Different Radiation Tolerances of Ultrafine-Grained Zirconia–Magnesia Composite Ceramics with Different Grain Sizes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Preparation

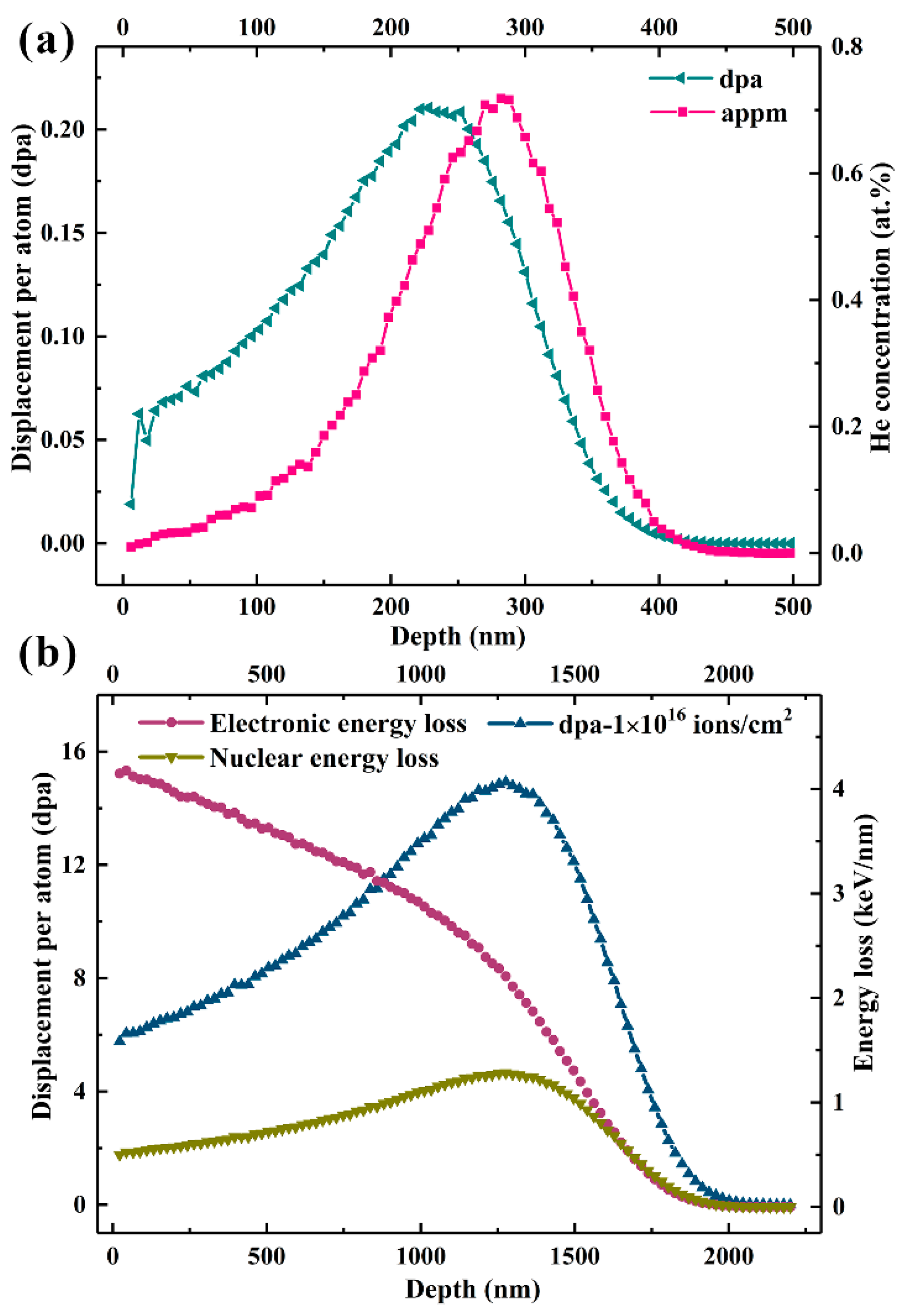

2.2. Light He+ Ion Irradiation

2.3. Heavy Xe23+ Ion Irradiation

2.4. Characterization Method

3. Results and Discussion

3.1. Properties of Pristine Samples

3.2. Microstructure Evolution under He+ Ion Irradiation

3.3. Heavy Xe23+ Ion Irradiation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Hong, M.; Ren, F.; Zhang, H.; Xiao, X.; Yang, B.; Tian, C.; Fu, D.; Wang, Y.; Jiang, C. Enhanced radiation tolerance in nitride multilayered nanofilms with small period-thicknesses. Appl. Phys. Lett. 2012, 101, 153117. [Google Scholar] [CrossRef]

