Contactless Manipulation of Soft Robots

Abstract

:1. Introduction

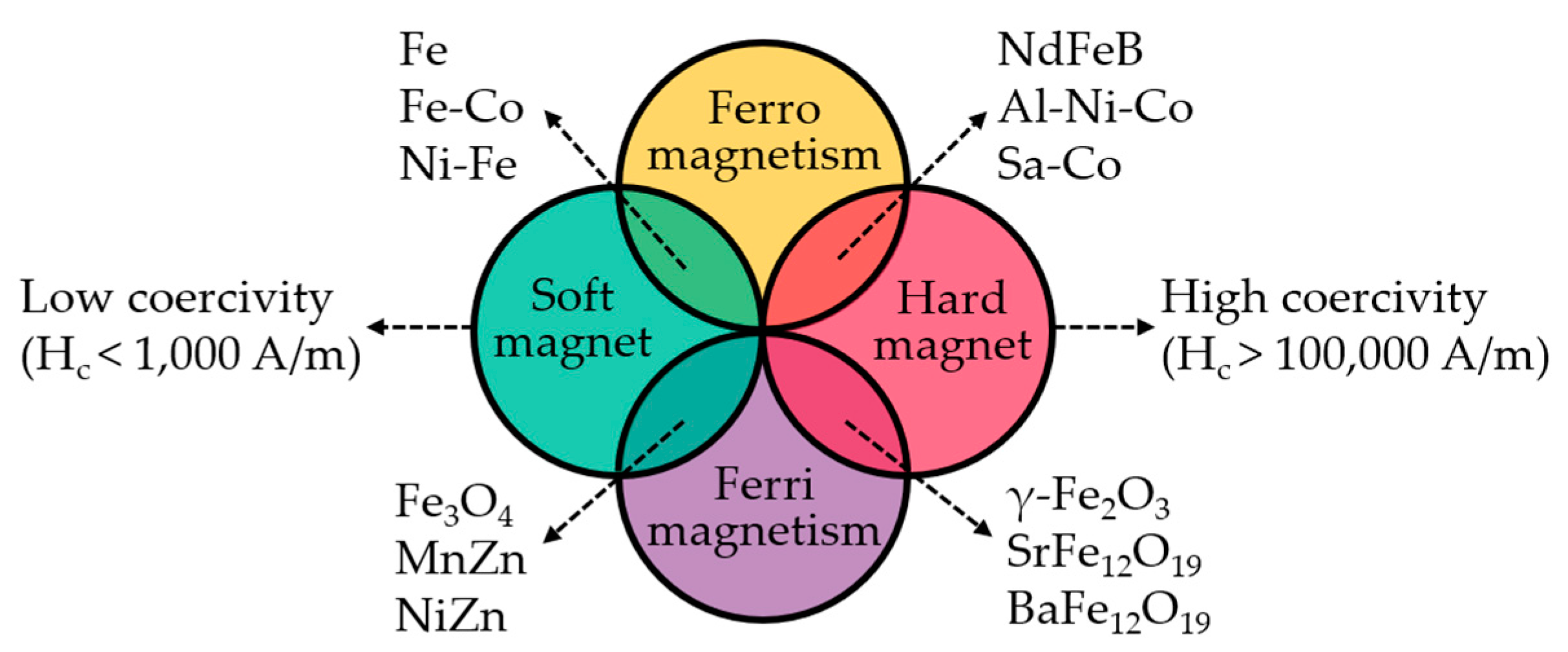

2. Magnetic Soft Robots

2.1. Programming Geometry of Robots for Desired Actuation

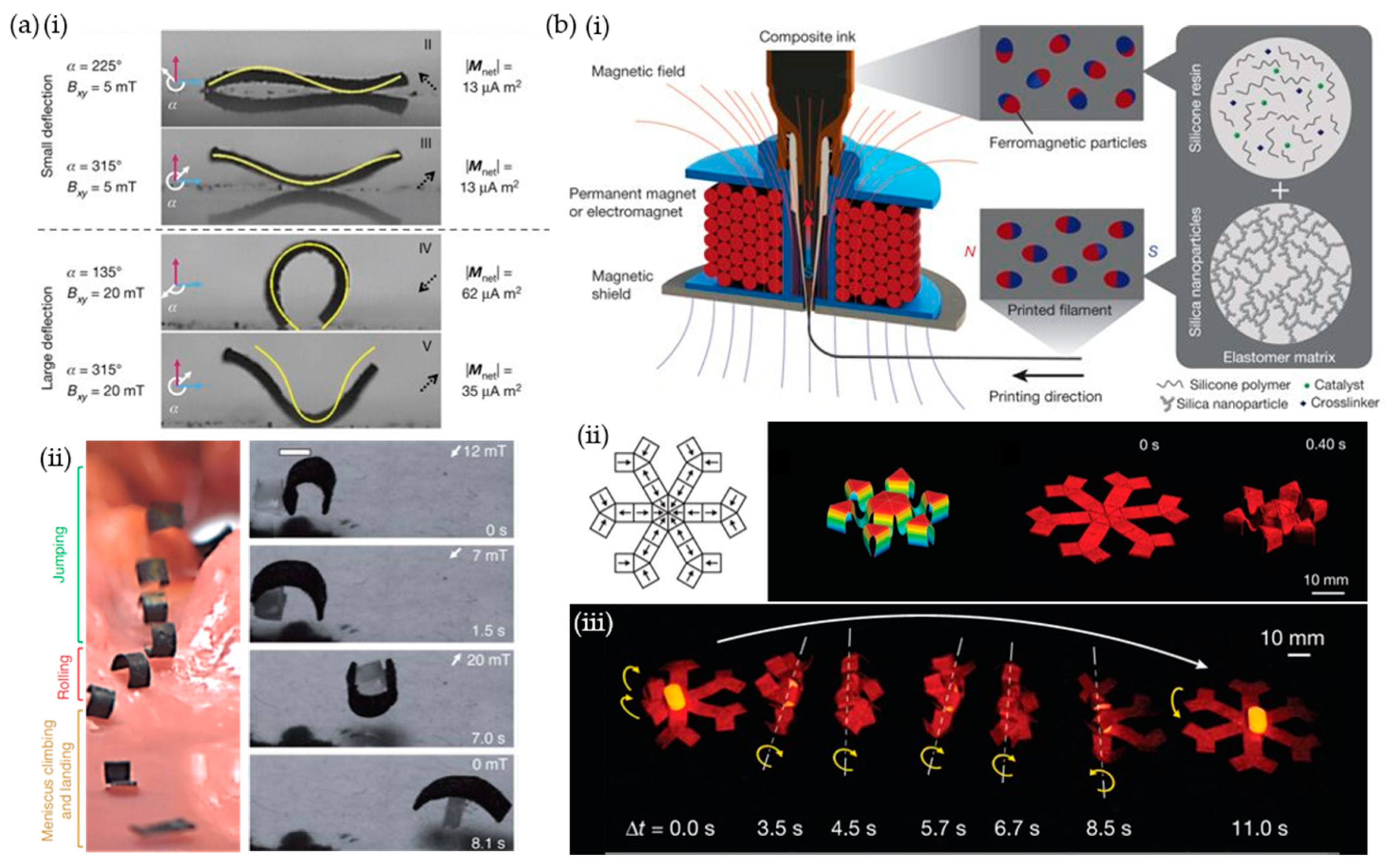

2.2. Programming Alignments of Magnetic Components for Single-Modal Actuation

2.3. Programming Polarity of Magnetic Components for Multi-Modal Actuation

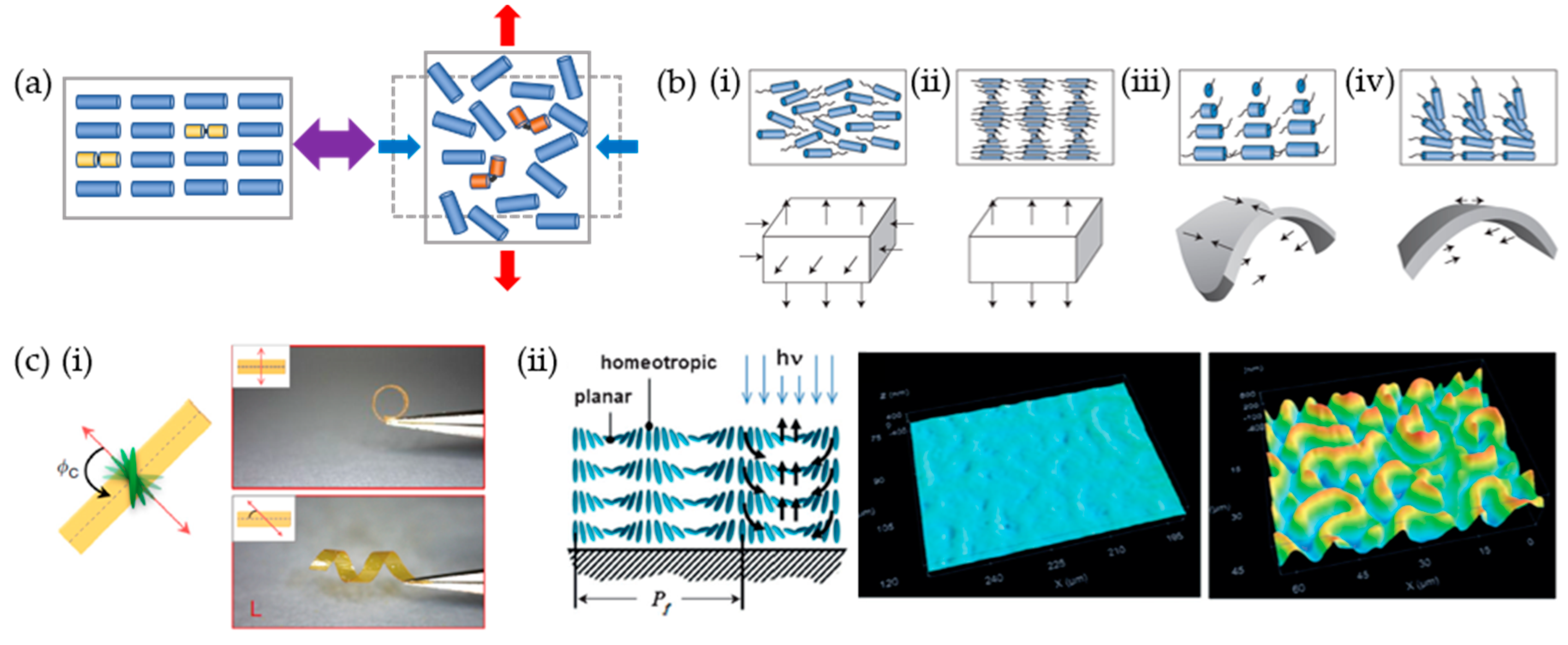

3. Liquid Crystalline Polymers

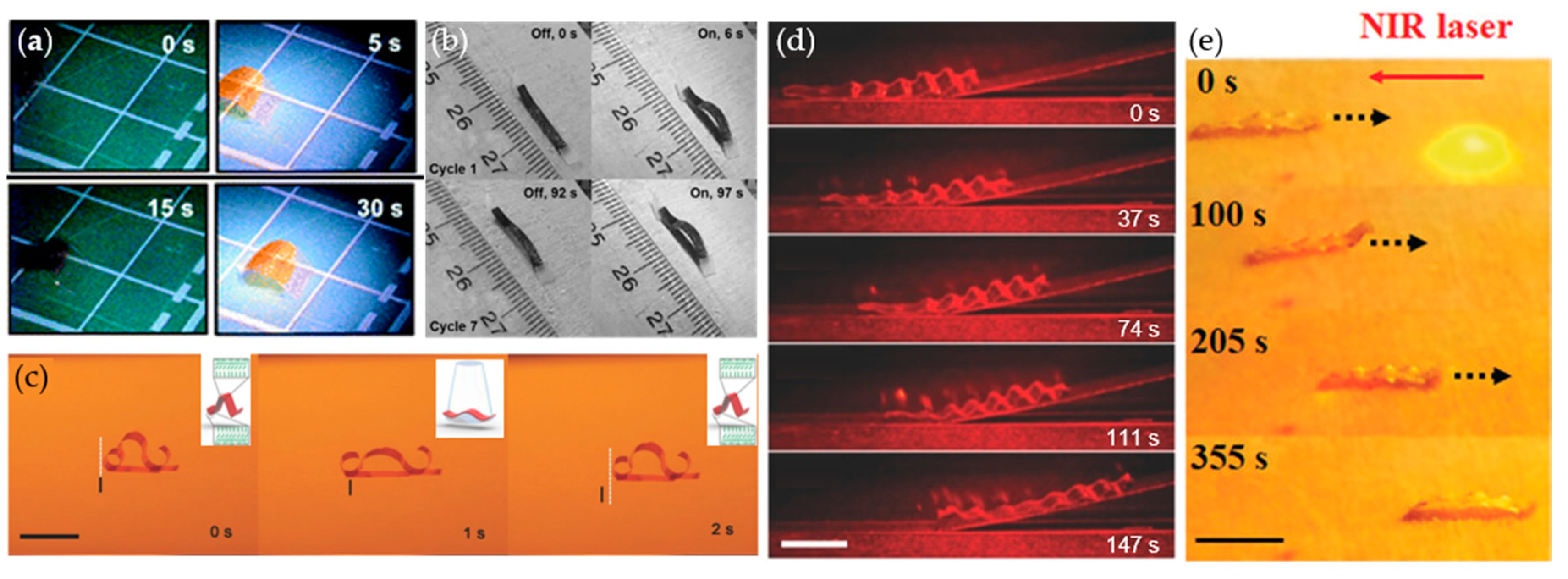

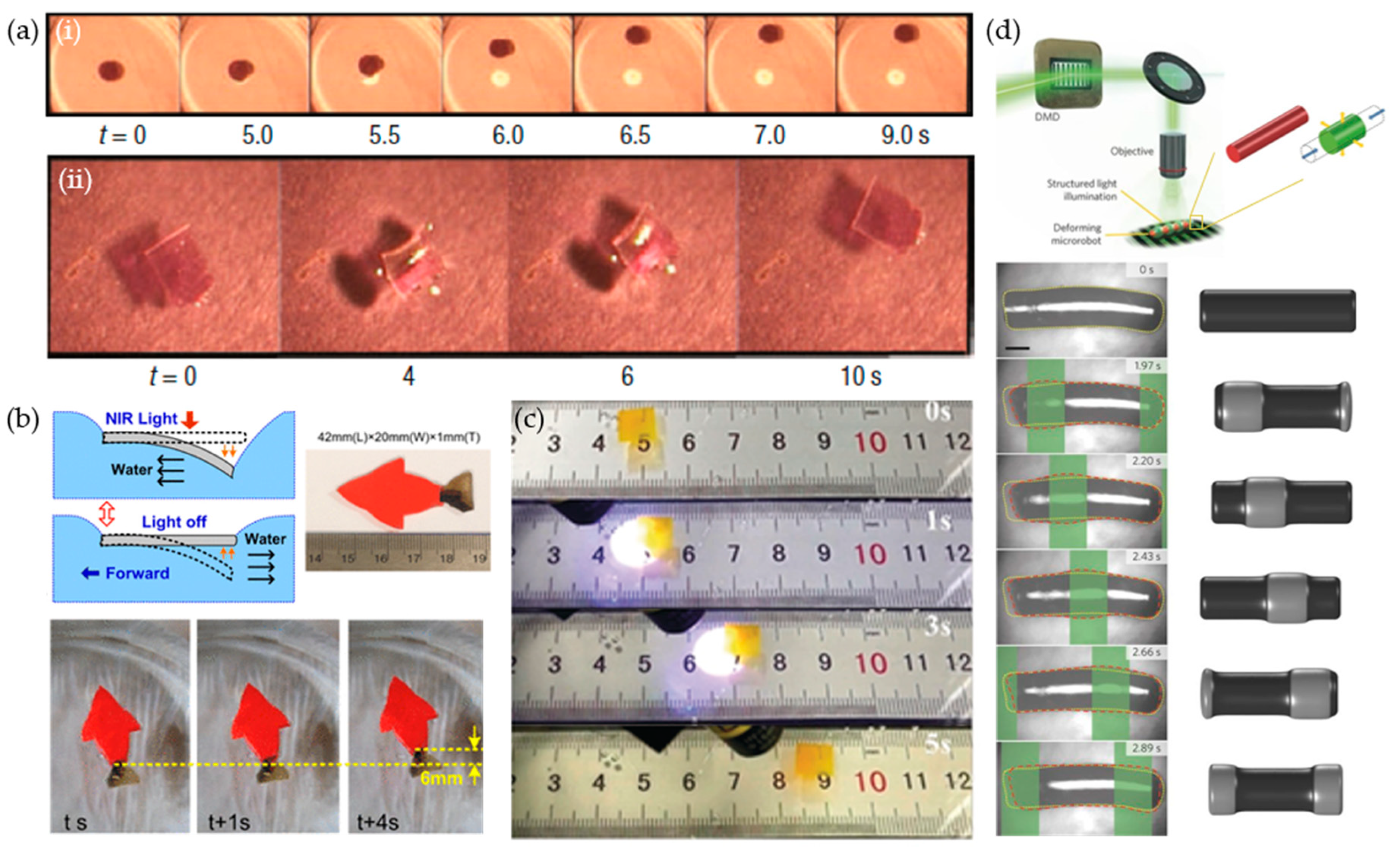

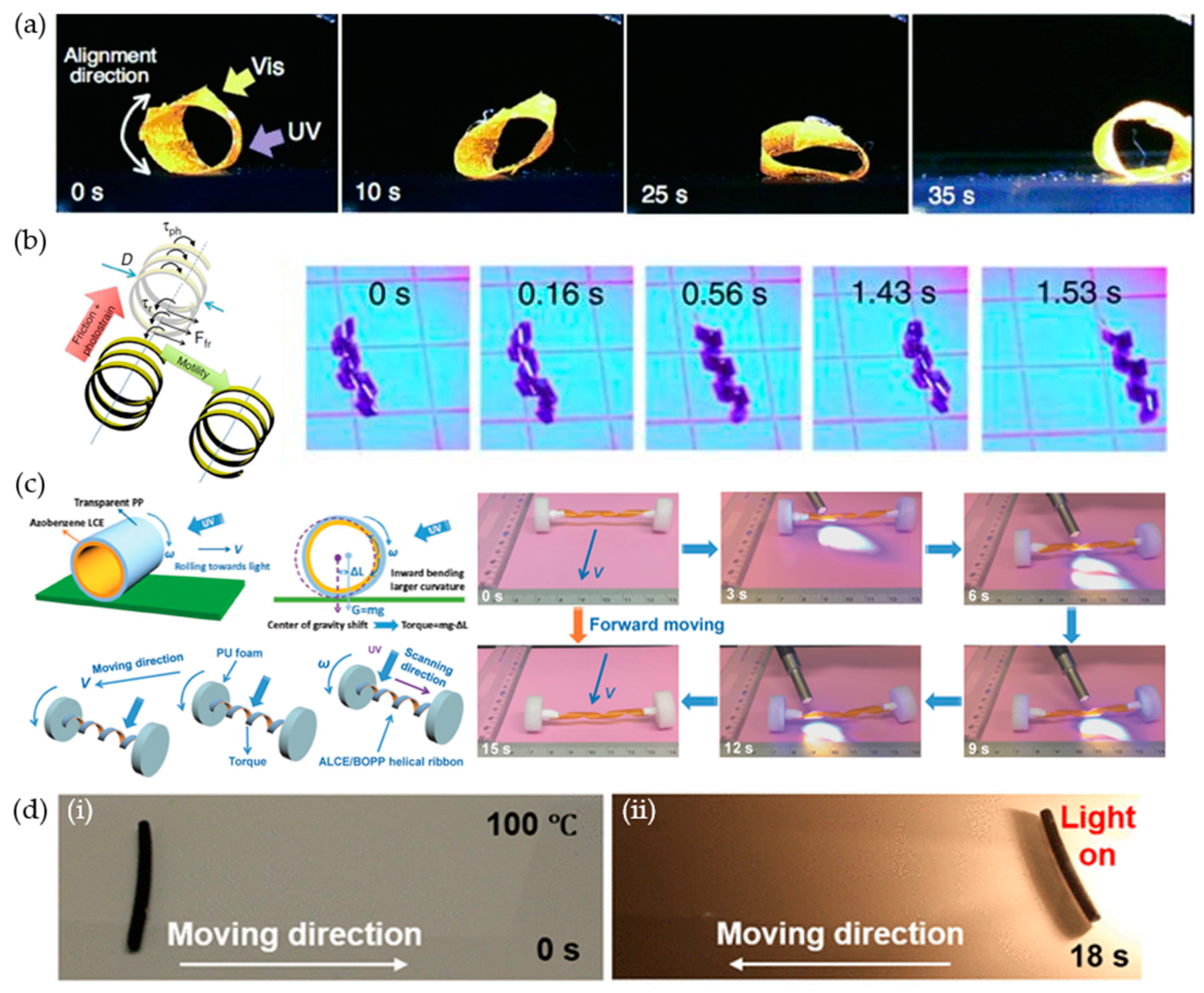

3.1. Walking and Crawling Motion of Liquid Crystalline Polymeric Soft Robots

3.2. Biomimetic Swimming Motion of Liquid Crystalline Polymeric Soft Robots

3.3. Rolling Motion of Liquid Crystalline Polymeric Soft Robots

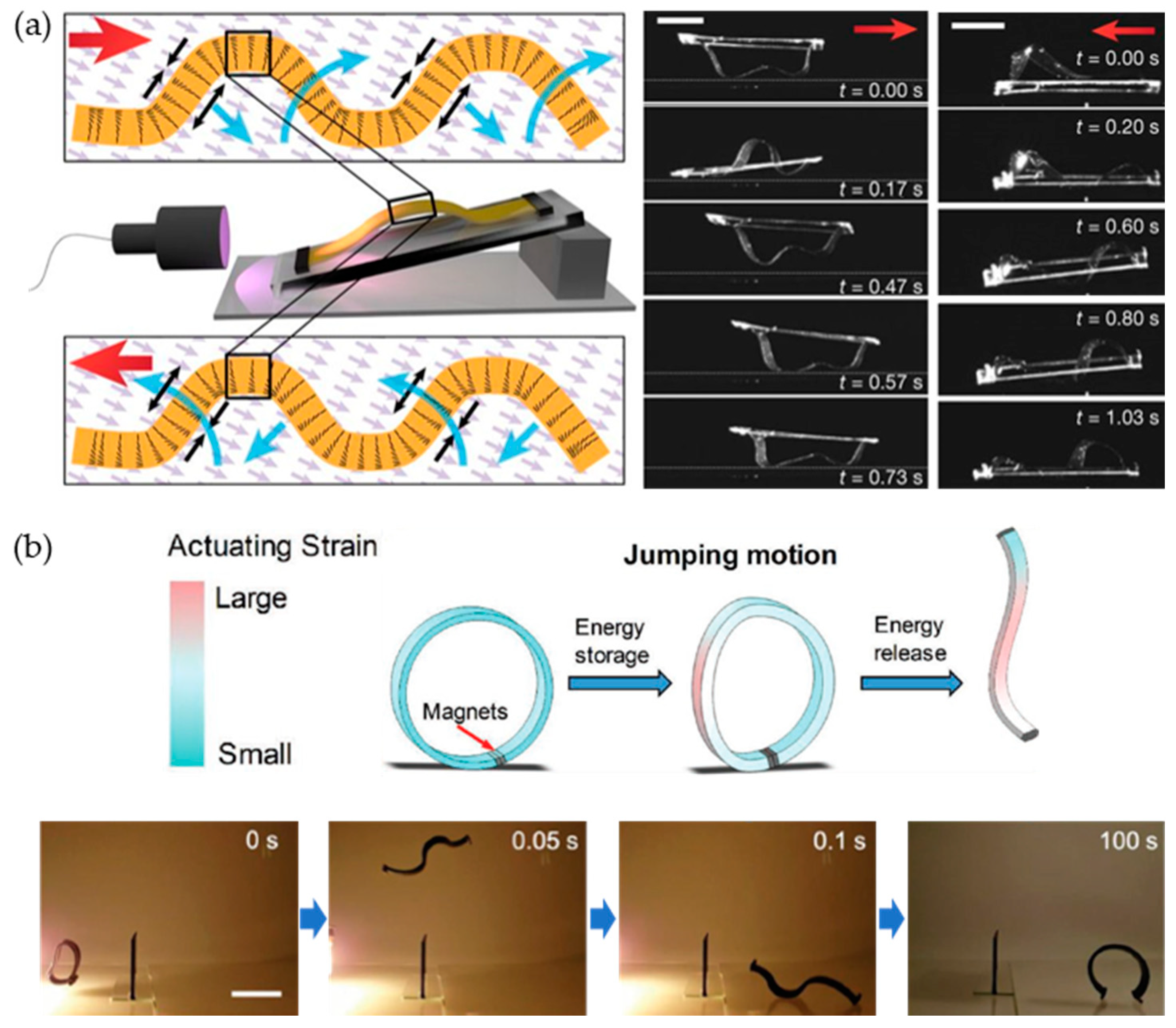

3.4. Wave and Jumping Motions of Liquid Crystalline Polymeric Soft Robots

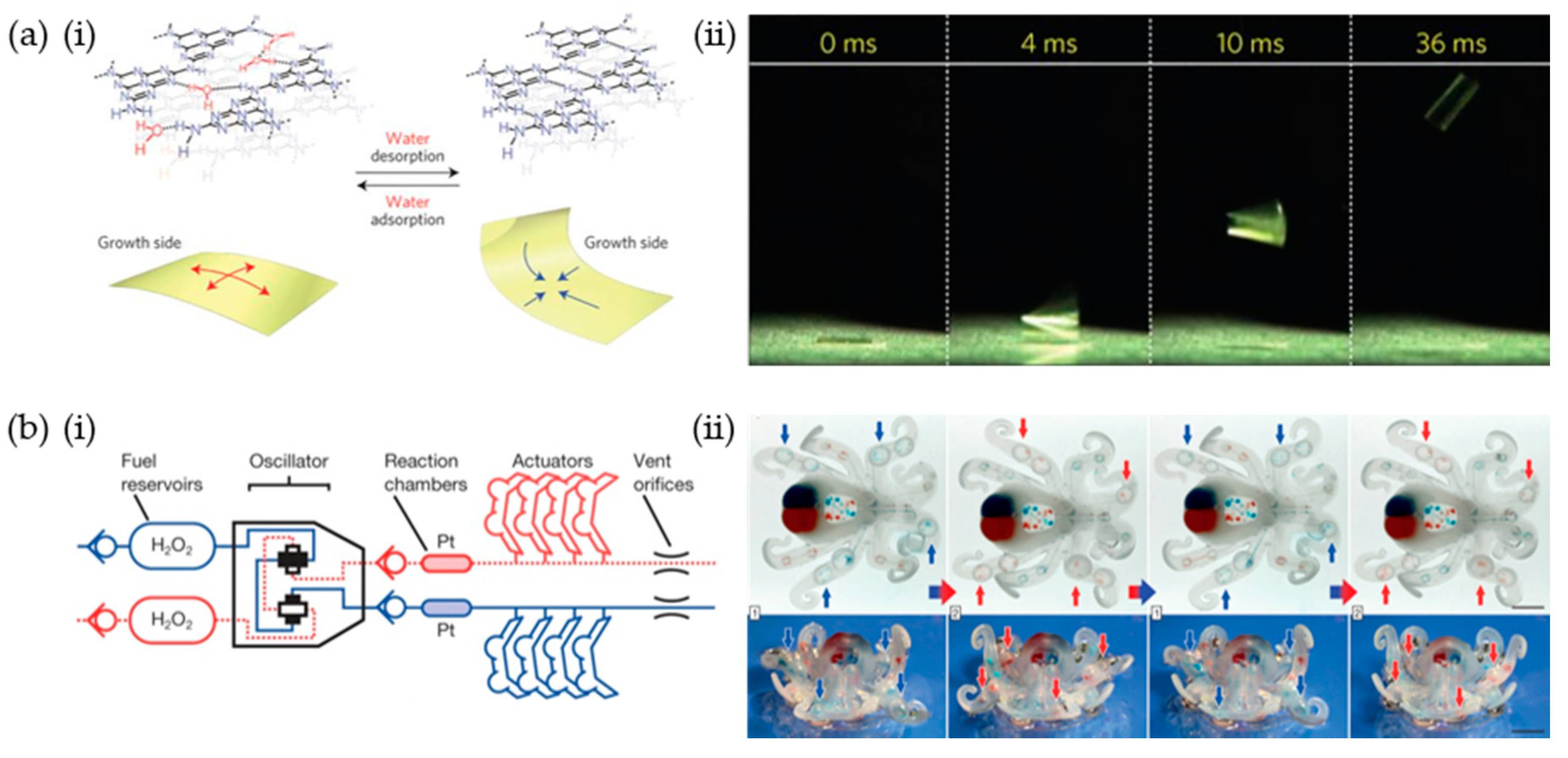

4. Hydrogel-Based Soft Robots

5. Chemical-Based Soft Robots: Solvent and Chemical Reaction

