Gradient Microstructures and Mechanical Properties of Ti-6Al-4V/Zn Composite Prepared by Friction Stir Processing

Abstract

:1. Introduction

2. Experimental

2.1. Fabrication of TC4/Zn Composite

2.2. Microstructural Observations

3. Results

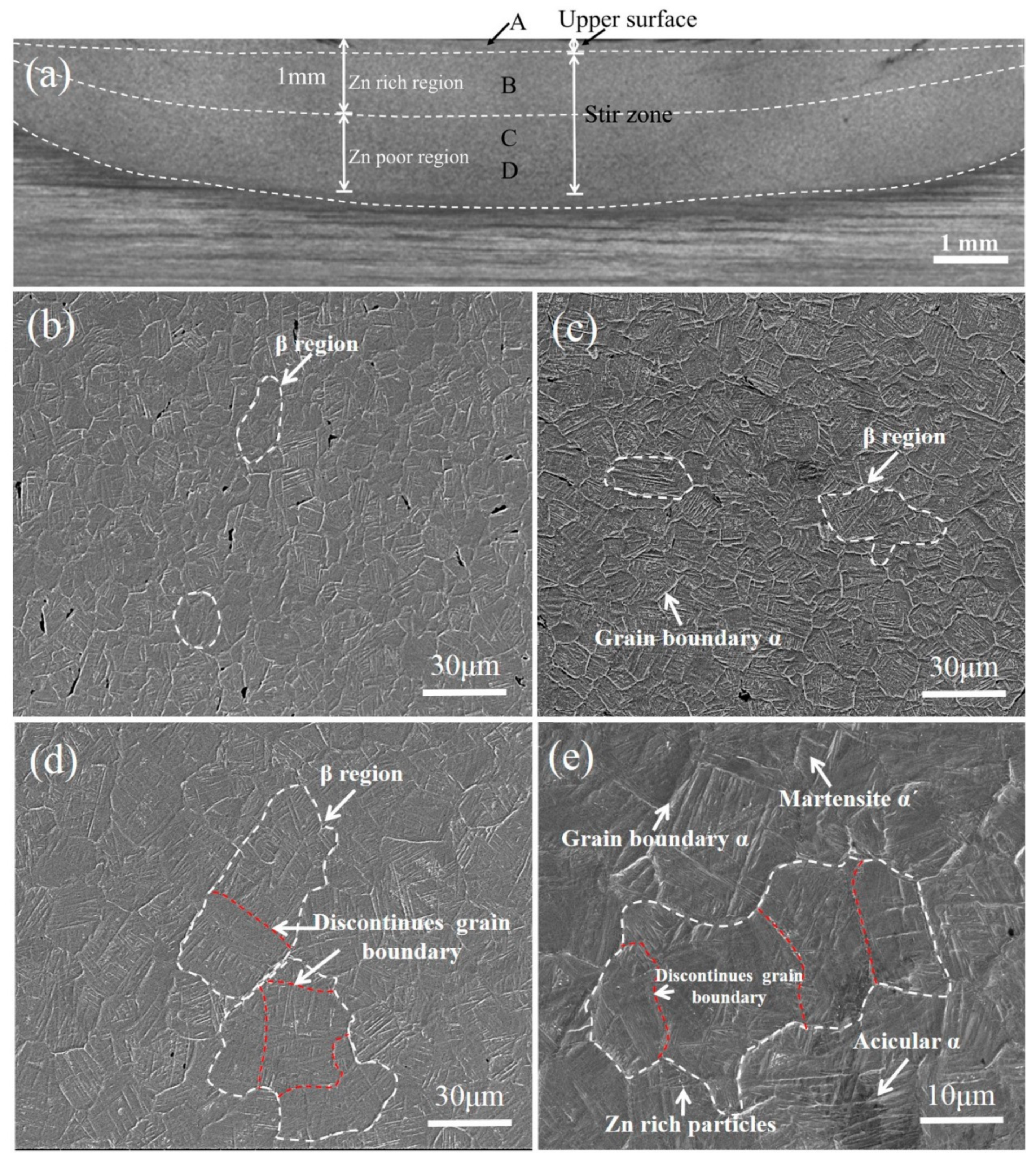