- Yang, T.; Huang, X.; Wang, C.; Zhang, Y.; Xue, J.; Yan, S.; Wang, Y. Enhanced structural stability of nanoporous zirconia under irradiation of He. J. Nucl. Mater. 2012, 427, 225–232. [Google Scholar] [CrossRef]

- Zhang, X.; Hattar, K.; Chen, Y.; Shao, L.; Li, J.; Sun, C.; Yu, K.; Li, N.; Taheri, M.L.; Wang, H.; et al. Radiation damage in nanostructured materials. Prog. Mater. Sci. 2018, 96, 217–321. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Caro, A.; Demkowicz, M.J.; Mara, N.A.; Misra, A.; Uberuaga, B.P. Radiation damage tolerant nanomaterials. Mater. Today 2013, 16, 443–449. [Google Scholar] [CrossRef] [Green Version]

- Sun, C.; Song, M.; Yu, K.Y.; Chen, Y.; Kirk, M.; Li, M.; Wang, H.; Zhang, X. In situ Evidence of Defect Cluster Absorption by Grain Boundaries in Kr Ion Irradiated Nanocrystalline Ni. Metall. Mater. Trans. A 2013, 44, 1966–1974. [Google Scholar] [CrossRef]

- Shen, T.D.; Feng, S.; Tang, M.; Valdez, J.A.; Wang, Y.; Sickafus, K.E. Enhanced radiation tolerance in nanocrystalline MgGa2O4. Appl. Phys. Lett. 2007, 90, 263115. [Google Scholar] [CrossRef]

- Bai, X.M.; Voter, A.F.; Hoagland, R.G.; Nastasi, M.; Uberuaga, B.P. Efficient annealing of radiation damage near grain boundaries via interstitial emission. Science 2010, 327, 1631–1634. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Liu, W.; Xu, Y.; Liu, C.S.; Pan, B.C.; Liang, Y.; Fang, Q.F.; Chen, J.-L.; Luo, G.N.; Lu, G.-H.; et al. Radiation resistance of nano-crystalline iron: Coupling of the fundamental segregation process and the annihilation of interstitials and vacancies near the grain boundaries. Acta Mater. 2016, 109, 115–127. [Google Scholar] [CrossRef]

- Lu, F.; Wang, J.; Lang, M.; Toulemonde, M.; Namavar, F.; Trautmann, C.; Zhang, J.; Ewing, R.C.; Lian, J. Amorphization of nanocrystalline monoclinic ZrO2 by swift heavy ion irradiation. Phys. Chem. Chem. Phys. 2012, 14, 12295–12300. [Google Scholar] [CrossRef] [PubMed]

- Shen, T.D. Radiation tolerance in a nanostructure: Is smaller better? Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2008, 266, 921–925. [Google Scholar] [CrossRef]

- Taylor, M.A.; Alonso, R.E.; Errico, L.A.; López-García, A.; de la Presa, P.; Svane, A.; Christensen, N.E. Structural, electronic, and hyperfine properties of pure and Ta-doped m-ZrO2. Phys. Rev. B 2012, 85, 155202. [Google Scholar] [CrossRef]

- Dey, S.; Mardinly, J.; Wang, Y.; Valdez, J.A.; Holesinger, T.G.; Uberuaga, B.P.; Ditto, J.J.; Drazin, J.W.; Castro, R.H. Irradiation-induced grain growth and defect evolution in nanocrystalline zirconia with doped grain boundaries. Phys. Chem. Chem. Phys. 2016, 18, 16921–16929. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Ge, W.; Yang, T.; Du, C.; Wang, C.; Liu, S.; Lu, Y.; Yan, Z.; Liu, H.; Liu, F.; et al. Radiation tolerance of La-doped nanocrystalline steel under heavy-ion irradiation at different temperatures. Nanotechnology 2018, 29, 494001. [Google Scholar] [CrossRef] [PubMed]

- Ohtaki, K.K.; Patel, M.K.; Crespillo, M.L.; Karandikar, K.K.; Zhang, Y.; Graeve, O.A.; Mecartney, M.L. Improved high temperature radiation damage tolerance in a three-phase ceramic with heterointerfaces. Sci. Rep. 2018, 8, 13993. [Google Scholar] [CrossRef] [PubMed]