6. Outlook and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tottori, S.; Zhang, L.; Qiu, F.; Krawczyk, K.K.; Franco-Obregón, A.; Nelson, B.J. Magnetic helical micromachines: fabrication, controlled swimming, and cargo transport. Adv. Mater. 2012, 24, 811–816. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Zhou, Q.; Vincent, M.; Deng, Y.; Yu, J.; Xu, J.; Xu, T.; Tang, T.; Bian, L.; Wang, Y.-X.J.; et al. Multifunctional biohybrid magnetite microrobots for imaging-guided therapy. Sci. Robot. 2017, 2, eaaq1155. [Google Scholar] [CrossRef]

- Zhang, L.; Abbott, J.J.; Dong, L.; Peyer, K.E.; Kratochvil, B.E.; Zhang, H.; Bergeles, C.; Nelson, B.J. Characterizing the swimming properties of artificial bacterial flagella. Nano Lett. 2009, 9, 3663–3667. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.-W.; Sakar, M.S.; Petruska, A.J.; Pané, S.; Nelson, B.J. Soft micromachines with programmable motility and morphology. Nat. Commun. 2016, 7, 12263. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, J.; Chung, S.E.; Choi, S.-E.; Lee, H.; Kim, J.; Kwon, S. Programming magnetic anisotropy in polymeric microactuators. Nat. Mater. 