Energy Coupling of Laser Radiation on AISI 304 Stainless Steel: Effect of High Temperatures and Surface Oxidation

Abstract

:1. Introduction

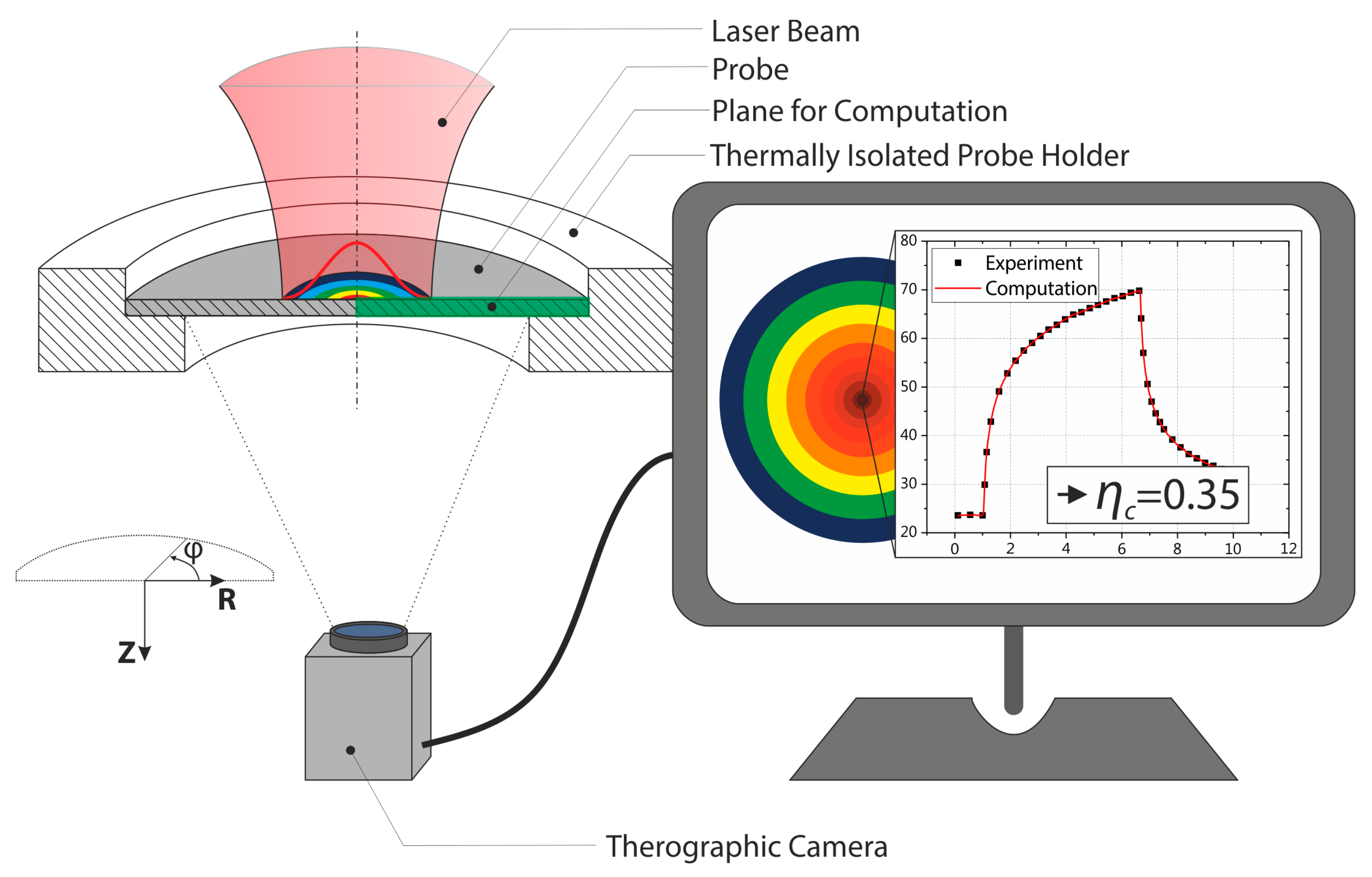

2. Materials and Methods

3. Results and Discussion

3.1. Temperature Dependence

3.2. Effect of Surface Oxidation

4. Summary and Conclusions

- The energy coupling mechanism of laser radiation at high temperatures depends on the wavelength.