- Bachiller-Perea, D.; Debelle, A.; Thomé, L.; Behar, M. Damage accumulation in MgO irradiated with MeV Au ions at elevated temperatures. J. Nucl. Mater. 2016, 478, 268–274. [Google Scholar] [CrossRef]

- Stoller, R.E.; Toloczko, M.B.; Was, G.S.; Certain, A.G.; Dwaraknath, S.; Garner, F.A. On the use of SRIM for computing radiation damage exposure. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2013, 310, 75–80. [Google Scholar] [CrossRef]

- Chen, L.; Chang, Y.; Guo, Q.; Zhang, J.; Wan, F.; Long, Y. Phase stability, grain growth and photoluminescence property of nanocrystalline yttria-stabilized zirconia film under 500keV Xe6+ ion irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2014, 328, 84–88. [Google Scholar] [CrossRef]

- Yang, T.; Huang, X.; Gao, Y.; Wang, C.; Zhang, Y.; Xue, J.; Yan, S.; Wang, Y. Damage evolution of yttria-stabilized zirconia induced by He irradiation. J. Nucl. Mater. 2012, 420, 430–436. [Google Scholar] [CrossRef]

- Usov, I.O.; Valdez, J.A.; Sickafus, K.E. Temperature dependence of lattice disorder in Ar-irradiated (100), (110) and (111) MgO single crystals. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2011, 269, 288–291. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, H.; Amekura, H.; Ren, F.; Chettah, A.; Hong, M.; Qin, W.; Tang, J.; Hu, L.; Wang, H.; et al. Period-thickness dependent responses of Cu/W multilayered nanofilms to ions irradiation under different ion energies. J. Nucl. Mater. 2017, 497, 117–127. [Google Scholar] [CrossRef]

- Valdez, J.A.; Chi, Z.; Sickafus, K.E. Light ion irradiation-induced phase transformation in the monoclinic polymorph of zirconia. J. Nucl. Mater. 2008, 381, 259–266. [Google Scholar] [CrossRef]

- Li, Y.H.; Wang, Y.Q.; Valdez, J.A.; Tang, M.; Sickafus, K.E. Swelling effects in Y2Ti2O7 pyrochlore irradiated with 400keV Ne2+ ions. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2012, 274, 182–187. [Google Scholar] [CrossRef]

- Lokesha, H.S.; Nagabhushana, K.R.; Singh, F. Swift heavy ion induced phase transformation and thermoluminescence properties of zirconium oxide. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2016, 379 (Suppl. C), 131–135. [Google Scholar] [CrossRef]

- Moll, S.; Zhang, Y.; Debelle, A.; Thomé, L.; Crocombette, J.P.; Zihua, Z.; Jagielski, J.; Weber, W.J. Damage processes in MgO irradiated with medium-energy heavy ions. Acta Mater. 2015, 88, 314–322. [Google Scholar] [CrossRef] [Green Version]

- Jiao, L.; Chen, A.; Myers, M.T.; General, M.J.; Shao, L.; Zhang, X.; Wang, H. Enhanced ion irradiation tolerance properties in TiN/MgO nanolayer films. J. Nucl. Mater. 2013, 434, 217–222. [Google Scholar] [CrossRef]

- Taylor, C.A.; Patel, M.K.; Aguiar, J.A.; Zhang, Y.; Crespillo, M.L.; Wen, J.; Xue, H.; Wang, Y.; Weber, W.J. Bubble formation and lattice parameter changes resulting from He irradiation of defect-fluorite Gd2Zr2O7. Acta Mater. 2016, 115, 115–122. [Google Scholar] [CrossRef] [Green Version]

- Qin, W.J.; Ren, F.; Zhang, J.; Dong, X.N.; Feng, Y.J.; Wang, H.; Tang, J.; Cai, G.X.; Wang, Y.Q.; Jiang, C.Z. Helium retention in krypton ion pre-irradiated nanochannel W film. Nucl. Fusion 2018, 58, 026021. [Google Scholar] [CrossRef]

- Miro, S.; Bordas, E.; Thomé, L.; Costantini, J.M.; Leprêtre, F.; Trocellier, P.; Serruys, Y.; Beck, L.; Gosset, D.; Verlet, R.; et al. Monitoring of the microstructure of ion-irradiated nuclear ceramics by in situ Raman spectroscopy. J. Raman Spectrosc. 2016, 47, 476–485. [Google Scholar] [CrossRef]