2011, 10, 747. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Zhang, M.; Yang, Y.; Huang, Q.; Fukuda, T.; Wang, Z.; Shen, Y. A bioinspired multilegged soft millirobot that functions in both dry and wet conditions. Nat. Commun. 2018, 9, 3944. [Google Scholar] [CrossRef] [PubMed]

- Park, J.E.; Jeon, J.; Cho, J.H.; Won, S.; Jin, H.-J.; Lee, K.H.; Wie, J.J. Magnetomotility of untethered helical soft robots. RSC Adv. 2019, 9, 11272–11280. [Google Scholar] [CrossRef] [Green Version]

- Bi, C.; Guix, M.; Johnson, V.B.; Jing, W.; Cappelleri, J.D. Design of microscale magnetic tumbling robots for locomotion in multiple environments and complex terrains. Micromachines 2018, 9, 68. [Google Scholar] [CrossRef] [PubMed]

- Hu, W.; Lum, G.Z.; Mastrangeli, M.; Sitti, M. Small-scale soft-bodied robot with multimodal locomotion. Nature 2018, 554, 81–85. [Google Scholar] [CrossRef]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing ferromagnetic domains for untethered fast—Transforming soft materials. Nature 2018, 558, 274–279. [Google Scholar] [CrossRef]

- Zhang, L.; Abbott, J.J.; Dong, L.; Kratochvil, B.E.; Bell, D.; Nelson, B.J. Artificial bacterial flagella: Fabrication and magnetic control. Appl. Phys. Lett. 2009, 94, 064107. [Google Scholar] [CrossRef] [Green Version]

- Yamada, M.; Kondo, M.; Miyasato, R.; Naka, Y.; Mamiya, J.I.; Kinoshita, M.; Shishido, A.; Yu, Y.; Barrett, C.J.; Ikeda, T. Photomobile polymer materials—various three-dimensional movements. J. Mater. Chem. 2009, 19, 60–62. [Google Scholar] [CrossRef]

- Zeng, H.; Wani, O.M.; Wasylczyk, P.; Priimagi, A. Light-driven, caterpillar-inspired miniature inching robot. Macromol. Rapid Commun. 2018, 39, 1700224. [Google Scholar] [CrossRef] [PubMed]

- Wie, J.J.; Shankar, M.R.; White, T.J. Photomotility of polymers. Nat. Commun. 2016, 7, 13260. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Guo, S.; Tong, X.; Xia, H.; Zhao, Y. Tunable photocontrolled motions using stored strain energy in malleable azobenzene liquid crystalline polymer actuators. Adv. Mater. 2017, 29, 1606467. [Google Scholar] [CrossRef] [PubMed]