- The energy coupling efficiency of visible laser irradiation (λ = 0.515 µm) shows an approximately linear decrease with temperature.

- The energy coupling efficiency for laser irradiation in the near infrared (λ = 1.07 µm) is below 1000 °C independent of the temperature, above a linear decrease was measured with temperature.

- The energy coupling efficiency for CO2 laser irradiation (λ = 10.6 µm) is completely independent of the temperature for the evaluated temperature range.

- The process-induced oxidation leads to a dramatic increase of the energy coupling efficiency above 650 °C and stays at this high level also in the liquid phase.

Author Contributions

Acknowledgments

Conflicts of Interest

Appendix A

| Density (kg/m3) | 293 K | 8030 |

| Heat conductivity (W/(mK)) | 293 K | 14.8 |

| 400 K | 16.6 | |

| 500 K | 18.3 | |

| 600 K | 19.8 | |

| 700 K | 21.2 | |

| 800 K | 22.6 | |

| 900 K | 24 | |

| 1000 K | 25.4 | |

| 1100 K | 25.7 | |

| Heat capacity (J/(kg·K)) | 293 K | 500 |

| 473 K | 510 | |

| 673 K | 550 | |

| 873 K | 585 | |

| 1073 K | 630 |

| Header | Wavelenth λ (µm) | Beam Radius (mm) | Laser Power (W) |

|---|---|---|---|

| Frequency-doubled disk laser | 0.515 | 3.68 | 0–1000 |

| Fiber laser | 1.07 | 0.486 | 0–400 |

| CO2 laser | 10.6 | 3 | 0–2400 |

References

- Palik, E.D. Handbook of Optical Constants of Solids; Academic Press: Orlando, FL, USA, 1985. [Google Scholar]

- Haynes, W.M.; Lide, D.R.; Bruno, T.J. CRC Handbook of Chemistry and Physics, 96th ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Weaver, J.H.; Krafka, C.; Lynch, D.W.; Koch, E.E. Optical Properties of Metals Pt. I: The Transition Metals; Fachinformationszentrum Energie Physik Mathematik GmbH: Karlsruhe, Germany, 1981. [Google Scholar]

- Wang, H.; Kawahito, Y.; Yoshida, R.; Nakashima, Y.; Shiokawa, K. A Model to Calculate the Laser Absorption Property of Actual Surface. Int. J. Heat Mass Transf. 2018, 118, 562–569. [Google Scholar] [CrossRef]

- Bergström, D.; Powell, J.; Kaplan, A.F.H. The Absorption of Light by Rough Metal Surfaces - A Three-Dimensional Ray-Tracing Analysis. J. Appl. Phys. 2008, 103, 103515. [Google Scholar] [CrossRef]

- Kaplan, A.F.H. Local Absorptivity Modulation of a 1μm-Laser Beam Through Surface Waviness. Appl. Surf. Sci. 2012, 258, 9732–9736. [Google Scholar] [CrossRef]

- Hipp, D.; Mahrle, A.; Beyer, E. Beyond Fresnel: Absorption of fibre laser radiation at rough stainless steel surfaces. J. Phys. D Appl. Phys. 2019, 52, 355302. [Google Scholar] [CrossRef]

- Stern, G. Absorptivity of CW CO2, CO and YAG-Laser Beams by Different Metallic Alloys. In Proceedings of 3rd European Conferfence on Laser Treamnet of Materials, AWT, Erlangen, Germany, 17–19 September 1990; Sprechsaal Publishing Group: Coburg, Germany, 1990; pp. 25–35. [Google Scholar]

- Price, D.J. The Temperature Variation of the Emissivity of Metals in the Near Infra-Red. Proc. Phys. Soc. 1947, 59, 131–138. [Google Scholar] [CrossRef]

- Seban, R.A. The Emissivity of Transition Metals in the Infrared. J. Heat Transf. 1965, 87, 173–176. [Google Scholar] [CrossRef]

- Kalenskii, A.V.; Zvekov, A.A. Temperature Dependences of the Optical Properties of Aluminum Nanoparticles. Tech. Phys. Lett. 2017, 43, 535–538. [Google Scholar] [CrossRef]