3.1. Effects of Added Zn on Microstructures of TC4/Zn Composites

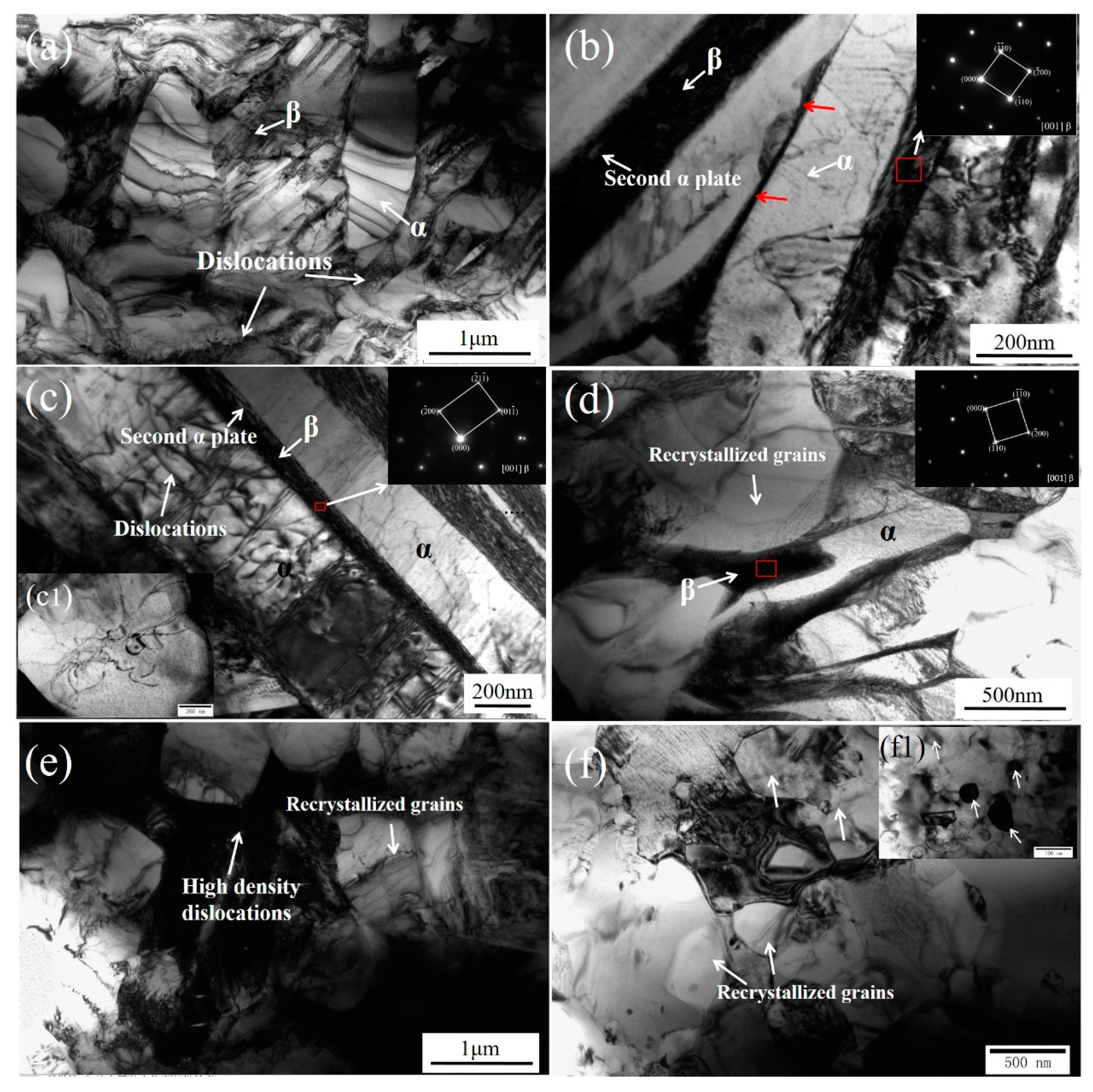

3.2. TEM Observations of Microstructural Variation with Decreasing Distance from the Upper Surface (150 μm–1500 μm)

3.3. X-ray Diffraction Pattern Analysis

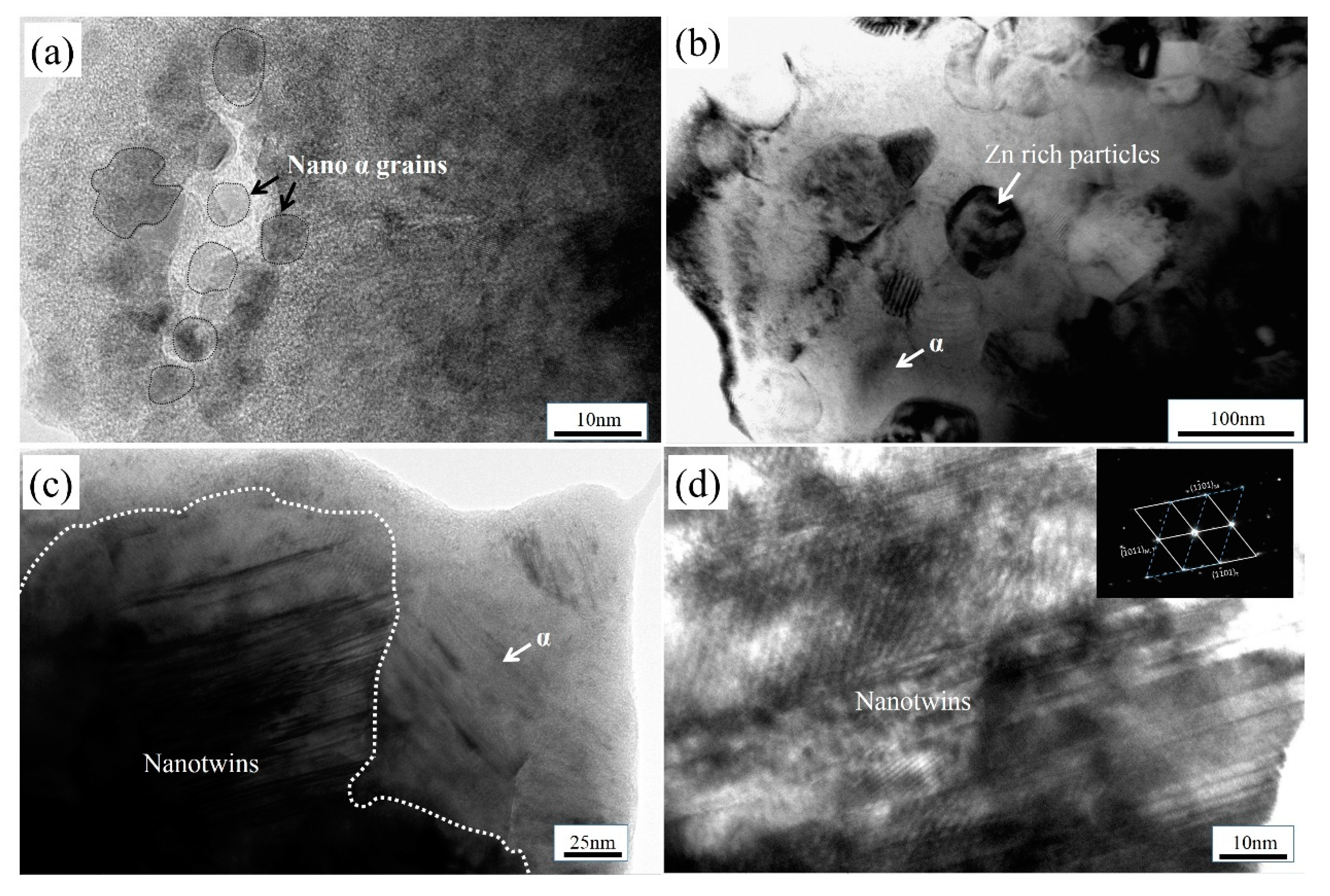