- Ahn, C.; Li, K.; Cai, S. Light or thermally powered autonomous rolling of an elastomer rod. ACS Appl. Mater. Interfaces 2018, 10, 25689–25696. [Google Scholar] [CrossRef] [PubMed]

- Gelebart, A.H.; Jan Mulder, D.; Varga, M.; Konya, A.; Vantomme, G.; Meijer, E.W.; Selinger, R.L.B.; Broer, D.J. Making waves in a photoactive polymer film. Nature 2017, 546, 632–636. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahn, C.; Liang, X.; Cai, S. Bioinspired design of light-powered crawling, squeezing, and jumping untethered soft robot. Adv. Mater. Technol. 2019, 4, 1900185. [Google Scholar] [CrossRef]

- Zeng, H.; Wasylczyk, P.; Parmeggiani, C.; Martella, D.; Burresi, M.; Wiersma, D.S. Light-fueled microscopic walkers. Adv. Mater. 2015, 27, 3883–3887. [Google Scholar] [CrossRef]

- Kohlmeyer, R.R.; Chen, J. Wavelength-selective, IR light-driven hinges based on liquid crystalline elastomer composites. Angew. Chem. Int. Ed. 2013, 52, 9234–9237. [Google Scholar] [CrossRef]

- Rogóż, M.; Zeng, H.; Xuan, C.; Wiersma, D.S.; Wasylczyk, P. Light-driven soft robot mimics caterpillar locomotion in natural scale. Adv. Opt. Mater. 2016, 4, 1689–1694. [Google Scholar] [CrossRef]

