Structural Safety Evaluation of Precast, Prestressed Concrete Deck Slabs Cast Using 120-MPa High-Performance Concrete with a Reinforced Joint

Abstract

:1. Introduction

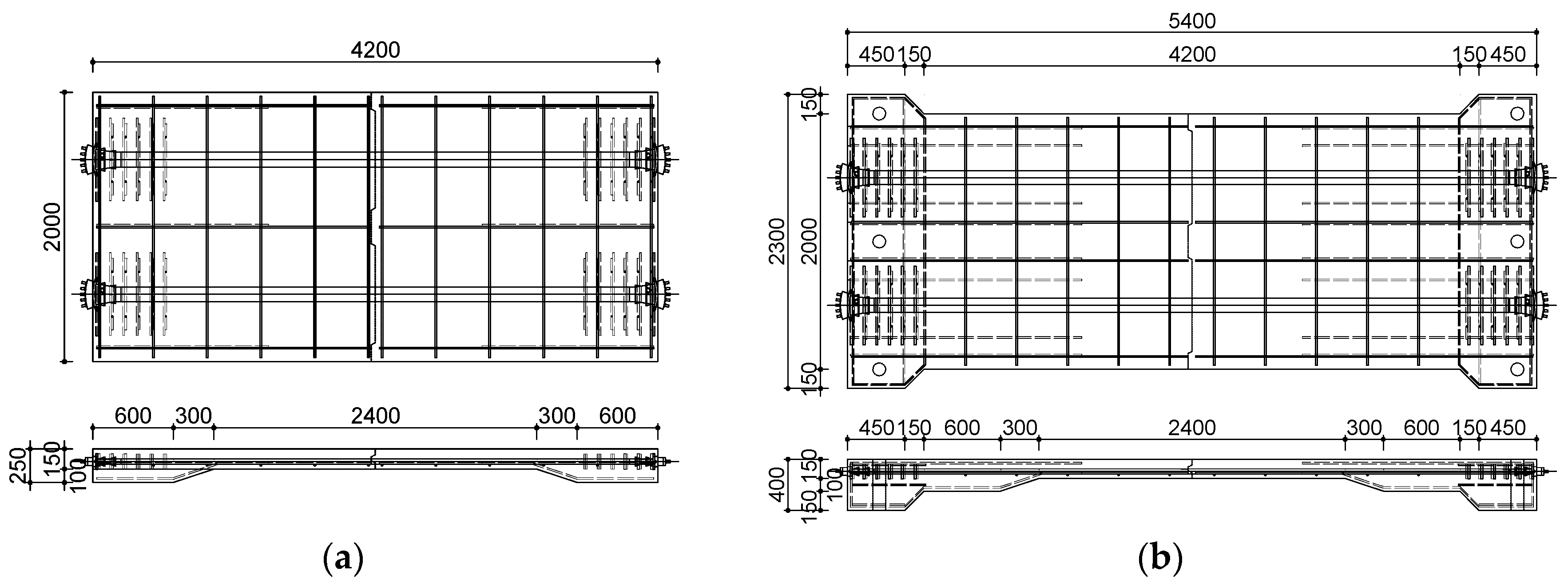

2. Description of Specimens

2.1. Specimens

2.2. Material Properties of SC120f

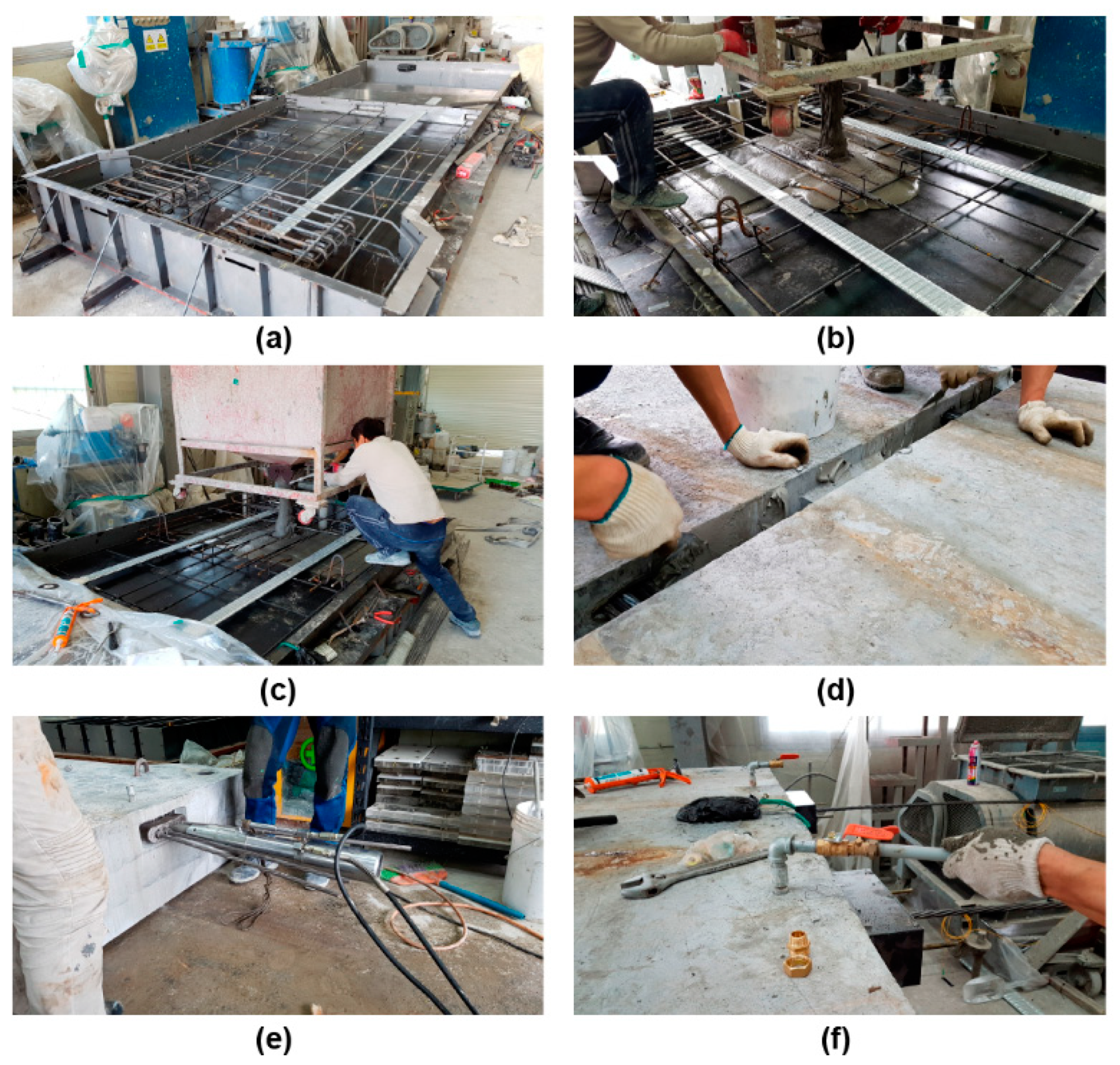

2.3. Fabrication

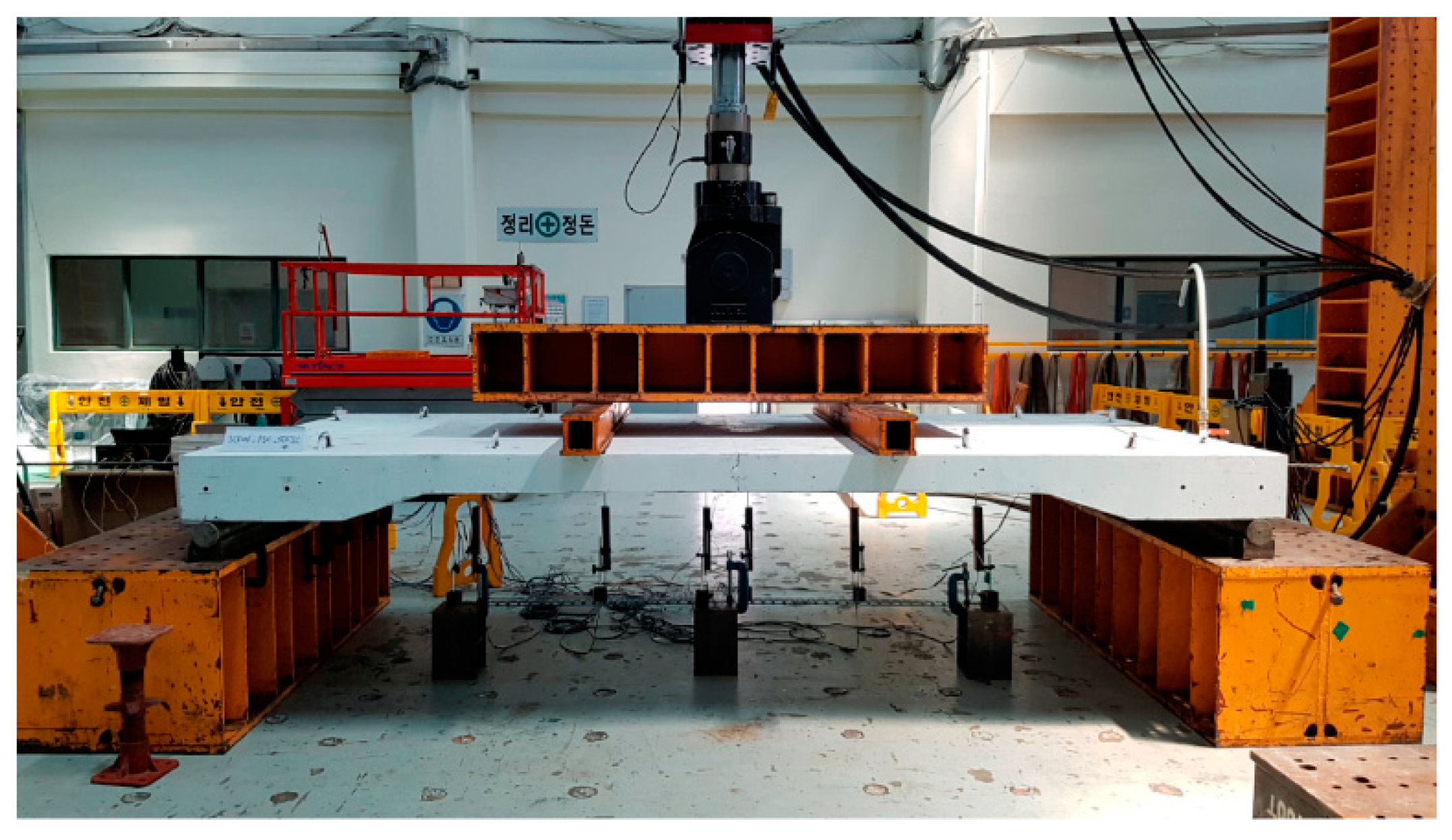

3. Static Performance Evaluation

3.1. Static Loading Test (SC120f-PSC-NJ, J1, and J2 Specimens)

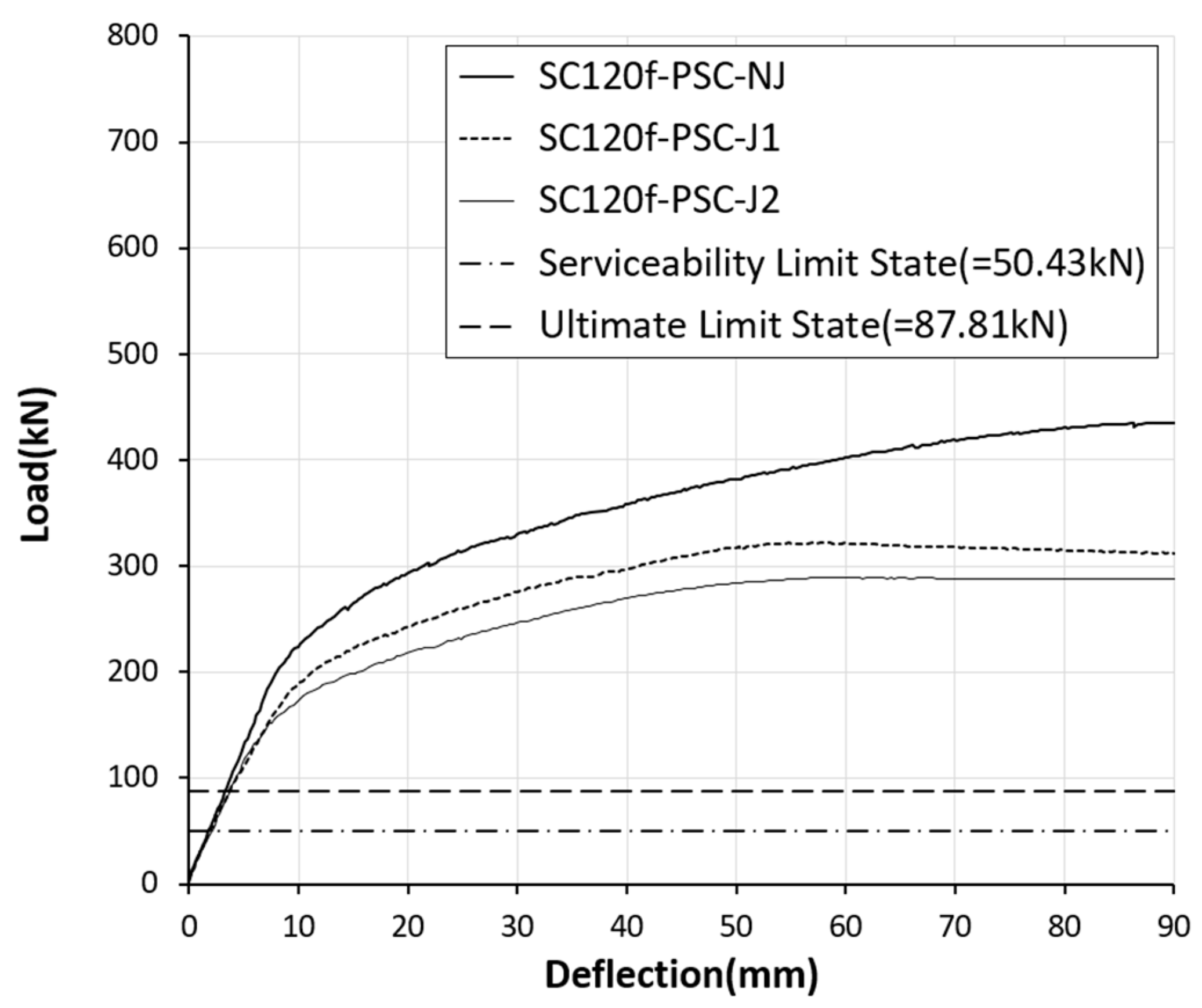

3.2. Result of Static Loading Test

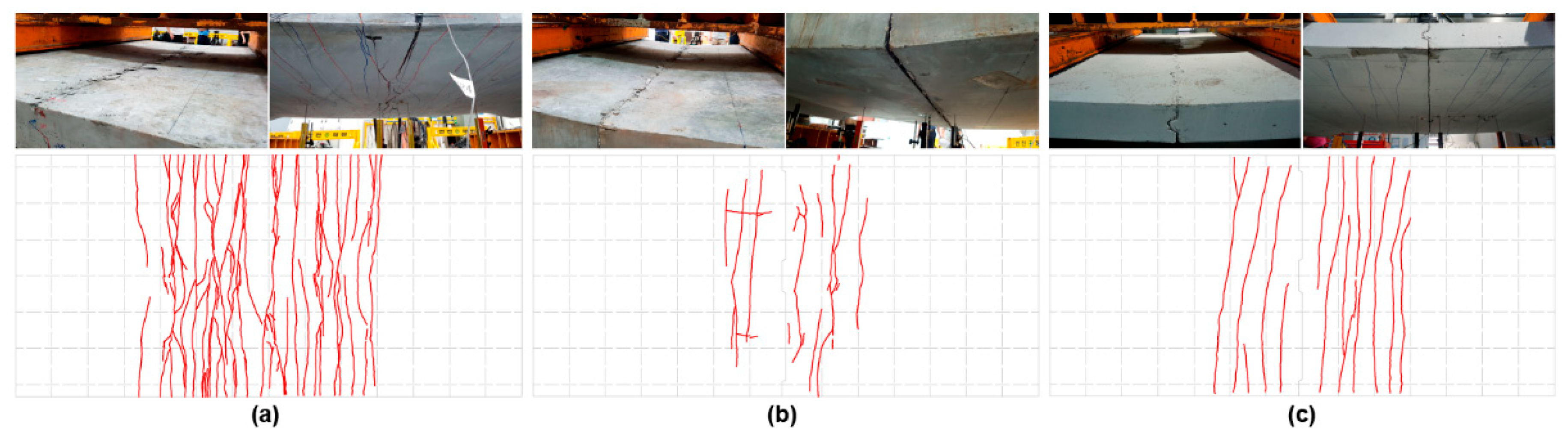

3.2.1. Failure Mode

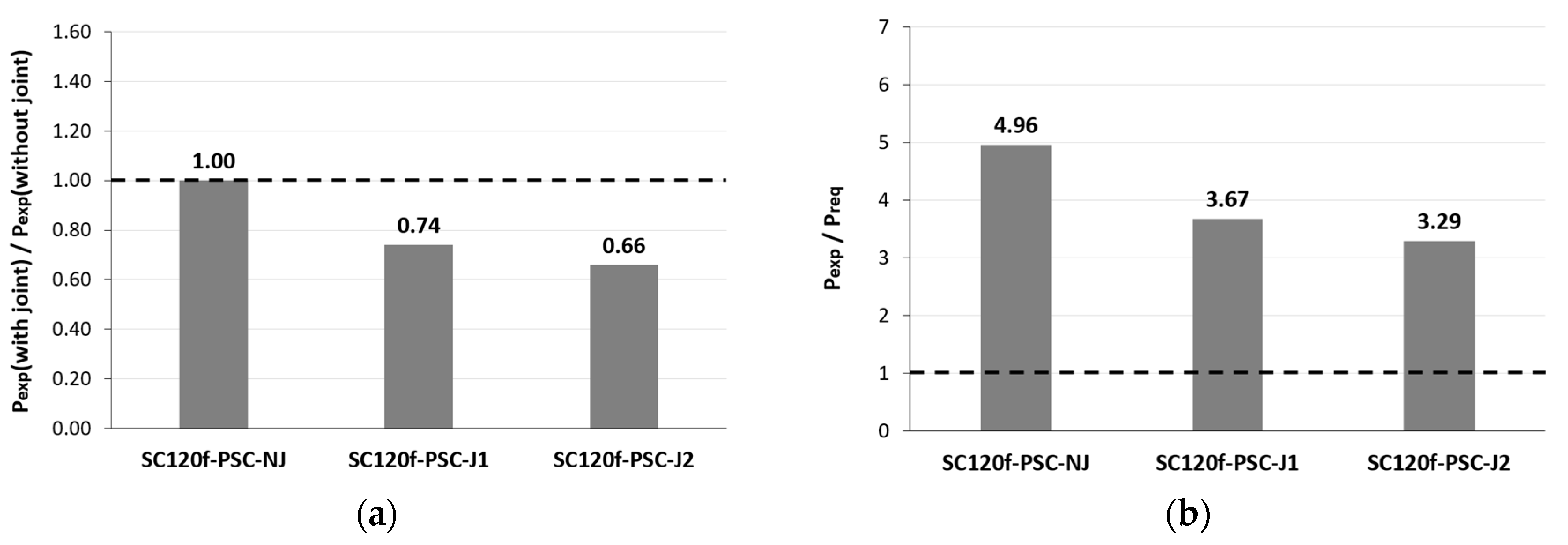

3.2.2. Evaluation of Flexural Strength

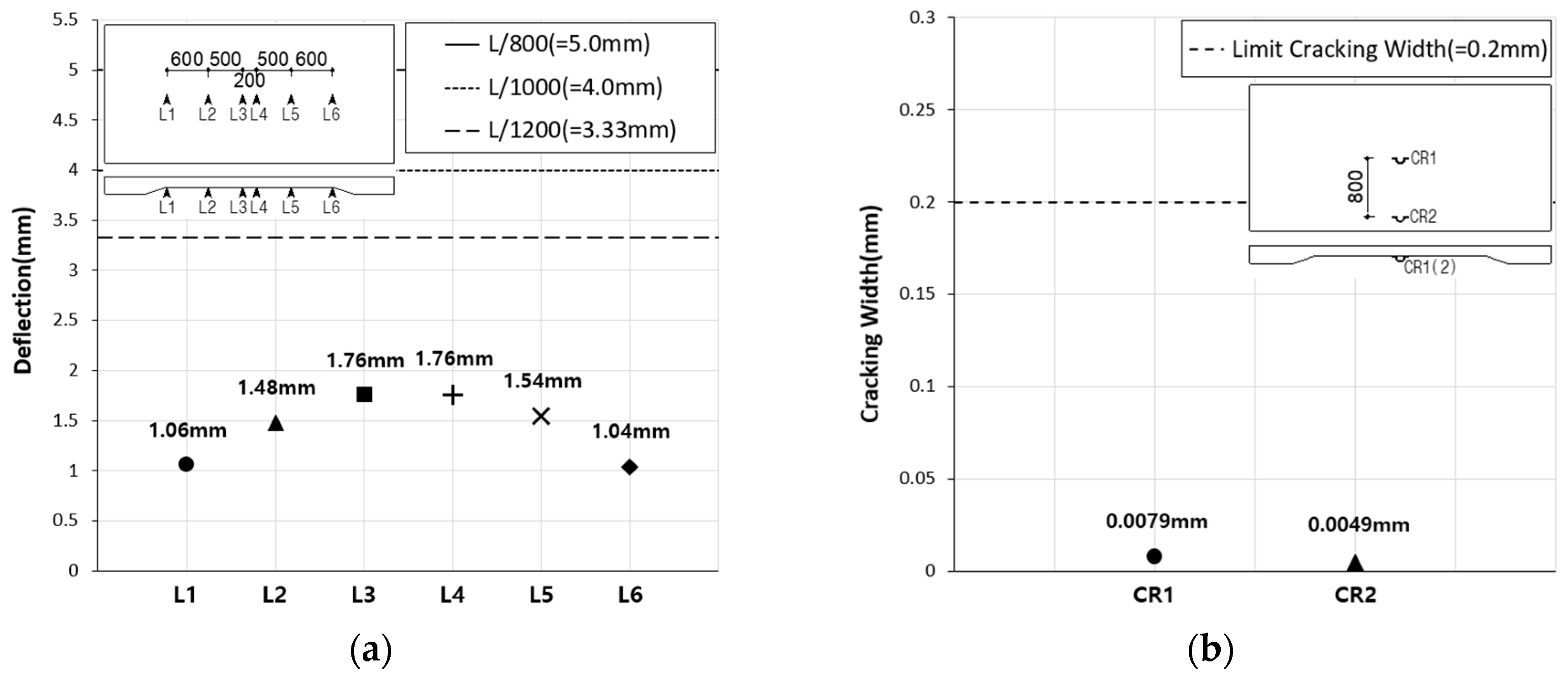

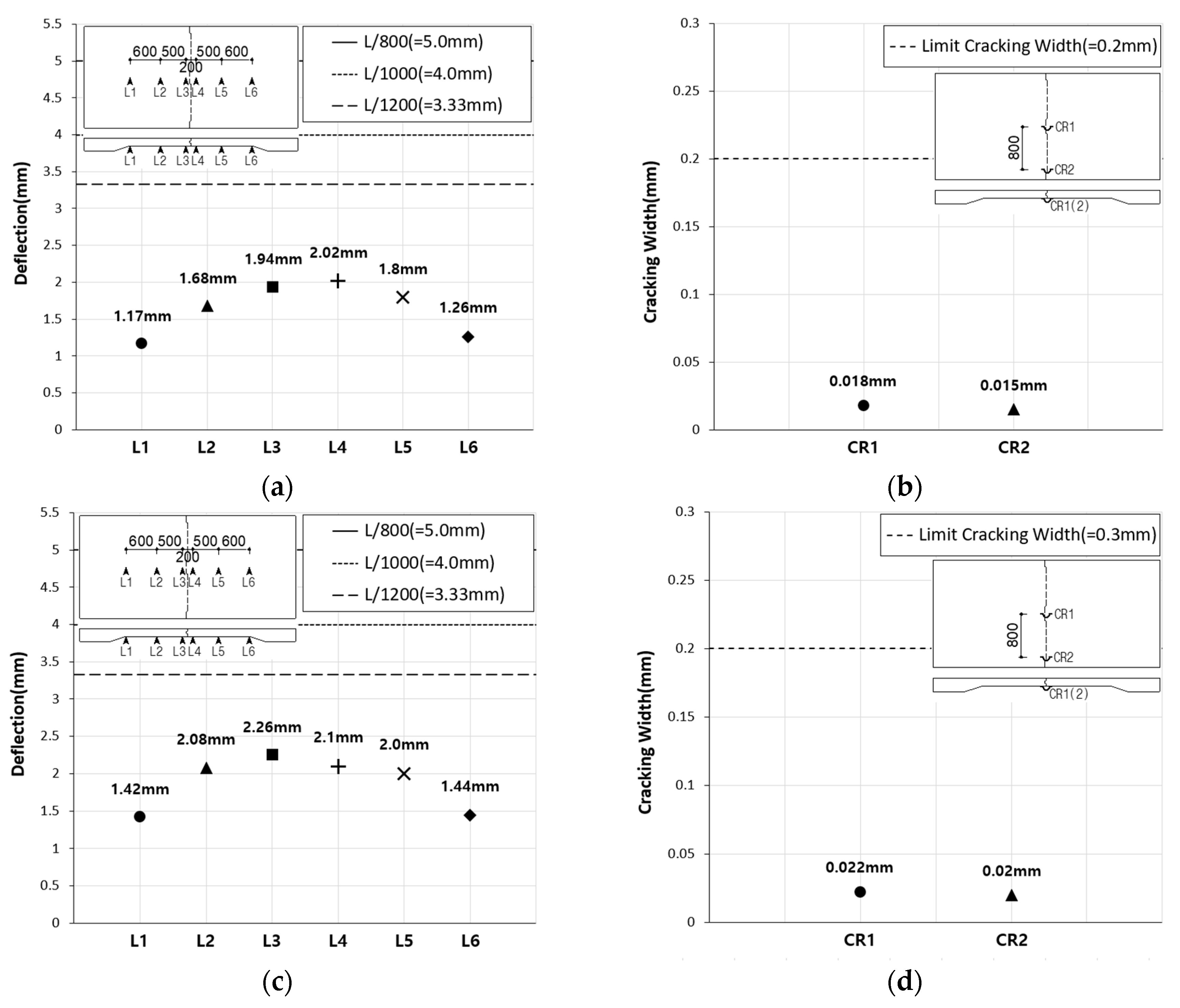

