Surface-Modified Nanofibrous PVDF Membranes for Liquid Separation Technology

Abstract

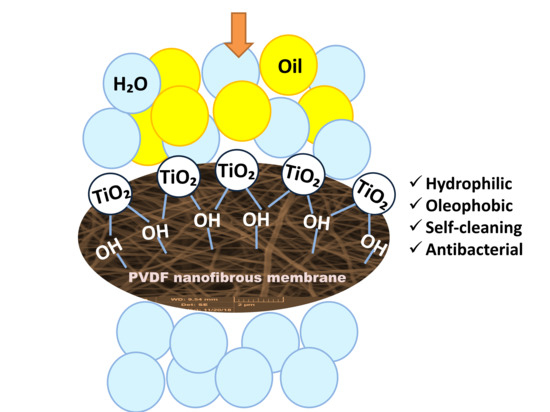

:1. Introduction

2. Materials and Methods

2.1. Membrane Preparation

2.2. Surface Modification

2.3. Characterization

2.4. Emulsion Preparation

- ⟶

- A few drops of pink color food colorant were mixed with 100 g of distilled water.

- ⟶

- Then, 2 g of surfactant was added to the water and mixed with a magnetic stirrer for 10 min.

- ⟶

- Next, 100 g of sunflower oil was added to the water/surfactant mixture.

- ⟶

- Finally, the solution was mixed with a magnetic stirrer at 500 rpm for 24 h.

2.5. Filtration Test

3. Results and Discussion

3.1. Characterization of the Membranes

3.2. Separation Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, W.; Shi, Z.; Zhang, F.; Liu, X.; Jin, J.; Jiang, L. Superhydrophobic and superoleophilic PVDF membranes for effective separation of water-in-oil emulsions with high flux. Adv. Mater. 2013, 25, 2071–2076. [Google Scholar] [CrossRef]

- Zhang, F.; Gao, S.; Zhu, Y.; Jin, J. Alkaline-induced superhydrophilic/underwater superoleophobic polyacrylonitrile membranes with ultralow oil-adhesion for high-efficient oil/water separation. J. Memb. Sci. 2016, 513, 67–73. [Google Scholar] [CrossRef]

- Fan, L.; Yan, J.; He, H.; Deng, N.; Zhao, Y.; Kang, W.; Cheng, B. Electro-blown spun PS/PAN fibrous membrane for highly efficient oil/water separation. Fibers Polym. 2017, 18, 1988–1994. [Google Scholar] [CrossRef]

- Yalcinkaya, F.; Siekierka, A.; Bryjak, M. Preparation of fouling-resistant nanofibrous composite membranes for separation of oily wastewater. Polymers 2017, 9, 679. [Google Scholar] [CrossRef]

- Yalcinkaya, F. Preparation of various nanofiber layers using wire electrospinning system. Arab. J. Chem. 2016. [Google Scholar] [CrossRef]

- Grimmelsmann, N.; Grothe, T.; Homburg, S.V.; Ehrmann, A. Electrospinning and stabilization of chitosan nanofiber mats. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Beijing, China, 24–27 October 2017; Volume 254, p. 102006. [Google Scholar]

- Charles, L.F.; Shaw, M.T.; Olson, J.R.; Wei, M. Fabrication and mechanical properties of PLLA/PCL/HA composites via a biomimetic, dip coating, and hot compression procedure. J. Mater. Sci. Mater. Med. 2010, 21, 1845–1854. [Google Scholar] [CrossRef]

- Roche, R.; Yalcinkaya, F. Incorporation of PVDF nanofibre multilayers into functional structure for filtration applications. Nanomaterials 2018, 8, 771. [Google Scholar] [CrossRef]

- Jahanbaani, A.R.; Behzad, T.; Borhani, S.; Darvanjooghi, M.H.K. Electrospinning of cellulose nanofibers mat for laminated epoxy composite production. Fibers Polym. 2016, 17, 1438–1448. [Google Scholar] [CrossRef]