- Jiang, Z.C.; Xiao, Y.Y.; Tong, X.; Zhao, Y. Selective decrosslinking in liquid crystal polymer actuators for optical reconfiguration of origami and light-fueled locomotion. Angew. Chem. Int. Ed. 2019, 58, 5332–5337. [Google Scholar] [CrossRef] [PubMed]

- Camacho-Lopez, M.; Finkelmann, H.; Palffy-Muhoray, P.; Shelley, M. Fast liquid-crystal elastomer swims into the dark. Nat. Mater. 2004, 3, 307–310. [Google Scholar] [CrossRef] [PubMed]

- Tian, H.; Wang, Z.; Chen, Y.; Shao, J.; Gao, T.; Cai, S. Polydopamine-coated main-chain liquid crystal elastomer as optically driven artificial muscle. ACS Appl. Mater. Interfaces 2018, 10, 8307–8316. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Li, X.; Huang, S.; Hu, J.; Yu, H. A Light-activated polymer composite enables on-demand photocontrolled motion: transportation at the liquid/air interface. Angew. Chem. Int. Ed. 2019, 58, 2655–2659. [Google Scholar] [CrossRef] [PubMed]

- Palagi, S.; Mark, A.G.; Reigh, S.Y.; Melde, K.; Qiu, T.; Zeng, H.; Parmeggiani, C.; Martella, D.; Sanchez-Castillo, A.; Kapernaum, N.; et al. Structured light enables biomimetic swimming and versatile locomotion of photoresponsive soft microrobots. Nat. Mater. 2016, 15, 647–653. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yamada, M.; Kondo, M.; Mamiya, J.I.; Yu, Y.; Kinoshita, M.; Barrett, C.J.; Ikeda, T. Photomobile polymer materials: towards light-driven plastic motors. Angew. Chem. Int. Ed. 2008, 47, 4986–4988. [Google Scholar] [CrossRef] [PubMed]

- Sydney Gladman, A.; Matsumoto, E.A.; Nuzzo, R.G.; Mahadevan, L.; Lewis, J.A. Biomimetic 4D printing. Nat. Mater. 2016, 15, 413. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.S.; Liu, M.; Ishida, Y.; Ebina, Y.; Osada, M.; Sasaki, T.; Hikima, T.; Takata, M.; Aida, T. Thermoresponsive actuation enabled by permittivity switching in an electrostatically anisotropic hydrogel. Nat. Mater. 2015, 14, 1002–1007. [Google Scholar] [CrossRef] [PubMed]

- Wang, E.; Desai, M.S.; Lee, S.W. Light-controlled graphene-elastin composite hydrogel actuators. Nano Lett. 2013, 13, 2826–2830. [Google Scholar] [CrossRef] [PubMed]

- Gao, G.; Wang, Z.; Xu, D.; Wang, L.; Xu, T.; Zhang, H.; Chen, J.; Fu, J. Snap-buckling motivated controllable jumping of thermo-responsive hydrogel bilayers. ACS Appl. Mater. Interfaces 2018, 10, 41724–41731. [Google Scholar] [CrossRef] [PubMed]

- Luo, R.; Wu, J.; Dinh, N.D.; Chen, C.H. Gradient porous elastic hydrogels with shape-memory property and anisotropic responses for programmable locomotion. Adv. Funct. Mater. 2015, 25, 7272–7279. [Google Scholar] [CrossRef]

- Sun, Z.; Yamauchi, Y.; Araoka, F.; Kim, Y.S.; Bergueiro, J.; Ishida, Y.; Ebina, Y.; Sasaki, T.; Hikima, T.; Aida, T. An anisotropic hydrogel actuator enabling earthworm-like directed peristaltic crawling. Angew. Chem. Int. Ed. 2018, 57, 15772–15776. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Xia, C.; Fang, N.X. First jump of microgel; actuation speed enhancement by elastic instability. Soft Matter 2010, 6, 4342–4345. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Zhang, Y.; Wu, B.; Sun, W.; Li, Z.; Sun, J. Polyelectrolyte multilayer films for building energetic walking devices. Angew. Chem. Int. Ed. 2011, 50, 6254–6257. [Google Scholar] [CrossRef] [PubMed]

- Hore, D.; Majumder, A.; Mondal, S.; Roy, A.; Ghatak, A. How to make a cylinder roll uphill. Soft Matter 2012, 8, 5038–5042. [Google Scholar] [CrossRef] [Green Version]

- Arazoe, H.; Miyajima, D.; Akaike, K.; Araoka, F.; Sato, E.; Hikima, T.; Kawamoto, M.; Aida, T. An autonomous actuator driven by fluctuations in ambient humidity. Nat. Mater. 2016, 15, 1084. [Google Scholar] [CrossRef] [PubMed]

- Shin, B.; Ha, J.; Lee, M.; Park, K.; Park, G.H.; Choi, T.H.; Cho, K.-J.; Kim, H.-Y. Hygrobot: A self-locomotive ratcheted actuator powered by environmental humidity. Sci. Robot. 2018, 3, eaar2629. [Google Scholar] [CrossRef] [Green Version]

- Kwon, G.H.; Park, J.Y.; Kim, J.Y.; Frisk, M.L.; Beebe, D.J.; Lee, S.-H. Biomimetic soft multifunctional miniature aquabots. Small 2008, 4, 2148–2153. [Google Scholar] [CrossRef]

- Morales, D.; Palleau, E.; Dickey, M.D.; Velev, O.D. Electro-actuated hydrogel walkers with dual responsive legs. Soft Matter 2014, 10, 1337–1348. [Google Scholar] [CrossRef]

- Yang, C.; Wang, W.; Yao, C.; Xie, R.; Ju, X.J.; Liu, Z.; Chu, L.Y. Hydrogel walkers with electro-driven motility for cargo transport. Sci. Rep. 2015, 5, 13622. [Google Scholar] [CrossRef] [PubMed]

- Han, D.; Farino, C.; Yang, C.; Scott, T.; Browe, D.; Choi, W.; Freeman, J.W.; Lee, H. Soft robotic manipulation and locomotion with a 3D printed electroactive hydrogel. ACS Appl. Mater. Interfaces 2018, 10, 17512–17518. [Google Scholar] [CrossRef] [PubMed]

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451–455. [Google Scholar] [CrossRef] [PubMed]

- Zolfagharian, A.; Kaynak, A.; Khoo, S.Y.; Zhang, J.; Nahavandi, S.; Kouzani, A. Control-oriented modelling of a 3D-printed soft actuator. Materials 2019, 12, 71. [Google Scholar] [CrossRef] [PubMed]

- Zolfagharian, A.; Kouzani, A.; Khoo, S.Y.; Nasri-Nasrabadi, B.; Kaynak, A. Development and analysis of a 3D printed hydrogel soft actuator. Sens. Actuators A Phys 2017, 265, 94–101. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kouzani, A.; Moghadam, A.; Khoo, S.Y.; Nahavandi, S.; Kaynak, A. Rigid elements dynamics modeling of a 3D printed soft actuator. Smart Mater. Struct. 2019, 28, 025003. [Google Scholar] [CrossRef]

