Microstructural Characterization of 3D Printed Cementitious Materials

Abstract

1. Introduction

2. Materials

3. Methods

3.1. Mortar Preparation

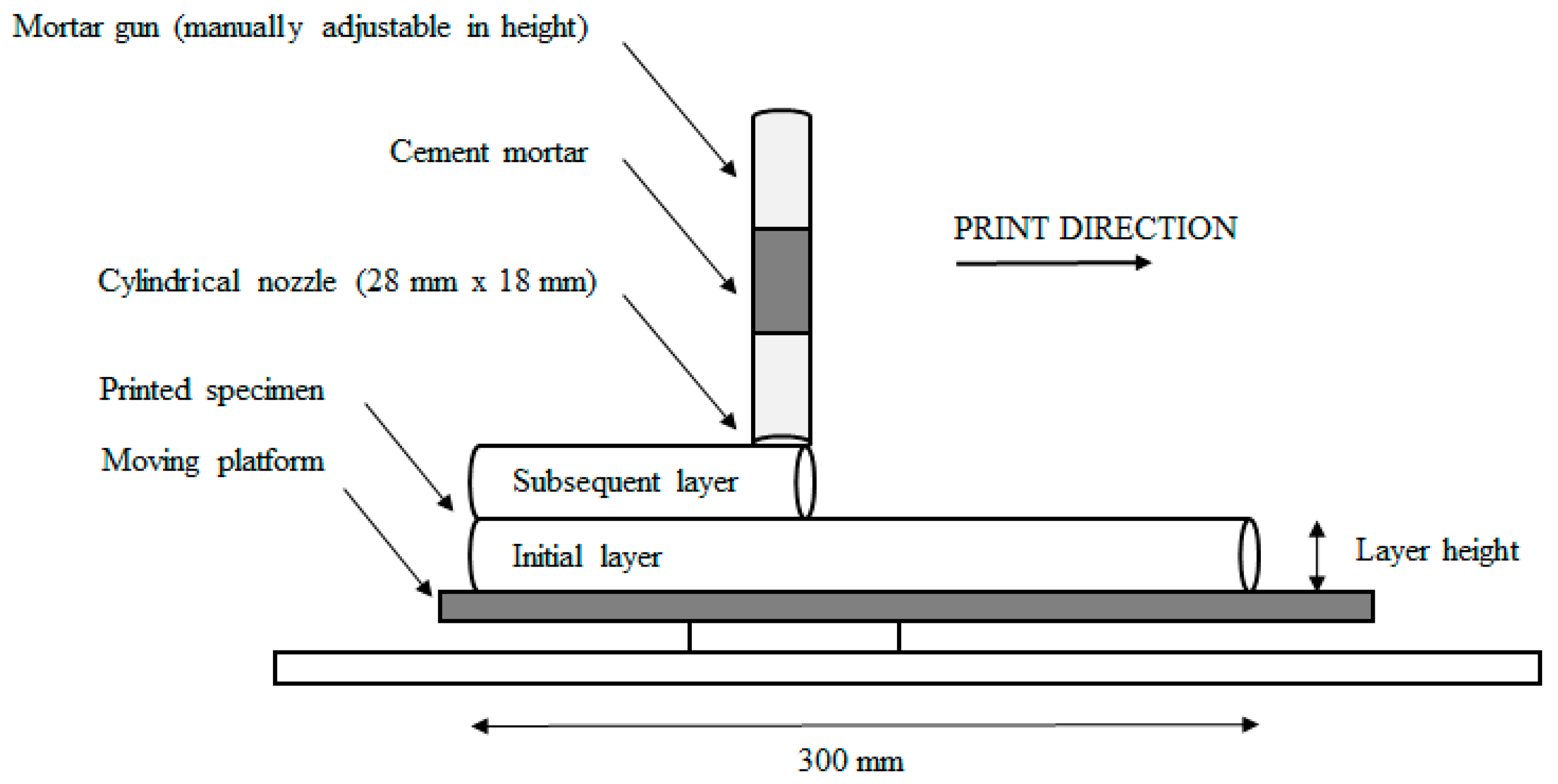

3.2. Printing Procedure

4. Characterization Methods

4.1. Fresh State Characterization

4.1.1. Extrudability

4.1.2. Buildability

4.1.3. Structural Build-Up Mechanism

4.2. Surface Roughness

4.3. Surface Moisture

- The paper strip is weighed (mdry [g]) with a precision of 0.001 g, placed on the printed surface at a predefined time and pressed onto it by means of a plastic weight for 60 s. The weight exerts a uniform pressure of 77.5 ± 0.1 Pa;

- The paper strip is weighed to obtain the mass after possible absorption (msat [g]);

- The mass of the absorbed fluid mabs [g] at a certain time is obtained by Equation (2):

- The exact surface of the paper strip (Astrip [cm2]) is obtained by reverse calculation knowing the areal paper density and the initial dry weight of the strip;

- The mass of absorbed surface fluid k can be calculated based on Equation (3).

