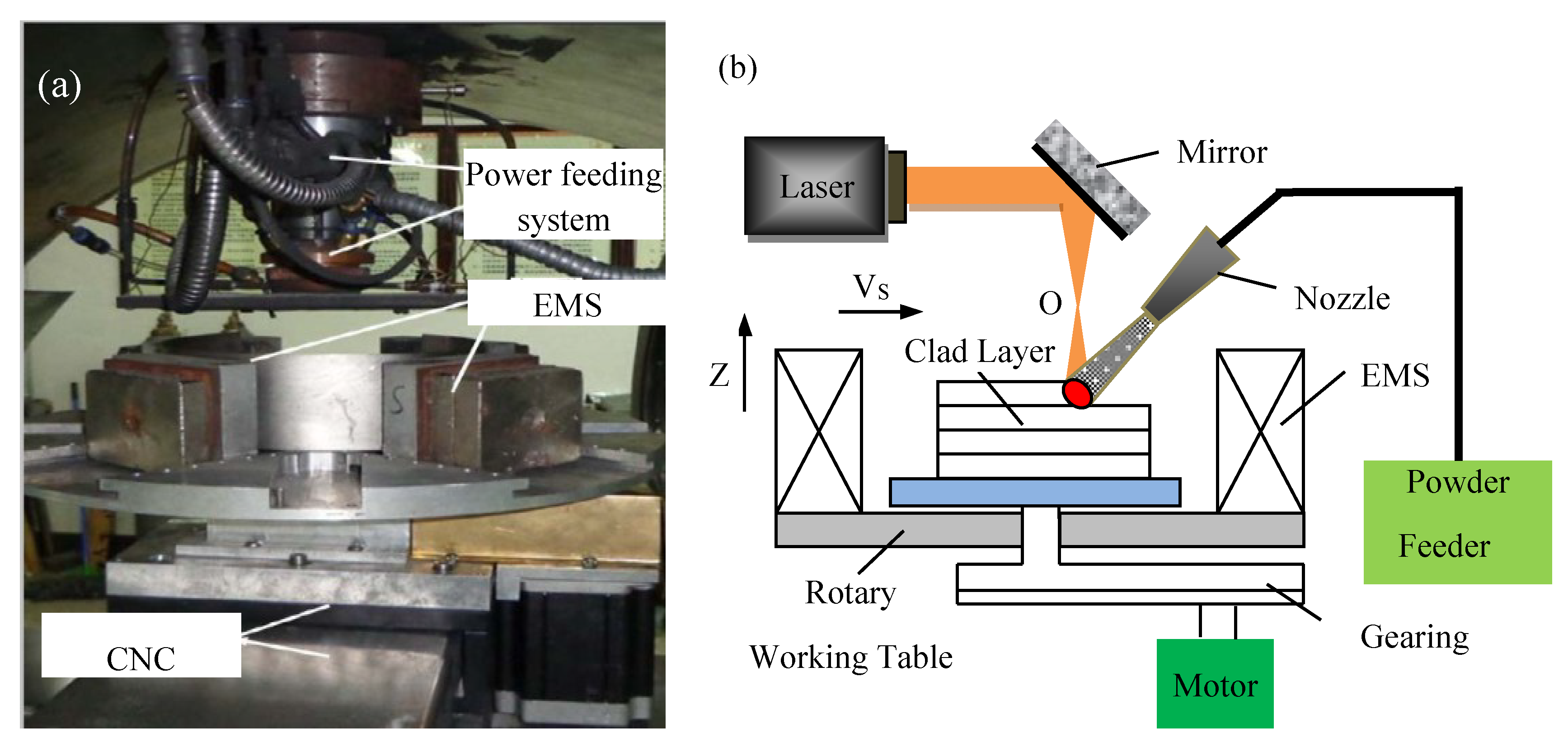

2. Experimental Methods

3. Results and Discussion

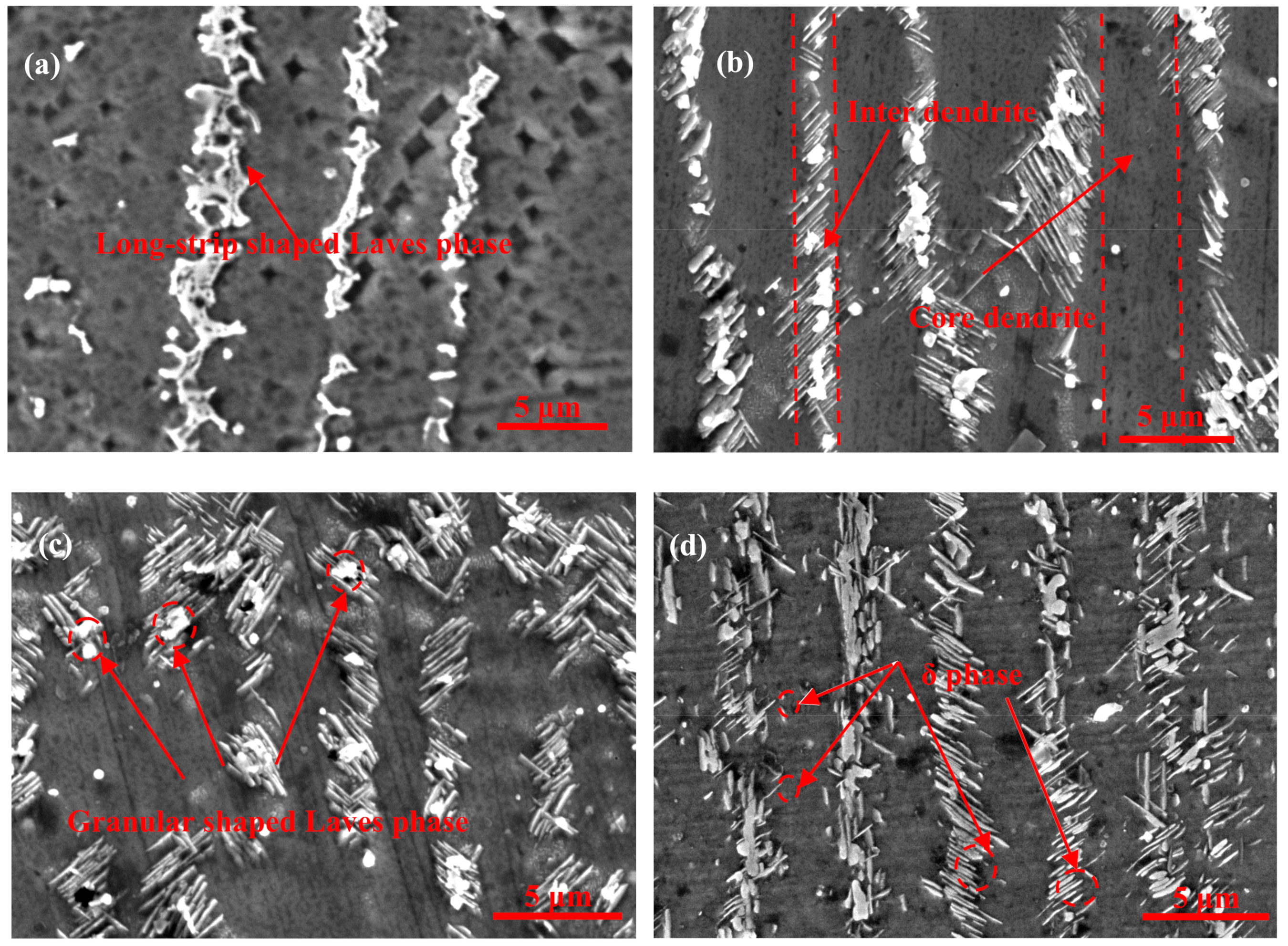

3.1. The “Cutting” and “Dissolution” of the Laves Phase Through the Precipitation of the δ Phase

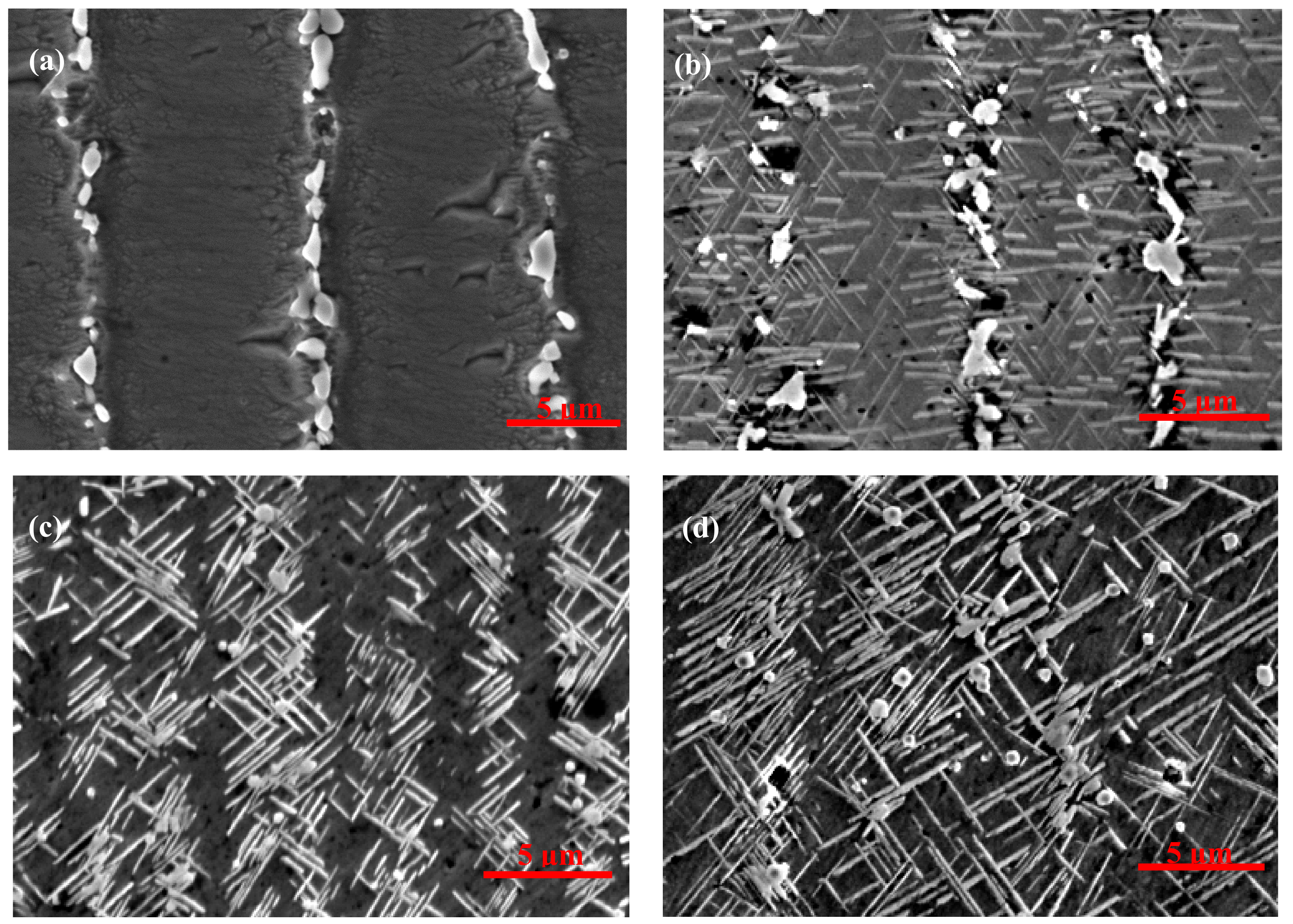

3.2. Effect of Electromagnetic Filed Intensity on Precipitation of the δ Phase

3.3. Precipitation Kinetics Analysis of Phase Precipitation

3.4. Electrochemical Corrosion of the Weld

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhuang, J.Y.; Du, J.H.; Deng, Q. Deformed Superalloy GH4169; Metallurgical Industry Press: Beijing, China, 2006. [Google Scholar]

- Liu, F.C.; Lin, X.; Leng, H. Microstructural changes in a laser solid forming Inconel 718 superalloy thin wall in the deposition direction. Opt. Laser Technol. 2013, 45, 330–335. [Google Scholar] [CrossRef]

