Influence of Preheating on the Microstructure Evolution of Laser Re-Melting Thermal Barrier Coatings/Ni-Based Single Crystal Superalloy Multilayer System

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. LSR Experiments

2.3. Characterization

3. Results

4. Discussion

4.1. Segmented Crack Behavior

4.2. Recrystallization Behavior

5. Conclusions

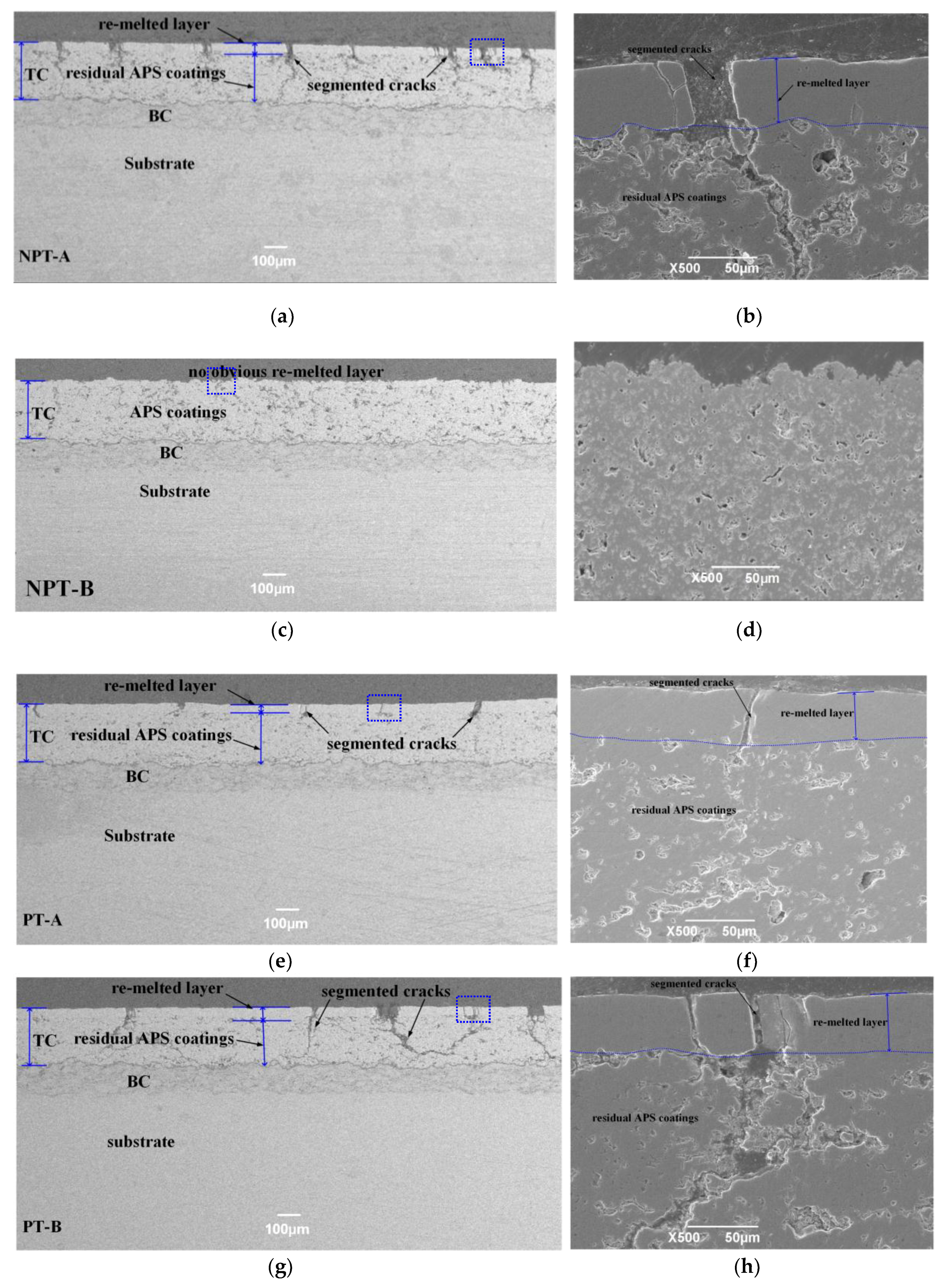

- Although they have the same laser energy, a continuous re-melted layer formed in the PT-A sample while there was no sign of melting in the NPT-B sample. It can conclude that preheating can lower the laser energy threshold that is required for continuously re-melting the coating.