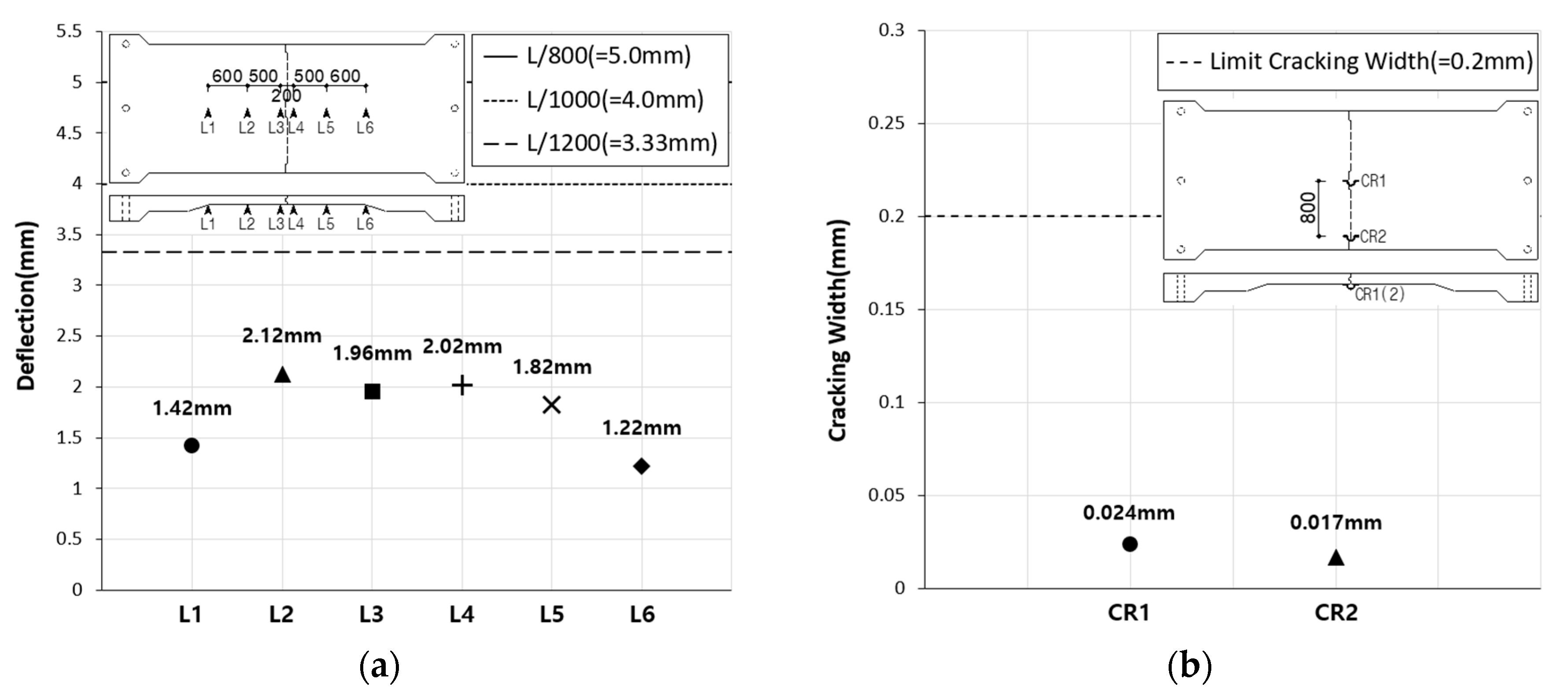

3.3. Evaluation of Serviceability

4. Fatigue Performance Evaluation

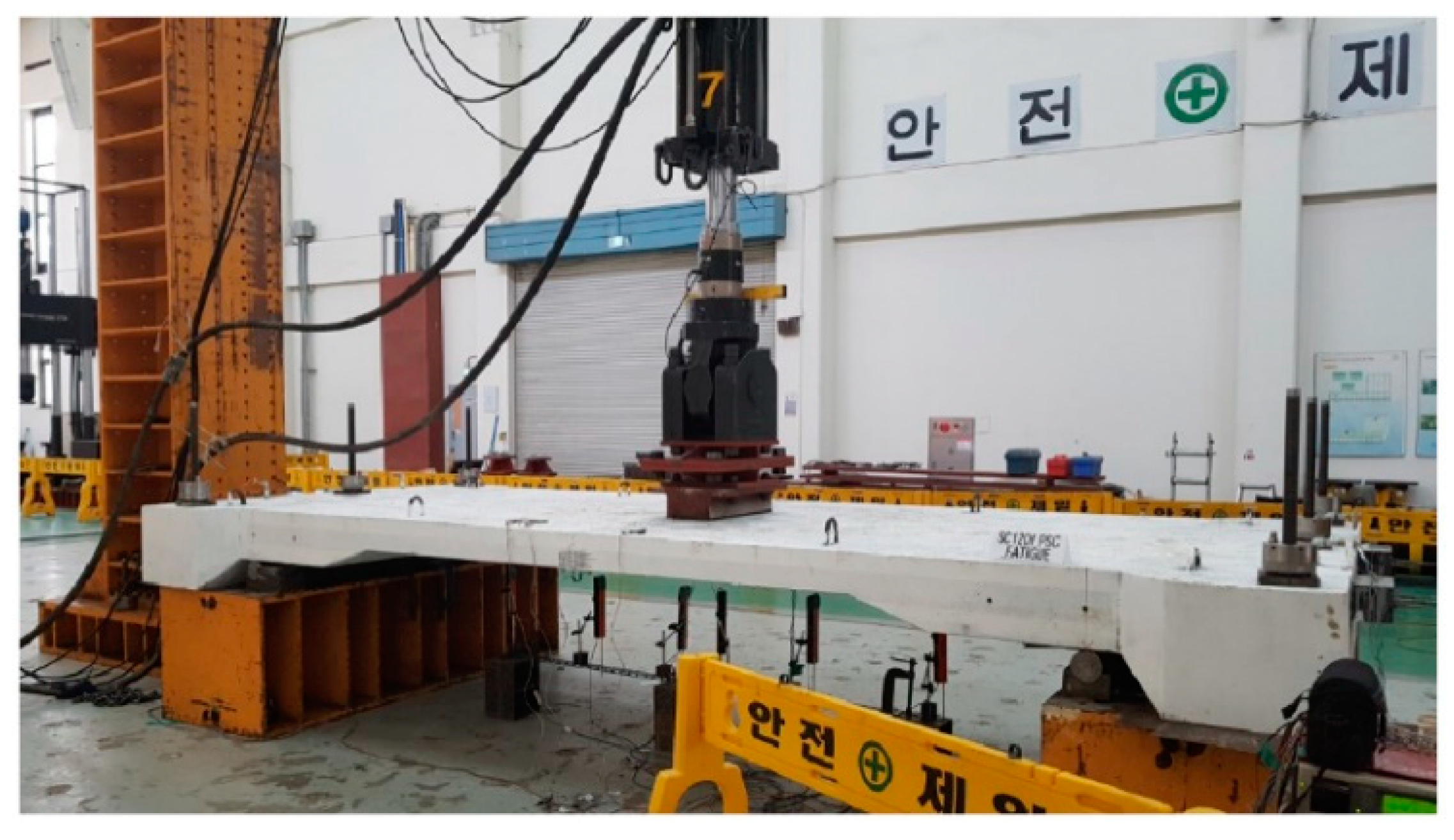

4.1. Fatigue Loading Test and Residual Strength Test (SC120f-PSC-JF Specimens)

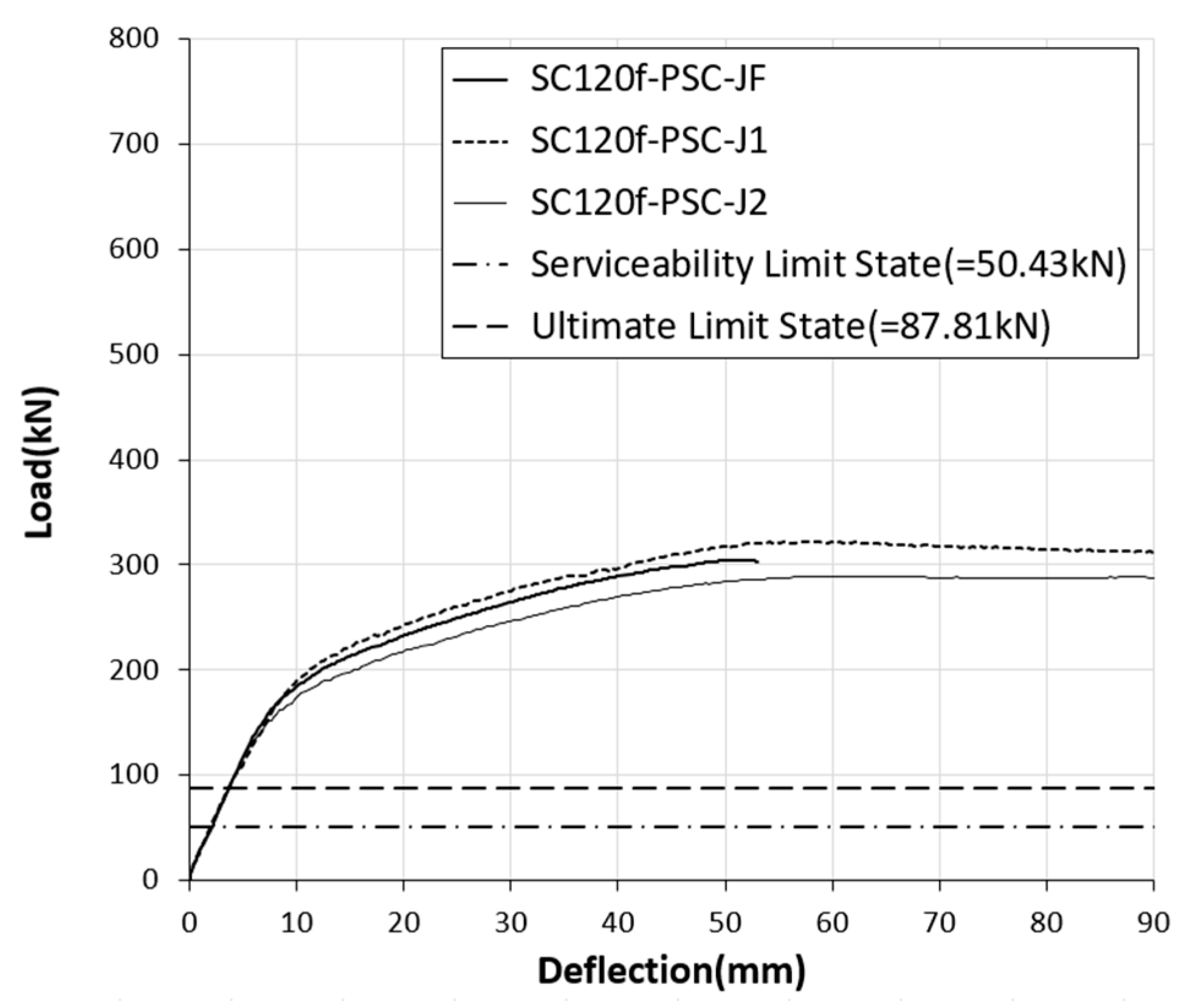

4.2. Result of Fatigue Loading Test and Residual Strength Test

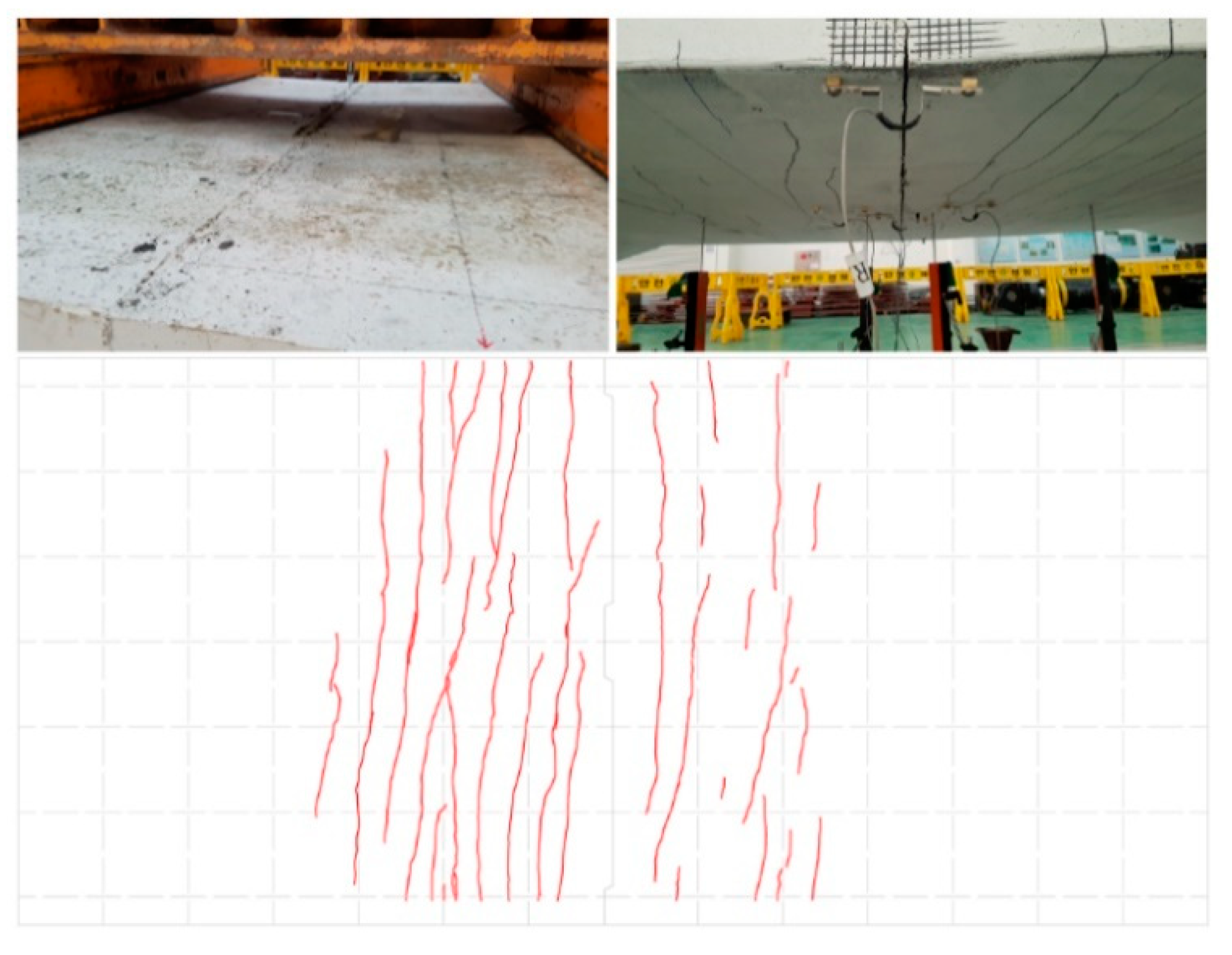

4.2.1. Failure Mode

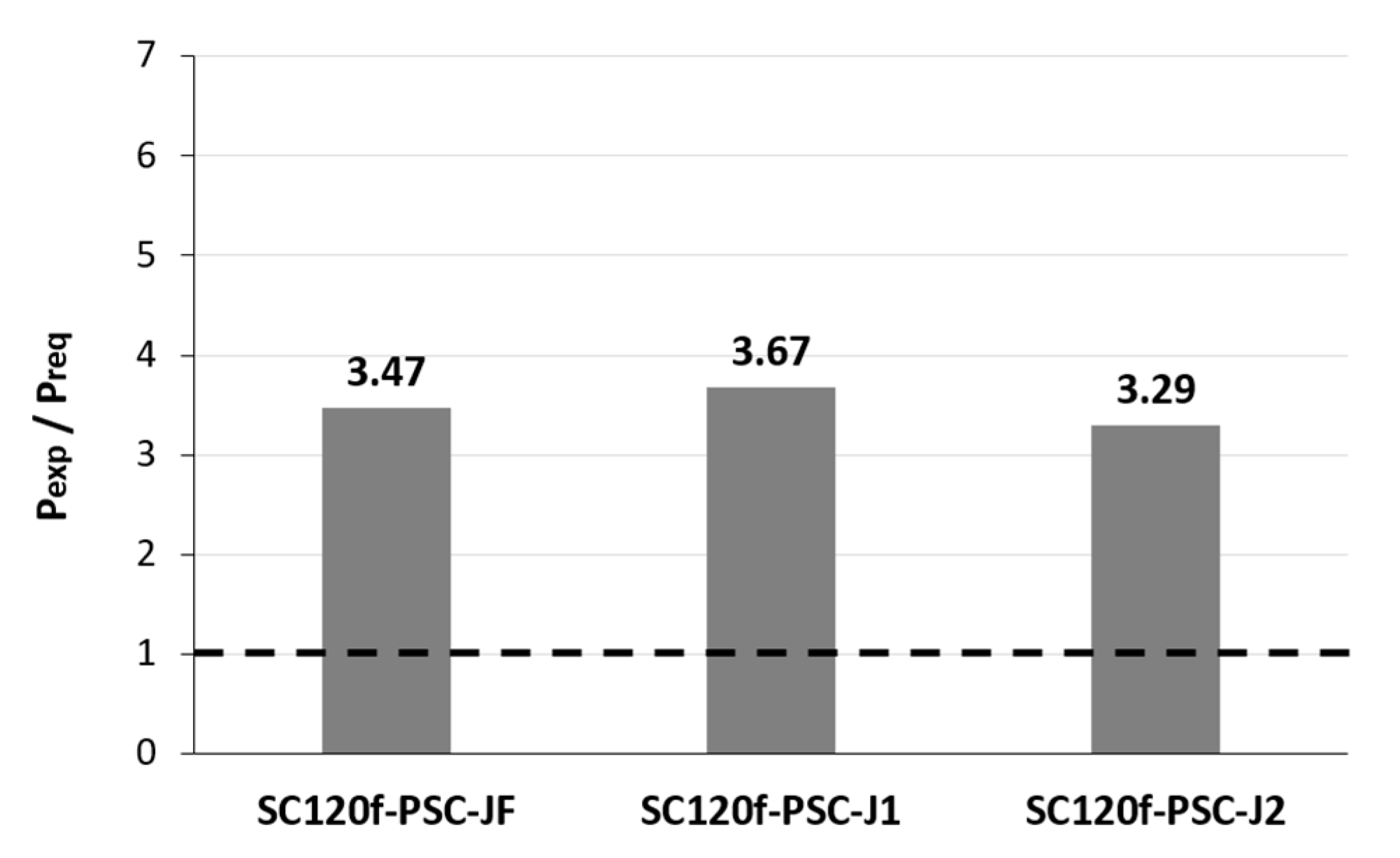

4.2.2. Evaluation of Flexural Strength

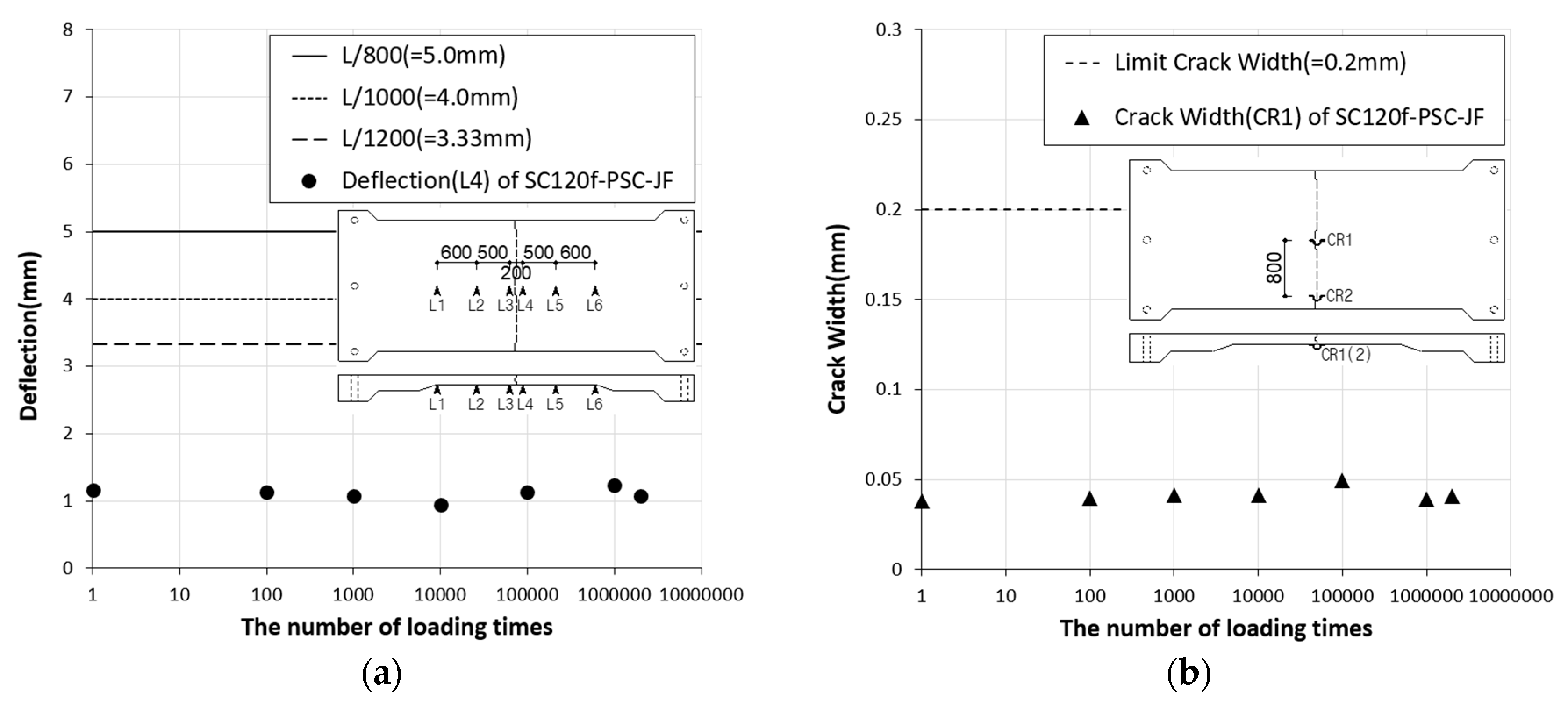

4.3. Evaluation of Serviceability

5. Conclusions

- (1)

- In the static loading test, the flexural strengths of the specimens with joints were 74% and 66% of that of the specimen without a joint. However, they were about 3.7 and 3.3 times higher than the levels required by the design code.