3.4. Microstructures in Upper Surface of TC4/Zn Composite (0–150 μm)

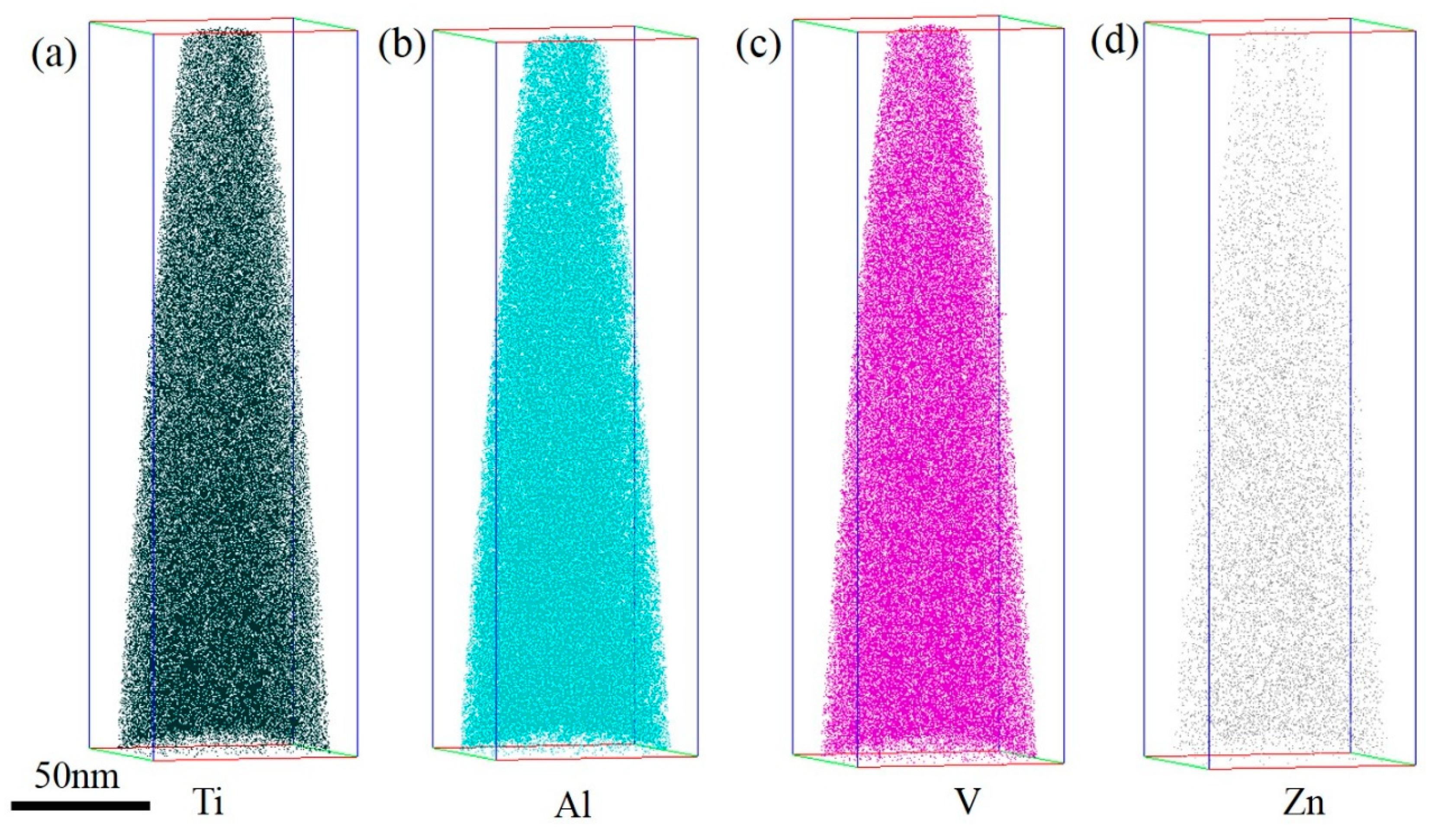

3.5. APT Characterization

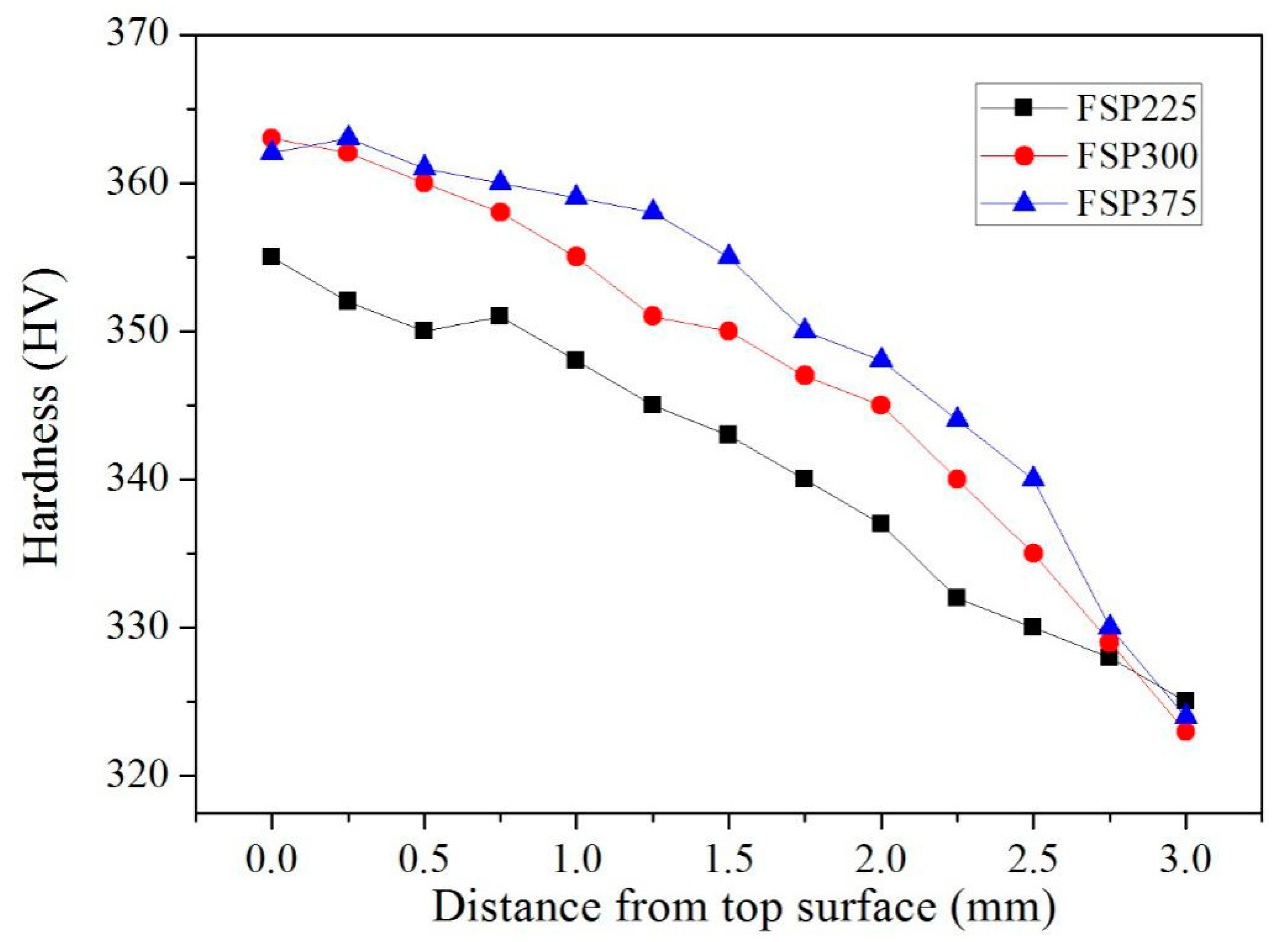

3.6. Microhardness

4. Discussion

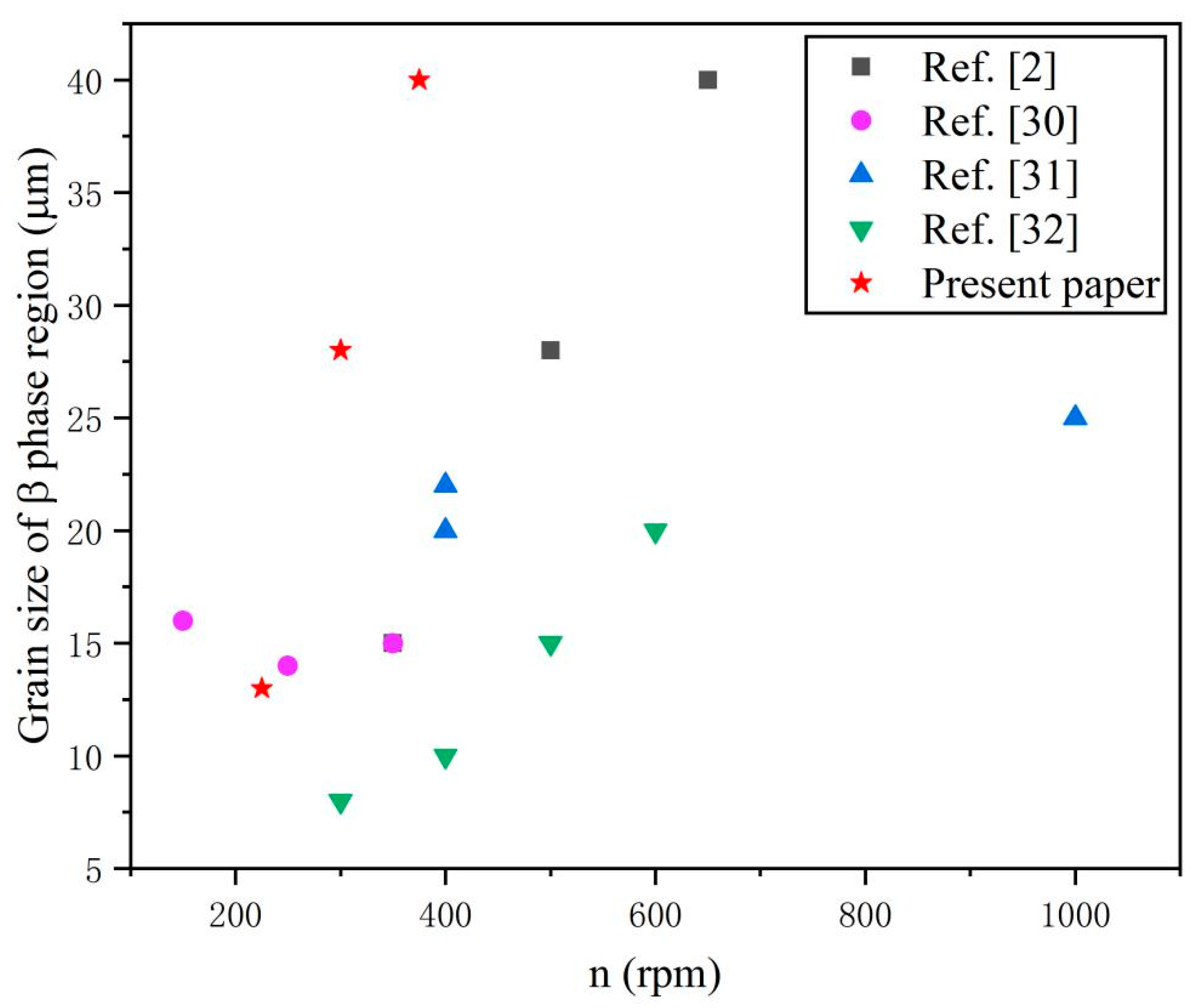

4.1. Effect of Added Zn on β Grain Growth Mechanism During FSP

4.2. Spheroidization Behavior of α Lamellae Microstructure in Stir Zone

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Ding, Z.; Zhang, C.; Xie, L.; Zhang, L.-C.; Wang, L.; Lu, W. Effects of Friction Stir Processing on the Phase Transformation and Microstructure of TiO2-Compounded Ti-6Al-4V Alloy. Met. Mater. Trans. A 2016, 47, 5675–5679. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.S.; Hu, W.Y.; Luo, L. Surface modification of Ti–6Al–4V alloy via friction-stir processing: Microstructure evolution and dry sliding wear performance. Surf. Coat. Technol. 2014, 239, 160–170. [Google Scholar] [CrossRef]