- Both lowering laser energy and increasing the preheating temperature can result in a decrease of thermal mismatch strain between the re-melted layer and residual as-sprayed layer, resulting in a relatively low-level residual stress in the re-melted layer. The PT-A sample has the less severe segmented cracks compared to the NPT-A and PT-B sample in terms of crack dimension and crack density.

- Surface recrystallization occurs at both NPT-A and PT-B samples, while only certain distorted γ′ phases and some coarse precipitated γ′ phases were found nearby the interface between the BC and SX matrix for the PT-A sample. The remarkably reduced thermal accumulation and stain stored energy close to the interface play a crucial role in developing the microstructure with no evident surface recrystallization.

Author Contributions

Funding

Conflicts of Interest

References

- Padture, N.P.; Gell, M.; Jordan, E.H. Thermal barrier coatings for gas-turbine engine applications. Science 2002, 296, 280–284. [Google Scholar] [CrossRef] [PubMed]

- Schulz, U.; Leyensa, C.; Fritscher, K. Some recent trends in research and technology of advanced thermal barrier coatings. Aerosp. Sci. Technol. 2003, 7, 73–80. [Google Scholar] [CrossRef]

- Zhang, X.F.; Zhou, K.S.; Liu, M.; Deng, C.M.; Deng, C.G.; Mao, J.Z.; Deng, Q. Mechanisms governing the thermal shock and tensile fracture of PS-PVD 7YSZ TBC. Ceram. Int. 2017, 44, 3973–3980. [Google Scholar] [CrossRef]

- Zhang, D. 1-Thermal barrier coatings prepared by electron beam physical vapor deposition (EB–PVD). In Thermal Barrier Coating; Woodhead Publishing Series in Metals and Surface Engineering; Woodhead Publishing: Cambridge, UK, 2011; pp. 3–24. [Google Scholar]

- Georgiopoulos, I.; Vourdasb, N.; Mirzac, S.; Andreoulia, C.; Stathopoulosb, V. LaAlO3 as overlayer in conventional thermal barrier coatings. Procedia Struct. Integr. 2018, 10, 280. [Google Scholar] [CrossRef]

- Stathopoulos, V.; Sadykov, V.; Pavlova, S.; Bespalko, Y.; Fedorova, Y.; Bobrova, L.; Salanov, A.; Ishchenko, A.; Stoyanovsky, V.; Larina, T.; et al. Design of functionally graded multilayer thermal barrier coatings for gas turbine application. Surf. Coat. Technol. 2016, 295, 20–28. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Sayre, G. Commercial thermal barrier coatings with a double-layer bondcoat on turbine vanes and the process repeatability. Surf. Coat. Technol. 2009, 203, 2186–2192. [Google Scholar] [CrossRef]

- Ahmadi-Pidani, R.; Shoja-Razavi, R.; Mozafarinia, R.; Jamali, H. Evaluation of hot corrosion behavior of plasma sprayed ceria and yttria stabilized zirconia thermal barrier coatings in the presence of Na2SO4 + V2O5 molten salt. Ceram. Int. 2012, 38, 6613–6620. [Google Scholar] [CrossRef]

- Jasim, K.M.; Rawlings, R.D.; West, D.R.F. Characterization of plasma-sprayed layers of fully yttria-stabilized zirconia modified by laser sealing. Surf. Coat. Technol. 1992, 53, 75–86. [Google Scholar] [CrossRef]

- Zhou, Y.C.; Hashida, T. Thermal fatigue failure induced by delamination in thermal barrier coating. Int. J. Fatigue 2002, 24, 407–417. [Google Scholar] [CrossRef]

- Ahmadi-Pidani, R.; Shoja-Razavi, R.; Mozafarinia, R.; Jamali, H. Improving the thermal shock resistance of plasma sprayed CYSZ thermal barrier coatings by laser surface modification. Opt. Lasers Eng. 2012, 50, 780–786. [Google Scholar] [CrossRef]