- Zhu, L.; Xu, Z.F.; Gu, Y.F. Effect of laser power on the microstructure and mechanical properties of heat treated Inconel 718 superalloy by laser solid forming. J. Alloys Compd. 2018, 746, 159–167. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, F.G.; Zhang, K. Dendritic microstructure and hot cracking of laser additive manufactured Inconel 718 under improved base cooling. J. Alloys Compd. 2016, 670, 312–321. [Google Scholar] [CrossRef]

- Qi, H.; Azer, M.; Ritter, A. Studies of Standard Heat Treatment Effects on Microstructure and Mechanical Properties of Laser Net Shape Manufactured INCONEL 718. Metall. Mater. Trans. A 2009, 10, 2410–2422. [Google Scholar] [CrossRef]

- Xi, M.Z.; Gao, S.Y. Study on Tensile Mechanical Properties of Inconel 718 Superalloy by Laser Rapid Prototyping. Chin. J. Lasers 2012, 39, 68–73. [Google Scholar]

- Zhao, W.W.; Lin, X.; Liu, F.C. Effect of heat treatment on microstructure and mechanical properties of Inconel 718 superalloy. Chin. J. Lasers 2009, 36, 3220–3225. [Google Scholar] [CrossRef]

- Ming, X.L.; Chen, J.; Tan, H. High-temperature coarsening behavior of γ″ phase of laser solid forming GH4169 superalloy. J. Mater. Eng. 2014, 8, 8–14. [Google Scholar]

- Chang, S.H. In situ TEM observation of γ′, γ″ and δ precipitations on Inconel 718 superalloy through HIP treatment. J. Alloys Compd. 2009, 486, 716–721. [Google Scholar] [CrossRef]

- Liu, F.C.; Lin, X.; Yang, G.L. Microstructure and residual stress of laser rapid formed Inconel 718 nickel-base superalloy. Opt. Laser Technol. 2011, 43, 208–213. [Google Scholar] [CrossRef]

- Du, J.H.; Lu, X.D.; Qu, J.L. High-temperature Structure Stability and Mechanical Properties of Novel 718 Superalloy. Mater. Sci. Eng. A 2007, 452, 584–591. [Google Scholar] [CrossRef]

- Xu, D.F.; Tian, C.S. Study on Laves phase resolving behavior of GH4169 alloy steel based on mathematical model during heat treatment. Foundry Technol. 2014, 35, 2570–2572. [Google Scholar]

- Liu, F.C.; Lin, X.; Yu, X.B. Interface and crystal orientation evolution during laser solid forming GH4169 alloy during recrystallization. Acta Metall. Sin. 2014, 50, 463–470. [Google Scholar]

- Chen, W.; Li, C.C.; Li, H. Effects of Heat Treatment on Microstructure and Mechanical Properties of Modified Inconel 718C Alloy. Trans. Metal Heat Treat. 2007, 32, 81–87. [Google Scholar]

- Song, K.; Yu, K.; Lin, X. Microstructure and mechanical properties of heat treated laser solid forming Inconel 718 superalloy. Acta Metall. Sin. 2015, 51, 935–942. [Google Scholar]

- Yang, Y.R.; Liang, X.F. Effect of δ phase on the long-term performance of GH4169 alloy at high temperature. J. Aeronaut. Mater. 1996, 16, 39–43. [Google Scholar]

- Slama, C.; Abdellaoui, M. Structural characterization of the aged Inconel 718. J. Alloys Compd. 2000, 306, 277–284. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, L. Effect of solid-solution treatment on microstructure and properties of GH4169 alloy. Trans. Metal Heat Treat. 2007, 28, 176–179. [Google Scholar] [CrossRef]

- Radavich, J.F. The physical metallurgy of cast and wrought alloy 718. In Proceedings of the Conference Proceedings on Superalloy, Pittsburgh, PA, USA, 12–14 June 1989; pp. 229–240. [Google Scholar]

- Cai, D.Y.; Zhang, W.H.; Liu, W.C. Dissolution Behavior of Phase δ in Inconel 718. J. Alloys Iron Steel Res. 2002, 14, 61–64. [Google Scholar]