- Song, X.; Han, Y.; Wang, X.; Liu, W.; Wu, J.; Cui, H. First-principles study of adhesion strength and stability of the TiB2/TiC interface in composite materials. Ceram. Int. 2018, 44, 1756–1763. [Google Scholar] [CrossRef]

- Zeng, R.C.; Li, X.T.; Liu, Z.G.; Zhang, F.; Li, S.Q.; Cui, H.Z. Corrosion resistance of Zn-Al layered double hydroxide/poly(lactic acid) composite coating on magnesium alloy AZ31. Front. Mater. Sci. 2015, 9, 355–365. [Google Scholar] [CrossRef]

- Wang, L.; Xie, L.; Shen, P.; Fan, Q.; Wang, W.; Wang, K.; Lu, W.; Hua, L.; Zhang, L.-C. Surface microstructure and mechanical properties of Ti-6Al-4V/Ag nanocomposite prepared by FSP. Mater. Charact. 2019, 153, 175–183. [Google Scholar] [CrossRef]

- Jiao, X.Y.; Wang, C.M.; Gong, Z.Q.; Wang, G.M.; Sun, H.F.; Yang, H.R. Effect of Ti on T15M composite coating fabricated by laser cladding technology. Surf. Coat. Technol. 2017, 325, 643–649. [Google Scholar] [CrossRef]

- Gu, H.; Ding, Z.; Yang, Z.; Yu, W.; Zhang, W.; Lu, W.; Zhang, L.-C.; Wang, K.; Wang, L.; Fu, Y.-F. Microstructure evolution and electrochemical properties of TiO2/Ti-35Nb-2Ta-3Zr micro/nano-composites fabricated by friction stir processing. Mater. Des. 2019, 169, 107680. [Google Scholar] [CrossRef]

- Kuroda, D.; Niinomi, M.; Morinaga, M.; Kato, Y.; Yashiro, T. Design and mechanical properties of new β type titanium alloys for implant materials. Mater. Sci. Eng. A 1998, 243, 244–249. [Google Scholar] [CrossRef]

- Guo, S.; Meng, Q.K.; Liao, G.Y.; Hu, L.; Zhao, X.Q. Microstructural evolution and mechanical behavior of metastable β-type Ti-25Nb-2Mo-4Sn alloy with high strength and low modulus. Prog. Nat. Sci. Mater. Int. 2013, 23, 174–182. [Google Scholar] [CrossRef]

- Zhang, W.; Cao, H.; Zhang, X.; Li, G.; Chang, Q.; Zhao, J.; Qiao, Y.; Ding, X.; Yang, G.; Liu, X.; et al. A strontium-incorporated nanoporous titanium implant surface for rapid osseointegration. Nanoscale 2016, 8, 5291–5301. [Google Scholar] [CrossRef]

- Zhang, H.B.; Zhou, H.P.; Qin, S.X.; Liu, J.; Xu, X.M. Effect of deformation parameters on twinning evolution during hot deformation in a typical nickel-based superalloy. Mat. Sci. Eng. A-Struct. 2017, 696, 290–298. [Google Scholar] [CrossRef]

- Zhu, C.; Lv, Y.; Qian, C.; Qian, H.; Jiao, T.; Wang, L.; Zhang, F. Proliferation and osteogenic differentiation of rat BMSCs on a novel Ti/SiC metal matrix nanocomposite modified by friction stir processing. Sci. Rep. 2016, 6, 38875. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, M.; Li, Y.; Dou, G.; Gong, S. The effect of titanium compounds addition on the microwave dielectric properties of the ZnO–Nb2O5 ceramics for LTCC. J. Mater. Sci. Mater. Electron. 2014, 25, 4319–4325. [Google Scholar] [CrossRef]

- Guo, X.; Wang, L.; Wang, M.; Qin, J.; Zhang, D.; Lu, W. Effects of degree of deformation on the microstructure, mechanical properties and texture of hybrid-reinforced titanium matrix composites. Acta Mater. 2012, 60, 2656–2667. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, L.; Xue, X.; Lu, W.; Qin, J.; Zhang, D. Microstructure evolution and mechanical properties of a Ti–35Nb–3Zr–2Ta biomedical alloy processed by equal channel angular pressing (ECAP). Mater. Sci. Eng. C 2013, 33, 4551–4561. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Li, J.; Huang, G.; Lv, Y.; Shao, X.; Lu, W.; Zhang, D. Effect of ECAP numbers on microstructure and properties of titanium matrix composite. Mater. Des. 2015, 75, 113–119. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Nandan, R.; Debroy, T.; Bhadeshia, H. Recent advances in friction-stir welding–Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Wang, L.; Qu, J.; Chen, L.; Meng, Q.; Zhang, L.-C.; Qin, J.; Zhang, D.; Lu, W. Investigation of Deformation Mechanisms in β-Type Ti-35Nb-2Ta-3Zr Alloy via FSP Leading to Surface Strengthening. Met. Mater. Trans. A 2015, 46, 4813–4818. [Google Scholar] [CrossRef]