- Zhang, P.; Li, F.; Zhang, X.; Zhang, Z.; Zhou, F.; Ren, L.; Liu, M. Thermal shock resistance of thermal barrier coatings with different surface shapes modified by laser remelting. J. Therm. Spray Tech. 2019, 28, 417–432. [Google Scholar] [CrossRef]

- Smurov, I.; Uglov, A.; Krivonogov, Y.; Sturlese, S.; Bartuli, C. Pulsed laser treatment of plasma-sprayed thermal barrier coatings: Effect of pulse duration and energy input. J. Mater. Sci. 1992, 27, 4523–4530. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, X.; Li, F.; Zhang, Z.; Li, H.; Wang, Y.; Ren, L.; Liu, M. Effects of selective laser modification and Al deposition on the hot corrosion resistance of ceria and yttria-stabilized zirconia thermal barrier coatings. Coatings 2019, 9, 353. [Google Scholar] [CrossRef]

- Ahmadi-Pidani, R.; Shoja-Razavi, R.; Mozafarinia, R.; Jamali, H. Laser surface modification of plasma sprayed CYSZ thermal barrier coatings. Ceram. Int. 2013, 39, 2473–2480. [Google Scholar] [CrossRef]

- Ghasemi, R.; Shoja-Razavi, R.; Mozafarinia, R.; Jamali, H. Laser glazing of plasma-sprayed nanostructured yttria stabilized zirconia thermal barrier coatings. Ceram. Int. 2013, 39, 9483–9490. [Google Scholar] [CrossRef]

- Zhu, C.; Li, P.; Javed, A.; Liang, G.Y.; Xiao, P. An investigation on the microstructure and oxidation behavior of laser remelted air plasma sprayed thermal barrier coatings. Surf. Coat. Technol. 2012, 206, 3739–3746. [Google Scholar] [CrossRef]

- Antou, G.; Montavon, G.; Hlawka, F.; Cornet, A.; Coddet, C.; Frédérique, M. Modification of ceramic thermal spray deposit microstructures implementing in situ laser remelting. Surf. Coat. Technol. 2003, 172, 279–290. [Google Scholar] [CrossRef]

- Morks, M.F.; Berndt, C.C.; Durandet, Y.; Brandt, M.; Wang, J. Microscopic observation of laser glazed yttria-stabilized zirconia coatings. Appl. Surf. Sci. 2010, 256, 6213–6218. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, K.; Dong, X.; Duan, W.; Mei, X.; Wang, W.; Cui, J.; Lv, J. Influence of columnar grain microstructure on thermal shock resistance of laser re-melted ZrO2-7wt.% Y2O3 coatings and their failure mechanism. Surf. Coat. Technol. 2015, 277, 188–196. [Google Scholar] [CrossRef]

- Tsai, P.-C.; Hsu, C.-S. High Temperature Corrosion Resistance and Microstructural Evaluation of Laser-Glazed Plasma-Sprayed Zirconia/MCrAlY Thermal Barrier Coatings. Surf. Coat. Technol. 2004, 183, 29–34. [Google Scholar] [CrossRef]

- Ghasemi, R.; Shoja-Razavi, R.; Mozafarinia, R.; Jamali, H.; Hajizadeh-Oghaz, M.; Ahmadi-Pidani, R. The influence of laser treatment on hot corrosion behavior of plasma-sprayed nanostructured yttria stabilized zirconia thermal barrier coatings. J. Eur. Ceram. Soc. 2014, 34, 2013–2021. [Google Scholar] [CrossRef]

- Ahmadi-Pidani, R.; Shoja-Razavi, R.; Mozafarinia, R.; Jamali, H. Improving the hot corrosion resistance of plasma sprayed ceria-yttria stabilized zirconia thermal barrier coatings by laser surface treatment. Mater. Des. 2014, 57, 336–341. [Google Scholar] [CrossRef]