- (2)

- In addition, the deflections and crack widths of the specimens with joints satisfied the limit of the design code at the serviceability limit state.

- (3)

- After two million fatigue load cycles were applied, the residual strength of the specimen with a joint was similar (95%, 105%) to the flexural strengths of the specimens with joints in the static loading test.

- (4)

- In the fatigue loading test, the deflection at the serviceability limit according to the number of loads, was about 28.2–37.2% of the allowable deflection specified in the design code, and the joint widening of the specimen was 19.2–24.8% of the limit.

Author Contributions

Funding

Conflicts of Interest

References

- Graybeal, B.A. UHPC in the U.S. Highway Transportation System. In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 11–17. [Google Scholar]

- Rebentrost, M.; Wight, G. Experience and Applications of Ultra-High Performance Concrete. In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 19–30. [Google Scholar]

- Graybeal, B.A. Design and Construction of Field-Cast UHPC Connections; Report No. FHWA-HRT-14-084; USDOT FHWA: Washington, DC, USA, 2014. [Google Scholar]

- Badie, S.S.; Tadros, M.K. Full-Depth Precast Concrete Bridge Deck Panel Systems; NCHRP Report 584; Transportation Research Board: Washington, DC, USA, 2008. [Google Scholar]

- Graybeal, B.A.; Swenty, M. UHPFRC for Prefabricated Bridge Component Connections. In Proceedings of the Third International Symposium on Ultra High Performance Concrete, Kassel, Germany, 7–9 March 2012; Volume 1223. [Google Scholar]