- Schneider, A.; Avilov, V.; Gumenyuk, A. Laser Beam Welding of Aluminum Alloys Under the Influence of an Electromagnetic Field. Phys. Procedia 2013, 41, 4–11. [Google Scholar] [CrossRef] [Green Version]

- Zhai, L.L.; Ban, C.Y.; Zhang, J.W. Investigation on Laser Cladding Ni-base Coating Assisted by Electromagnetic Field. Opt. Laser Technol. 2019, 114, 81–88. [Google Scholar] [CrossRef]

- Zhou, J.Z.; Xu, J.L.; Huang, S. Effect of laser surface melting with alternating magnetic field on wear and corrosion resistance of magnesium alloy. Surf. Coay. Technol. 2017, 309, 212–219. [Google Scholar] [CrossRef]

- Qin, L.Y.; Yang, G.; Bian, H.Y. Experimental study on electromagnetic stirring assisted laser deposition of titanium alloy. Chin. J. Lasers 2014, 41, 0303004. [Google Scholar]

- Yu, X.B.; Liu, F.C.; Lin, X. Microstructure and hardness analysis of laser solid forming GH4169 alloy by electromagnetic stirring. Appl. Laser 2014, 34, 513–516. [Google Scholar]

- Li, Y.J.; Ma, X.P.; Yang, Y.S. Grain refinement of as-cast superalloy IN718 under action of low voltage pulsed magnetic field. Trans. Nonferrous Metals Soc. China 2011, 6, 1277–1282. [Google Scholar] [CrossRef]

- Jia, P.; Wang, N.G.; Lu, H. Effect of Electromagnetic Field on Solidification Structure and Mechanical Properties of Inconel 625 Alloy. Acta Metall. Sin. 2013, 49, 1573–1580. [Google Scholar] [CrossRef]

- Zhan, G.F.; Wang, N.G.; Jiang, N. Effect of Electromagnetic Stirring on As-Cast Microstructure of GH3030 Superalloy. Spec. Cast. Nonferrous Alloys 2012, 32, 6–8. [Google Scholar]

- Idell, Y.; Levine, L.E.; Allen, A.J. Unexpected δ-Phase Formation in Additive-Manufactured Ni-Based Superalloy. J. Minerals Metals Mater. Soc. 2016, 68, 950–959. [Google Scholar] [CrossRef]

- Ding, R.G.; Huang, Z.W.; Li, H.Y. Electron microscopy study of direct laser deposited IN718. Mater. Charact. 2015, 106, 324–337. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.C.; Cheng, H.M.; Yu, X.B. Control of microstructure and mechanical properties of laser solid formed Inconel 718 superalloy by electromagnetic stirring. Opt. Laser Technol. 2018, 99, 342–350. [Google Scholar] [CrossRef]

- Azadian, S.; Wei, L.Y.; Warren, R. Delta phase precipitation in Inconel 718. Mater. Charact. 2004, 53, 7–16. [Google Scholar] [CrossRef]

- Lu, T.; Wang, Y.; Yao, Q. Microstructure and Bending Properties of High Volume Fraction SiC Particle Reinforced Aluminum Matrix Composites. Hot Work. Technol. 2017, 24, 158–161. [Google Scholar]

- Avrami, M. Kinetics of phase change. I General theory. J. Chem. Phys. 1939, 7, 1103–1112. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of Phase Change. II Transformation Time Relations for Random Distribution of Nuclei. J. Chem. Phys. 1940, 8, 212–224. [Google Scholar] [CrossRef]

- Avrami, M. Granulation, phase change, and microstructure kinetics of phase change. J. Chem. Phys. 2004, 9, 177–184. [Google Scholar] [CrossRef]

| Material | C | Nb | Cr | Fe | Al | Ti | Mo | Ni |

|---|---|---|---|---|---|---|---|---|

| Powder | 0.03 | 5.2 | 19.7 | 18.4 | 0.6 | 1.0 | 3.0 | Bal. |

| LSF sample | 0.05 | 5.6 | 19.6 | 18.2 | 0.5 | 1.1 | 3.3 | Bal. |

| AMS: 5663 | 0.08 max | 4.75–5.5 | 17–21 | 16–20 | 0.2–0.8 | 0.65–1.15 | 2.8–3.3 | Bal. |