- Verlet, R.; Tupin, M.; Baldacchino, G.; Wolski, K.; Miro, S.; Gosset, D.; Colas, K.; Jublot, M.; Jomard, F. Influence of light ion irradiation of the oxide layer on the oxidation rate of Zircaloy-4. Corros. Sci. 2015, 98, 327–338. [Google Scholar] [CrossRef]

- Ciszak, C.; Mermoux, M.; Miro, S.; Gutierrez, G.; Lepretre, F.; Popa, I.; Hanifi, K.; Zacharie-Aubrun, I.; Fayette, L.; Chevalier, S. Micro-Raman analysis of the fuel-cladding interface in a high burnup PWR fuel rod. J. Nucl. Mater. 2017, 495 (Suppl. C), 392–404. [Google Scholar] [CrossRef]

- Rawat, M.; Das, A.; Shukla, D.K.; Rajput, P.; Chettah, A.; Phase, D.M.; Ramola, R.C.; Singh, F. Micro-Raman and electronic structure study on kinetics of electronic excitations induced monoclinic-to-tetragonal phase transition in zirconium oxide films. RSC Adv. 2016, 6, 104425–104432. [Google Scholar] [CrossRef]

- Kurpaska, L.; Jasinski, J.; Wyszkowska, E.; Nowakowska-Langier, K.; Sitarz, M. Influence of Ar-ion implantation on the structural and mechanical properties of zirconia as studied by Raman spectroscopy and nanoindentation techniques. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2018, 195, 184–190. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.K.; Hamaguchi, H.O. Mode Assignments of the Raman Spectrum of Monoclinic Zirconia by Isotopic Exchange Technique. Phys. Status Solidi (B) 1997, 203, 557–563. [Google Scholar] [CrossRef]

- Simeone, D.; Baldinozzi, G.; Gosset, D.; Le Caër, S. Phase transition of pure zirconia under irradiation: A textbook example. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2006, 250, 95–100. [Google Scholar] [CrossRef]

- Ciszak, C.; Mermoux, M.; Gutierrez, G.; Leprêtre, F.; Duriez, C.; Popa, I.; Fayette, L.; Chevalier, S. Raman spectra analysis of ZrO2 thermally grown on Zircaloy substrates irradiated with heavy ion: Effects of oxygen isotopic substitution. J. Raman Spectrosc. 2018, 3, 425–435. [Google Scholar]

| Sample | Pristine | 3 × 1016 | 5 × 1016 | 1 × 1017 |

|---|---|---|---|---|

| SGs—{111}m | 28.42 | 28.34 (−0.08) | 28.28 (−0.14) | 28.34 (−0.08) |

| LGs—{111}m | 28.40 | 28.36 (−0.04) | 28.32 (−0.08) | 28.30 (−0.10) |

| SGs—{101}t | 30.50 | 30.44 (−0.06) | 30.34 (−0.16) | 30.40 (−0.10) |

| LGs—{101}t | 30.40 | 30.46 (+0.06) | 30.46 (+0.06) | 30.46 (+0.06) |

| SGs—{200}MgO | 43.18 | 43.02 (−0.16) | 43.00 (−0.18) | 43.04 (−0.14) |

| LGs—{200}MgO | 43.04 | 43.16 (+0.12) | 43.10 (+0.06) | 43.04 (+0) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, W.; Hong, M.; Wang, Y.; Tang, J.; Cai, G.; Yin, R.; Ruan, X.; Yang, B.; Jiang, C.; Ren, F. Different Radiation Tolerances of Ultrafine-Grained Zirconia–Magnesia Composite Ceramics with Different Grain Sizes. Materials 2019, 12, 2649. https://doi.org/10.3390/ma12172649

Qin W, Hong M, Wang Y, Tang J, Cai G, Yin R, Ruan X, Yang B, Jiang C, Ren F. Different Radiation Tolerances of Ultrafine-Grained Zirconia–Magnesia Composite Ceramics with Different Grain Sizes. Materials. 2019; 12(17):2649. https://doi.org/10.3390/ma12172649

Chicago/Turabian StyleQin, Wenjing, Mengqing Hong, Yongqiang Wang, Jun Tang, Guangxu Cai, Ran Yin, Xuefeng Ruan, Bing Yang, Changzhong Jiang, and Feng Ren. 2019. "Different Radiation Tolerances of Ultrafine-Grained Zirconia–Magnesia Composite Ceramics with Different Grain Sizes" Materials 12, no. 17: 2649. https://doi.org/10.3390/ma12172649