- Wang, L.Q.; Xie, L.C.; Lv, Y.T.; Zhang, L.C.; Chen, L.Y.; Meng, Q.; Qu, J.; Zhang, D.; Lu, W.J. Microstructure Evolution and Superelastic Behavior in Ti-35Nb-2Ta-3Zr Alloy Processed by Friction Stir Processing. Acta Mater. 2017, 131, 499–510. [Google Scholar] [CrossRef]

- Jiang, S.; Jia, Y.; Zhang, H.; Du, Z.; Lu, Z.; Zhang, K.; He, Y.; Wang, R. Plastic Deformation Behavior of Ti Foil Under Ultrasonic Vibration in Tension. J. Mater. Eng. Perform. 2017, 42, 556–1775. [Google Scholar] [CrossRef]

- Li, J.; Xing, C.; Qiao, H.; Chen, H.; Yang, J.; Dong, H.; Shi, F. Crystal structure characteristics, dielectric loss, and vibrational spectra of Zn-rich non-stoichiometric Ba[(Zn1/3Nb2/3)1−xZnx]O3 ceramics. Mater. Res. Express 2017, 4, 075910. [Google Scholar] [CrossRef]

- Cui, H.Z.; Li, S.H.; Cui, D.Y. Effects of SiC on Phases, Microstructure and Mechanical Property of Porous Al2TiO5 Fabricated by Reaction Sintering. J. Inorg. Mater. 2014, 29, 509–514. [Google Scholar]

- Brice, D.; Samimi, P.; Ghamarian, I.; Liu, Y.; Mendoza, M.; Kenney, M.; Reidy, R.; Garcia-Avila, M.; Collins, P. On the eutectoid transformation behavior of the Ti-Zn system and its metastable phases. J. Alloys Compd. 2017, 718, 22–27. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.; Sun, Y.; Wan, Z.; Zhou, H.; Hu, L. Nanocrystalline Ti/AZ61 magnesium matrix composite: Evolution of microstructure and mechanical property during annealing treatment. J. Alloys Compd. 2018, 741, 231–239. [Google Scholar] [CrossRef]

- Vassilev, G.; Liu, X.; Ishida, K. Reaction kinetics and phase diagram studies in the Ti–Zn system. J. Alloys Compd. 2004, 375, 162–170. [Google Scholar] [CrossRef]

- Yang, S.; Su, X.; Wang, J.; Yin, F.; Li, Z.; Tu, H.; Peng, H. The Zn-rich corner of the Zn–Al–Ti system at 723K. J. Alloys Compd. 2010, 499, 194–199. [Google Scholar] [CrossRef]

- Li, C.; Sha, G.; Xia, J.; Liu, Y.; Ringer, S.P. Si-induced precipitation modification and related age-hardening response of an Al–4Mg–1Cu–0.5Si alloy. Mater. Chem. Phys. 2017, 193, 421–426. [Google Scholar] [CrossRef]

- Zhu, C.Y.; Lv, Y.T.; Qian, C.; Ding, Z.H.; Jiao, T.; Gu, X.Y.; Lu, E.; Wang, L.Q.; Zhang, F.Q. Microstructures, mechanical, and biological properties of a novel Ti-6Al-4V/zinc surface nanocomposite prepared by friction stir processing. Int. J. Nanomed. 2018, 13, 1881. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.; Luo, L.; Hu, W. Fabrication of TiCp/Ti–6Al–4V surface composite via friction stir processing (FSP): Process optimization, particle dispersion-refinement behavior and hardening mechanism. Mater. Sci. Eng. A 2013, 574, 75–85. [Google Scholar] [CrossRef]

- Kitamura, K.; Fujii, H.; Iwata, Y.; Sun, Y.; Morisada, Y.; Sun, Y. Flexible control of the microstructure and mechanical properties of friction stir welded Ti–6Al–4V joints. Mater. Des. 2013, 46, 348–354. [Google Scholar] [CrossRef]

- Zhang, Y.; Sato, Y.S.; Kokawa, H.; Park, S.H.C.; Hirano, S. Microstructural characteristics and mechanical properties of Ti–6Al–4V friction stir welds. Mater. Sci. Eng. A 2008, 485, 448–455. [Google Scholar] [CrossRef]

- Lv, Y.; Ding, Z.; Xue, J.; Sha, G.; Lu, E.; Wang, L.; Lu, W.; Su, C.; Zhang, L.-C. Deformation mechanisms in surface nano-crystallization of low elastic modulus Ti6Al4V/Zn composite during severe plastic deformation. Scr. Mater. 2018, 157, 142–147. [Google Scholar] [CrossRef]