| Laser Power (W) | Scanning Speed (mm/s) | Powder Supply Rate (g/min) | Shielding Gas Flux (L/min) | Spot Diameter (mm) | Overlap of Adjacent Passes (%) | Δ Z (mm) |

|---|---|---|---|---|---|---|

| 2000–2200 | 6–8 | 8–12 | 6 | 3 | 25–40 | 0.3 |

| Aging Time | 1 h | 4 h | 16 h |

|---|---|---|---|

| Length | 1.205 | 1.687 | 1.770 |

| Width | 0.066 | 0.086 | 0.096 |

| Length-width ratio | 0.055 | 0.051 | 0.054 |

| Laves Phase | γ (Eutectic) | Core Dendrite | |

|---|---|---|---|

| Aging 0 h | 25.3 | 9.1 | 2.5 |

| Aging 12 h | 24.8 | 6.3 | 3.5 |

| Aging Time | 0 mT | 30 mT | 50 mT |

|---|---|---|---|

| 1 h | 1.205 μm | 1.273 μm | 1.852 μm |

| 4 h | 1.687 μm | 1.810 μm | 2.120 μm |

| 16 h | 1.770 μm | 1.820 μm | 2.861 μm |

| Aging Time | 0 mT | 30 mT | 50 mT |

|---|---|---|---|

| 1 h | 0.066 μm | 0.073 μm | 0.087 μm |

| 4 h | 0.086 μm | 0.089 μm | 0.095 μm |

| 16 h | 0.091 μm | 0.093 μm | 0.098 μm |

| Length–Width Ratio | 0 mT | 30 mT | 50 mT |

|---|---|---|---|

| 1 h | 0.055 | 0.057 | 0.047 |

| 4 h | 0.051 | 0.049 | 0.045 |

| 16 h | 0.053 | 0.050 | 0.034 |

| 0 mT | 30 mT | 50 mT | |

|---|---|---|---|

| Core dendrite | 2.4 | 5.8 | 6.5 |

| 0 mT | 30 mT | 50 mT | |

|---|---|---|---|

| 1 h | 6.284 | 7.937 | 16.183 |

| 4 h | 7.316 | 11.895 | 16.841 |

| 16 h | 11.413 | 12.880 | 18.142 |

| Electromagnetic Field Intensities/mT | Precipitation Rate α | Time Index n |

|---|---|---|

| 0 | 0.032 | 0.290 |

| 30 | 0.071 | 0.247 |

| 50 | 0.567 | 0.125 |

| Microhardness | 0 mT | 30 mT | 50 mT |

|---|---|---|---|

| 1 h | 297.70 | 309.69 | 363.16 |

| 4 h | 285.66 | 304.80 | 330.95 |

| 16 h | 279.69 | 290.86 | 315.02 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lyu, F.; Liu, F.; Hu, X.; Yang, X.; Huang, C.; Shi, D. The δ Phase Precipitation of an Inconel 718 Superalloy Fabricated by Electromagnetic Stirring Assisted Laser Solid Forming. Materials 2019, 12, 2604. https://doi.org/10.3390/ma12162604

Lyu F, Liu F, Hu X, Yang X, Huang C, Shi D. The δ Phase Precipitation of an Inconel 718 Superalloy Fabricated by Electromagnetic Stirring Assisted Laser Solid Forming. Materials. 2019; 12(16):2604. https://doi.org/10.3390/ma12162604

Chicago/Turabian StyleLyu, Feiyue, Fencheng Liu, Xiaoan Hu, Xiaoguang Yang, Chunping Huang, and Duoqi Shi. 2019. "The δ Phase Precipitation of an Inconel 718 Superalloy Fabricated by Electromagnetic Stirring Assisted Laser Solid Forming" Materials 12, no. 16: 2604. https://doi.org/10.3390/ma12162604

APA StyleLyu, F., Liu, F., Hu, X., Yang, X., Huang, C., & Shi, D. (2019). The δ Phase Precipitation of an Inconel 718 Superalloy Fabricated by Electromagnetic Stirring Assisted Laser Solid Forming. Materials, 12(16), 2604. https://doi.org/10.3390/ma12162604