- Hwang, H.H.; Park, S.Y. A study on the flexural behavior of lap-spliced cast-in-place joints under static loading in ultra-high performance concrete bridge deck slabs. Can. J. Civ. Eng. 2014, 41, 615–623. [Google Scholar] [CrossRef]

- Arafa, A.; Farghaly, A.; Ahmed, E.; Benmokrane, B. Laboratory testing of GFRP-RC panels with UHPFRC joints of the Nipigon River Cable-Stayed Bridge in Northwest Ontario, Canada. J. Bridge Eng. 2016, 21, 05016006. [Google Scholar] [CrossRef]

- Mantawy, I.; Chennareddy, R.; Genedy, M.; Taha, M.R. Polymer Concrete for Bridge Deck Closure Joints in Accelerated Bridge Construction. Infrastructures 2019, 4, 31. [Google Scholar] [CrossRef]

- MOLIT (Ministry of Land, Infrastructure and Transport). Korean Highway Bridges Design Code (Limit State Design Method); MOLIT: Sejong-si, Korea, 2015.

- KCI (Korea Concrete Institute). The Structural Design Guideline of the Fiber Reinforced SUPER Concrete; KCI: Seoul, Korea, 2019. [Google Scholar]

- ASTM C78/C78M, Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2018.

| Specimen | Joint | Test Type |

|---|---|---|

| SC120f-PSC-NJ | No | Static |

| SC120f-PSC-J1 | Yes | Static |

| SC120f-PSC-J2 | Yes | Static |

| SC120f-PSC-JF | Yes | Fatigue |

| W/B | Mass Unit (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|

| Water | Premix Binder | Fine Aggregates | Steel Fiber | Super Plasticizer | Air-Entraining Agent | ||

| 16 mm | 20 mm | ||||||

| 0.23 | 210 | 1180 | 847 | - | 78 | 7 | 17 |

| Specimen | Deflection at Maximum Load | Maximum Load | Ultimate Limit State Load | Pexp (with Joint)/Pexp (without Joint) | Pexp/Preq |