- Jones, M.C.; Palmer, D.C.; Tien, C.L. Infrared Absorptivities of Transition Metals at Room and Liquid-Helium Temperatures. J. Opt. Soc. Am. 1972, 62, 353–360. [Google Scholar] [CrossRef]

- Ujihara, K. Reflectivity of Metals at High Temperatures. J Appl Phys 1972, 43, 2376–2383. [Google Scholar] [CrossRef]

- Konov, V.I.; Tokarev, V.N. Temperature Dependence of the Absorptivity of Aluminum Targets at the 10.6 μm Wavelength. Sov. J. Quantum Electron. 1983, 13, 177–180. [Google Scholar] [CrossRef]

- Dreehsen, H.G.; Hartwich, C.; Schaefer, J.H.; Uhlenbusch, J. Measurement of the Optical Constants of Al Above the Melting Point at λ=10.6 μm. J. Appl. Phys. 1984, 56, 238–240. [Google Scholar] [CrossRef]

- Ursu, I.; Mihailescu, I.N.; Apostol, I.; Dinescu, M.; Hening, A.; Stoica, M.; Prokhorov, A.M.; Ageev, V.P.; Konov, V.I.; Tokarev, V.N. On the Behaviour of Aluminium under Microsecond Pulsed TEA CO2 Laser Radiation in Vacuum. J Phys D Appl Phys. 1984, 17, 1315–1324. [Google Scholar] [CrossRef]

- Brückner, M.; Schäfer, J.H.; Uhlenbusch, J. Ellipsometric Measurement of the Optical Constants of Solid and Molten Aluminum and Copper at λ=10.6 μm. J. Appl. Phys. 1989, 66, 1326–1332. [Google Scholar]

- Crane, K.C.A.; Garnsworthy, R.K.; Mathias, L.E.S. Ablation of Materials Subjected to Laser Radiation and High-Speed Gas Flows. J. Appl. Phys. 1980, 51, 5954–5961. [Google Scholar] [CrossRef]

- Duley, W.W.; Semple, D.J.; Morency, J.-P.; Gravel, M. Coupling Coefficient for cw CO2 Laser Radiation on Stainless Steel. Opt. Laser Technol. 1979, 11, 313–316. [Google Scholar] [CrossRef]

- Miyamoto, I.; Maruo, H. The Mechanism of Laser Cutting. Weld World 1991, 29, 283–294. [Google Scholar] [CrossRef]

- Arzuov, M.I.; Karasev, M.E.; Konov, V.I.; Kostin, V.V.; Metev, S.M.; Silenok, A.S.; Chapliev, N.I. Investigation of the Absorption Coefficient of Metal Targets Irradiated by Pulse-Periodic CO2 Laser Radiation in Air. Sov. J. Quantum Electron. 1978, 8, 892–897. [Google Scholar] [CrossRef]

- Ursu, I.; Apostol, I.; Mihailescu, I.N.; Nistor, L.C.; Teodorescu, V.S.; Turcu, E.; Prokhorov, A.M.; Chapliev, N.I.; Konov, V.I.; Ralchenko, V.G.; et al. A Study of the Compounds which are Induced on the Metallic Target Surface under the Action of a Pulsed Laser Plasmatron. Appl. Phys. A 1982, 29, 209–212. [Google Scholar] [CrossRef]

- Ursu, I.; Apostol, I.; Craciun, D.; Dinescu, M.; Mihailescu, I.N.; Nistor, L.; Popa, A.; Teodorescu, V.S.; Prokhorov, A.M.; Chapliev, N.I.; et al. On the Influence of Surface Condition on Air Plasma Formation near Metals Irradiated by Microsecond TEA CO2 Laser Pulses. J. Phys. D Appl. Phys. 1984, 17, 709–720. [Google Scholar] [CrossRef]

- Kwon, H.; Baek, W.-K.; Kim, M.-S.; Shin, W.-S.; Yoh, J.J. Temperature-Dependent Absorptance of Painted Aluminum, Stainless Steel 304, and Titanium for 1.07 μm and 10.6 μm Laser Beams. Opt. Lasers Eng. 2012, 50, 114–121. [Google Scholar] [CrossRef]

- Bergström, D.; Powell, J.; Kaplan, A.F.H. The Absorptance of Steels to Nd:YLF and Nd:YAG Laser Light at Room Temperature. Appl. Surf. Sci. 2007, 253, 5017–5028. [Google Scholar] [CrossRef]

- Willamowski, U.; Ristau, D.; Welsch, E. Measuring the Absolute Absorptance of Optical Laser Components. Appl. Opt. 1998, 37, 8362–8370. [Google Scholar] [CrossRef]

- Key to Metals AG. Total Materia Database. Available online: https://www.totalmateria.com (accessed on 16 October 2018).