- Tsai, H.L.; Tsai, P.C.; Tu, D.C. Characterization of laser glazed plasma sprayed yttria stabilized zirconia coatings. Mater. Sci. Eng. 1993, 161, 145–155. [Google Scholar] [CrossRef]

- Sivakumar, R.; Mordike, B.L. Laser melting of plasma sprayed ceramic. Surf. Eng. 1988, 4, 127–140. [Google Scholar] [CrossRef]

- Ghasemi, R.; Shoja-Razavi, R.; Mozafarinia, R.; Jamali, H. The influence of laser treatment on thermal shock resistance of plasma-sprayed nanostructured yttria stabilized zirconia thermal barrier coatings. Ceram. Int. 2014, 40, 347–355. [Google Scholar] [CrossRef]

- Chen, H.; Hao, Y.; Wang, H.; Tang, W. Analysis of the microstructure and thermal shock resistance of laser glazed nanostructured zirconia TBCs. J. Therm. Spray Technol. 2010, 19, 558–565. [Google Scholar] [CrossRef]

- Tsai, H.L.; Tsai, P.C. Performance of laser-glazed plasma-sprayed (ZrO2-12wt.%Y2O3)/(Ni-22wt.%Cr-10wt.%Al-1wt.%Y) thermal barrier coatings in cyclic oxidation tests. Surf. Coat. Technol. 1995, 71, 53. [Google Scholar] [CrossRef]

- Das, B.; Nath, A.K.; Bandyopadhyay, P.P. Online monitoring of laser remelting of plasma sprayed coatings to study the effect of cooling rate on residual stress and mechanical properties. Ceram. Int. 2018, 44, 7524–7534. [Google Scholar] [CrossRef]

- Batista, C.; Portinha, A.; Ribeiro, R.M.; Teixeira, V.; Costa, M.F.; Oliveira, C.R. Morphological and microstructural characterization of laser-glazed plasma-sprayed thermal barrier coatings. Surf. Coat. Technol. 2006, 200, 2929–2937. [Google Scholar] [CrossRef]

- Kadhim, M.J.; Al-Rubaiey, S.I.; Hammood, A.S. The influence of laser specific energy on laser sealing of plasma sprayed yttria partially stabilized zirconia coating. Opt. Laser Eng. 2013, 51, 159–166. [Google Scholar] [CrossRef]

- Fan, Z.; Dong, X.; Wang, K.; Wang, R.; Duan, W.; Wang, W.; Mei, X.; Cui, J.; Zhang, S.; Xu, C. The role of the surface morphology and segmented cracks on the damage forms of laser re-melted thermal barrier coatings in presence of a molten salt (Na2SO4 + V2O5). Corros. Sci. 2017, 115, 56–67. [Google Scholar] [CrossRef]

- Chwa, S.O.; Ohmori, A. Thermal diffusivity and erosion resistance of ZrO2–8 wt.% Y2O3 coatings prepared by a laser hybrid spraying technique. Thin Solid Film. 2002, 415, 160–166. [Google Scholar] [CrossRef]

- Li, R.; Li, Z.; Huang, J.; Zhu, Y. Dilution effect on the formation of amorphous phase in the laser cladded Ni–Fe–B–Si–Nb coatings after laser remelting process. Appl. Surf. Sci. 2012, 258, 7956–7961. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, D. Influence of recrystallization on high-temperature stress rupture property and fracture behavior of single crystal superalloy. Mat. Sci. Eng. A 2012, 551, 149–153. [Google Scholar] [CrossRef]

- Chao, L.C.; Xu, T.; Wang, F.; Xiong, J.C.; Zhu, J. Microstructural evolution on the initiation of sub-solvus recrystallization of a grit-blasted single-crystal superalloy. Mater. Lett. 2015, 148, 159–162. [Google Scholar]

- Xie, G.; Lou, L.H. Influence of the characteristic of recrystallization grain boundary on the formation of creep cracks in a directionally solidified Ni-base superalloy. Mat. Sci. Eng. A Struct. 2012, 532, 579. [Google Scholar] [CrossRef]

- Pollock, T.; Tin, S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure and properties. J. Propuls. Power 2006, 22, 361–371. [Google Scholar] [CrossRef]