- Neeraj, T.; Savage, M.F.; Tatalovich, J.; Kovarik, L.; Hayes, R.W.; Mills, M.J. Observation of tension–compression asymmetry in α and titanium alloys. Philos. Mag. 2005, 85, 279–292. [Google Scholar] [CrossRef]

- Malinov, S.; Sha, W.; Guo, Z.; Tang, C.; Long, A. Synchrotron X-ray diffraction study of the phase transformations in titanium alloys. Mater. Charact. 2002, 48, 279–295. [Google Scholar] [CrossRef] [Green Version]

- Murray, J.L. The Ti-Zn (Titanium-Zinc) system. Bull. Alloy Phase Diagrams 1984, 5, 52–56. [Google Scholar] [CrossRef]

- Ghosh, G.; Delsante, S.; Borzone, G.; Asta, M.; Ferro, R. Phase stability and cohesive properties of Ti–Zn intermetallics: First-principles calculations and experimental results. Acta Mater. 2006, 54, 4977–4997. [Google Scholar] [CrossRef]

- Lv, Y.; Ding, Y.; Han, Y.; Zhang, L.-C.; Wang, L.; Lu, W. Strengthening mechanism of friction stir processed and post heat treated NiAl bronze alloy: Effect of rotation rates. Mater. Sci. Eng. A 2017, 685, 439–446. [Google Scholar] [CrossRef] [Green Version]

- Lv, Y.; Ding, Y.; Han, Y.; Wu, L.; Wang, L.; Lu, W. Effect of Microstructures on Fatigue Crack Growth Behavior of Friction Stir Processed NiAl Bronze Alloy. Met. Mater. Trans. A 2017, 48, 1121–1132. [Google Scholar] [CrossRef]

- Gil, F.; Planell, J. Behaviour of normal grain growth kinetics in single phase titanium and titanium alloys. Mater. Sci. Eng. A 2000, 283, 17–24. [Google Scholar] [CrossRef]

- Seetharaman, V.; Semiatin, S.L. Plastic-flow and microstructure evolution during hot deformation of a gamma titanium aluminide alloy. Metall. Mater. Trans. A 1996, 28, 2309–2321. [Google Scholar] [CrossRef]

- Lv, Y.T.; Wang, L.Q.; Han, Y.F.; Xu, X.Y.; Lu, W.J. Investigation of microstructure and mechanical properties of hot worked NiAl bronze alloy with different deformation degree. Mater. Sci. Eng. A 2015, 643, 17–24. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.G.; Li, M.Q. Nanocrystallization mechanism of beta phase in Ti-6Al-4V subjected to severe plastic deformation. Mater. Sci. Eng. A 2016, 669, 7–13. [Google Scholar] [CrossRef]

- Zhang, Z.; Qu, S.; Feng, A.; Shen, J. Achieving grain refinement and enhanced mechanical properties in Ti–6Al–4V alloy produced by multidirectional isothermal forging. Mater. Sci. Eng. A 2017, 692, 127–138. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.; Morgan, J.; Malas, J.; Frazier, W.; Prasad, Y. Hot deformation mechanisms in ELI Grade Ti-6a1-4V. Scr. Mater. 1999, 41, 283–288. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.; Morgan, J.; Malas, J.; Frazier, W.; Prasad, Y. Hot deformation and microstructural damage mechanisms in extra-low interstitial (ELI) grade Ti–6Al–4V. Mater. Sci. Eng. A 2000, 279, 289–299. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Murzinova, M.; Salishchev, G.; Semiatin, S. Spheroidization of the lamellar microstructure in Ti–6Al–4V alloy during warm deformation and annealing. Acta Mater. 2011, 59, 4138–4150. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. The thermomechanical processing of alpha/beta titanium alloys. JOM-J. Miner. Met. Mater. Soc. 1997, 49, 33–39. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.; Hu, W. Surface nitriding on Ti–6Al–4V alloy via friction stir processing method under nitrogen atmosphere. Appl. Surf. Sci. 2013, 274, 356–364. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Y.; Ding, Z.; Sun, X.; Li, L.; Sha, G.; Liu, R.; Wang, L. Gradient Microstructures and Mechanical Properties of Ti-6Al-4V/Zn Composite Prepared by Friction Stir Processing. Materials 2019, 12, 2795. https://doi.org/10.3390/ma12172795

Lv Y, Ding Z, Sun X, Li L, Sha G, Liu R, Wang L. Gradient Microstructures and Mechanical Properties of Ti-6Al-4V/Zn Composite Prepared by Friction Stir Processing. Materials. 2019; 12(17):2795. https://doi.org/10.3390/ma12172795

Chicago/Turabian StyleLv, Yuting, Zihao Ding, Xueyan Sun, Lei Li, Gang Sha, Rui Liu, and Liqiang Wang. 2019. "Gradient Microstructures and Mechanical Properties of Ti-6Al-4V/Zn Composite Prepared by Friction Stir Processing" Materials 12, no. 17: 2795. https://doi.org/10.3390/ma12172795