- Liu, R.; Ma, L.; Mei, J.; Huang, S.; Yang, S.; Li, E.; Yuan, G. Large areal mass, mechanically tough and freestanding electrode based on heteroatom-doped carbon nanofibers for flexible supercapacitors. Chem. A Eur. J. 2017, 23, 2610–2618. [Google Scholar] [CrossRef]

- Wirth, E.; Sabantina, L.; Weber, M.; Finsterbusch, K.; Ehrmann, A. Preliminary study of ultrasonic welding as a joining process for electrospun nanofiber mats. Nanomaterials 2018, 8, 746. [Google Scholar] [CrossRef]

- Sabantina, L.; Hes, L.; Mirasol, J.R.; Cordero, T.; Ehrmann, A. Water vapor permeability through PAN nanofiber mat with varying membrane-like areas. Fibres Text. East. Eur. 2019, 27, 12–15. [Google Scholar] [CrossRef]

- Roche, R.; Yalcinkaya, F. Electrospun polyacrylonitrile nanofibrous membranes for point-of-use water and air cleaning. ChemistryOpen 2019, 8, 97–103. [Google Scholar] [CrossRef] [PubMed]

- Sabantina, L.; Kinzel, F.; Hauser, T.; Többer, A.; Klöcker, M.; Döpke, C.; Böttjer, R.; Wehlage, D.; Rattenholl, A.; Ehrmann, A. Comparative Study of Pleurotus ostreatus Mushroom Grown on Modified PAN Nanofiber Mats. Nanomaterials 2019, 9, 475. [Google Scholar] [CrossRef] [PubMed]

- Yalcinkaya, F.; Hruza, J. Effect of laminating pressure on polymeric multilayer nanofibrous membranes for liquid filtration. Nanomaterials 2018, 8, 272. [Google Scholar] [CrossRef] [PubMed]

- Yalcinkaya, F.; Siekierka, A.; Bryjak, M. Surface modification of electrospun nanofibrous membranes for oily wastewater separation. RSC Adv. 2017, 7, 56704–56712. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.; Wu, X.F. Electrospinning superhydrophobic-superoleophilic fibrous PVDF membranes for high-efficiency water-oil separation. Mater. Lett. 2015, 160, 423–427. [Google Scholar] [CrossRef]

- Xiao, L.; Davenport, D.M.; Ormsbee, L.; Bhattacharyya, D. Polymerization and functionalization of membrane pores for water related applications. Ind. Eng. Chem. Res. 2015, 54, 4174–4182. [Google Scholar] [CrossRef]

- Martakov, I.S.; Torlopov, M.A.; Mikhaylov, V.I.; Krivoshapkina, E.F.; Silant’ev, V.E.; Krivoshapkin, P.V. Interaction of cellulose nanocrystals with titanium dioxide and peculiarities of hybrid structures formation. J. Sol-Gel Sci. Technol. 2018, 88, 13–21. [Google Scholar] [CrossRef]

- Dong, L.; Liu, X.; Xiong, Z.; Sheng, D.; Lin, C.; Zhou, Y.; Yang, Y. Preparation of UV-blocking poly(vinylidene fluoride) films through SI-AGET ATRP using a colorless polydopamine initiator layer. Ind. Eng. Chem. Res. 2018, 57, 12662–12669. [Google Scholar] [CrossRef]

- Shi, F.; Wu, J.; Zhao, B. Preparation and investigation of intelligent polymeric nanocapsule for enhanced oil recovery. Materials 2019, 12, 1093. [Google Scholar] [CrossRef]

- Naseeb, N.; Mohammed, A.A.; Laoui, T.; Khan, Z. A novel PAN-GO-SiO2 hybrid membrane for separating oil and water from emulsified mixture. Materials 2019, 12, 212. [Google Scholar] [CrossRef] [PubMed]

- Hobbs, C.; Hong, S.; Taylor, J. Effect of surface roughness on fouling of RO and NF membranes during filtration of a high organic surficial groundwater. J. Water Supply Res. Technol. AQUA 2006, 55, 559–570. [Google Scholar] [CrossRef]