- Rettberg, L.H.; Pollock, T.M. Localized recrystallization during creep in nickel-based superalloys GTD444 and René N5. Acta Mater. 2014, 73, 287. [Google Scholar] [CrossRef]

- Li, Z.; Xiong, J.; Xu, Q.; Li, J.; Liu, B. Deformation and recrystallization of single crystal nickel-based superalloys during investment casting. J. Mater Process. Technol. 2015, 217, 1–12. [Google Scholar] [CrossRef]

- Kromera, R.; Cormierb, J.; Costila, S.; Courapiedc, D.; Berthec, L.; Peyrec, P. High temperature durability of a bond-coatless plasma-sprayed thermal barrier coating system with laser textured Ni-based single crystal substrate. Surf. Coat. Technol. 2018, 337, 168–176. [Google Scholar] [CrossRef]

- Wang, Y.; Daruta, G.; Luo, X.; Poirier, T.; Stella, J.; Liao, H.; Planche, M. Influence of preheating processes on the microstructure of laser glazed YSZ coatings. Ceram. Int. 2017, 43, 4606–4611. [Google Scholar] [CrossRef]

- Das, B.; Gopinath, M.; Nath, A.K.; Bandyopadhyay, P.P. Effect of cooling rate on residual stress and mechanical properties of laser remelted ceramic coating. J. Eur. Ceram. Soc. 2018, 38, 3932–3944. [Google Scholar] [CrossRef]

- Farahmand, P.; Kovacevic, R. Laser cladding assisted with an induction heater (LCAIH) of Ni-60%WC coating. J. Mater. Process. Technol. 2015, 222, 244–258. [Google Scholar] [CrossRef]

- Wang, J.T.; Weng, C.I.; Chang, J.G.; Hwang, C.C. The influence of temperature and surface conditions on surface absorptivity in laser surface treatment. J. Appl. Phys. 2000, 87, 3245–3253. [Google Scholar] [CrossRef]

- Jamali, H.; Mozafarinia, R.; Razavi, R.S.; Ahmadi-Pidani, R.; Loghman-Estarki, M.R. Fabrication and evaluation of plasma-sprayed nanostructured and conventional YSZ thermal barrier coatings. Curr. Nanosci. 2012, 8, 402–409. [Google Scholar] [CrossRef]

- Acharya, M.V.; Fuchs, G.E. The effect of long-term thermal exposures on the microstructure and properties of CMSX-10 single crystal Ni-base superalloys. Mater. Sci. Eng. A 2004, 381, 143. [Google Scholar] [CrossRef]

- Li, Z.; Xu, Q.; Liu, B. Experimental investigation on recrystallization mechanism of a Ni-base single crystal superalloy. J. Alloy. Compd. 2016, 672, 457–469. [Google Scholar] [CrossRef]

- Kearsey, R.M.; Hegde, S.R.; Beddoes, J.C. Design solutionizing heat treatments for an experimental single crystal superalloy. In Proceedings of the 11th International Symposium on Superalloys, Champion, PA, USA, 14–18 September 2008; pp. 301–310. [Google Scholar]

- Hedge, S.R.; Kearsey, R.M.; Beddoes, J.C. Designing homogenization-solution heat treatments for single crystal superalloys. Mater. Sci. Eng. A 2010, 527, 5528–5538. [Google Scholar]

- Su, X.; Xu, Q.; Wang, R.; Xu, Z.; Liu, S.; Liu, B. Microstructural evolution and compositional homogenization of a low re-bearing Ni-based single crystal superalloy during through progression of heat treatment. Mater. Des. 2018, 141, 296–322. [Google Scholar] [CrossRef]

- Thompson, J.A.; Clyne, T.W. The effect of heat treatment on the stiffness of zirconia top coats in plasma-sprayed TBCs. Acta Mater. 2001, 49, 1565–1575. [Google Scholar] [CrossRef]

- Nie, G.L.; Bao, Y.W.; Wan, D.T.; Tian, Y. Evaluation high temperature elastic modulus of ceramic coatings by relative method. J. Adv. Ceram. 2005, 6, 288–303. [Google Scholar] [CrossRef]