4.4. Mechanical Performance

4.4.1. Compressive Strength

4.4.2. Inter-Layer Bonding Strength

4.5. Microstructure

4.5.1. Optical Microscopy

4.5.2. Pore Size Characterization

| P | Pressure | [N.m−2] |

| ϒ | Surface energy of Hg (=0.483 N.m−1) | [N.m−1] |

| Contact angle (=140°) | [°] | |

| d | Nominal diameter of the pore | [mm] |

| A | Air content | [%] |

| Ta | Number of voids intersected by the traverse lines | [m] |

| Ttot | Total chord length | [m] |

| Vpaste | Paste content | [vol%] |

| Vcement | Cement volume (depending on the mix design) | [m3] |

| Vwater | Water volume (depending on the mix design) | [m3] |

| Vtotal | Total volume of the mortar mixture | [m3] |

5. Results and Discussion

5.1. Fresh State Characterization

5.2. Surface Characterization

5.2.1. Surface Roughness

| Shear stress | [Pa] | |

| Yield stress | [Pa] | |

| Shear rate | [m/s] | |

| Plastic viscosity | - | |

| vxy | Velocity | (m/s) |

5.2.2. Moisture Content

5.3. Mechanical Performance

5.4. Microstructure

6. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pegna, J. Exploratory investigation of solid freeform construction. Autom. Constr. 1997, 5, 427–437. [Google Scholar] [CrossRef]

- Khoshnevis, B. Automated construction by contour crafting—related robotics and information technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

- Reiter, L.; Wangler, T.; Roussel, N.; Flatt, R.J. The role of early age structural build-up in digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 86–95. [Google Scholar] [CrossRef]

- Holt, E. Contribution of mixture design to chemical and autogenous shrinkage of concrete at early ages. Cem. Concr. Res. 2005, 35, 464–472. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Dudziak, L. Effects of superabsorbent polymers on shrinkage of concrete: Plastic, autogenous, drying. In Application of Super Absorbent Polymers (SAP) in Concrete Construction: State-of-the-Art Report Prepared by Technical Committee 225-SAP, V. Mechtcherine and H.-W. Reinhardt, Editors; Springer: Dordrecht, Netherlands, 2012; pp. 63–98. [Google Scholar]

- Boel, V. Microstructuur van zelfverdichtend beton in relatie met gaspermeabiliteit en duurzaamheidsaspecten. Ph.D. Thesis, University of Ghent, Ghent, Belgium, January 2006; p. 320. [Google Scholar]

- De Belie, N.; Monteny, J.; Beeldens, A.; Vincke, E.; Van Gemert, D.; Verstraete, W. Experimental research and prediction of the effect of chemical and biogenic sulfuric acid on different types of commercially produced concrete sewer pipes. Cem. Concr. Res. 2004, 34, 2223–2236. [Google Scholar] [CrossRef]

- Khalil, N.; Aouad, G.; El Cheikh, K.; Rémond, S. Use of calcium sulfoaluminate cements for setting control of 3D-printing mortars. Constr. Build. Mater. 2017, 157, 382–391. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Cochran, E.; Khoshnevis, B. Cementitious materials for construction scale 3D printing: Laboratory testing of fresh printing mixture. Constr. Build. Mater. 2017, 145, 639–647. [Google Scholar] [CrossRef]

- Ma, G.; Wang, L. A critical review of preparation design and workability measurement of concrete material for largescale 3D printing. Front. Struct. Civ. Eng. 2018, 12, 382–400. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.F.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Grosse, C.U. Continuous monitoring of setting and hardening of mortar and concrete. Constr. Build. Mater. 2004, 18, 145–154. [Google Scholar] [CrossRef]

- Robeyst, N.; Grosse, C.U.; De Belie, N. Measuring the change in ultrasonic p-wave energy transmitted in fresh mortar with additives to monitor the setting. Cem. Concr. Res. 2009, 39, 868–875. [Google Scholar] [CrossRef]

- Robeyst, N.; Gruyaert, E.; Grosse, C.U.; De Belie, N. Monitoring the setting of concrete containing blast-furnace slag by measuring the ultrasonic p-wave velocity. Cem. Concr. Res. 2008, 38, 1169–1176. [Google Scholar] [CrossRef]