- Lancia, F.; Ryabchun, A.; Katsonis, N. Life-like motion driven by artificial molecular machines. Nat. Rev. Chem. 2019, 1–16, 536–551. [Google Scholar] [CrossRef]

- Boelke, J.; Hecht, S. Designing molecular photoswitches for soft materials applications. Adv. Opt. Mater. 2019, 7. [Google Scholar] [CrossRef]

- Laschi, C.; Mazzolai, B.; Cianchetti, M. Soft robotics: technologies and systems pushing the boundaries of robot abilities. Sci. Robot. 2016, 1, eaah3690. [Google Scholar] [CrossRef]

- Jiang, Z.C.; Xiao, Y.Y.; Zhao, Y. Shining light on liquid crystal polymer networks: Preparing, reconfiguring, and driving soft actuators. Adv. Opt. Mater. 2019, 7. [Google Scholar] [CrossRef]

- Kageyama, Y. Light-powered self-sustainable macroscopic motion for the active locomotion of materials. ChemPhotoChem 2019, 3, 327–336. [Google Scholar] [CrossRef]

- Zeng, H.; Wasylczyk, P.; Wiersma, D.S.; Priimagi, A. Light robots: bridging the gap between microrobotics and photomechanics in soft materials. Adv. Mater. 2018, 30. [Google Scholar] [CrossRef] [PubMed]

- Hines, L.; Petersen, K.; Lum, G.Z.; Sitti, M. Soft actuators for small-scale robotics. Adv. Mater. 2017, 29, 1603483. [Google Scholar] [CrossRef] [PubMed]

- White, T.J.; Broer, D.J. Programmable and adaptive mechanics with liquid crystal polymer networks and elastomers. Nat. Mater. 2015, 14, 1087–1098. [Google Scholar] [CrossRef] [PubMed]

- Aubin, C.A.; Choudhury, S.; Jerch, R.; Archer, L.A.; Pikul, J.H.; Shepherd, R.F. Electrolytic vascular systems for energy-dense robots. Nature 2019, 571, 51–57. [Google Scholar] [CrossRef] [PubMed]

- Ilievski, F.; Mazzeo, A.D.; Shepherd, R.F.; Chen, X.; Whitesides, G.M. Soft robotics for chemists. Angew. Chem. Int. Ed. 2011, 50, 1890–1895. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Qin, X.H.; Hu, C.; Terzopoulou, A.; Chen, X.Z.; Huang, T.Y.; Maniura-Weber, K.; Pané, S.; Nelson, B.J. 3D printed enzymatically biodegradable soft helical microswimmers. Adv. Funct. Mater. 2018, 28, 1804107. [Google Scholar] [CrossRef]

- Tumanski, S. Handbook of Magnetic Measurements, 1st ed.; CRC Press: Boca Raton, FL, USA, 2016; ISBN 978-1439829516. [Google Scholar]

- Sung Lee, J.; Myung Cha, J.; Young Yoon, H.; Lee, J.-K.; Keun Kim, Y. Magnetic multi-granule nanoclusters: A model system that exhibits universal size effect of magnetic coercivity. Sci. Rep. 2015, 5, 12135. [Google Scholar] [CrossRef]

- Zeng, Q.; Jiang, D.; Yang, S. Enhancement of magnetic properties in hard/soft CoFe2O4/Fe3O4 nanocomposites. RSC Adv. 2016, 6, 46143–46148. [Google Scholar] [CrossRef]

- Fei, C.; Zhang, Y.; Yang, Z.; Liu, Y.; Xiong, R.; Shi, J.; Ruan, X. Synthesis and magnetic properties of hard magnetic (CoFe2O4)-soft magnetic (Fe3O4) nano-composite ceramics by SPS technology. J. Magn. Magn. Mater. 2011, 323, 1811–1816. [Google Scholar] [CrossRef]

- Victora, R.H.; Shen, X. Composite media for perpendicular magnetic recording. IEEE Trans. Magn. 2005, 41, 537–542. [Google Scholar] [CrossRef]

- Davies, J.E.; Hellwig, O.; Fullerton, E.E.; Jiang, J.S.; Bader, S.D.; Zimányi, G.T.; Liu, K. Anisotropy dependence of irreversible switching in Fe/SmCo and FeNi/FePt exchange spring magnet films. Appl. Phys. Lett. 2005, 86, 262503. [Google Scholar] [CrossRef]

- Ullah, Z.; Atiq, S.; Naseem, S. Influence of Pb doping on structural, electrical and magnetic properties of Sr-hexaferrites. J. Alloys Compd. 2013, 555, 263–267. [Google Scholar] [CrossRef]

- Liu, X.M.; Wang, L.S.; Wang, L.; Huang, J.; He, C. The effect of salt and pH on the phase-transition behaviors of temperature-sensitive copolymers based on N-isopropylacrylamide. Biomaterials 2004, 25, 5659–5666. [Google Scholar] [CrossRef] [PubMed]

- Jánossy, I.; Lloyd, A.D.; Wherrett, B.S. Anomalous optical freedericksz transition in an absorbing liquid crystal. Mol. Cryst. Liq. Cryst. Inc. Nonlinear Opt. 1990, 179, 1–12. [Google Scholar] [CrossRef]

- Wermter, H.; Finkelmann, H. Liquid crystalline elastomers as artificial muscles. E-Polymers 2001. [Google Scholar] [CrossRef]

- Ware, T.H.; McConney, M.E.; Wie, J.J.; Tondiglia, V.P.; White, T.J. Voxelated liquid crystal elastomers. Science 2015, 347, 982–984. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Disch, S.; Schmidt, C.; Finkelmann, H. Nematic elastomers beyond the critical point. Macromol. Rapid Commun. 1994, 15, 303–310. [Google Scholar] [CrossRef]

- Iamsaard, S.; Aßhoff, S.J.; Matt, B.; Kudernac, T.; Cornelissen, J.J.L.M.; Fletcher, S.P.; Katsonis, N. Conversion of light into macroscopic helical motion. Nat. Chem. 2014, 6, 229. [Google Scholar] [CrossRef]

- Liu, D.; Broer, D.J. Self-assembled dynamic 3D fingerprints in liquid-crystal coatings towards controllable friction and adhesion. Angew. Chem. Int. Ed. 2014, 53, 4542–4546. [Google Scholar] [CrossRef]

- Kotikian, A.; Truby, R.L.; Boley, J.W.; White, T.J.; Lewis, J.A. 3D printing of liquid crystal elastomeric actuators with spatially programed nematic order. Adv. Mater. 2018, 30, 1706164. [Google Scholar] [CrossRef] [PubMed]

- Ambulo, C.P.; Burroughs, J.J.; Boothby, J.M.; Kim, H.; Shankar, M.R.; Ware, T.H. Four-dimensional printing of liquid crystal elastomers. ACS Appl. Mater. Interfaces 2017, 9, 37332–37339. [Google Scholar] [CrossRef] [PubMed]