- Martins, P.M.; Ribeiro, J.M.; Teixeira, S.; Petrovykh, D.Y.; Cuniberti, G.; Pereira, L.; Lanceros-Méndez, S. Photocatalytic microporous membrane against the increasing problem of water emerging pollutants. Materials 2019, 12, 1649. [Google Scholar] [CrossRef] [PubMed]

- Montazer, M.; Seifollahzadeh, S. Enhanced self-cleaning, antibacterial and UV protection properties of nano TiO2 treated textile through enzymatic pretreatment. Photochem. Photobiol. 2011, 87, 877–883. [Google Scholar] [CrossRef] [PubMed]

- Tavares, M.T.S.; Santos, A.S.F.; Santos, I.M.G.; Silva, M.R.S.; Bomio, M.R.D.; Longo, E.; Paskocimas, C.A.; Motta, F.V. TiO2/PDMS nanocomposites for use on self-cleaning surfaces. Surf. Coatings Technol. 2014, 239, 16–19. [Google Scholar] [CrossRef]

- Xu, Q.F.; Liu, Y.; Lin, F.J.; Mondal, B.; Lyons, A.M. Superhydrophobic TiO2-polymer nanocomposite surface with UV-induced reversible wettability and self-cleaning properties. ACS Appl. Mater. Interfaces 2013, 5, 8915–8924. [Google Scholar] [CrossRef] [PubMed]

| Polymer | Density (g/m2) | Modification | Abbreviation | Fiber Diameter (nm) |

|---|---|---|---|---|

| PVDF | 1 | - | PVDF 1 | 148.9 ± 23.1 |

| 2 | - | PVDF 2 | 148.5 ± 45.6 | |

| 3 | - | PVDF 3 | 134.2 ± 37.2 | |

| 3 | NaOH | PVDF_N | 164.9 ± 40.3 | |

| 3 | NaOH + TiO2 | PVDF_NT | 248.2 ± 47.8 | |

| 3 | KOH | PVDF_K | 174.9 ± 57.6 | |

| 3 | KOH + TiO2 | PVDF_KT | 197.0 ± 54.7 |

| Sample | Maximum Pore Size (µm) | Average Pore Size (µm) |

|---|---|---|

| PVDF 1 | 4.54 ± 0.14 | 2.50 ± 0.29 |

| PVDF 2 | 4.20 ± 0.00 | 1.15 ± 0.08 |

| PVDF 3 | 4.23 ± 0.05 | 0.72 ± 0.04 |

| Sample | CA before Separation (°) | CA after Separation (°) | Image (Before Separation) |

|---|---|---|---|

| PVDF 1 | 71.23 ± 1.31 | 62.40 ± 2.17 |  |

| PVDF 2 | 80.83 ± 1.53 | 47.46 ± 1.93 |  |

| PVDF 3 | 89.40 ± 4.67 | 35.32 ± 8.71 |  |

| PVDF_N | 0 | 0 | - |

| PVDF_NT | 39.43 ± 3.01 | 0 |  |

| PVDF_K | 0 | 0 | - |

| PVDF_KT | 0 | 0 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boyraz, E.; Yalcinkaya, F.; Hruza, J.; Maryska, J. Surface-Modified Nanofibrous PVDF Membranes for Liquid Separation Technology. Materials 2019, 12, 2702. https://doi.org/10.3390/ma12172702

Boyraz E, Yalcinkaya F, Hruza J, Maryska J. Surface-Modified Nanofibrous PVDF Membranes for Liquid Separation Technology. Materials. 2019; 12(17):2702. https://doi.org/10.3390/ma12172702

Chicago/Turabian StyleBoyraz, Evren, Fatma Yalcinkaya, Jakub Hruza, and Jiri Maryska. 2019. "Surface-Modified Nanofibrous PVDF Membranes for Liquid Separation Technology" Materials 12, no. 17: 2702. https://doi.org/10.3390/ma12172702

APA StyleBoyraz, E., Yalcinkaya, F., Hruza, J., & Maryska, J. (2019). Surface-Modified Nanofibrous PVDF Membranes for Liquid Separation Technology. Materials, 12(17), 2702. https://doi.org/10.3390/ma12172702