|---|---|---|---|---|---|

| SC120f-PSC-NJ | 88.06 mm | 435.65 kN | 87.81 kN | 1.00 | 4.96 |

| SC120f-PSC-J1 | 58.6 mm | 322.07 kN | 0.74 | 3.67 | |

| SC120f-PSC-J2 | 60.18 mm | 289.04 kN | 0.66 | 3.29 |

| Specimen | Deflection at Maximum Load | Maximum Load | Ultimate Limit State Load | Pexp/Preq |

|---|---|---|---|---|

| SC120f-PSC-JF | 50.48 mm | 304.53 kN | 87.81 kN | 3.47 |

| SC120f-PSC-J1 | 58.6 mm | 322.07 kN | 3.67 | |

| SC120f-PSC-J2 | 60.18 mm | 289.04 kN | 3.29 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bae, J.-H.; Hwang, H.-H.; Park, S.-Y. Structural Safety Evaluation of Precast, Prestressed Concrete Deck Slabs Cast Using 120-MPa High-Performance Concrete with a Reinforced Joint. Materials 2019, 12, 3040. https://doi.org/10.3390/ma12183040

Bae J-H, Hwang H-H, Park S-Y. Structural Safety Evaluation of Precast, Prestressed Concrete Deck Slabs Cast Using 120-MPa High-Performance Concrete with a Reinforced Joint. Materials. 2019; 12(18):3040. https://doi.org/10.3390/ma12183040

Chicago/Turabian StyleBae, Jae-Hyun, Hoon-Hee Hwang, and Sung-Yong Park. 2019. "Structural Safety Evaluation of Precast, Prestressed Concrete Deck Slabs Cast Using 120-MPa High-Performance Concrete with a Reinforced Joint" Materials 12, no. 18: 3040. https://doi.org/10.3390/ma12183040

APA StyleBae, J.-H., Hwang, H.-H., & Park, S.-Y. (2019). Structural Safety Evaluation of Precast, Prestressed Concrete Deck Slabs Cast Using 120-MPa High-Performance Concrete with a Reinforced Joint. Materials, 12(18), 3040. https://doi.org/10.3390/ma12183040