- Saed, M.O.; Ambulo, C.P.; Kim, H.; De, R.; Raval, V.; Searles, K.; Siddiqui, D.A.; Cue, J.M.O.; Stefan, M.C.; Shankar, M.R.; et al. Molecularly-engineered, 4D-printed liquid crystal elastomer actuators. Adv. Funct. Mater. 2019, 29, 1806412. [Google Scholar] [CrossRef]

- Zeng, H.; Wasylczyk, P.; Cerretti, G.; Martella, D.; Parmeggiani, C.; Wiersma, D.S. Alignment engineering in liquid crystalline elastomers: Free-form microstructures with multiple functionalities. Appl. Phys. Lett. 2015, 106, 111902. [Google Scholar] [CrossRef]

- Akdeniz, B.; Bukusoglu, E. Liquid crystal templates combined with photolithography enable synthesis of chiral twisted polymeric microparticles. Macromol. Rapid Commun. 2019, 40. [Google Scholar] [CrossRef]

- Shepherd, R.F.; Ilievski, F.; Choi, W.; Morin, S.A.; Stokes, A.A.; Mazzeo, A.D.; Chen, X.; Wang, M.; Whitesides, G.M. Multigait soft robot. Proc. Natl. Acad. Sci. USA 2011, 108, 20400–20403. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tolley, M.T.; Shepherd, R.F.; Mosadegh, B.; Galloway, K.C.; Wehner, M.; Karpelson, M.; Wood, R.J.; Whitesides, G.M. A Resilient, Untethered soft robot. Soft Robot. 2014, 1, 213–223. [Google Scholar] [CrossRef]

- Marchese, A.D.; Onal, C.D.; Rus, D. Autonomous soft robotic fish capable of escape maneuvers using fluidic elastomer actuators. Soft Robot. 2014, 1, 75–87. [Google Scholar] [CrossRef]

- Shepherd, R.F.; Stokes, A.A.; Freake, J.; Barber, J.; Snyder, P.W.; Mazzeo, A.D.; Cademartiri, L.; Morin, S.A.; Whitesides, G.M. Using explosions to power a soft robot. Angew. Chem. Int. Ed. 2013, 52, 2892–2896. [Google Scholar] [CrossRef]

- Bartlett, N.W.; Tolley, M.T.; Overvelde, J.T.B.; Weaver, J.C.; Mosadegh, B.; Bertoldi, K.; Whitesides, G.M.; Wood, R.J. A 3D-printed, functionally graded soft robot powered by combustion. Science 2015, 349, 161–165. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.H.; Wie, J.J.; Lee, K.M.; White, T.J.; Tan, L.-S. Impact of backbone rigidity on the photomechanical response of glassy, azobenzene-functionalized polyimides. Macromolecules 2014, 47, 659–667. [Google Scholar] [CrossRef]

- Wie, J.J.; Wang, D.H.; Lee, K.M.; Tan, L.S.; White, T.J. Molecular engineering of azobenzene-functionalized polyimides to enhance both photomechanical work and motion. Chem. Mater. 2014, 26, 5223–5230. [Google Scholar] [CrossRef]

- Guin, T.; Settle, M.J.; Kowalski, B.A.; Auguste, A.D.; Beblo, R.V.; Reich, G.W.; White, T.J. Layered liquid crystal elastomer actuators. Nat. Commun. 2018, 9, 2531. [Google Scholar] [CrossRef]

| Categories | Motility | Magnetic Source for Actuation | Geometry | Materials | Fabrication Method for Geometry | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

| Programming geometry of robots for desired actuation | Swimming | Rotating magnetic field of Helmholtz coil | Helical coil | SU-8 or IP-L and Ni/Ti | DLW (dynamic light writing) [1] | High resolution morphology and transportability of cargo using carrier | Fragile body of matrix materials |

| S. Platensis and magnetite | Dip coating [2] | Biocompatibility, biodegradability, and MR imaging functionality | |||||

| Rolling | Linearly applied magnetic field of permanent magnets | PDMS (polydimethylsiloxane) and iron microparticles | Wrapping precured film around sticks [7] | Facile fabrication method, linear motility despite of helix geometry and climbing uphill and discrete walls | Difficult control of precise locomotion directions | ||

| Crawling | Multi-legs with body | Assembly of uncured composite resin [6] | Facile fabrication method, fast locomotion speed, loading cargo and climbing uphill | ||||

| Programming alignments of magnetic components for single-modal actuation | Crawling | Linearly applied magnetic field of Helmholtz coil | Head and tail | PEGDA (poly ethylene glycol diacrylate) and silicon coated magnetite | SLM (spatial light modulator) with aligning of magnetic particles by permanent magnets [5] | Uncomplicated control of locomotion directions (forward/backward) | Multiple manipulation steps of magnetic field for one motion |

| Swimming | Rotating magnetic field of Helmholtz coil | PEGDA (poly ethylene glycol diacrylate), PNIPAM (poly N-isopropylacrylamide) and magnetite | Lithography with alignment of magnetic particles by solenoid coil and folding/defolding of body by temperature variation [4] | Multiple stimuli responses and reversible shape morphing | Complicated fabrication steps | ||

| Tumbling | Bridged body | SU-8 and NdFeB (neodymium) microparticles | Lithography with alignments of magnetic particles by permanent magnets [8] | Climbing uphill and steerability to desired positions | Fragile body of matrix materials | ||

| Programming polarity of magnetic components for multi-modal actuation | Multimodality (swimming, climbing, rolling, walking, jumping, crawling) | Linearly applied magnetic field of electromagnets and Helmholtz coil | Film | Ecoflex and NdFeB (neodymium) microparticles | Wrapping precured film around sticks and aligning of particle polarity by electromagnets [9] | Multimodal locomotion of a single body, transportability of cargo, and steerability to desired positions with precise regulation | Difficulty of remaining desired geometry without magnetic field |

| Rolling/crawling /jumping | Linearly applied magnetic field of Helmholtz coil | Diverse structures (e.g., hexapedal body) | Ecoflex, PDMS and NdFeB (neodymium) microparticles | Inkjet printing and alignment of particle polarity by electromagnets [10] | Facile alignment process along printing directions, construction of diverse hierarchical three-dimensional structures |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.G.; Park, J.E.; Won, S.; Jeon, J.; Wie, J.J. Contactless Manipulation of Soft Robots. Materials 2019, 12, 3065. https://doi.org/10.3390/ma12193065

Kim JG, Park JE, Won S, Jeon J, Wie JJ. Contactless Manipulation of Soft Robots. Materials. 2019; 12(19):3065. https://doi.org/10.3390/ma12193065

Chicago/Turabian StyleKim, Jae Gwang, Jeong Eun Park, Sukyoung Won, Jisoo Jeon, and Jeong Jae Wie. 2019. "Contactless Manipulation of Soft Robots" Materials 12, no. 19: 3065. https://doi.org/10.3390/ma12193065

APA StyleKim, J. G., Park, J. E., Won, S., Jeon, J., & Wie, J. J. (2019). Contactless Manipulation of Soft Robots. Materials, 12(19), 3065. https://doi.org/10.3390/ma12193065