- Hipp, D.; Mahrle, A.; Jäckel, S.; Beyer, E.; Leyens, C.; Füssel, U. Method for high Accuracy Measurements of Energy Coupling and Melting Efficiency Under Welding Conditions. J Laser Appl. 2018, 30, 32414. [Google Scholar] [CrossRef]

- Bergström, D.; Powell, J.; Kaplan, A.F.H. Absorptance of Nonferrous Alloys to Nd:YLF and Nd:YAG Laser Light at Room Temperature. Appl. Opt. 2007, 46, 1290–1301. [Google Scholar] [CrossRef] [PubMed]

- Porneala, C.; Willis, D.A. Observation of Nanosecond Laser-Induced Phase Explosion in Aluminum. Appl. Phys. Lett. 2006, 89, 211121. [Google Scholar] [CrossRef]

- Comins, N.R. The Optical Properties of Liquid Metals. Philos. Mag. 1972, 25, 817–831. [Google Scholar] [CrossRef]

- Tran, T.Q.; Chinnappan, A.; Lee, J.K.Y.; Loc, N.H.; Tran, L.T.; Wang, G.; Kumar, V.V.; Jayathilaka, W.A.D.M.; Ji, D.; Doddamani, M.; et al. 3D Printing of Highly Pure Copper. Metals 2019, 9, 756. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dadbakhsh, S.; Vleugels, J.; Hofkens, J.; van Puyvelde, P.; Yang, S.; Kruth, J.-P.; van Humbeeck, J.; Vanmeensel, K. Influence of Carbon Nanoparticle Addition (and Impurities) on Selective Laser Melting of Pure Copper. Materials (Basel) 2019, 12, 2469. [Google Scholar] [CrossRef] [PubMed]

- Beyer, E. Schweissen mit Laser. Grundlagen; Springer: Heidelberg, Germany, 1995. [Google Scholar]

- Cui, C.Y.; Cui, X.G.; Ren, X.D.; Qi, M.J.; Hu, J.D.; Wang, Y.M. Surface Oxidation Phenomenon and Mechanism of AISI 304 Stainless Steel Induced by Nd:YAG Pulsed Laser. Appl. Surf. Sci. 2014, 305, 817–824. [Google Scholar] [CrossRef]

- Hones, P.; Diserens, M.; Lévy, F. Characterization of Sputter-Deposited Chromium Oxide Thin Films. Surf. Coat. Technol. 1999, 120–121, 277–283. [Google Scholar] [CrossRef]

- Gulbransen, E.A.; Andrew, K.F. Oxidation Studies on 304 Stainless Steel. J. Electrochem. Soc. 1962, 109, 560–564. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hipp, D.; Mahrle, A.; Beyer, E. Energy Coupling of Laser Radiation on AISI 304 Stainless Steel: Effect of High Temperatures and Surface Oxidation. Materials 2019, 12, 2802. https://doi.org/10.3390/ma12172802

Hipp D, Mahrle A, Beyer E. Energy Coupling of Laser Radiation on AISI 304 Stainless Steel: Effect of High Temperatures and Surface Oxidation. Materials. 2019; 12(17):2802. https://doi.org/10.3390/ma12172802

Chicago/Turabian StyleHipp, Dominik, Achim Mahrle, and Eckhard Beyer. 2019. "Energy Coupling of Laser Radiation on AISI 304 Stainless Steel: Effect of High Temperatures and Surface Oxidation" Materials 12, no. 17: 2802. https://doi.org/10.3390/ma12172802

APA StyleHipp, D., Mahrle, A., & Beyer, E. (2019). Energy Coupling of Laser Radiation on AISI 304 Stainless Steel: Effect of High Temperatures and Surface Oxidation. Materials, 12(17), 2802. https://doi.org/10.3390/ma12172802