- Guo, S.; Kagawa, Y. Young’s moduli of zirconia top-coat and thermally grown oxide in a plasma-sprayed thermal barrier coating system. Scr. Mater. 2004, 50, 1401–1406. [Google Scholar] [CrossRef]

- Tan, Y.; Shyam, A.; Choi, W.B.; Lara-Curzio, E.; Sampath, S. Anisotropic elastic properties of thermal spray coatings determined via resonant ultrasound spectroscopy. Acta Mater. 2010, 58, 5305–5315. [Google Scholar] [CrossRef]

- Rong, L.G.; Rong, L.G.; Jun, Y.G.; Feng, C.X.; Xin, L.C.; Jiu, L.C. Strain/sintering co-induced multiscale structural changes in plasma-sprayed thermal barrier coatings. Ceram. Int. 2018, 44, 14408–14416. [Google Scholar]

- Anderson, P.S.; Wang, X.; Xiao, P. Effect of isothermal heat treatment on plasma sprayed yttria-stabilized zirconia studied by impedance spectroscopy. J. Am. Ceram. Soc. 2005, 88, 324–330. [Google Scholar] [CrossRef]

- Erk, K.A.; Deschaseaux, C.; Trice, R.W. Grain-boundary grooving of plasma-sprayed yttria-stabilized zirconia thermal barrier coatings. J. Am. Ceram. Soc. 2006, 89, 1673–1678. [Google Scholar] [CrossRef]

- Jo, C.Y.; Cho, H.Y.; Kim, H.M. Effect of recrystallisation on microstructural evolution and mechanical properties of single crystal nickel based superalloy CMSX-2 Part 2-Creep behaviour of surface recrystallised single crystal. Mater. Sci. Technol. 2003, 19, 1671. [Google Scholar] [CrossRef]

- Qiu, Y.Y. Retarded coarsening phenomenon of γ′ precipitates in Ni-based alloy. Acta Mater. 1996, 44, 4969–4980. [Google Scholar] [CrossRef]

- Banerjee, D.; Banerjee, R.; Wang, Y. Formation of split patterns of γ′ precipitates in Ni-Al via particle aggregation. Scr. Mater. 1999, 41, 1023–1030. [Google Scholar] [CrossRef]

| Label | Preheating Temperature (°C) | Pulse Energy Density (J/cm2) | PULSE Width (ms) | Spot Diameter (mm) | Laser Frequency (Hz) | Laser Scanning (mm s−1) |

|---|---|---|---|---|---|---|

| NPT-A | Room Temperature | 86 | 1 | 4 | 40 | 10 |

| NPT-B | Room Temperature | 56.6 | ||||

| PT-A | 800 | 56.6 | ||||

| PT-B | 800 | 86 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Z.; Duan, W.; Zhang, X.; Mei, X.; Wang, W.; Cui, J. Influence of Preheating on the Microstructure Evolution of Laser Re-Melting Thermal Barrier Coatings/Ni-Based Single Crystal Superalloy Multilayer System. Materials 2019, 12, 3088. https://doi.org/10.3390/ma12193088

Fan Z, Duan W, Zhang X, Mei X, Wang W, Cui J. Influence of Preheating on the Microstructure Evolution of Laser Re-Melting Thermal Barrier Coatings/Ni-Based Single Crystal Superalloy Multilayer System. Materials. 2019; 12(19):3088. https://doi.org/10.3390/ma12193088

Chicago/Turabian StyleFan, Zhengjie, Wenqiang Duan, Xiaofeng Zhang, Xuesong Mei, Wenjun Wang, and Jianlei Cui. 2019. "Influence of Preheating on the Microstructure Evolution of Laser Re-Melting Thermal Barrier Coatings/Ni-Based Single Crystal Superalloy Multilayer System" Materials 12, no. 19: 3088. https://doi.org/10.3390/ma12193088

APA StyleFan, Z., Duan, W., Zhang, X., Mei, X., Wang, W., & Cui, J. (2019). Influence of Preheating on the Microstructure Evolution of Laser Re-Melting Thermal Barrier Coatings/Ni-Based Single Crystal Superalloy Multilayer System. Materials, 12(19), 3088. https://doi.org/10.3390/ma12193088