- Snoeck, D. Self-healing and microstructure of cementitious materials with microfibres and superabsorbent polymers. Ph.D. Thesis, Ghent University, Ghent, Belgium, October 2015. [Google Scholar]

- Perrot, A.; Rangeard, D.; Pierre, A. Structural built-up of cement-based materials used for 3D-printing extrusion techniques. Mater. Struct. 2016, 49, 1213–1220. [Google Scholar] [CrossRef]

- Ye, G. Experimental Study and numerical simulation of the development of the microstructure and permeability in cementitious materials. Ph.D. Thesis, Technical University of Delft, Delft, The Netherlands, December 2003; p. 207. [Google Scholar]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.F.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Panda, B.; Chandra Paul, S.; Jen Tan, M. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Audenaert, K. Transportmechanismen in zelfverdichtend beton in relatie met carbonatatie en chloridepenetratie. Ph.D. Thesis, Univeristy of Ghent, Ghent, Belgium, May 2006; p. 369. [Google Scholar]

- Masschaele, B.; Dierick, M.; Van Loo, D.; Boone, M.N.; Brabant, L.; Pauwels, E. HECTOR: A 240kV micro-CT setup optimized for research. J. Phys. Conf. Ser. 2013, 463, 012012. [Google Scholar] [CrossRef]

- Vlassenbroeck, J.; Dierick, M.; Masschaele, B.; Cnudde, V.; Van Hoorebeke, L.; Jacobs, P. Software tools for quantification of X-ray microtomography at the UGCT. Nucl. Instrum. Meth. A 2007, 580, 442–445. [Google Scholar] [CrossRef]

- Marchon, D.; Kawashima, S.; Bessaies-Bey, H.; Mantellato, S.; Ng, S. Hydration and rheology control of concrete for digital fabrication: Potential admixtures and cement chemistry. Cem. Concr. Res. 2018, 112, 96–110. [Google Scholar] [CrossRef]

- Di Carlo, T. Experimental and numerical techniques to characterize structural properties of fresh concrete relevant to contour crafting. Ph.D. Thesis, University of Southern California, California, CA, USA, September 2012; p. 196. [Google Scholar]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Hardened properties of 3D printed concrete: The influence of process parameters on interlayer adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar] [CrossRef]

- Van Zijl, G.P.A.G.; Paul, S.C.; Tan, M.J. Properties of 3D Printable Concrete. In Proceedings of the 2nd International Conference on Progress in Additive Manufacturing (Pro-AM 2016), Nanyang, Singapore, 16–19 May 2016. [Google Scholar]

| Component | CEM I 52.5 N Strong | Sand 0/2 | Water | SP |

|---|---|---|---|---|

| Amount [kg/m3] | 620.5 | 1241.0 | 226.5 | 0.15 [woc%] |

| Composition | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | K2O | SO3 |

|---|---|---|---|---|---|---|---|---|

| - | 64.30 | 18.30 | 5.20 | 4.00 | 1.40 | 0.32 | 0.43 | 3.50 |

| - | C3S | C2S | C3A | C4AF | Blaine [m2/kg] | Density [kg/m3] | ||

| - | 71.98 | 1.75 | 7.02 | 12.16 | 408 | 3160 | ||

| Printing Speed [cm/s] | Ra,x [-] | Stdev [-] | Ra,y [-] | Stdev [-] |

|---|---|---|---|---|

| 1.7 | 0.95 | 0.05 | 0.68 | 0.15 |

| 3.0 | 0.39 | 0.07 | 0.46 | 0.08 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Van Der Putten, J.; Deprez, M.; Cnudde, V.; De Schutter, G.; Van Tittelboom, K. Microstructural Characterization of 3D Printed Cementitious Materials. Materials 2019, 12, 2993. https://doi.org/10.3390/ma12182993

Van Der Putten J, Deprez M, Cnudde V, De Schutter G, Van Tittelboom K. Microstructural Characterization of 3D Printed Cementitious Materials. Materials. 2019; 12(18):2993. https://doi.org/10.3390/ma12182993

Chicago/Turabian StyleVan Der Putten, Jolien, Maxim Deprez, Veerle Cnudde, Geert De Schutter, and Kim Van Tittelboom. 2019. "Microstructural Characterization of 3D Printed Cementitious Materials" Materials 12, no. 18: 2993. https://doi.org/10.3390/ma12182993

APA StyleVan Der Putten, J., Deprez, M., Cnudde, V., De Schutter, G., & Van Tittelboom, K. (2019). Microstructural Characterization of 3D Printed Cementitious Materials. Materials, 12(18), 2993. https://doi.org/10.3390/ma12182993